Patents

Literature

83results about How to "Significantly environmentally friendly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

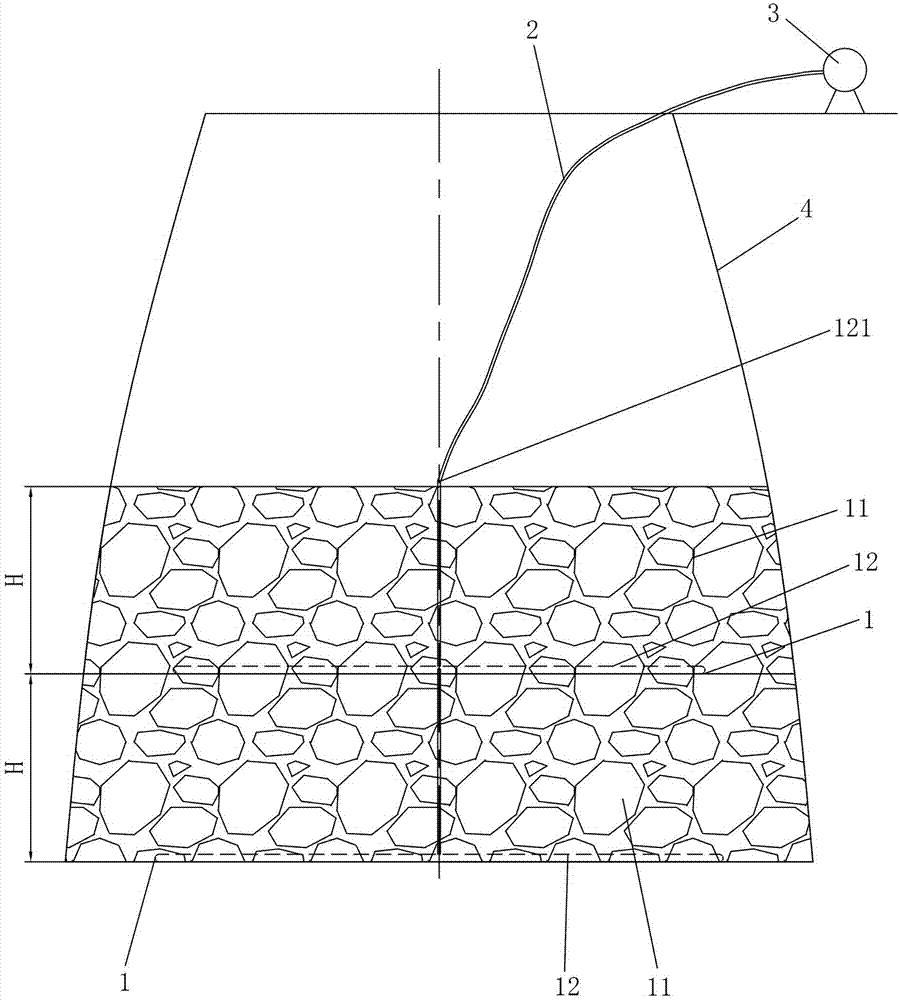

Modified sand body

ActiveCN103348831AWith mechanical stabilitySystem stabilityCultivating equipmentsHorticultureWater solubleMoisture

The invention disclose a modified sand body, which is formed by the mixing of solution and sand, wherein the solution with cohesiveness and adhesion is formed by dissolving water-soluble solid state organic substance in water. According to the invention, after the water is evaporated, the water-soluble solid state organic substance can bond sand particles, and dissolve in water again to form the solution with the cohesiveness and the adhesion to bond the sand particles; the modified sand body allows a common sand body to be in 'pedogenesis', changes the interaction relation between sand body particles, and forms a particle pore structure with binding force (cohesive force); when the modified sand body is in the use process, the substance is difficult to run off due to the characteristics of the cohesiveness and the adhesion; the sand body is allowed to have same properties of stabilizing and storing moisture and nutrient as the properties of the soil, so as to be able to provide strong conditions for the growing of plants, and be an ideal measure for the governing of deserts; meanwhile, the modified sand body can also be taken as a means to utilize sand resources of a sand beach and the like to conduct plant planting.

Owner:易志坚 +1

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

Harmless treatment method for urban domestic garbage and its novel use

InactiveCN1701865ASimple processCrushing requirements are not highSolid waste disposalEngineeringLow calorie

New method and application of innocent energylization treatment for urban house garbage. Separate the house garbage, break up; add lime, binding agent and burning-rate accelerator, finally, form, solidify and dry; the product can be used to low-calorie fuels for cement manufacture. This invention needs low cost, simple to operate and provides new resource and application for building material.

Owner:长沙紫宸科技开发有限公司

Technological method for upwardly continuously casting, rolling, drawing and producing copper alloy tubes

The invention provides a technological method for upwardly and continuously casting, rolling, drawing and producing copper alloy tubes. The technological method comprises the following steps: melting copper alloy raw materials according to a content proportion; further homogenizing the contents of an undercurrent passing by a standing chamber; keeping the temperature of the undercurrent by a maintaining furnace; cooling the undercurrent by a crystallizer to enter a tractor; upwardly drawing and continuously casting copper alloy tube blanks; then rolling the copper alloy tube blanks by a rolling mill; and drawing finished products of copper alloy tubes by a drawing mill. The technological method simplifies a traditional technological process in a new once-forming technology and has little investment, small occupation of land, low energy consumption, high efficiency, high rolling yield, little pollution and low cost, thereby being an advanced technological method with a certain market competitiveness.

Owner:高玉树

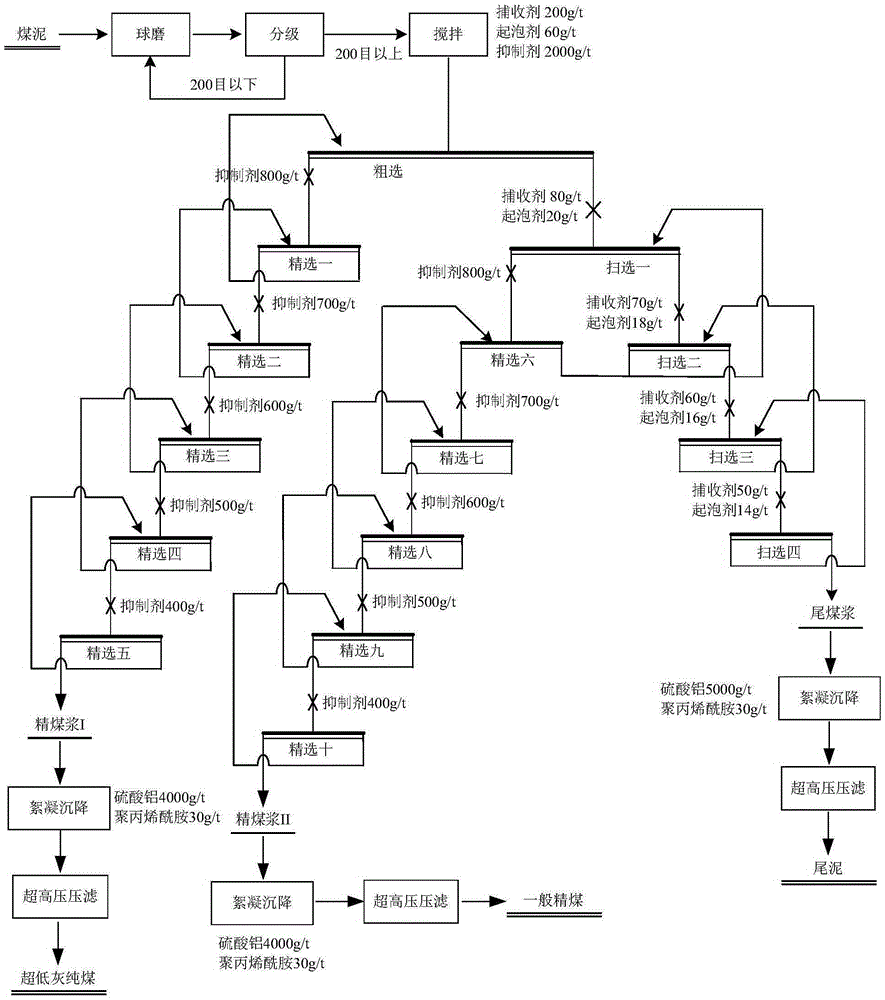

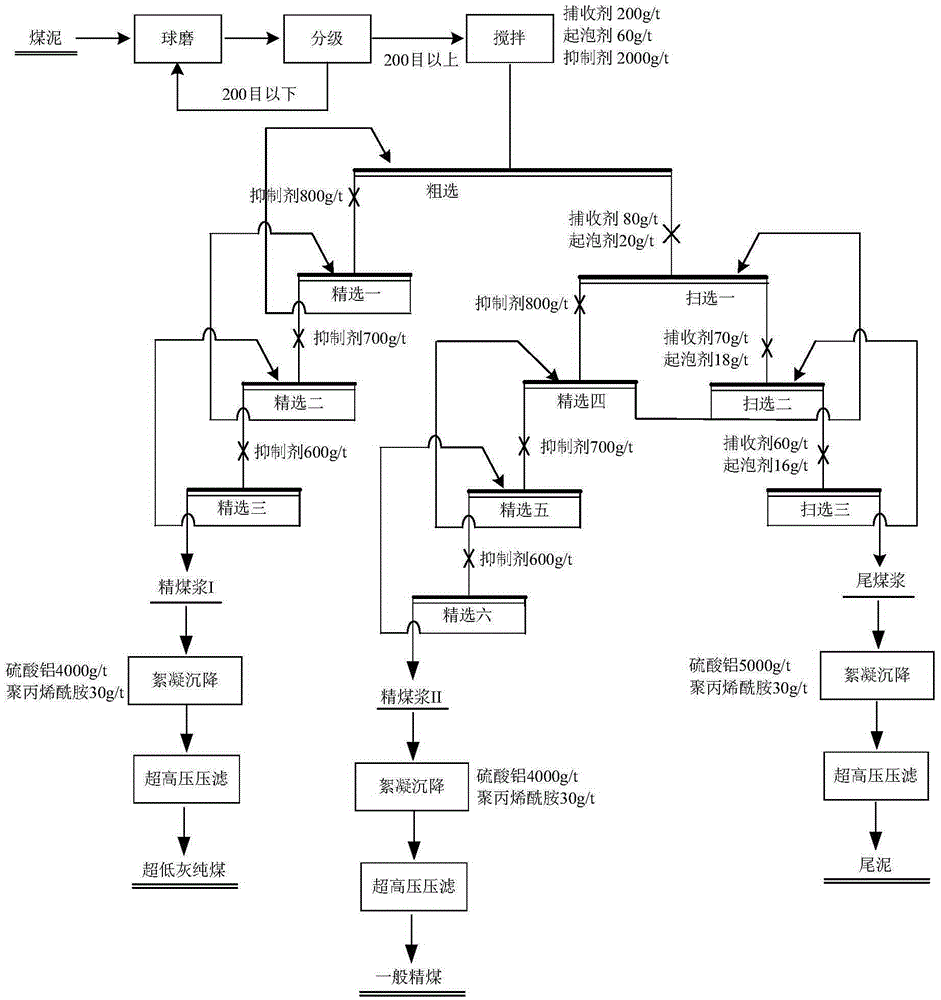

Method for extracting ultra-low-ash-content pure coal from coal slime

InactiveCN105396684ALow recovery rateGood technical effectDifferential sedimentationFlotationFlocculationFoaming agent

The invention discloses a method for extracting ultra-low-ash-content pure coal from coal slime. The method comprises the following steps: ball-milling slurrying, specifically, milling coal slime until particles with less than 200 meshes occupy more than 90%, and controlling the mass percent concentration of the coal slime slurry to be 10-35%; grading, specifically, conveying the particles with less than 200 meshes to a flotation step; flotation, specifically, adding a collecting agent, a foaming agent and an inhibitor in the obtained coal slime slurry, uniformly mixing, and carrying out one-time rough flotation, two sections of three-to-six-time fine flotation and one section of three-to-six-time scavenging to obtain refined coal slurry I, refined coal slurry II and tailing coal slurry respectively; and dehydration, specifically, adding a flocculant in the refined coal slurry I, the refined coal slurry II and the tailing coal slurry which are obtained through the flotation, carrying out flocculation settling, then dehydrating by virtue of an ultrahigh-pressure pressure filter, and controlling a pressure filter pressure to be 4.5-5.5Mpa, thus obtaining ultra-low-ash-content pure coal products, common refined coal products and tailing coal products. The method disclosed by the invention is simple in process flow, and capable of efficiently extracting the ultra-low-ash-content pure coal products from the coal slime; and moreover, the water contents of the obtained coal products are low and can achieve less than 15%, thus the coal products have remarkable economic benefits and environmental protection value.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

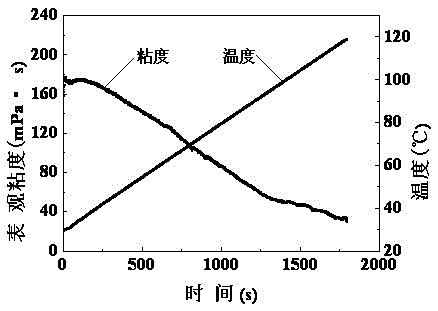

Fracturing fluid solution capable of being prepared from high-mineralization water and application of fracturing fluid

InactiveCN105647505AAlleviate the problem of inability to prepare fracturing fluidExpand sourceDrilling compositionPolymer scienceBrackish water

The invention belongs to the technical field of oilfield chemistry, and relates to a fracturing fluid solution capable of being high-mineralization water and a fracturing fluid prepared from the solution. Special hydrophobic groups are introduced into a high-molecular polymer structure. After a long-time low-temperature reaction, the synthesized polymer is improved in temperature resistance, salt tolerance, and bacterial corrosion resistance. A compatible additive matches the synthesized polymer to form a fracturing fluid system with excellent drag reduction performance and sand transportation ability. The fracturing fluid system can effectively satisfy fracturing construction requirements. The fracturing fluid can be prepared from high-mineralization water, such as oilfield underground brackish water, a fracturing flowback fluid, and oil and gas well produced water. The prepared fracturing liquid has temperature resistance and salt tolerance performance, low damage, and low frictional resistance, and can effectively satisfy fracturing construction requirements.

