A Construction Method of Built-in Hollow Steel Fiber Concrete Protective Layer

A technology of steel fiber reinforced concrete and concrete-filled steel tube columns, which can be applied to coastline protection, building structure, structural elements, etc., can solve problems such as loss of protection of steel tubes, poor bonding effect of concrete protective layers, etc., and improve crack resistance stiffness and deformation The effect of improving capacity and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Introduce below in conjunction with accompanying drawing the construction method of built-in hollow steel pipe steel fiber concrete protective layer of the present invention:

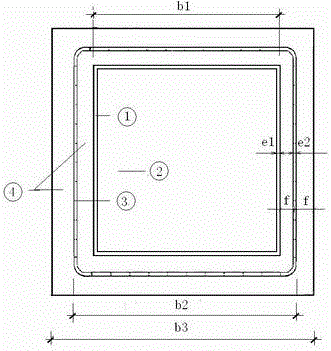

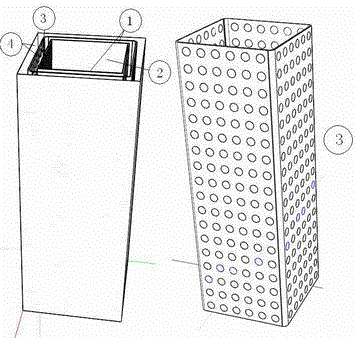

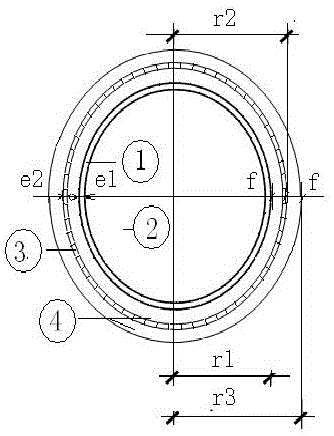

[0033] figure 1 , image 3 They are the square and circular cross-section protective layer structures of the present invention, the outermost layer is a steel fiber protective layer, and in the middle of the protective layer, hollow steel pipes are built in, and the inner layer is the structural part of ordinary steel pipe concrete columns, and concrete is poured inside the steel pipes.

[0034] According to the figure, the sequence from the outer layer to the inner layer is ④-③-④-①-②.

[0035] The steel fiber concrete is bonded to the outer surface of the inner steel pipe, which is protected from corrosion by a protective layer.

[0036] figure 2 , Figure 4 It is a schematic diagram of the structure of the hollow steel pipe and the protective layer, indicating the specific position betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com