Technological method for preparing zirconium tetrachloride by-product silicon tetrachloride by chlorinating zircon sand

A technology for by-product silicon tetrachloride and zirconium tetrachloride, which is applied in chemical instruments and methods, zirconium halide, silicon halide compounds, etc. Equipment service life and other issues, to achieve significant economic and environmental value, continuous and smooth production, slowing down the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

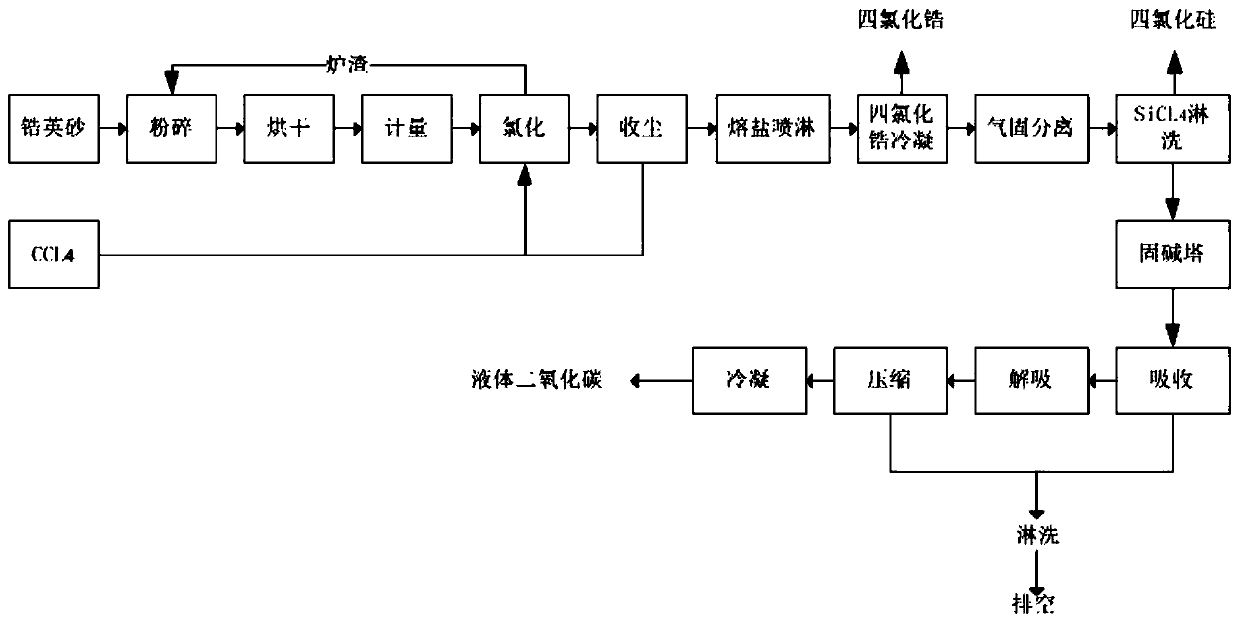

[0027] With reference to the drawings, the purpose of the present invention is to use industrial waste CCl against the defects of the existing zircon sand chlorination technology 4 It can replace chlorine as a chlorinating agent and petroleum coke as a reducing agent to make the two into one. It provides a metered, continuous feeding and discharging, loose raw material particle size, and fluidization that matches the chlorinating agent and the material, ideal The low-temperature chlorination method of zircon sand can greatly reduce energy consumption, improve recovery rate and product quality, and extend equipment service life. Reaction principle: ZrSiO 4 +2CCl 4 =ZrCl 4 +SiCl 4 +2CO 2

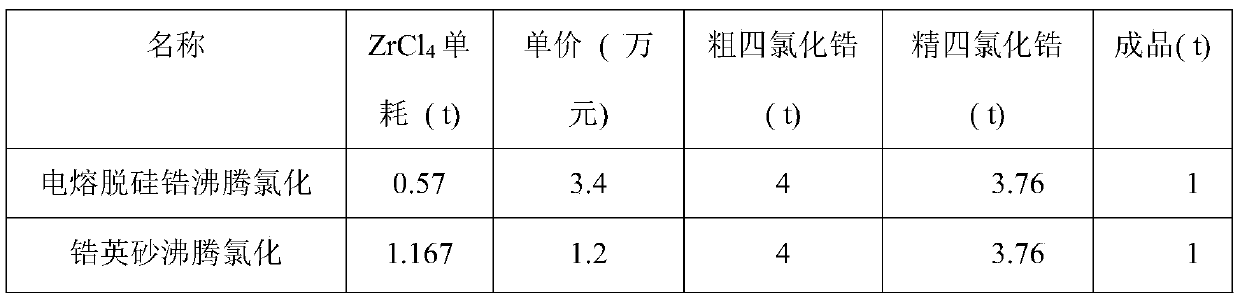

[0028] The present invention has the following key technical features: 1. Use CCl 4 Zirconium chloride sand is used to prepare refined zirconium tetrachloride while by-product silicon tetrachl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com