Owner:PETROCHINA CO LTD

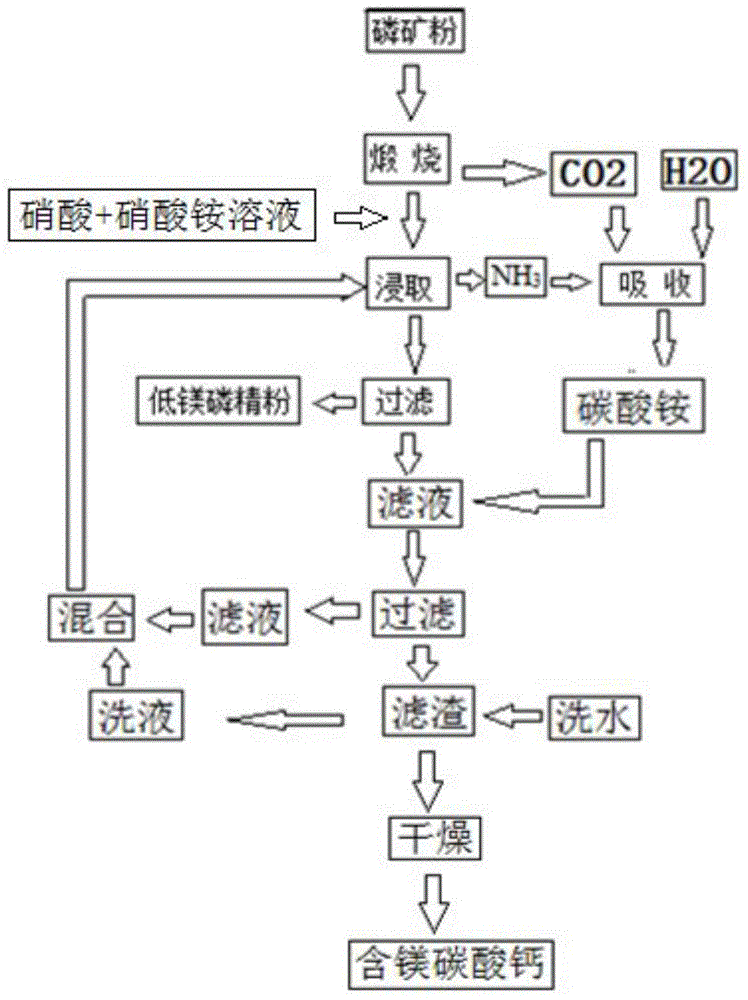

Medium and low grade phosphorus ore magnesium removal treatment method

ActiveCN104860277AAvoid emissionsIncrease added valueRaw phosphate material treatmentPhosphoriteLower grade

The invention relates to the technical field of medium and low grade phosphorus ore pretreatment, particularly to a medium and low grade phosphorus ore magnesium removal treatment method. A magnesium element in a phosphorus ore is converted into an oxide from carbonate after steps of calcining digestion, leaching, absorption, separation and ammonium carbonate treatment, the ionic state is presented in a solution to enable the magnesium element to be separated out, and the treatment is performed on obtained filtrate to enable nitrate in the filtrate to be recycled; absorption and utilization are performed on the waste gas produced in the calcining process and the ammonia gas produced in the leaching process to obtain ammonium carbonate; the ammonium carbonate is reacted in the filtrate to obtain an ammonium nitrate solution and magnesium contained calcium carbonate, the ammonium nitrate solution is returned to the leaching step, and accordingly the discharge of the waste liquid is avoided, the magnesium contained calcium carbonate additional product is obtained, and the additional process value is increased.

Owner:贵州盛源新材料股份有限公司

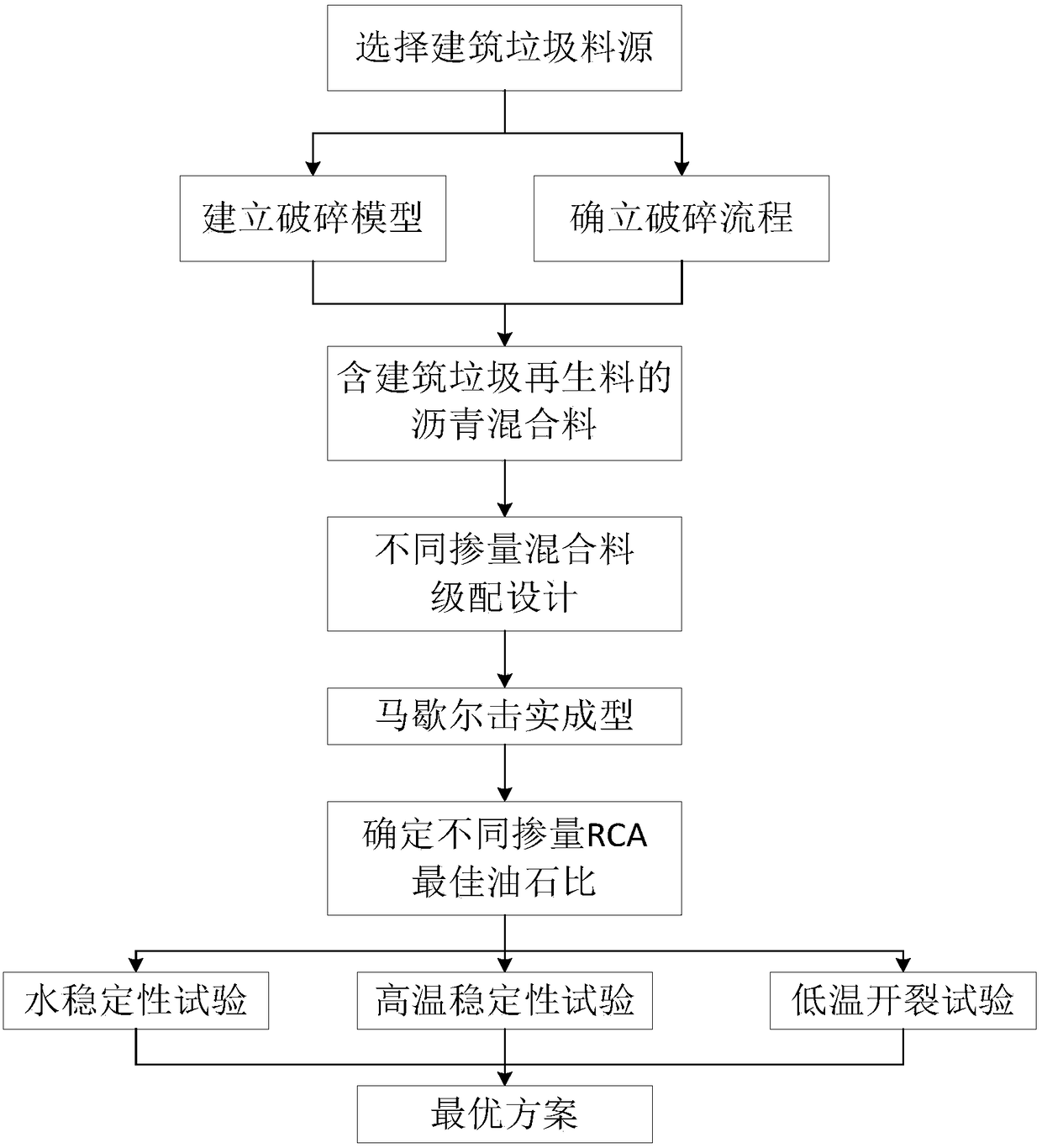

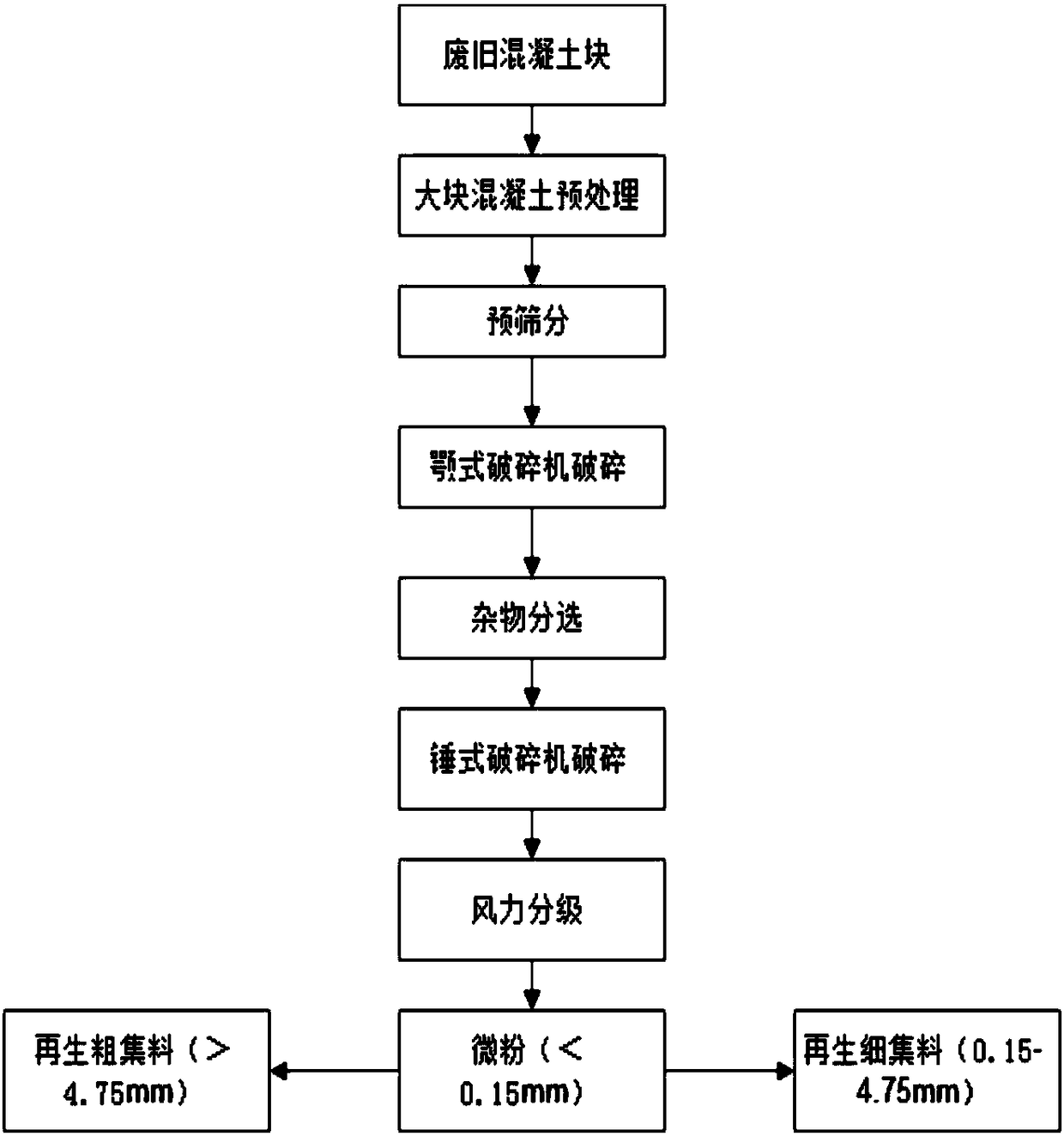

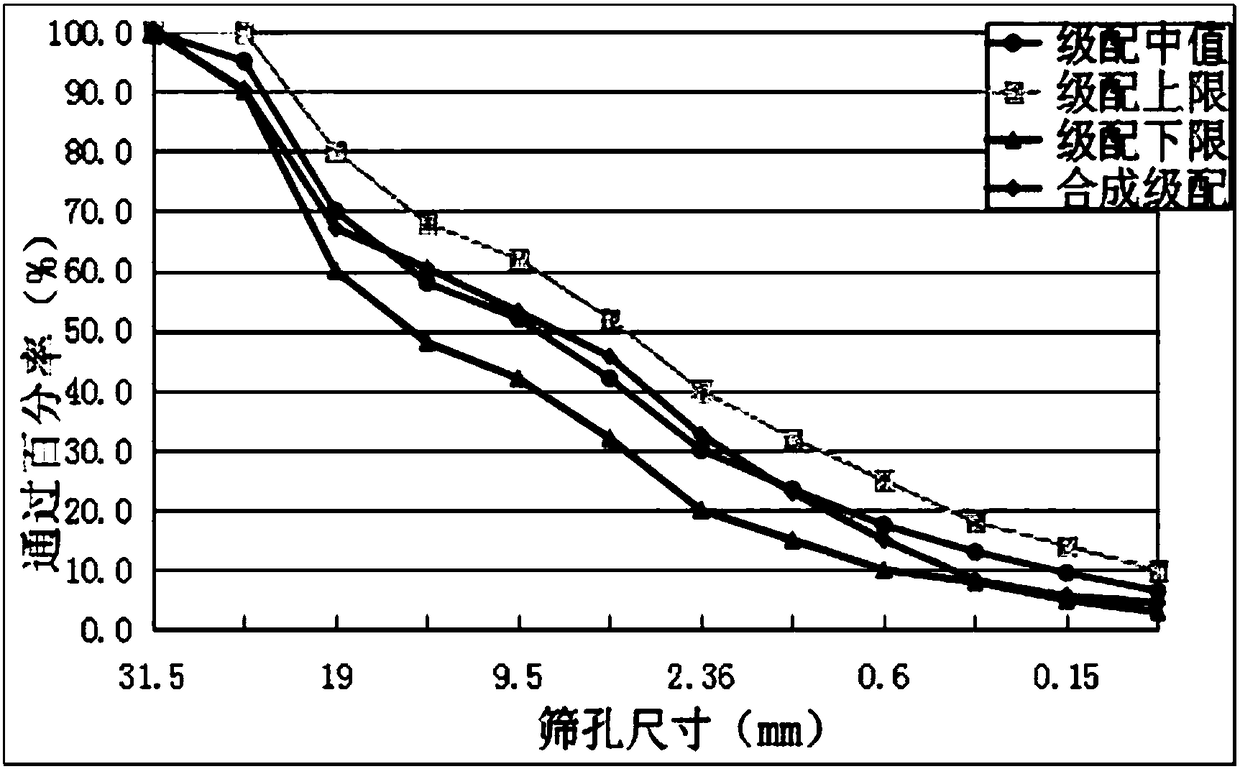

Method for designing mixing ratio of construction waste for asphalt mixture

InactiveCN108536956AEnsure possibilityEnsure feasibilityGeometric CADDesign optimisation/simulationRoad surfaceEngineering

The invention relates to a method for designing mixing ratio of construction waste for asphalt mixture, which comprises the following steps of: utilizing suitable waste source, establishing a buildinggarbage crushing model and a crushing process, and proposing a new crushing process; a recycled aggregate is obtained through the new crushing process, the corresponding matching ratio design is carried out, the design of the index data is detected to meet the latest specification requirement, then, the test data is used to optimize the gradation design, and RCA with different dosage is used to replace part of raw materials in road construction, and the possibility and feasibility of the construction waste for the asphalt mixture design are ensured; in this way, replacing the natural crushedstone with the construction waste generated by the waste building, which is used as the main raw material of the road construction; not only can the resources be saved, but also the influence of the construction waste on the environment can be relieved, the problem of insufficient supply of the natural aggregate in the construction process can be relieved to a certain extent, and the supply of high-quality aggregate is provided; the method has a remarkable environmental protection meaning, economic significance and social benefit.

