Processing method of rubbish or dirt

A treatment method and sludge technology, applied in the direction of combustion method, combined combustion mitigation, combustion type, etc., can solve the problems of difficult recycling of renewable garbage, waste of resources, low income, etc., achieve high operating costs and maintenance costs, and increase speed and efficiency, low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The method for treating garbage or sludge of the present invention will be further described in detail below.

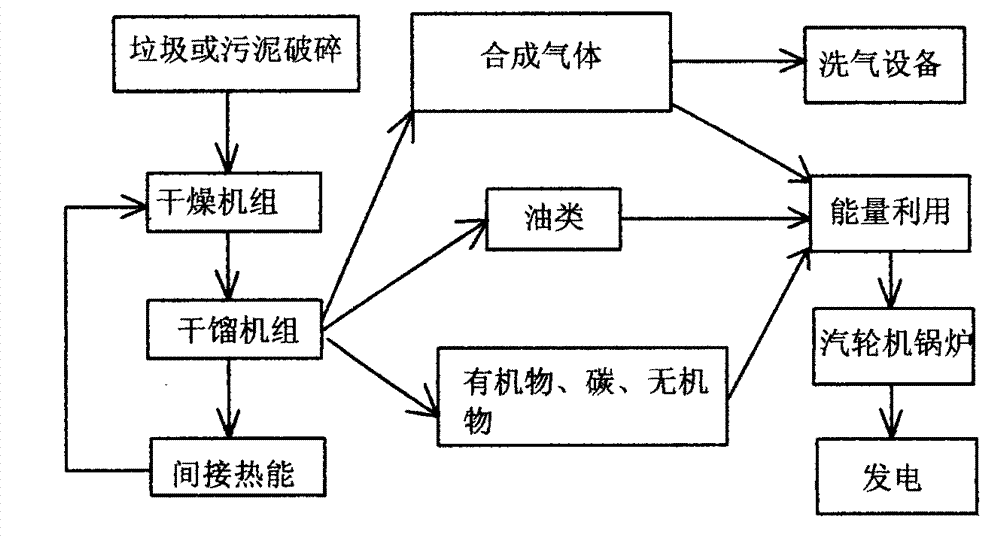

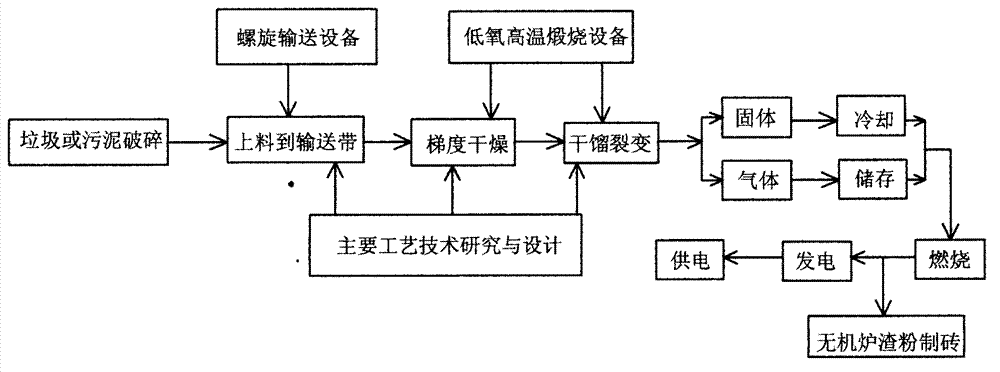

[0031] The treatment method of garbage or sludge of the present invention is exactly to carry out dry distillation fission treatment to garbage or sludge, comprises the following steps:

[0032] 1) Garbage or sludge is crushed;

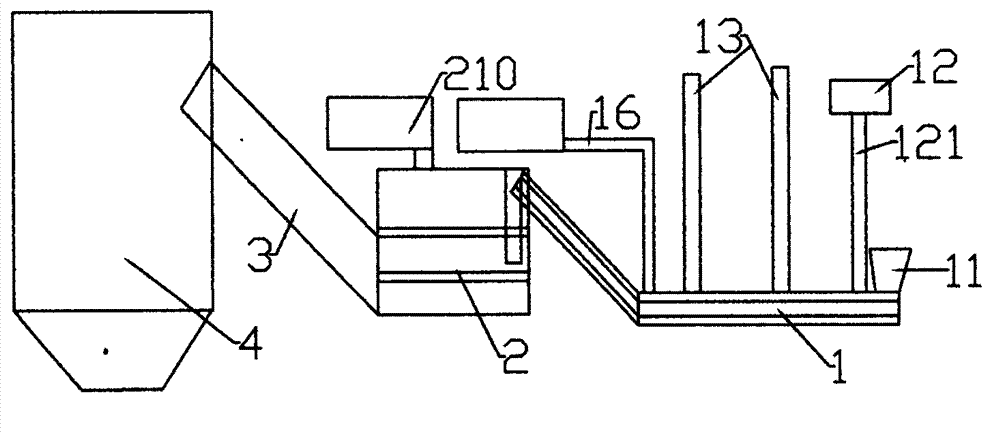

[0033] 2) Use the screw extrusion device to automatically transport the garbage or sludge;

[0034] 3) The gas produced by biomass particles under the condition of low-oxygen incomplete combustion is fully burned in the high-temperature layer to generate enough heat to dry the garbage or sludge, and then dry the garbage or sludge in the dry distillation fission treatment area dry distillation fission;

[0035] 4) After carbonization and fission of garbage or sludge, the obtained solids are cooled, the obtained gases are stored, and the obtained solids and gases are combusted and then reused. The reuse includes power generation and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com