Electromagnetic pump wave crest generator with function of recovering welding flux

A technology of solder recovery and generator, which is applied in the direction of assembling printed circuit with electrical components, metal processing, etc., can solve the problems of high environmental pollution and power consumption, and achieve the effects of high solder utilization rate, simple structure, and novel and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

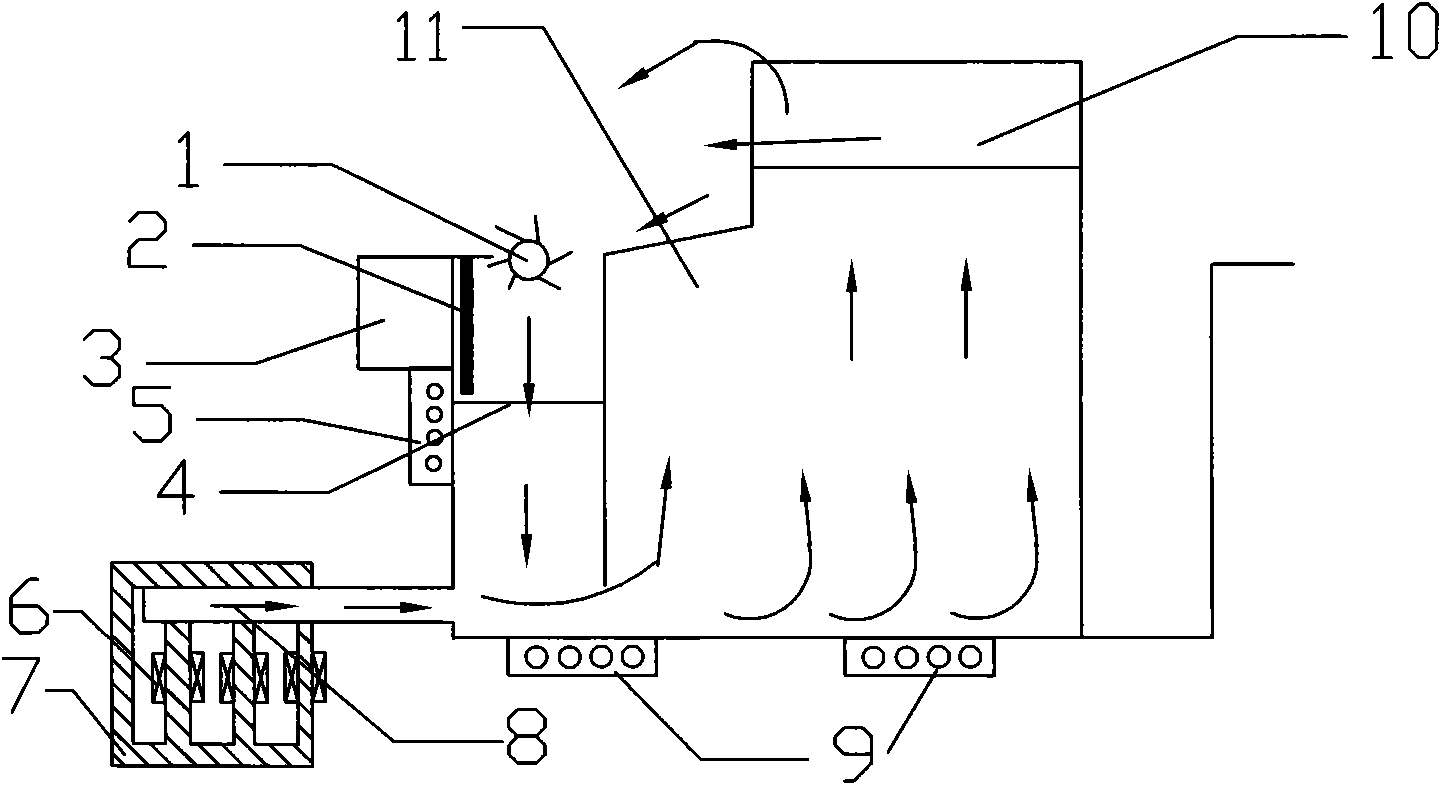

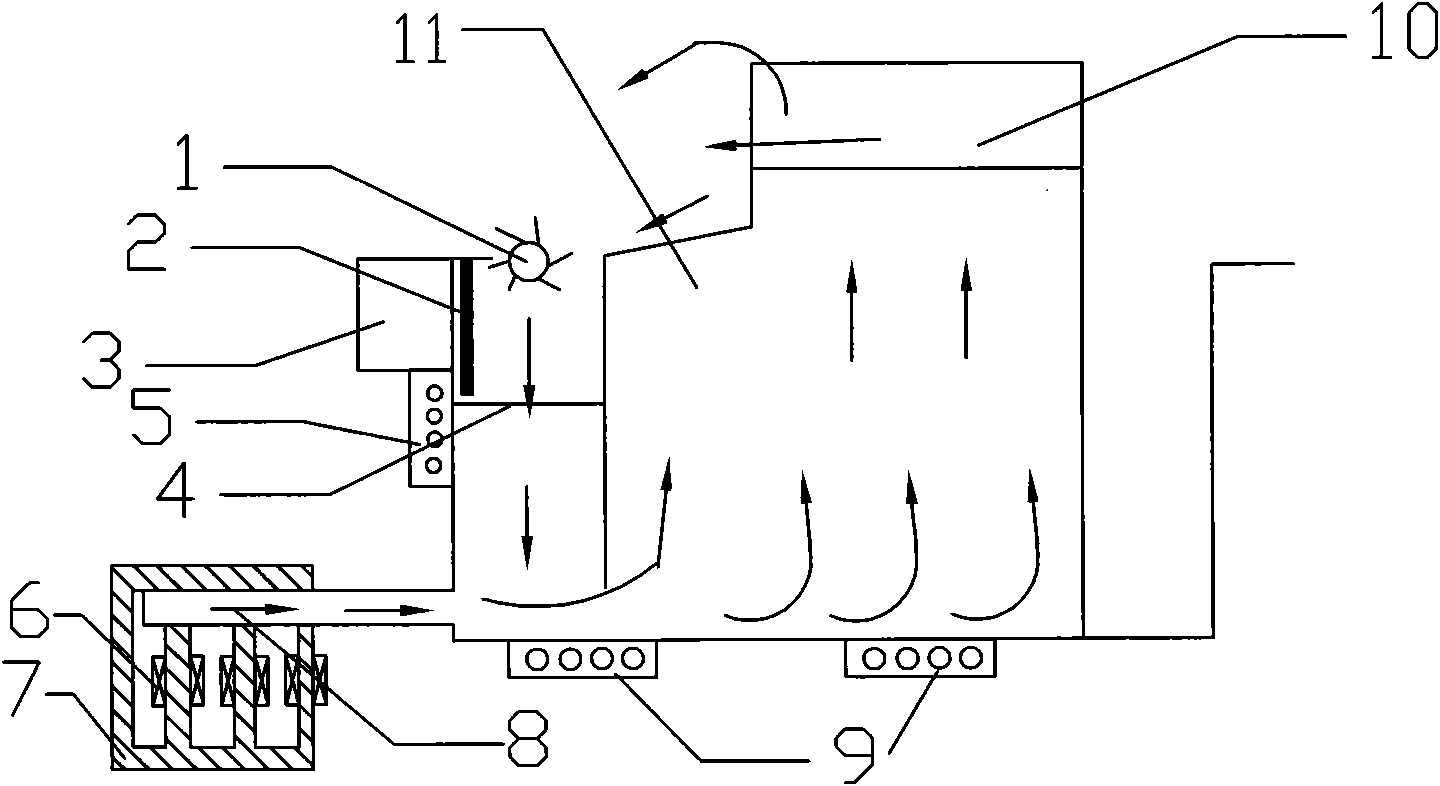

[0021] Such as figure 1 As shown, the present invention includes a wave crest generator composed of a wave crest liner 5 and a power mechanism, and also includes a solder recovery device embedded in the wave crest generator. The power mechanism is a three-phase asynchronous induction electromagnetic pump, and the three-phase asynchronous induction electromagnetic pump is installed at the bottom of the wave crest liner 5, and the outside of the wave crest nozzle 10 set on the wave crest liner 5 is connected to the three-phase asynchronous induction electromagnetic pump. The pump grooves 8 are communicated through the side channel and the inside of the wave crest liner 5 is communicated with the pump groove 8 through the main channel, and the main channel and the side channel are connected to form a circulation channel for the solder to circulate. The solder recovery device includes a stirrer 1 and a filter system for separating tin material and oxidized slag in the solder, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com