Owner:CHANGAN UNIV

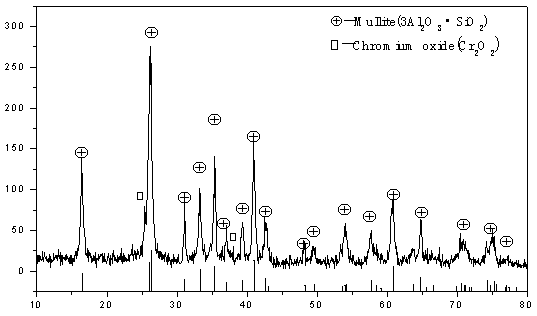

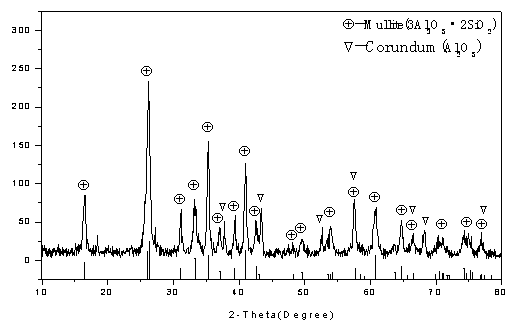

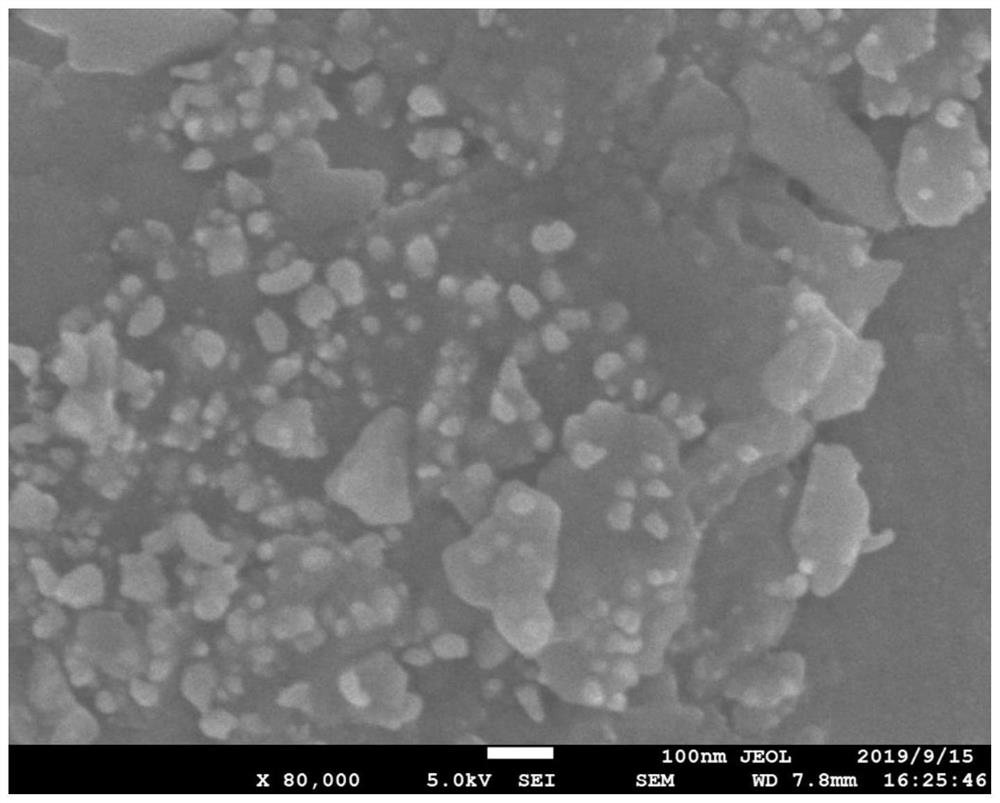

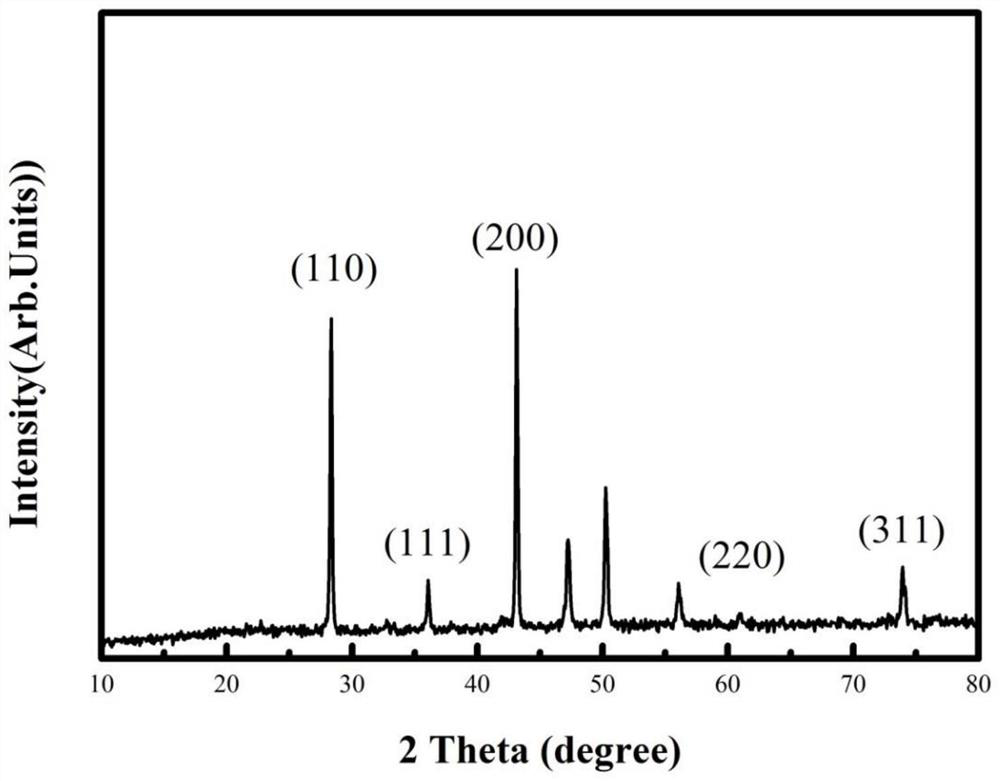

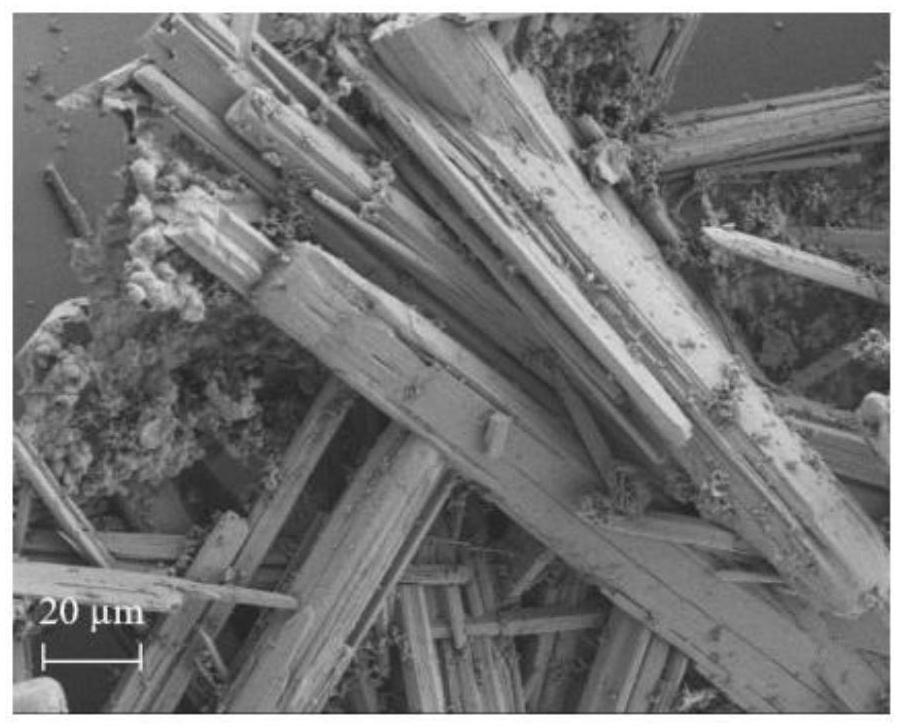

Mullite nano-whisker prepared by using pyrite tailing as raw material and preparation method of mullite nano-whisker

InactiveCN104313695AUniform diameterUniform length distributionPolycrystalline material growthFrom solid statePyriteIron removal

The invention discloses a method for preparing a mullite nano-whisker by using pyrite tailing as a raw material, and belongs to the field of nano-whisker preparation and mineral resource recycling. The method comprises the following steps: preparing the raw material, pickling for removing iron, calcinating for removing C, S and organic matters, preparing a precursor, and performing calcination and acid soaking for removing a glass phase. According to the invention, the prepared nanoscale mullite whisker has good quality, has excellent properties of both the mullite whisker and the nano-whisker, and has a high additional value and a remarkable economic benefit; in addition, the adopted raw material pyrite tailing is waste mineral materials after mineral dressing, so that the products are low in cost of raw materials, and the secondary recycling of pyrite resources is achieved; meanwhile, compared with other preparation methods, the preparation process of the invention requires lower calcination temperature and shorter calcination time, so that reduction of energy consumption is facilitated, thereby reducing production cost and resource consumption, and increasing economic benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

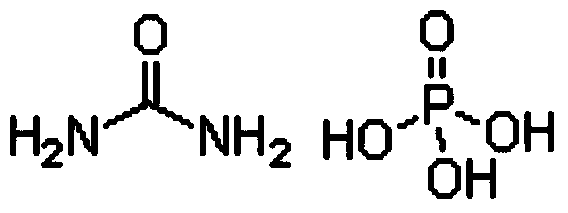

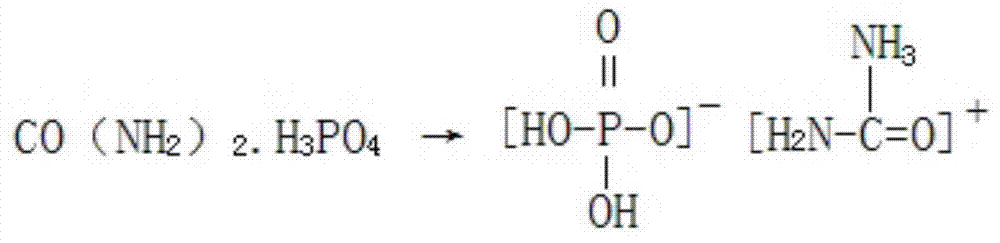

Production method for calcium hydrogen phosphate

InactiveCN104016326AQuality improvementLow impurity contentPhosphorus compoundsPhosphoric acidCalcium EDTA

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for calcium hydrogen phosphate. A calcium hydrogen phosphate product is prepared by reacting calcium oxide with a certain amount of water to form a calcium hydroxide solution; then reacting the calcium hydroxide solution with urea phosphate under stirring; controlling a pH value at 5.5-6.5; reacting for 5-20 min under stirring continuously and terminating the reaction. By adopting urea phosphate as a direct resource of phosphorus in the calcium hydrogen phosphate product, processes of removing impurities such as metal ions and fluorine in a process for producing feed level calcium hydrogen phosphate by using wet-process phosphoric acid are omitted; phosphorus utilization rate in the whole process is high; removal of a lot of wastes is prevented; and production cost of calcium hydrogen phosphate is reduced. In the obtained calcium hydrogen phosphate product, phosphorus content is 16.8-17.3%; calcium content is 20.35-22.2%; and fluorine content is 0.012-0.023%. The obtained calcium hydrogen phosphate product can fully meet the standard of feed level calcium hydrogen phosphate.

Owner:GUIZHOU KAILIN GRP MINERAL FERTILIZER CO LTD

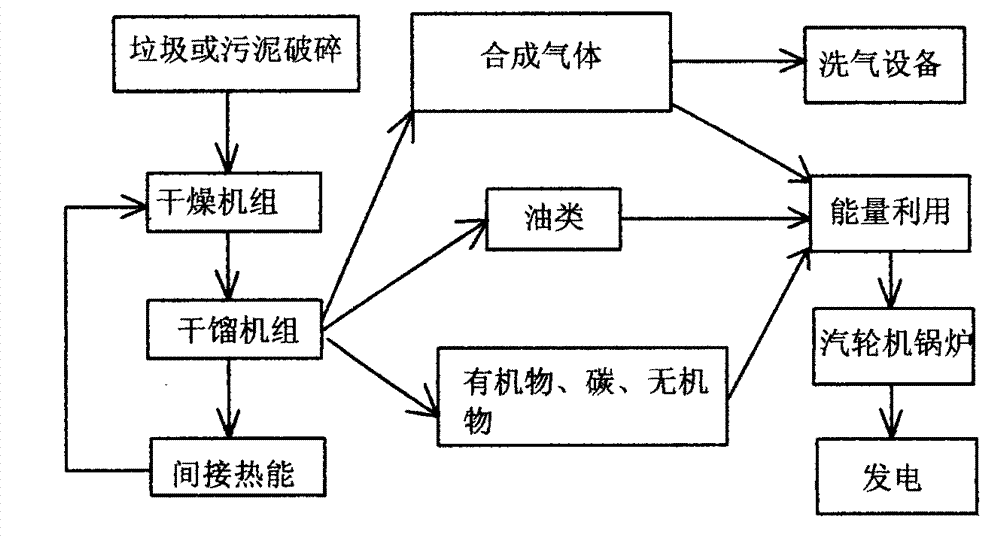

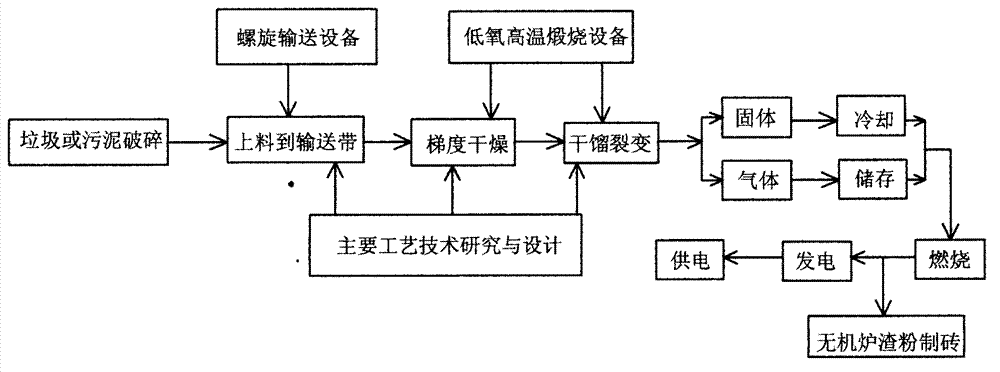

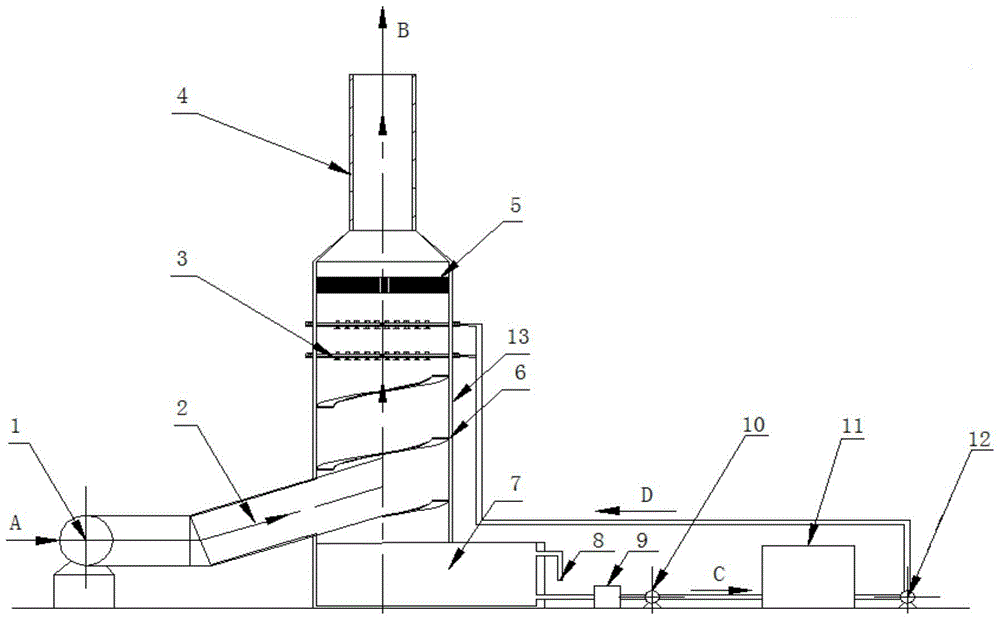

Processing method of rubbish or dirt

InactiveCN103162298ANo emissionsNo pollution in the processIncinerator apparatusCombined combustion mitigationBrickLife quality

