Integrated device and process for carrying out desulfurization, dust removal and modification on coal-pyrolyzed gas

A technology of coal pyrolysis and pyrolysis of gas, which is applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of high energy consumption of tar processing, pollution of waste water and waste residue, low quality of tar products, etc. The effect of regeneration cycle and service life, reduction of tar dust content rate, and improvement of filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

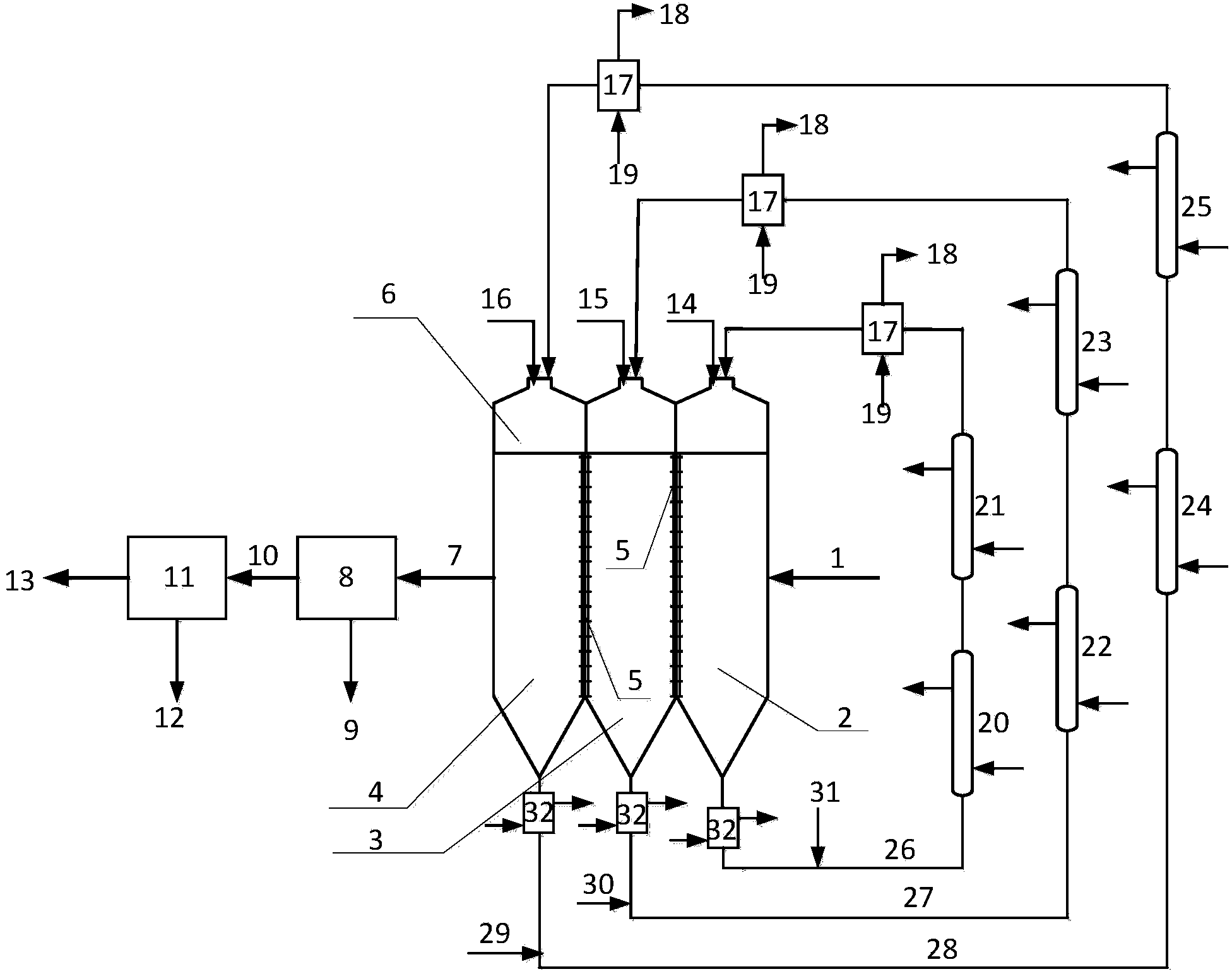

[0029] In conjunction with the accompanying drawings, an integrated device for coal pyrolysis gas desulfurization, dust removal, and upgrading includes an integrated moving bed purifier, an electric tar catcher 8, and a condenser 11. The integrated moving bed purifier is divided into a desulfurization area 2. Primary catalytic zone 3 and secondary catalytic zone 4. Desulfurization agent is filled in desulfurization zone 2, and catalyst is filled in primary catalytic zone 3 and secondary catalytic zone 4. Particles are separated by orifice plate 5 between each zone. The desulfurization zone 2 is connected to the pyrolysis gas inlet pipeline 1, the primary catalytic zone 3 is located between the desulfurization zone 2 and the secondary catalytic zone 4, and the secondary catalytic zone 4 is connected to the purified gas outlet pipeline 7. The purified gas outlet pipeline 7 is connected to the electric tar catcher 8 , the electric tar catcher 8 is connected to the condenser 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com