Vertical type gas filtering and purifying device

A clean gas, vertical technology, applied in the direction of gas dust removal, combustible gas production, removal of gas pollutants, etc., can solve the problems of inability to cure air, cumbersome treatment process, high engineering cost, etc., to save engineering construction investment, protect Environmental and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

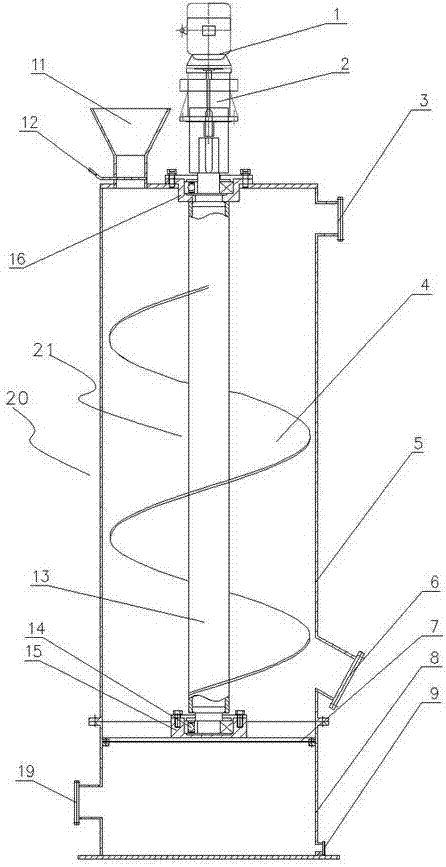

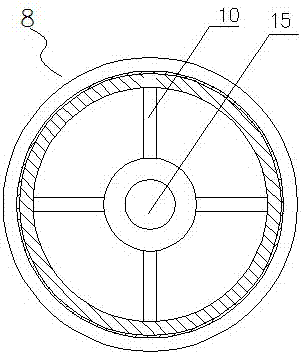

[0024] Such as figure 1 , 2 As shown, a vertical filter air purification device includes a cylinder body 20, and a screw shaft 21 is installed in the inner cavity of the cylinder body 20 along the axis of the cylinder body 20. The screw shaft 21 includes a rotating shaft 13 and a spiral blade 4 spirally rising around the rotating shaft 13 . A plurality of connecting ribs 10 are uniformly distributed in the cylinder body 20 perpendicular to the axis of the cylinder body 20 along the circumferential direction, and the center of the connecting ribs 10 is fixedly connected with a bearing seat 15 . The top of the cylinder body 20 is also provided with a bearing seat 16 . Both ends of the rotating shaft 13 are respectively fixed on the bearing housing 15 and the bearing housing 16 through bearings 14 .

[0025] The top of the cylinder body 20 is provided with a drive device capable of driving the screw shaft 21 forward and reverse, and the drive device includes a motor 1 and a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com