Production method for preparing ammonium phosphate and coproducing special fertilizer for mulberry

A production method, ammonium phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, application, etc., can solve the problems of affecting the quality and yield of mulberry leaves, poor quality of mulberry leaves, and reducing disease resistance, etc., achieving significant environmental protection value and Economic benefits, improved yield and quality, and reduced waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

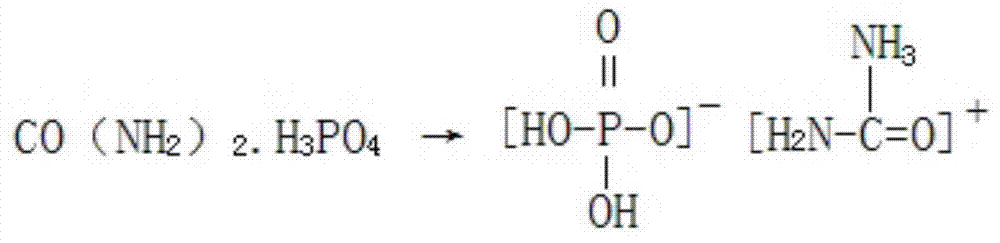

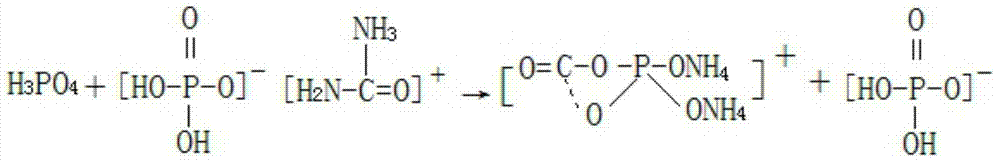

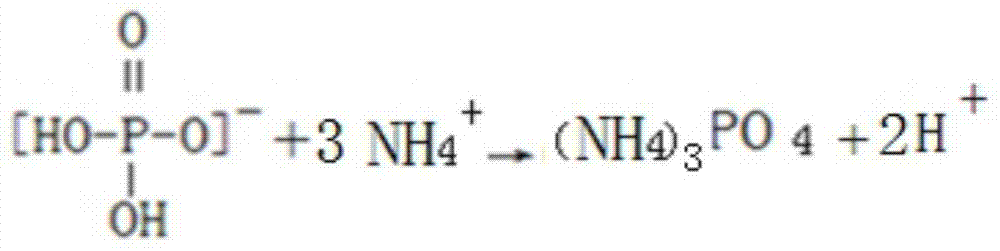

Method used

Image

Examples

Embodiment 1

[0047] A production method for preparing ammonium phosphate by-product special fertilizer for mulberry trees,

[0048] Mix phosphoric acid and urea at a molar ratio of 1.1:1, and stir for 0.8 hours at a temperature of 83°C to obtain an intermediate slurry;

[0049] When the intermediate slurry was prepared by the reaction of phosphoric acid and urea, the stirring speed was 170r / min;

[0050] Then feed ammonia gas into the intermediate slurry, and control the reaction temperature to 70°C, stir and react for 26 minutes, and control the end point pH value to 10.1 to obtain ammonium phosphate slurry;

[0051] The stirring speed when carrying out the stirring reaction for 26 minutes after the described feeding of ammonia gas is 410r / min

[0052] Then the ammonium phosphate slurry is placed in a circulating cooling crystallizer for circulating cooling crystallization treatment, and the nitrogen and phosphorus elements in the solution are detected, analyzed and adjusted so that the ...

Embodiment 2

[0060] A production method for preparing ammonium phosphate by-product special fertilizer for mulberry trees,

[0061] Mix phosphoric acid and urea at a molar ratio of 1.2:1, and stir for 1.3 hours at a temperature of 96°C to obtain an intermediate slurry;

[0062] When described phosphoric acid and urea react to prepare intermediate slurry, the stirring speed is 205r / min;

[0063] Then feed ammonia gas into the intermediate slurry, and control the reaction temperature to 80°C, stir and react for 28 minutes, and control the end point pH value to 11.6 to obtain ammonium phosphate slurry;

[0064] The stirring speed when carrying out the stirring reaction for 28 minutes after passing through the ammonia gas is 485r / min

[0065] Then the ammonium phosphate slurry is placed in a circulating cooling crystallizer for circulating cooling crystallization treatment, and the nitrogen and phosphorus elements in the solution are detected, analyzed and adjusted so that the molar ratio of ...

Embodiment 3

[0072] A production method for preparing ammonium phosphate by-product special fertilizer for mulberry trees,

[0073] Mix phosphoric acid and urea at a molar ratio of 1.15:1, stir and react for 1.1 h at a temperature of 88°C to obtain an intermediate slurry;

[0074] When the intermediate slurry was prepared by the reaction of phosphoric acid and urea, the stirring speed was 184r / min;

[0075] Then feed ammonia gas into the intermediate slurry, and control the reaction temperature to 75°C, stir and react for 27 minutes, and control the end point pH value to 11.3 to obtain ammonium phosphate slurry;

[0076] The stirring speed when carrying out the stirring reaction for 27 minutes after passing through the ammonia gas is 456r / min

[0077] Then the ammonium phosphate slurry is placed in a circulating cooling crystallizer for circulating cooling crystallization treatment, and the nitrogen and phosphorus elements in the solution are detected, analyzed and adjusted so that the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com