The invention discloses a processing method of rubbish or dirt. The processing method of the rubbish and the dirt is characterized in that distillation fission is conducted on the rubbish or the dirt and the processing method of the rubbish and the dirt comprises the following steps: 1, the rubbish or the dirt is crushed; 2, a spiral squeezing device is applied to automatically convey the rubbish and the dirt; 3, gas generated by biomass particles in a hypoxia and incomplete combustion condition is sufficiently burnt in a high temperature layer, enough heat energy is generated to dry the rubbish or the dirt, and then destructive distillation fission is conducted on the rubbish or the dirt in a destructive distillation fission processing zone; 4, after the destructive distillation fission is conducted on the rubbish or the dirt, obtained solid is cooled, the gas is stored, the solid and the gas are reused through a burning process, the reusing comprises power generation, power supply and inorganic slag powder brick making. The processing method of the rubbish or the dirt is environmental-friendly, energy-saving, low in cost, high in reuse ratio, and capable of saving a large quantity of land resources, reducing burden of environmental protection bureaus and improving city life quality, and capable of promoting city economy development.

Owner:HUIDONG COUNTY TONGLIXING ENVIRONMENTAL PROTECTION SCI & TECH

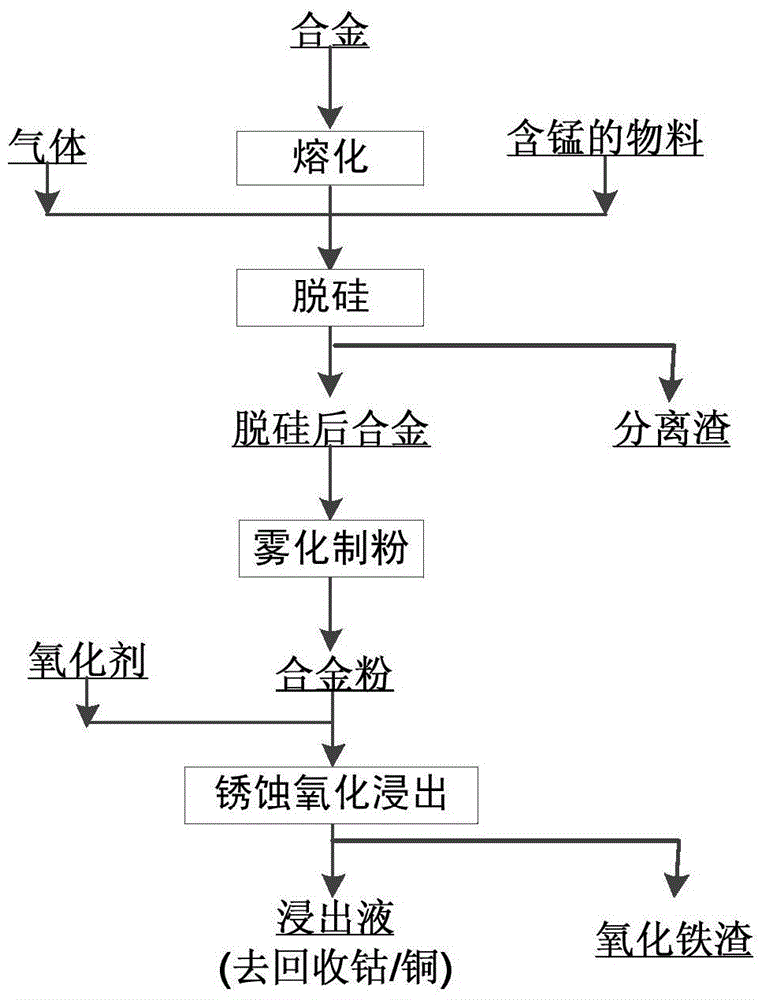

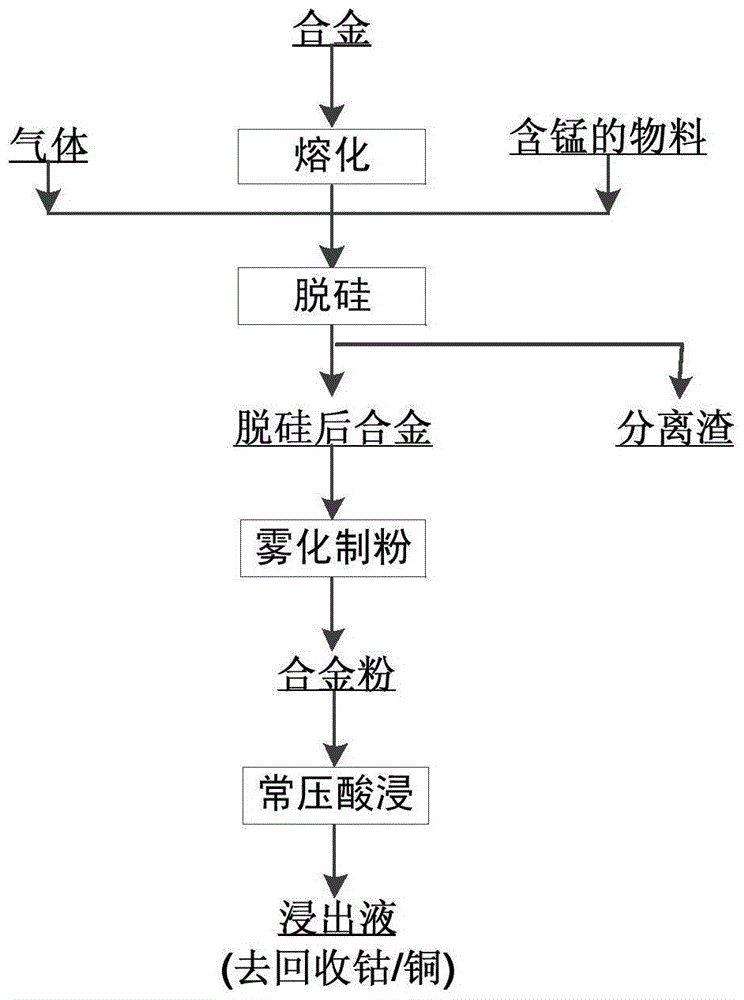

Method for leaching valuable metal from cobalt-copper white alloy

ActiveCN105063353AGuaranteed not to be oxidizedAchieve separationProcess efficiency improvementSlagManganese

The invention discloses a method for leaching valuable metal from cobalt-copper white alloy. The method includes the following steps that (1) the cobalt-copper white alloy is melted into an alloy melt, wherein the cobalt-copper white alloy contains silicon and almost contains no manganese; (2) a Mn-containing material is added into the alloy melt, and meanwhile gas is led in for blowing and slagging; (3) obtained slag is separated from the melt; (4) the melt with the slag separated out is atomized into alloy powder, wherein the mass friction of Mn in the alloy powder is 0.5%-20%; and (5) the alloy powder is subjected to acid leaching, and the valuable metal is recovered. Due to the fact that the Mn-containing material is added and reacts with the silicon in the cobalt-copper white alloy to generate the MnO-SiO2 slag, the silicon removal effect is achieved, and the method has the beneficial effects of being good in silicon removal effect and small in valuable metal loss. Besides, the melting temperature is much lower than the melting point of CaO-(MgO)-SiO2 binary system or ternary system slag in the prior art.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

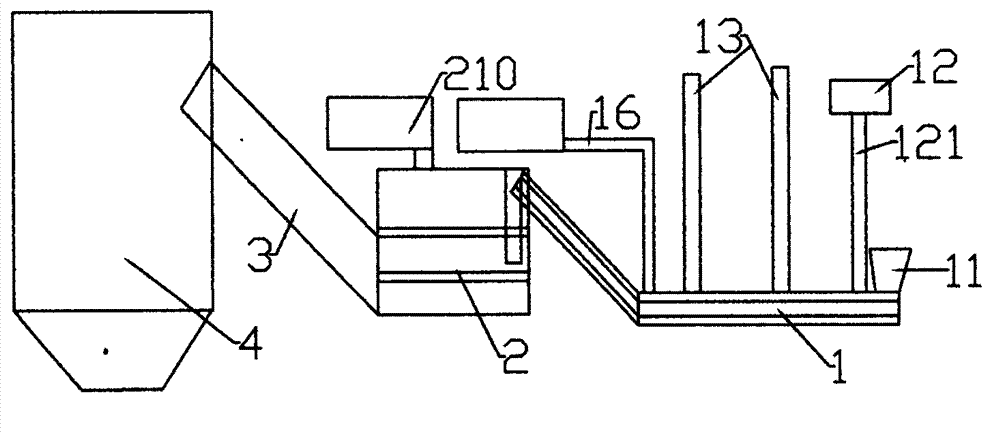

Dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and application method thereof

ActiveCN108441590AHighlight the effective effectPromote fragmentationRecycling and recovery technologiesBlast furnace smeltingCrusher

The invention relates to a treatment method of blast furnace slag from blast furnace smelting production, in particular to a dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and an application method thereof. The apparatus comprises a grate unit, a cooler, a slag trough, a crusher and a conveying lifter and is characterized in that the grate unit isarranged below the head of the slag trough, the grate unit is mounted at a positive angle of 2-5 degrees relative to a horizontal flowing direction of liquid slag, a condensing column is arranged above the grate unit, a grate plate of the grate unit is composed of a plurality of chain plate groups connected together, a water distributor and an upper cooler are arranged above the grate unit, the crusher is arranged below a head scraper of the grate unit, and a guide plate and the conveying lifter are arranged below a collection channel. Blast furnace slag can be quickly set and can be granulated and loosened via multiple pores, the high temperature is still retained which helps recycle subsequent heat, and the apparatus has the advantages of high efficiency, low energy consumption, and good convenience of arrangement.

Owner:吕艳

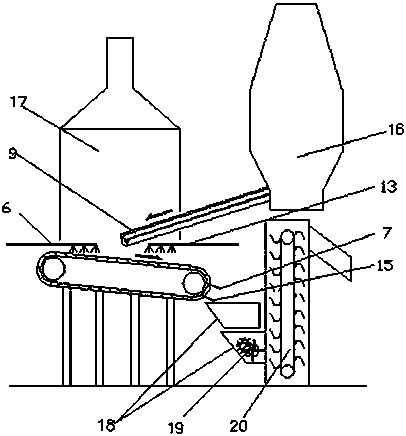

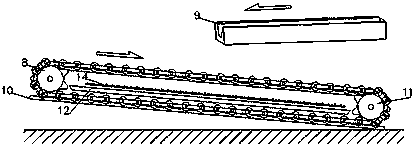

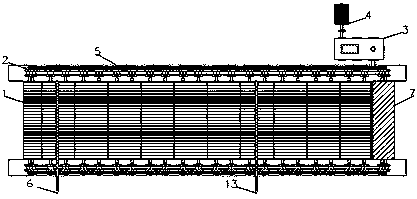

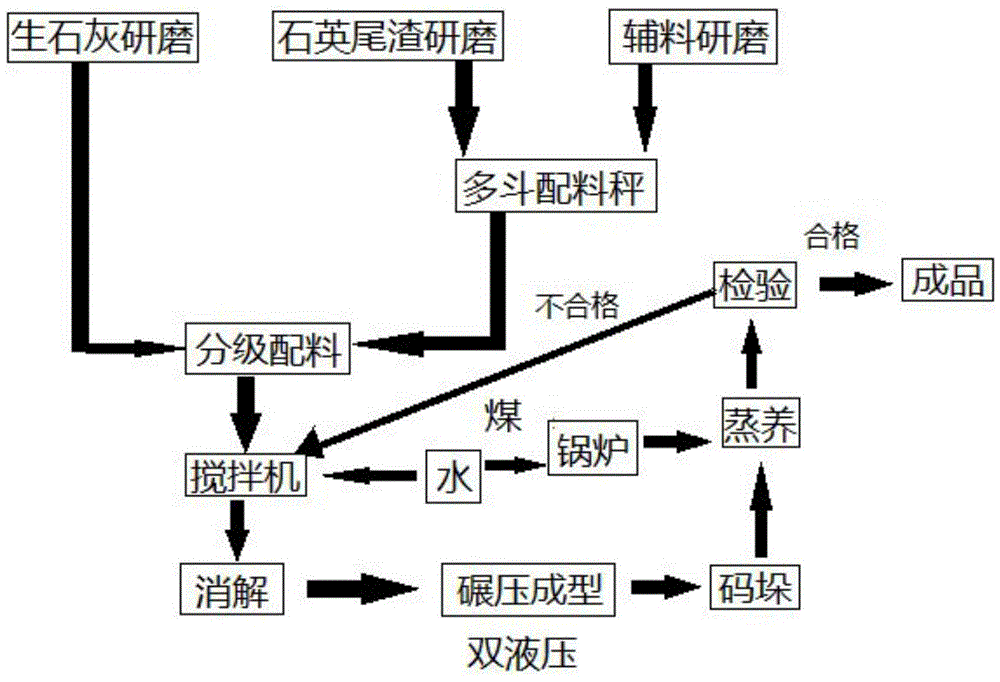

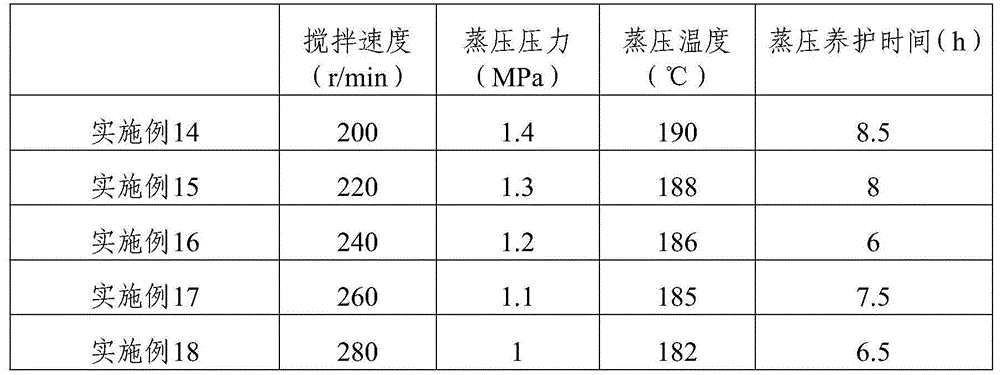

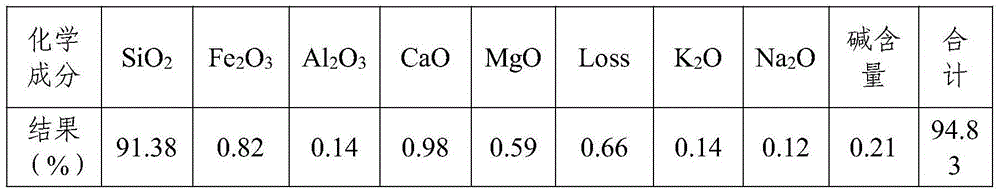

Quartz tailing brick and preparation method thereof

ActiveCN104003689ASolve technical problems that are prone to shrinkageHigh compressive strengthSolid waste managementHydration reactionBrick

