Fracturing fluid solution capable of being prepared from high-mineralization water and application of fracturing fluid

A high salinity, fracturing fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem that the water source cannot be used for fracturing fluid preparation, achieves significant environmental protection and water saving benefits, and alleviates water loss. The effect of resource requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a solution that can use high-salinity water to prepare fracturing fluid. The composition of the solution is as follows in terms of weight percentage:

[0032] Anti-high salinity thickener 0.15-0.45%;

[0033] Temperature stabilizer 0.1% (the temperature stabilizer is one or more of NaOH solution, KOH solution, triethanolamine, phosphoric acid);

[0034] Drainage aid 0.2% (drainage aid is a non-ionic surfactant, and its specific formula is one of nonylphenol polyoxyethylene ether, lauryl alcohol, and cetyl alcohol with ethanol and water in a mass ratio of 1:0.5:3 compounded);

[0035] High salinity water 99.15-99.54% (such as oil field underground brackish water, fracturing flowback fluid, oil and gas well produced water, etc.);

[0036] Gel breaker 0.01-0.1% (gel breaker is one of ammonium persulfate, potassium persulfate, hydrogen peroxide, and magnesium hypochlorite wrapped in capsules).

[0037] The above-mentioned anti-high salinity thick...

Embodiment 2

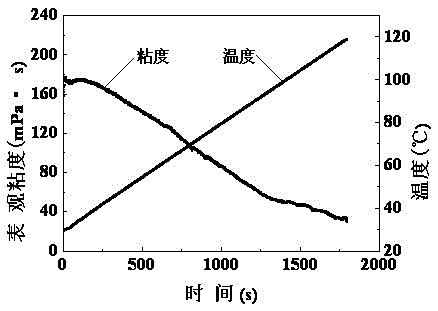

[0045]This example provides a jelly fracturing fluid prepared from a solution of high salinity water to prepare a fracturing fluid as described in Example 1. The volume ratio of the solution and the cross-linking agent is 100:0.5 ~3.0 ratio to make jelly fracturing fluid.

[0046] The above-mentioned jelly fracturing fluid can be prepared by using high-salinity water to prepare a fracturing fluid solution, and the cross-linking agent is composite titanium triethoxide and NaHCO 3 Stir in the organic solvent tert-butanol according to the mass ratio of 1:1:50 to form the finished crosslinking agent.

[0047] 30m on site 3 Add 28m to the container 3 For high-salinity water, add thickener slowly while circulating the pump, and then add drainage aid in sequence according to the formula ratio (nonylphenol polyoxyethylene ether, ethanol, and water are compounded at a mass ratio of 1:0.5:3 obtained), stabilizer (triethanolamine), and continue to circulate for 10 minutes. Continue t...

Embodiment 3

[0053] This example provides a slick water fracturing fluid that can be prepared by using a solution of high salinity water to prepare a fracturing fluid as described in Example 1. The solution is mixed with clean water at a volume ratio of 1:2 to prepare into slippery water fracturing fluid.

[0054] 30m on site 3 Add 10m to the container 3 Clean water, slowly add the thickener under the condition of pump circulation, and then add the drainage aid nonylphenol polyoxyethylene ether, ethanol, and clean water according to the mass ratio of 1:0.5:3), stabilizer ( Triethanolamine), continue to circulate for 10 minutes, continue to circulate and replenish the liquid, and continue for 20 minutes to ensure that the liquid is fully mixed to form a slick water fracturing fluid, which can be used directly as a fracturing fluid for downhole fracture.

[0055] The slick water fracturing fluid formed is used for downhole fracturing. After testing, the total fluid volume of the entire co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com