Waste plastic bottle classification and recovery method

A recycling method and technology for waste plastics, applied in the direction of waste collection and transfer, garbage collection, bottle filling, etc., which can solve the problems of accelerated regular cleaning frequency, no sorting and recycling of bottle bodies and bottle caps, and different products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

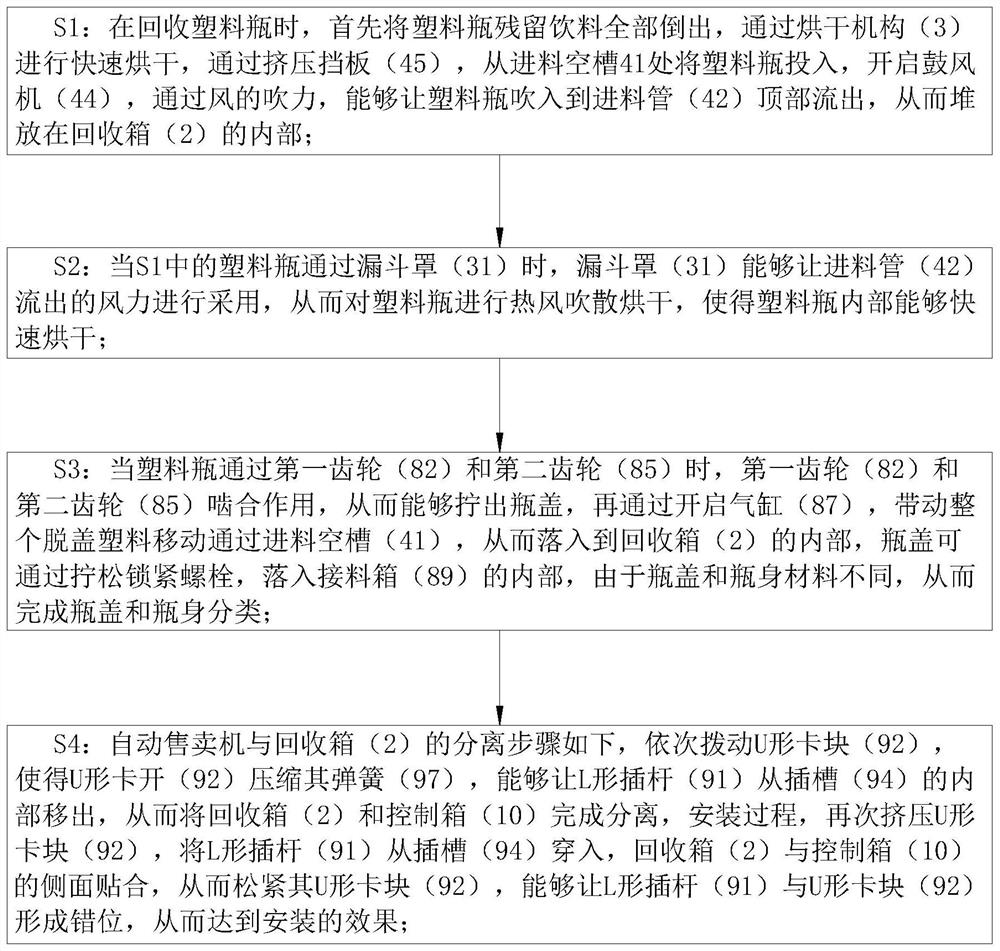

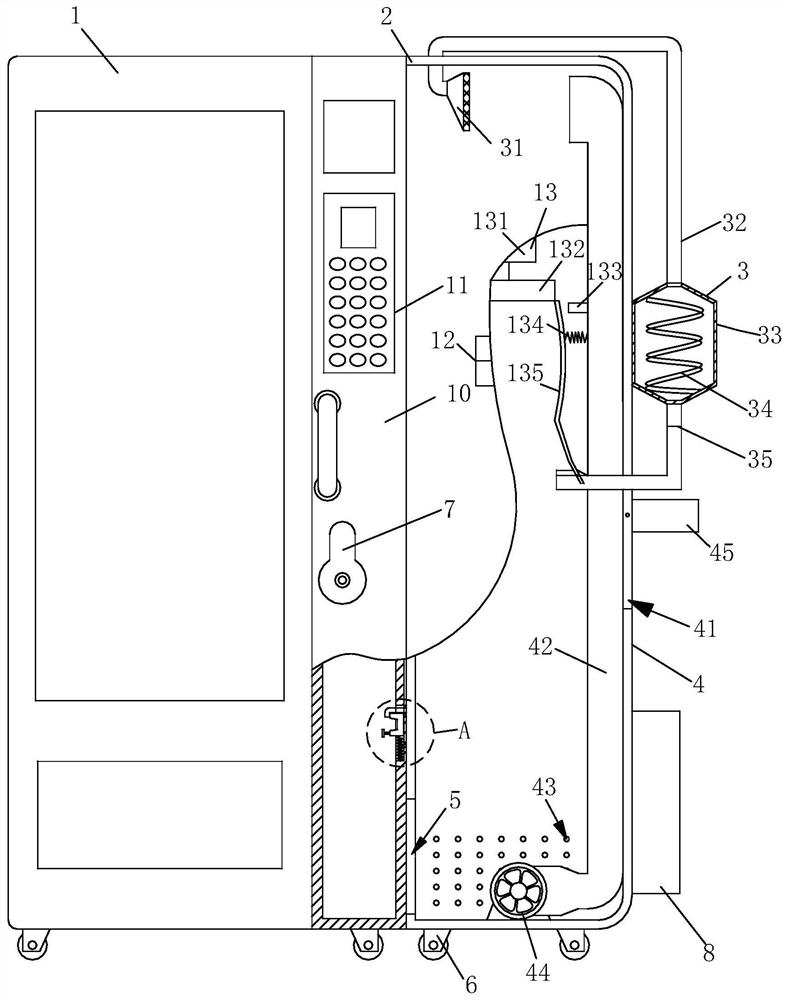

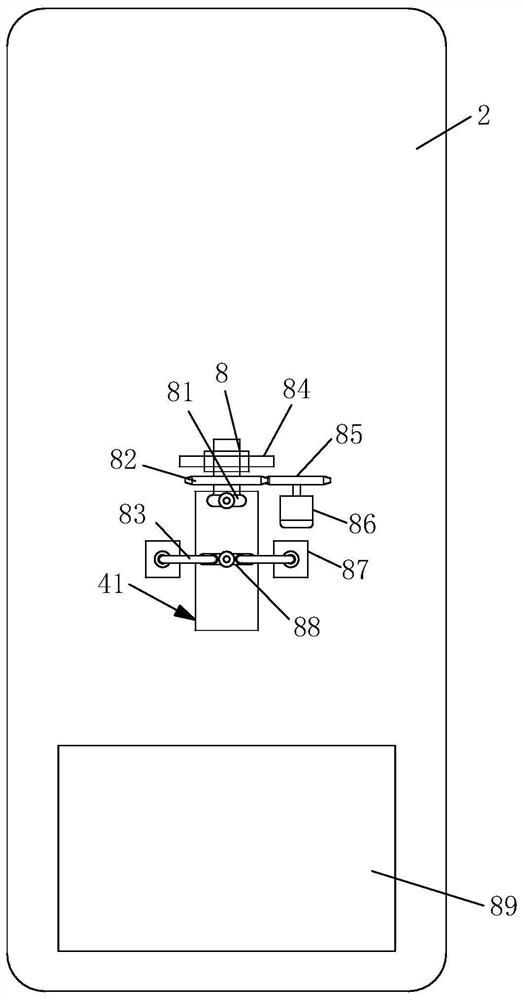

[0029] Please refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a method for sorting and recycling waste plastic bottles, the method comprises the following steps:

[0030] S1: When recycling plastic bottles, first pour out all the residual beverages in the plastic bottles, and quickly dry them through the drying mechanism 3, put the plastic bottles into the empty feeding slot 41 by squeezing the baffle 45, and turn on the blower 44 , through the blowing force of the wind, the plastic bottles can be blown into the top of the feed pipe 42 and flow out, thereby stacking in the inside of the recycling bin 2;

[0031] S2: When the plastic bottle in S1 passes through the funnel cover 31, the funnel cover 31 can allow the wind fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com