The invention relates to the technical field of constructional autoclaved bricks, especially to a quartz tailing brick and a preparation method thereof. The quartz tailing brick comprises the following raw materials by weight: 65 to 75 parts of quartz tailings, 5 to 7 parts of quicklime and 23 to 25 parts of an auxiliary material. According to the invention, double hydraulic forming is employed, so a forming pressure is large, a compact interfacial structure of raw materials is ensured, and a blank has high strength; an autoclave is employed and silicon, aluminum and calcium materials undergo a hydration reaction under proper pressure and temperature conditions in saturated vapor, so a silicate product with certain flexural and compressive strength is formed; waste residues discharged by chemical enterprises are used, so the waste is turned into the valuable, cyclic utilization of resources is realized, the environment is protected, environmental pollution is treated, industrial waste residues are comprehensively treated and utilized, and a substantial environmental protection value and substantial economic benefits are obtained.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

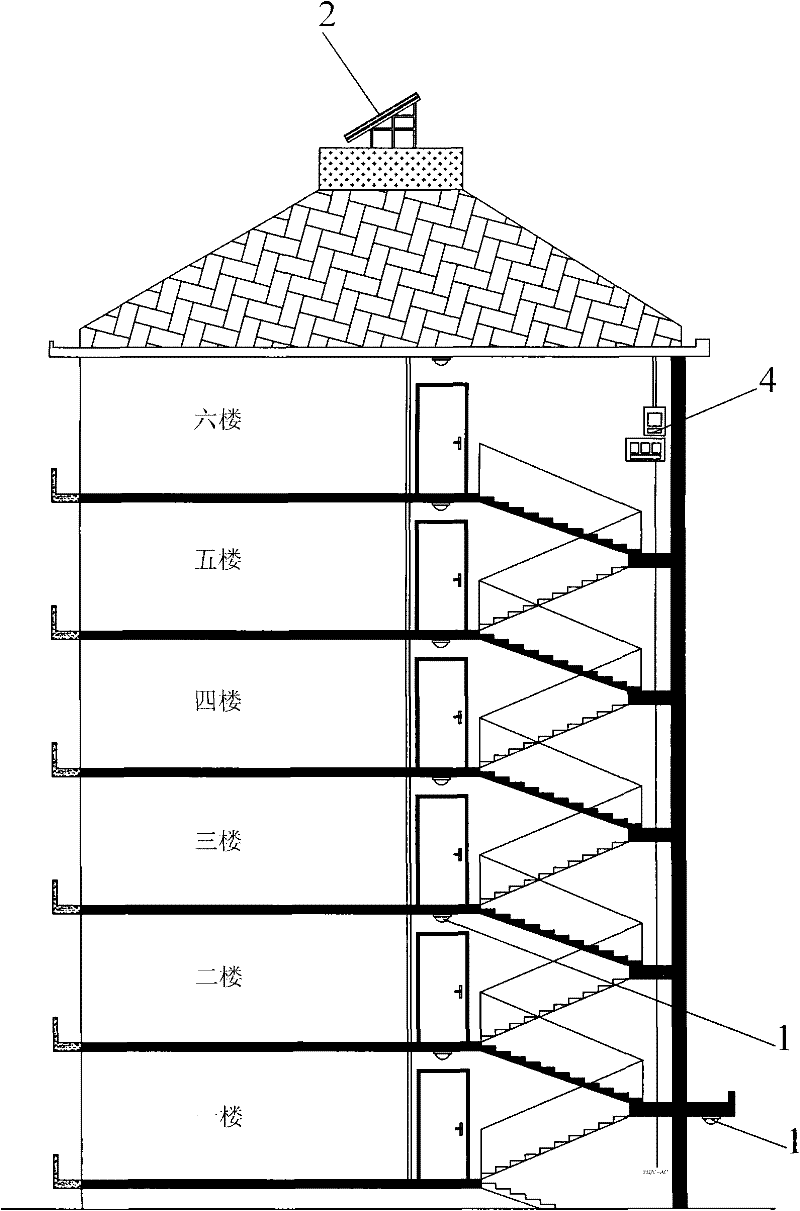

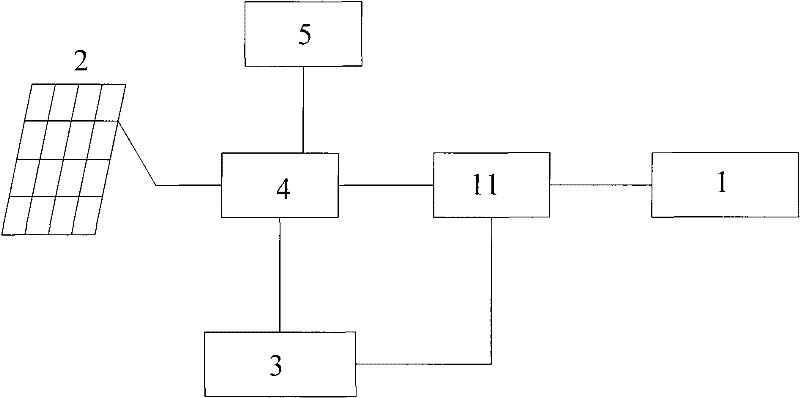

Solar corridor sensing LED lighting device

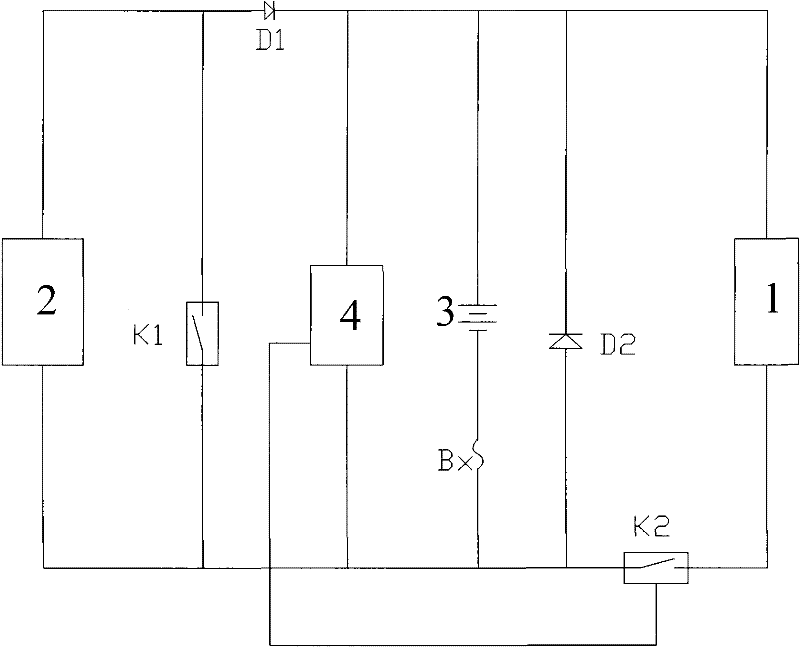

InactiveCN101749635AWith overchargeWith undervoltagePoint-like light sourceElectric circuit arrangementsElectrical batteryEffect light

The invention discloses a solar corridor sensing LED lighting device, which comprises an LED lighting device, a solar power generation device, a battery and a detection control unit. The battery forms a power supply circuit and a first charging circuit respectively with the LED lighting device and the solar power generation device. The solar corridor sensing LED lighting device also comprises a first switching device which is connected with the anode end and the cathode end of the solar cell power generation device in a crossing way and a second switching device which is connected with the LED lighting device in series. The invention has the advantages of convenient and intelligent use, energy conservation, environmental protection and the like. Moreover, since the whole circuit has the function of multi-level protection, the device can be used more safely and stably, and has a longer service life.

Owner:苏州东大光普科技有限公司 +1

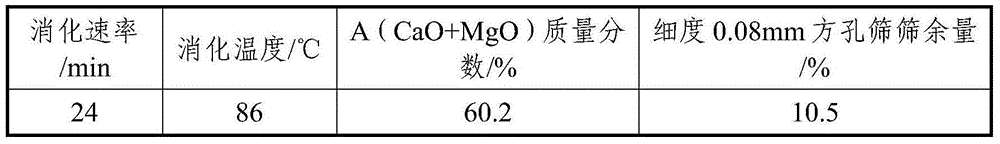

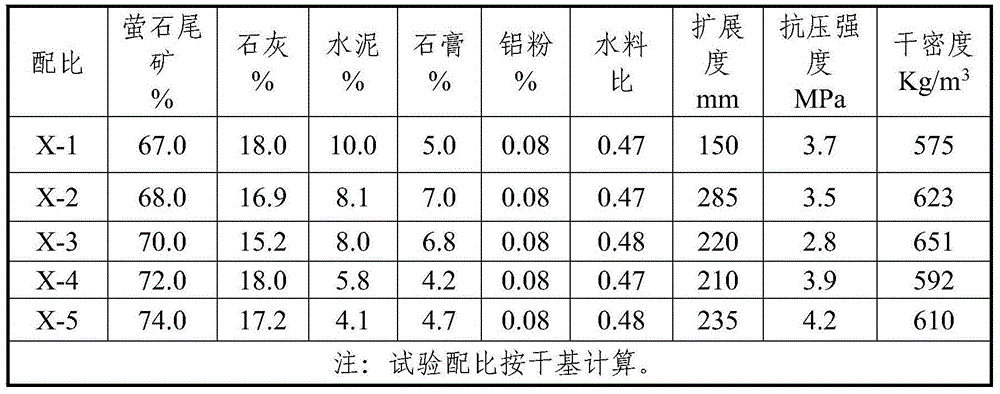

Tailing aerated concrete block and preparation method thereof

InactiveCN104402372AQuality improvementImprove insulation effectSolid waste managementDigestionGypsum

The invention relates to the technical field of concrete blocks and especially provides a tailing aerated concrete block and a preparation method thereof. In the tailing aerated concrete block, through control and adjustment of proportions among fluorite tailings, lime, cement, gypsum, aluminum powder, with combination of control of physical and chemical parameters in treatment on the raw materials, with combination of sequence in raw material mixing and with combination of control of a mixing temperature, a stirring speed and a stirring time, the lime can be directly and directionally subjected to a digestion process and a water material ratio can be controlled so that a raw material mixture is moderate in thickness, is easy to cut, is free of mould collapse and is easy and uniform in gas generation, by which a manufactured product is not liable to crack and the aerated concrete block is improved in quality. Furthermore, a thermal insulating effect and a sound insulating effect of the aerated concrete block are enhanced.

Owner:贵州省工业固体废弃物综合利用(建材)工程技术研究中心 +1

Di-ammonium phosphate produced by wet process phosphoric acid and production method of di-ammonium phosphate

ActiveCN104401953AIncrease productionImprove impactPhosphatesAlkali orthophosphate fertiliserPhosphatePhosphoric acid

The invention relates to the technical field of di-ammonium phosphate produced by wet process phosphoric acid, in particular to di-ammonium phosphate produced by wet process phosphoric acid and a production method of the di-ammonium phosphate. Ammonia is added into wet process phosphoric acid, and the molar ratio of ammonia and total phosphoric acid is controlled to enable the neutralization degree to be 0.5-0.8; impurities in the wet process phosphoric acid can produce a deposit together with phosphoric acid, fluorine and the like, so that wet process phosphoric acid is purified to a certain degree, the phenomenon of relatively low available phosphate content caused by the deposit produced by the impurities in the prepared di-ammonium phosphate, phosphoric acid and fluorine, the quality of di-ammonium phosphate is further improved, the available phosphate content accounts for 92-96% of the total phosphorus content in di-ammonium phosphate, and the content of fluorine in di-ammonium phosphate is reduced to 0.4-0.71%.

Owner:GUIZHOU KAILIN GRP CO LTD

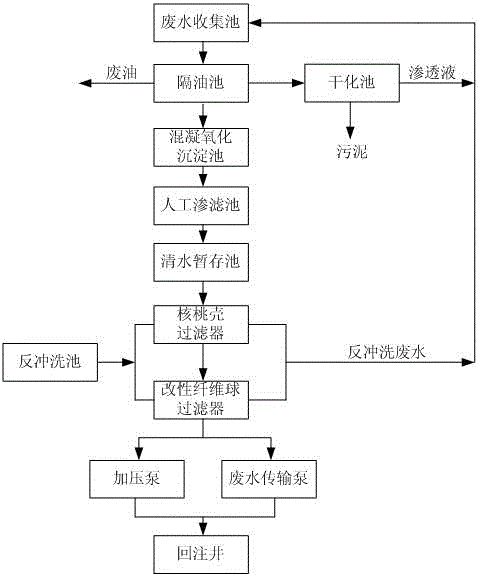

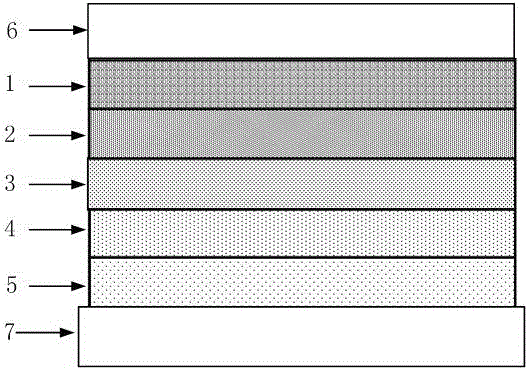

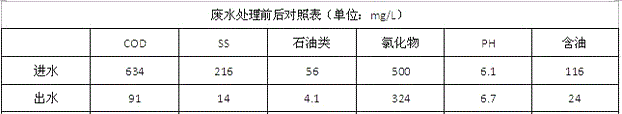

Shale gas wastewater treatment method and system

InactiveCN106800345AReduce concentrationSignificantly environmentally friendlyWaste water treatment from quariesMultistage water/sewage treatmentFlocculationFenton reaction

The invention discloses a shale gas wastewater treatment method which comprises the following steps: step 1 of separating oil from water in shale gas wastewater; step 2 of performing fenton reaction on wastewater of which waste oil is separated, then adding a coagulant to precipitate, filtering and drying a precipitated solid flocculation product and sending filtered supernate into the next step; step 3 of artificially infiltrating liquid obtained in the step 2 and then filtering sequentially through a walnut shell filter and a modified fiber ball filter, wherein artificially infiltrating is that liquid sequentially passes through filter layers with different particle sizes. A shale gas wastewater treatment system comprises a wastewater collecting tank, an oil partitioning tank, a coagulating, oxidizing and sedimentation basin, an artificial infiltrating tank, a clean water temporary storage tank, the walnut shell filter and the modified fiber ball filter which are sequentially connected. The shale gas wastewater treatment method disclosed by the invention can effectively reduce the concentration of flocculate in the wastewater, the treated wastewater can meet a national related environmental requirement, shale gas exploit water can be directly drained outwards or recycled, and an obvious environment-friendly effect and economical benefit are achieved.

