Infrared gas stove provided with burner easy to clean

A technology for burners and gas stoves, which is applied in the field of gas stoves, can solve the problems of clogging of heating plates, difficult to remove dirt on heating plates, corrosion of stoves, etc., and achieves the effect of convenient assembly and disassembly, remarkable environmental protection effect, and guaranteeing normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

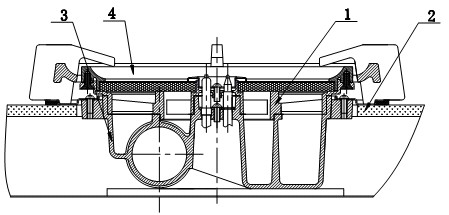

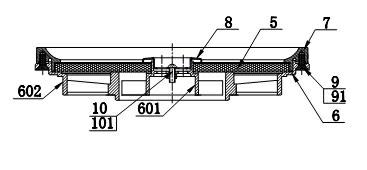

[0055] Such as figure 1 , figure 2 As shown, the infrared gas stove equipped with an easy-to-clean burner is composed of a burner 1 and a gas stove body 2. The burner includes a burner body 3 and a heating plate assembly 4. There is a cavity in the center of the heating plate assembly. The gas stove The ignition pin on the main body and the probe of the flameout protection device are installed in the cavity in the center of the burner. The heating plate assembly consists of a heating plate 5, a gas distribution plate 6, an outer ring positioning ring 7, an inner ring positioning ring 8, and an outer ring positioning ring The locking device 9 and the inner ring positioning ring locking device 10 are composed of the heating plate installed on the gas distribution plate, through the outer ring positioning ring, the inner ring positioning ring and the outer ring positioning ring locking device, and the inner ring positioning ring locking device , connecting the heating plate an...

Embodiment 2

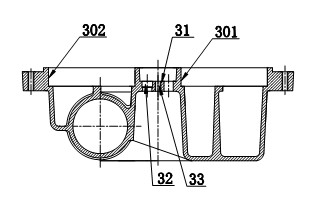

[0065] This embodiment is the same as that of embodiment 1 except that the gas distribution plate, the outer ring positioning ring, and the locking device of the outer ring positioning ring in the heating plate assembly are partly different from that of embodiment 1, and the details are as follows:

[0066] Such as Figure 9As shown, the gas distribution plate is composed of an inner ring 61 and an outer ring 62, and a partition ring 63 is arranged between the inner and outer rings to divide the inner and outer rings into two annular cavities; the top of the partition ring is planar 631 , with an annular boss 632 at the bottom of the separating ring; several ventilation grooves 64 and several swirl fins 65 are arranged in the annular cavity; on the plane connecting the inner ring and the plane connecting the outer ring, there are positioning steps for installing the heating plate 66 and heating plate installation positioning boss 67; In the cavity of gas distribution disc inne...

Embodiment 3

[0071] This embodiment is the same as that of embodiment 1 except that the gas distribution plate, the outer ring positioning ring, and the locking device of the outer ring positioning ring in the heating plate assembly are partly different from that of embodiment 1, and the details are as follows:

[0072] Such as Figure 11 As shown, the gas distribution plate is composed of an inner ring 61 and an outer ring 62, and a partition ring 63 is arranged between the inner and outer rings to divide the inner and outer rings into two annular cavities; the top of the partition ring is planar 631 , with an annular groove 633 at the bottom of the separation ring; several ventilation grooves 65 are arranged in the annular cavity; on the plane connecting the inner ring and the plane connecting the outer ring, there are heating plate installation and positioning steps 66, 67, which are connected with the top surface of the separation ring flush; a separation layer 68 is provided in the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com