Medium and low grade phosphorus ore magnesium removal treatment method

A treatment method, low-grade technology, applied in the direction of phosphate material treatment, etc., to achieve the effect of reducing emissions, avoiding emissions, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

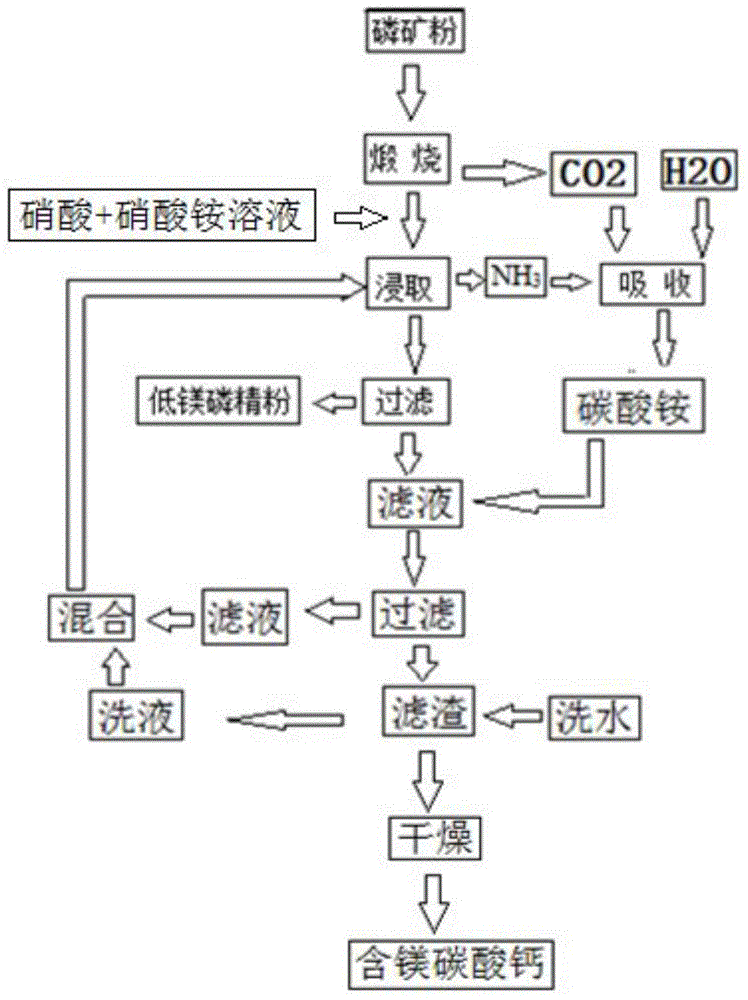

[0031] like figure 1 Shown, a kind of process method for removing magnesium of middle and low grade phosphate rock, comprises the following steps:

[0032] (1) Calcination and digestion: the medium and low-grade phosphate rocks are calcined in a calcination furnace at a temperature of 900°C for 0.5h, and then digested with 45ml of water per 100g of phosphate rocks; the water digestion process is carried out with hot water Digestive processing. The temperature of the hot water was 60°C.

[0033] (2) Leaching: the digested slurry is placed in the leaching tank, and the ammonium nitrate solution and the nitric acid solution of 65% are added into the leaching tank with a concentration of 25%, and the temperature in the leaching tank is controlled at 80 ℃, and the material in the leaching tank was stirred for 50 minutes; the amount of the ammonium nitrate solution added was 300ml per 100g of phosphate rock. The addition amount of described nitric acid solution is to add 5g accor...

Embodiment 2

[0038] like figure 1 Shown, a kind of process method for removing magnesium of middle and low grade phosphate rock, comprises the following steps:

[0039] (1) Calcination and digestion: In the low-grade phosphate rock calciner, the temperature of 950°C is used for 1.5h, and then 55ml of water is used for every 100g of phosphate rock; the water digestion is carried out with hot water. deal with. The temperature of the hot water was 70°C.

[0040] (2) Leaching: the phosphate ore that has been digested is placed in the leaching tank, and in the leaching tank, adding a concentration of 50% ammonium nitrate solution and a 90% nitric acid solution to the leaching tank The temperature is controlled at 90°C, and the material in the leaching tank is stirred for 80 minutes; the amount of the ammonium nitrate solution added is 400ml per 100g of phosphate rock. The addition amount of described nitric acid solution is to add 5g according to every 100g phosphate rock.

[0041] (3) Abso...

Embodiment 3

[0045] Such as figure 1 Shown, a kind of process method for removing magnesium of middle and low grade phosphate rock, comprises the following steps:

[0046] (1) Calcination and digestion: in the low-grade phosphate rock calciner, the temperature of 910 ℃ is used for calcination for 0.7h, and then 50ml of water is used for every 100g of phosphate rock for digestion; the water digestion is carried out with hot water deal with. The temperature of the hot water was 65°C.

[0047] (2) Leaching: the phosphate ore that has been digested and processed is placed in the leaching tank, and in the leaching tank, adding a concentration of 10% ammonium nitrate solution and a 5% nitric acid solution to the leaching tank The temperature is controlled at 85°C, and the material in the leaching tank is stirred for 30 minutes; the amount of the ammonium nitrate solution added is 350ml per 100g of phosphate rock. The addition amount of described nitric acid solution is to add 70g according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com