Owner:宜宾清和环保科技有限责任公司

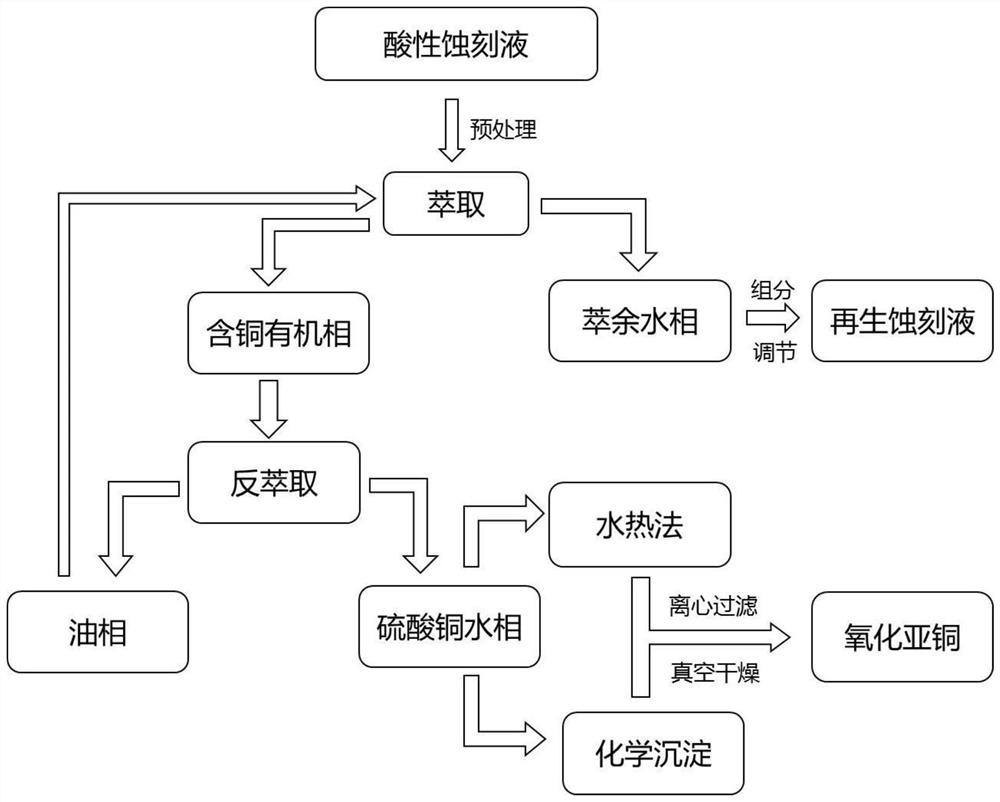

Method for recovering copper from acidic copper-containing etching solution and preparing cuprous oxide

InactiveCN111635994AEasy to handleAvoid pollutionRotary drum furnacesCrucible furnacesPhysical chemistrySulfuric acid

The invention discloses a method for recovering copper from an acidic copper-containing etching solution and preparing cuprous oxide. The method comprises the following steps of: S1, filtering the acidic copper-containing etching solution to obtain a crude copper-containing solution; S2, adjusting the pH of the crude copper-containing solution to 2-4, adding an extractant, mixing and stirring, standing for layering, wherein the upper layer is a primary copper-containing organic phase, and the lower layer is a primary water phase; recovering the primary water phase for an etching production line; S3, washing the copper-containing organic phase with deionized water, and separating to obtain a secondary copper-containing organic phase and a primary washing water phase; S4, adding sulfuric acid into the secondary copper-containing organic phase, fully stirring, standing for layering, wherein the upper layer is an extractant-containing organic phase, and the lower layer is a CuSO 4-containing water phase; S5, adding the primary washing water phase into the extractant-containing organic phase, washing, standing for layering to obtain a pure extractant organic phase for use in the step S2; and S6, preparing cuprous oxide from the CuSO 4-containing water phase by a hydrothermal method or a chemical precipitation method.

Owner:SICHUAN UNIV

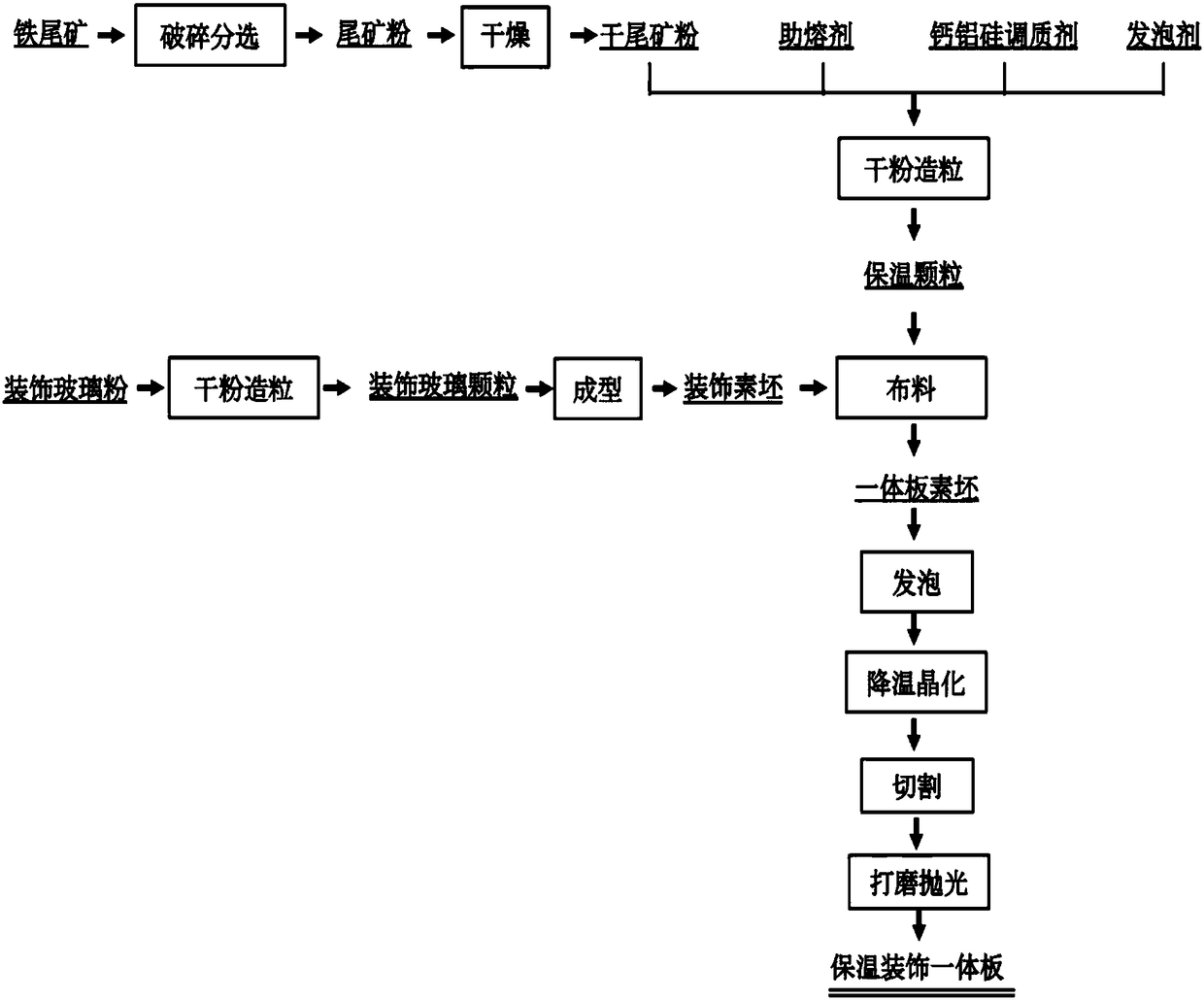

Method for preparing heat preservation and decoration integrated board through single-step sintering of iron tailings

InactiveCN108166697AImprove bindingEasy to useCovering/liningsCeramicwareEconomic benefitsBinding force

A method for preparing a heat preservation and decoration integrated board through single-step sintering of iron tailings mainly comprises the steps of preparation of heat preservation particles, preparation of a decoration biscuit and a main technical part of single-step sintering of the heat preservation and decoration integrated board. The main components of the heat preservation particles andthe decoration biscuit are adjusted to be within the close range, material distributing is conducted on the decoration biscuit to form an integrated biscuit, and the building material with the functions of heat preservation and decoration is obtained through single-step sintering. Compared with a traditional method that the heat preservation and decoration integrated building material is formed through secondary forming, binding and mechanical anchoring, the heat preservation and decoration board can be formed through one-time sintering by adopting the method, a heat preservation layer and a decoration layer have good binding forces, thus the service life is prolonged, and the construction difficulty is lowered. Meanwhile, the iron tailings are adopted to serve as main raw materials, largeamount consumption and high-valued utilization of the iron tailings are achieved, and the method has obvious environment-friendly and economic benefits.

