Dry granulation apparatus of blast furnace slag using continuous thin single-layer hot sprinkling and application method thereof

A dry granulation and blast furnace slag technology, applied in the direction of recycling technology, etc., to achieve the effect of speeding up the diffusion rate, facilitating crushing and heat exchange, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

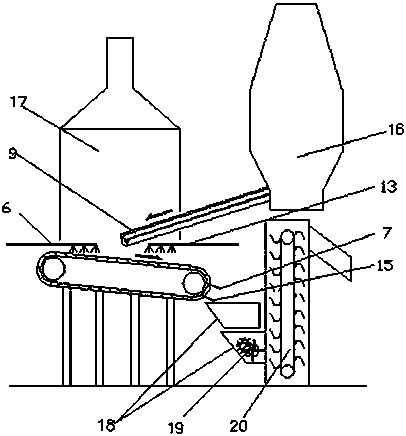

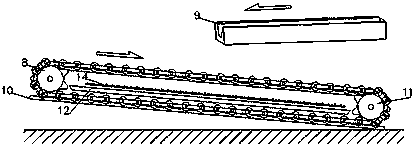

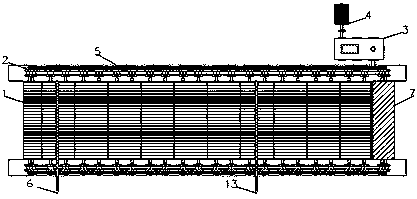

[0032] Such as figure 1 As shown, the continuous thin-layer single-layer hot-splash blast furnace slag dry granulation device of the present invention includes a grate machine, a cooler, a slag ditch, a crusher 19 and a transport lifting device 20 . The grate is arranged directly below the ditch head of the slag ditch 9 of the blast furnace 16, with a height difference of about 0.2-0.5m, and its centerline is on the same plane as the ditch head centerline. Such as figure 2 As shown, the chain grate is installed with a positive slope of 2~5° to the horizontal flow direction of the liquid slag, and the rotation direction of the chain grate is opposite to the horizontal flow direction of the liquid slag in the horizontal direction, and its rotation speed must ensure that the liquid slag falls to the surface of the chain grate Finally, it will not be left in the water distribution area at the tail of the machine, and the size should be equal to the horizontal flow velocity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com