Production method for calcium hydrogen phosphate

A technology of calcium hydrogen phosphate and production methods, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of not having better economic benefits, difficult separation of slag, high production costs, etc., and achieve significant environmental protection value and economy Benefits, avoiding the removal of waste residues, and the effect of avoiding waste removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

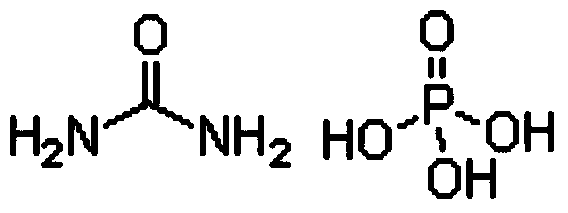

[0057] A production method of calcium hydrogen phosphate, specifically comprising the following steps:

[0058] (1) Preparation of calcium hydroxide solution: measure and add a certain amount of water in the calcium hydroxide preparation tank, then add calcium oxide with a purity of 80% according to the mass ratio of calcium oxide and water at a ratio of 1:2, and add it while adding Stir the mixed solution of calcium oxide and water at a speed of 100r / min according to the stirring speed. After the addition is completed, continue to stir for 20min to mix the calcium oxide and water evenly to obtain a calcium hydroxide solution for subsequent use;

[0059] (2) Preparation of urea phosphate solution: add 1000kg of water into the urea phosphate dissolving tank, then add urea phosphate solid with a purity of 80%, stir while adding to make it dissolve evenly, and the stirring speed is 30r / min to prepare urea phosphate Saturated solution, spare;

[0060] (3) Synthesis of calcium hyd...

Embodiment 2

[0064] A production method of calcium hydrogen phosphate, specifically comprising the following steps:

[0065] (1) Preparation of calcium hydroxide solution: measure and add a certain amount of water in the calcium hydroxide preparation tank, then add calcium oxide with a purity of 85% according to the mass ratio of calcium oxide to water at a ratio of 1:3.5, and add it while adding Stir the mixed solution of calcium oxide and water at a speed of 30 r / min according to the stirring speed. After the addition is completed, continue to stir for 5 minutes to mix the calcium oxide and water evenly to obtain a calcium hydroxide solution for subsequent use;

[0066] (2) Preparation of urea phosphate solution: add 1000kg of water into the urea phosphate dissolving tank, then add urea phosphate solid with a purity of 87%, stir while adding to make it dissolve evenly, the stirring speed is 50r / min, and prepare urea phosphate Saturated solution, spare;

[0067] (3) Synthetic of calcium ...

Embodiment 3

[0071] A production method of calcium hydrogen phosphate, specifically comprising the following steps:

[0072] (1) Preparation of calcium hydroxide solution: measure and add a certain amount of water in the calcium hydroxide preparation tank, then add calcium oxide with a purity of 88% according to the mass ratio of calcium oxide to water at a ratio of 1:2.5, and add it while adding Stir the mixed solution of calcium oxide and water at a speed of 70r / min according to the stirring speed. After the addition is completed, continue to stir for 10min to mix the calcium oxide and water evenly to obtain a calcium hydroxide solution for subsequent use;

[0073] (2) Preparation of urea phosphate solution: add 1000kg of water into the urea phosphate dissolving tank, then add urea phosphate liquid with a purity of 90%, stir while adding to make it dissolve evenly, and the stirring speed is 40r / min to prepare saturated urea phosphate solution, spare;

[0074] (3) Synthesis of calcium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com