Owner:BEIJING UNIV OF TECH

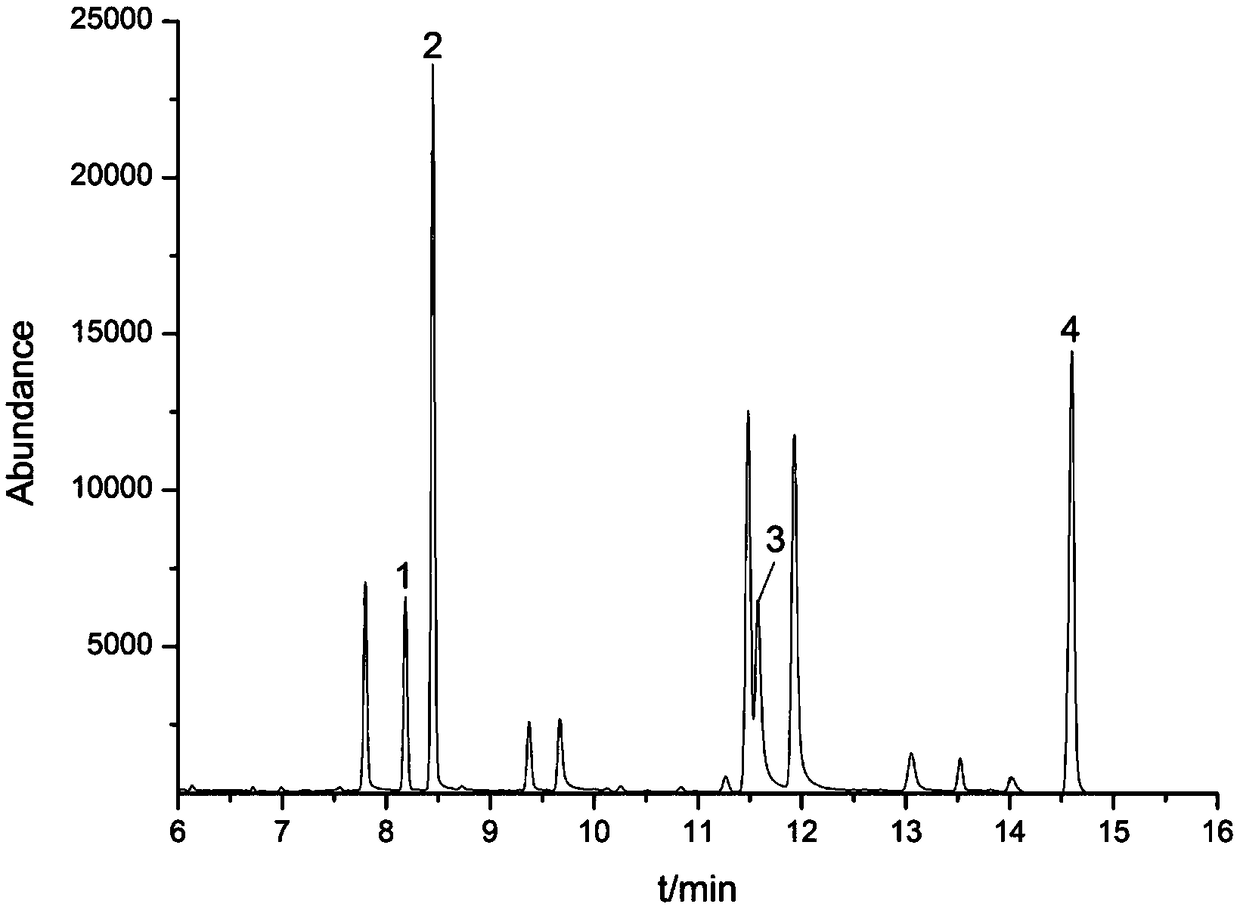

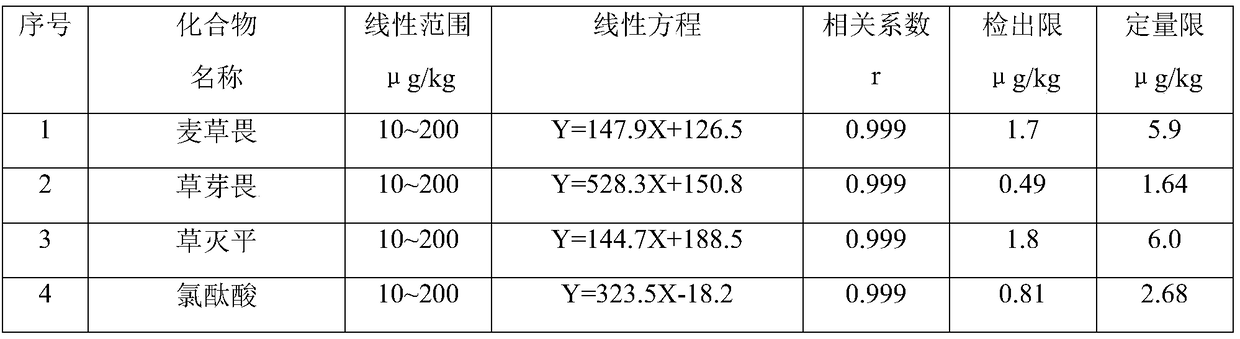

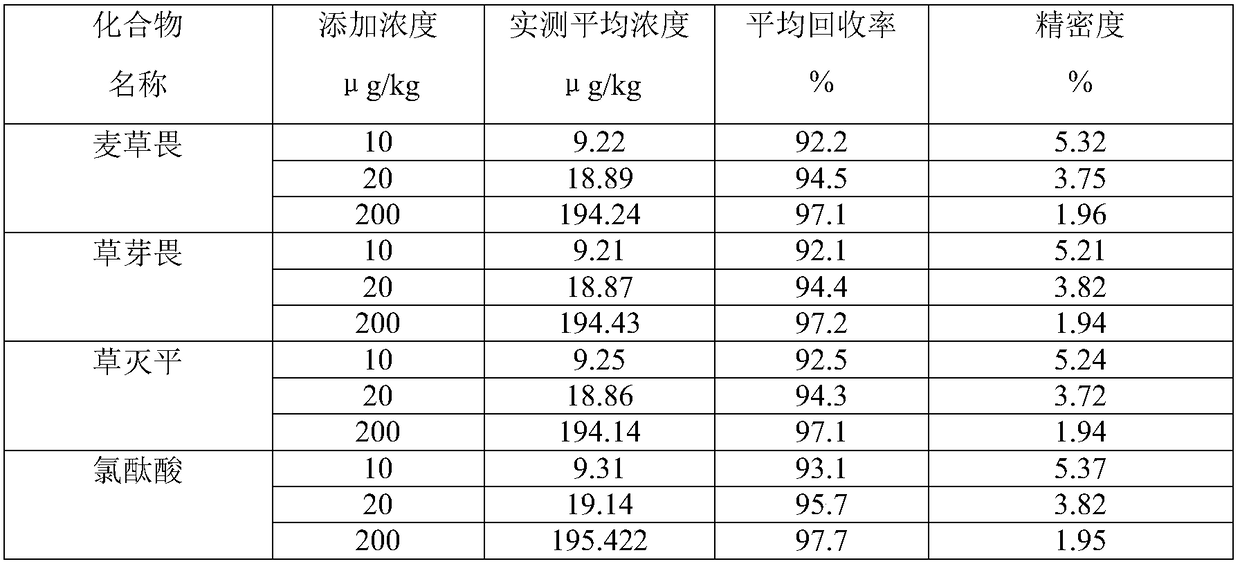

Gas chromatography method for simultaneously measuring four benzoic acid herbicides in grain

ActiveCN109212070AImprove adsorption capacityShort adsorption timeComponent separationBenzoic acidAqueous acetone

The invention relates to a method for analyzing and detecting trace harmful substances, in particular to a gas chromatography method for simultaneously measuring the residue of trace dicamba, 2,3,6-Trichlorobenzoic acid, amoben, and chlorthal in grain. The method comprises the following steps: ultrasonically extracting a target in a sample with a 10% water-acetone solution of pH=9; enriching a target compound in an extracting solution by using a novel adsorbent, benzsulfonate-magnesium-aluminum hydrotalcite calcined product; dissolving the adsorbent by using a hydrochloric acid solution to achieve complete elution of the target; efficiently extracting the compound with a small dose of organic solvent; and rapidly analyzing and measuring by gas chromatography method after derivatization. According to the gas chromatography method for simultaneously measuring the residue of trace dicamba, 2,3,6-Trichlorobenzoic acid, amoben, and chlorthal in grain, rapid and efficient adsorption of the target object is achieved by a novel adsorbent adopted in the method in a dispersed solid phase extraction mode, and a large amount of adsorption time can be saved compared with the gel permeation chromatography method and solid phase extraction method; the complete desorption of the target object can be achieved by using the acid to dissolve the adsorbent; and the method is only suitable for a small amount of organic solvent extraction, and has significant safety, environmental protection advantages and economic advantages.

Owner:丁立平 +1

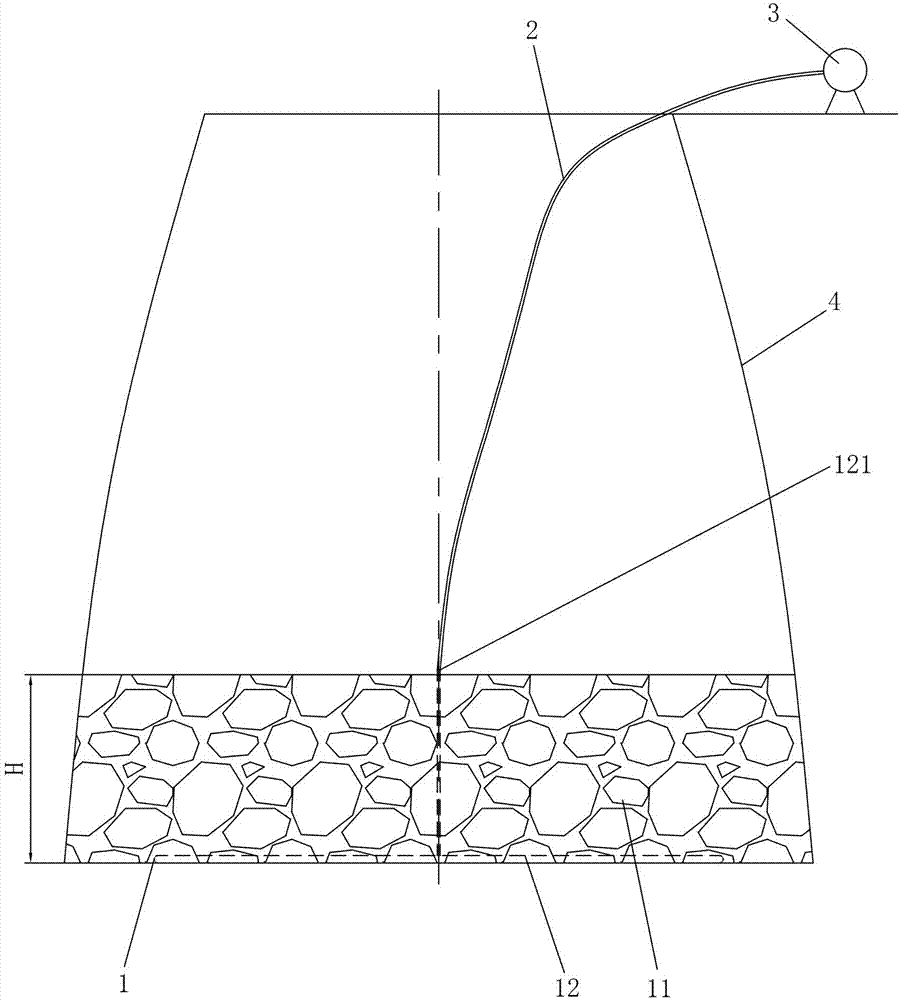

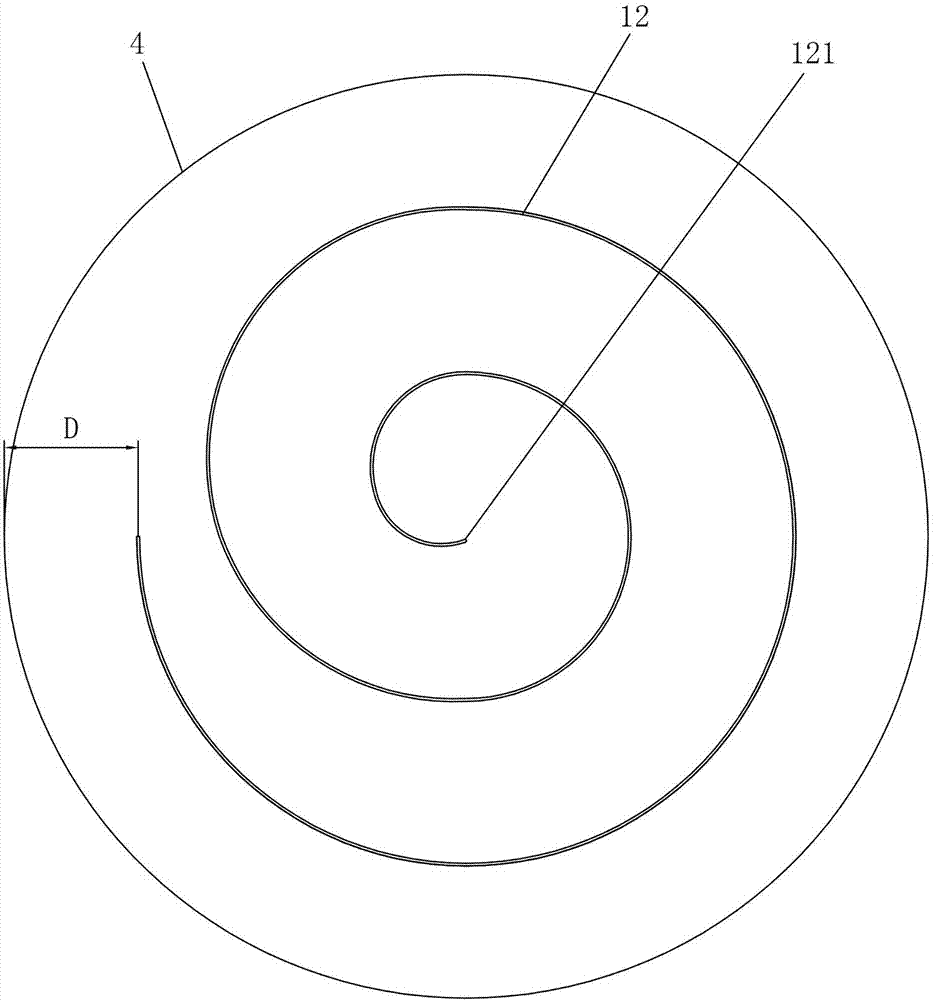

Shallow-buried karst cave filing construction method and shallow-buried karst cave filing construction structure

ActiveCN103046558AAvoiding technical difficulties of compactionHigh strengthEmbankmentsSoil scienceKarst

The invention discloses a shallow-buried karst cave filing construction method and a shallow-buried karst cave filing construction structure. The construction method includes steps: pre-making a grouting pipe, arranging the grouting pipe, filling soil and gravel mixed packing, grouting, reinforcing, completing shallow-buried karst cave filing and the like. The construction structure comprises the grouting pipe, a connection pipeline, a soil and gravel mixed packing layer filled in a shallow-buried karst cave and grouting equipment positioned outside the shallow-buried karst cave. The grouting pipe is arranged in the soil and gravel mixed packing layer and provided with a plurality of grout outlets on the wall, one end of the grouting pipe is provided with a grout inlet led out to the upper surface of the soil and gravel mixed packing layer, and the grouting equipment is connected with a grout inlet of the grouting pipe through the connection pipeline. The shallow-buried karst cave filing construction method and the shallow-buried karst cave filing construction structure have the advantages of simple construction process, low labor cost, material saving, low manufacturing cost, wide application range, high construction efficiency, high environment friendliness and the like.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

Smoke rotational flow condensation type heat exchange device and method for aluminum oxide calcining kiln

InactiveCN105698549AEvenly distributedReduce loadCharge composition/stateIncreasing energy efficiencyRed mudRotational flow

The invention provides a smoke rotational flow condensation type heat exchange device and method for an aluminum oxide calcining kiln. The smoke rotational flow condensation type heat exchange device comprises a fan, sprayers, a chimney, a fog receiver, a water recycling tank, an overflow pipe, a dust collector, a hot water pump, a cold water pump, spiral flow guide plates, an air pipe and a user. The smoke rotational flow condensation type heat exchange method comprises the steps that 150-170 DEG C hot and wet smoke from the aluminum oxide calcining kiln enters the lower portion of a condensation heat-exchange tower through the fan and the air pipe, and operates upwards after passing the spiral flow guide plates; and after spraying convective heat exchange through the sprayers, cooling water is heated to 80 DEG C from 50 DEG C and then joints condensate water in the smoke, and afterwards, mixed water is delivered to the user to be used through the hot water pump after entering the water recycling tank. The smoke rotational flow condensation type heat exchange device and method have the advantages that recycled hot water can be used for washing of red mud and a flat plate in aluminum oxide production, or heating for the user, or ORC waste heat power generation. 80%-90% or above of the heat in the moisture-heat-containing smoke can be recycled, and the economic benefit and the effects of energy conservation, emission reduction and environmental protection are significant.

Owner:北京中冶设备研究设计总院有限公司

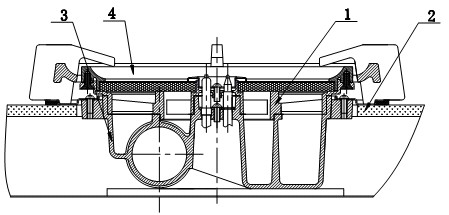

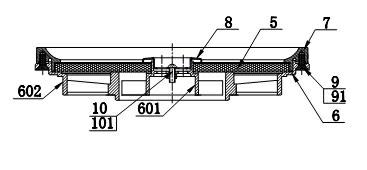

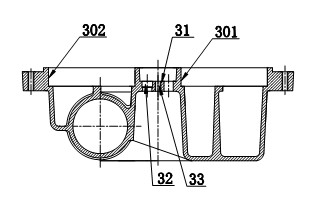

Infrared gas stove provided with burner easy to clean

InactiveCN102121716AEasy to assembleEasy to disassembleDomestic stoves or rangesLighting and heating apparatusMechanical engineeringGas cooking stove

The invention relates to an infrared gas stove provided with a burner easy to clean, consisting of the burner 1 and a gas stove main body 2, wherein the burner comprises a burner main body 3 and a heating plate component 4; the heating plate component consists of a heating plate 5, a gas distributing disc 6, an outer circular positioning ring 7, an inner circular positioning ring 8, an outer circular positioning ring locking device 9 and an inner circular positioning ring locking device 10; the heating plate is arranged on the gas distributing disc; the heating plate and the gas distributing disc are connected into a whole by virtue of the outer circular positioning ring, the inner circular positioning ring, the outer circular positioning ring locking device and the inner circular positioning ring locking device; the heating plate component and the burner main body are connected together based on that cylindrical surface sections 601 and 602 on the gas distributing disc in the heating plate component are in clearance fit with corresponding cylindrical surface sections 301 and 302 on the burner main body; and the heating plate component can be easily disassembled for cleaning and is provided with a heat-collecting reflection section, thus not only can the problem that the burner of the infrared gas stove is not easy to clean be solved, but also the energy-saving and environmentally-friendly effects are obvious.

Owner:MIDEA GRP CO LTD

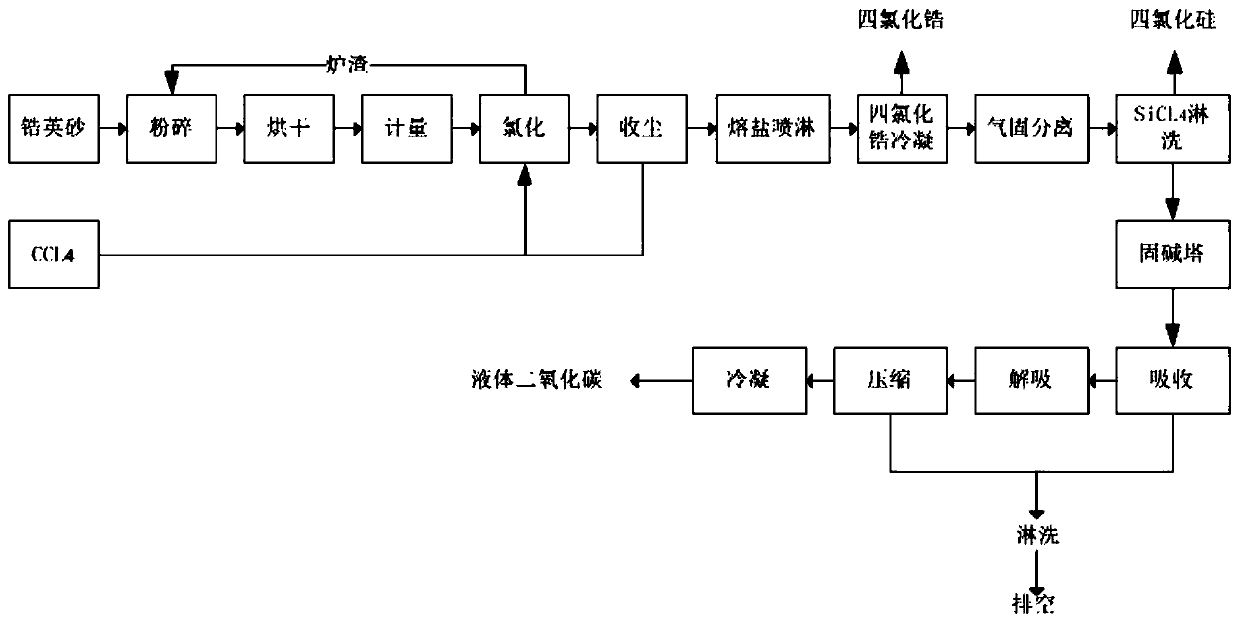

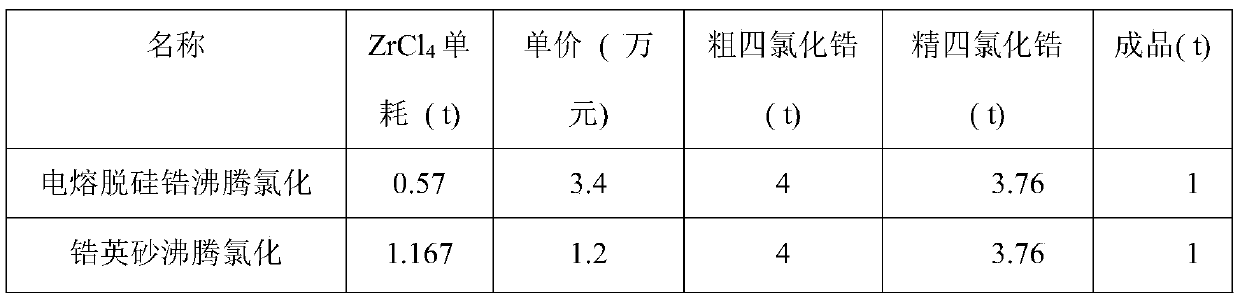

Technological method for preparing zirconium tetrachloride by-product silicon tetrachloride by chlorinating zircon sand

PendingCN109734128AIncrease profitNo stratificationCarbon compoundsHalogenated silanesChemical reactionReaction temperature

The invention discloses a technological method for preparing zirconium tetrachloride by-product silicon tetrachloride by chlorinating zircon sand. The technological method is characterized by comprising the following steps: (1) crushing: dry crushing zircon sand; (2) drying: drying the crushed zircon sand; (3) chlorination: adding the dry zircon sand into a boiling chlorination furnace, and addingCCl4 at that bottom of the furnace for chlorination; and (4) preparation: after the reaction, carrying out the gas-solid separation for ZrCl 4 and SiCl 4 gases generated in a fluidized bed by virtueof a dust collector at the top of the chlorination furnace, returning the collected dust to the furnace to continuously react, and washing and spraying the separated gases by virtue of molten salt. The technological method of the invention has the following advantages: the byproduct CCl4 of methyl chloride industry is converted into ZrCl 4 and SiCl 4 by utilizing the reaction process of zircon sand and CCl4, and the technological method is a pollution-free reaction process and has remarkable economic and environmental protection values; and by adopting the chemical reaction of solid and gas, the reaction temperature is low, the reaction speed is high, and the production capacity is high. The reacted exhaust gas carbon dioxide gas is liquefied and sold as a byproduct.

Owner:锦州旭日新材料科技有限公司

Method for manufacturing recycled paper by adding loofah sponge fiber

ActiveCN107164986AWell stockedShort regeneration periodPaper recyclingPaper/cardboardFiberEconomic benefits

Provided is a method for manufacturing recycled paper by adding loofah sponge fiber. The method comprises the steps that loofah sponge undergoes dry-smashing treatment; degumming treatment is performed; paper products are recovered, and coarse cutting, shake-screening, centrifugal classification and fine cutting treatment is performed; classified recovered paper chippings are soaked, stirred, filtered and stirred to produce pulp; degummed loofah sponge fiber chippings and the recovered paper pulp material are mixed and stirred according to the ratio of 1:9 to 1:1; a dye, a dye-fixing agent and starch are added or visible loofah sponge fiber chippings are supplemented for mixing and stirring treatment; pulp taking for papermaking, press mold water absorption, hot-air constant-temperature drying, paper taking through scrapers and press-polishing and paper rolling are performed to obtain a dyed loofah sponge recycled paper finished product. The fiber content of the recycled paper is supplemented by adding the loofah sponge fiber, and the adsorption and coloring properties of the recycled paper can be improved while the paper is flexible. In addition, in the mode of classified pulping of the recycled paper, the high-quality recycled paper output rate can be greatly improved, added economic benefits can be brought to enterprises by combining with natural texture of the loofah sponge, and meanwhile the method has the special significance on environmental protection.

Owner:湛江市原佳彩印包装材料有限公司

Modified sand soil

ActiveCN103351868AWith mechanical stabilityChange interactionAgriculture tools and machinesOrganic fertilisersGrowth plantSoil organic matter

The invention discloses modified sandy soil. The modified sandy soil is formed by stirring and mixing a solution having a caking property and adhesivity and sand soil, wherein the solution is formed by dissolving water-soluble solid organic matters in water. After the water is evaporated, the water-soluble solid organic matters can conglutinate grains of the sand soil, and when the solid organic matters meet the water, the solid organic matters can again dissolve in the water to form the solution having the caking property and adhesivity so as to conglutinate the grains of the sand soil. The modified sand soil can make general sand soil soil-like, interaction relationship among the grains of the sand soil can be fundamentally changed, and a grain-pore structure having bonding force (cohesive force) is formed. In the course of use of the modified sand soil, matters are hard to lose due to the characteristics of the caking property and adhesivity. The modified sand soil has soil-like stability and the water and nutrient storing properties, can provide solid conditions for plant growth, and is an ideal control measure for the sand soil. At the same time, the modified sand soil can be used as a means of utilization of sand resources such as sand beaches and the like for plant plantation.

Owner:易志坚 +1

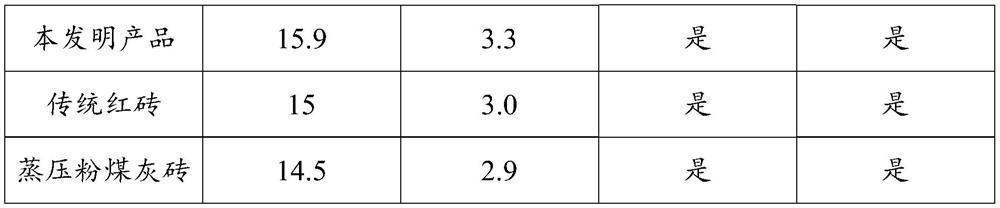

Porous phase material composite red mud brick and preparation method thereof

ActiveCN114031355ARealize comprehensive utilizationSignificantly environmentally friendlySolid waste managementAggregate (composite)Brick

The invention discloses a porous phase material composite red mud brick and a preparation method thereof. The porous phase material composite red mud brick is prepared by mixing and carbonizing the following raw materials in parts by mass: 10-20 parts of a porous phase material, 5-50 parts of red mud, 10-50 parts of modified slag powder and 10-30 parts of aggregate. The red mud and the porous phase material are used as a composite carrier, the modified slag powder is used as a main mineralization material, the aggregate is used as a framework, a carbonization treatment mode is matched, the porous phase material composite red mud brick is prepared, the compressive strength, radioactivity, leaching toxicity and other indexes of the porous phase material composite red mud brick all meet the standard requirements, and the porous phase material composite red mud brick can replace traditional red bricks to be applied. According to the preparation method, not only are solid waste resources such as red mud and slag utilized, but also carbon dioxide in industrial waste gas is utilized, comprehensive utilization of various wastes is achieved, and the preparation method has remarkable environmental protection significance and economic benefits.

Owner:山东京韵泰博负碳科技有限公司

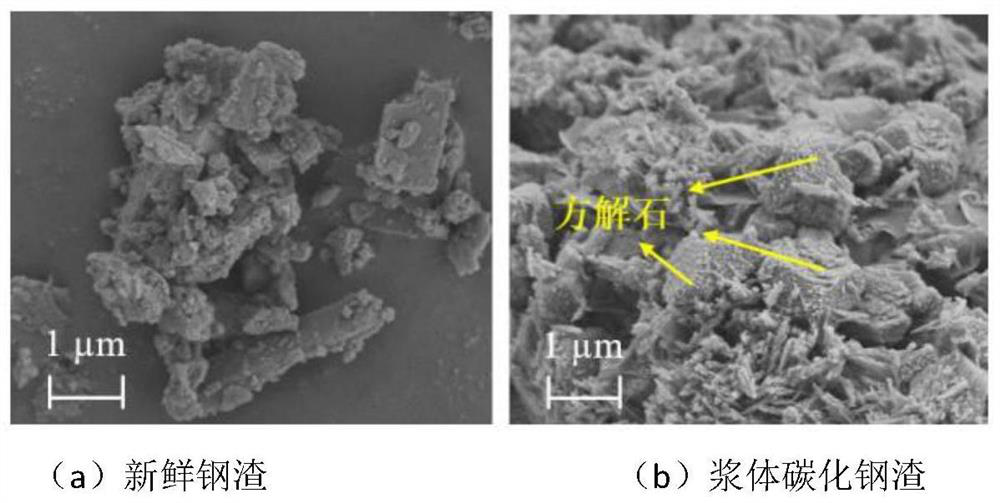

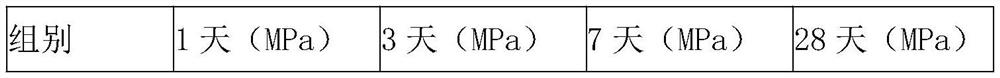

Method for preparing cement-based material from carbonized steel slag slurry

The invention relates to a method for preparing a cement-based material by using carbonized steel slag slurry, which comprises the following steps: introducing carbon dioxide while stirring steel slag and an aqueous solution, and controlling the stirring speed and temperature to obtain the carbonized steel slag slurry. And calculating the water replenishing mass according to the CO2 absorption rate, and mixing and stirring all carbonized slurry, replenishing water, cement and other materials to prepare the cement-based material. The steel slag used by the cement-based material is converter steel slag with the particle size of 0-75 microns, and the highest cement replacement rate can reach 30%. Compared with an uncarbonized steel slag composite cement-based material, the prepared carbonized steel slag composite cement-based material has the advantages that the 28-day strength can be improved by 15%, the problem of poor volume stability of the steel slag is solved, the utilization rate of the steel slag is improved, 10-16 wt.% of carbon dioxide can be absorbed, and the carbonized steel slag composite cement-based material has obvious economic benefits and environmental protection values.

Owner:HUNAN UNIV

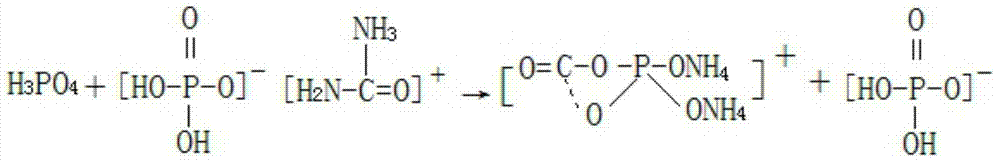

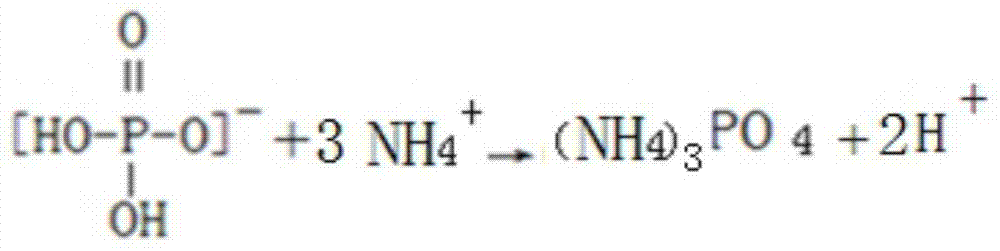

Production method for preparing ammonium phosphate and coproducing special fertilizer for mulberry

InactiveCN104261372AAvoid the disadvantage of lower purityQuality improvementPhosphatesFertilizer mixturesChemical industryEconomic benefits

The invention relates to the technical field of chemical industry, particularly a production method for preparing ammonium phosphate and coproducing a special fertilizer for mulberry. By analyzing nutrient demand conditions in the mulberry growth process in combination with analysis and understanding of the defects in the ammonium phosphate product preparation technique, the preparation technique of the special combined compound fertilizer for mulberry is combined with the preparation technique of the ammonium phosphate product to perform complementation, thereby lowering the waste liquid discharge amount in the ammonium phosphate product preparation technique, avoiding the defect of lower ammonium phosphate product purity due to deep crystallization, and improving the quality of the ammonium phosphate product. The method enhances the mulberry growth rate, improves the mulberry yield and quality, prevents excessive elements from residing in soil due to improper matching of nutrient elements, lowers the soil hardening rate, enhances the land utilization ratio, and has obvious environmental protection value and economic benefit.

Owner:GUIZHOU KAILIN GRP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com