Dry desulfurization agent pretreatment system and pretreatment method

A dry desulfurization and pretreatment technology, applied in separation methods, chemical instruments and methods, solid treatment gas purification, etc., can solve the problems of high operating costs, low temperature of coke oven flue exhaust gas, clogged catalysts, etc., and achieve low cost , less investment, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

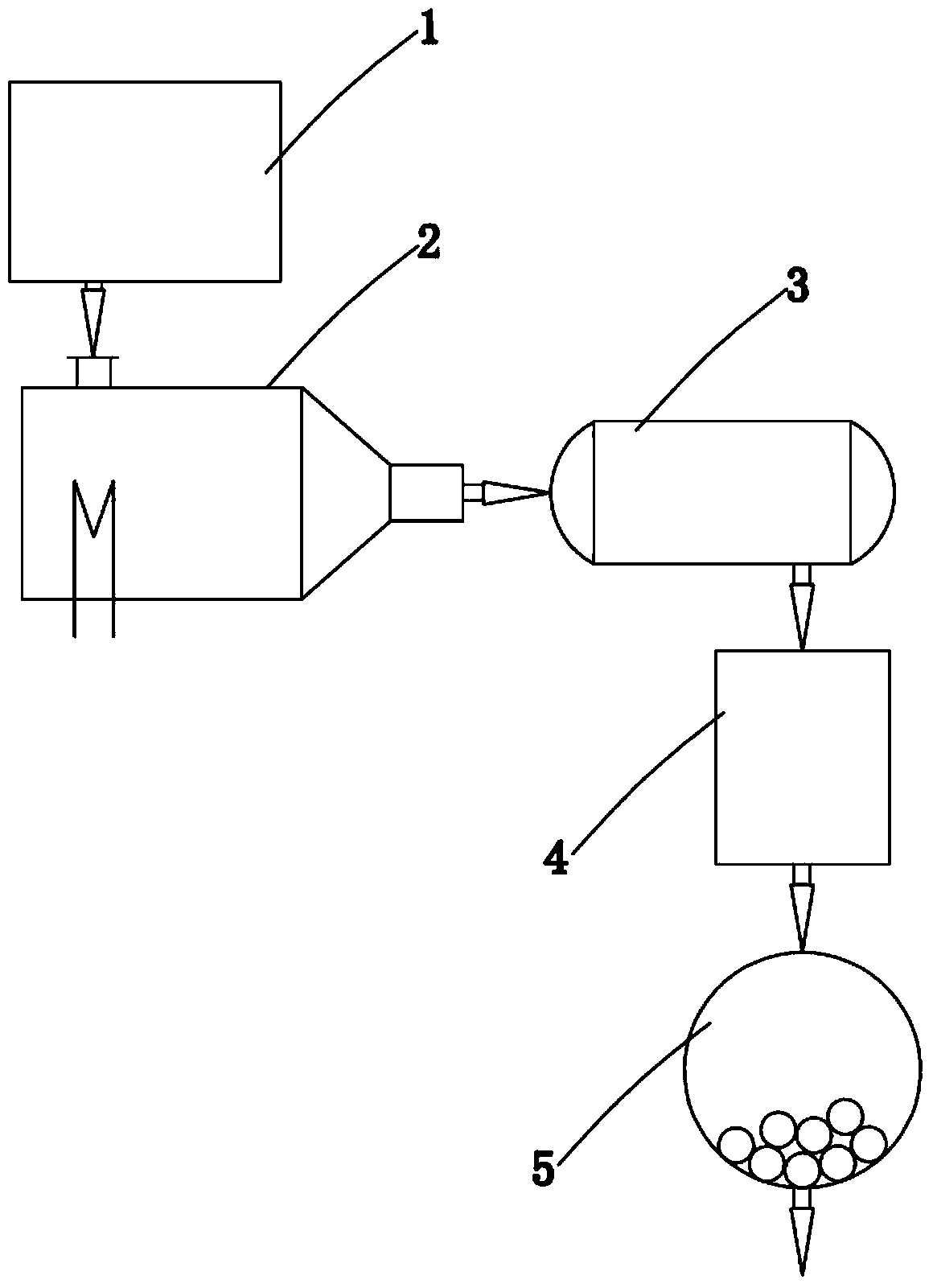

[0020] Embodiment 1: In conjunction with the accompanying drawings, the dry desulfurization agent pretreatment system includes:

[0021] The sodium bicarbonate storage tank 1, the expansion device 2, the buffer tank 3, the sodium carbonate storage tank 4 and the grinding device 5 connected in sequence are provided with a quantitative valve in the communication pipeline between the sodium bicarbonate storage tank 1 and the expansion device 2, The expansion device 2 is equipped with a heating and roasting device, which can control the heating rate, reaction pressure and other conditions; the communication pipeline between the expansion device 2 and the buffer tank 3 is provided with an instant pressure relief valve, and the buffer tank is connected to the atmosphere. In the specific setting, the sodium bicarbonate storage tank 1, the expansion device 2, the buffer tank 3, the sodium carbonate storage tank 4 and the inner cavity of the grinding device 5 are all provided with side ...

Embodiment 2

[0027] Embodiment 2: adopt same system with embodiment 1, pretreatment method step is:

[0028] Sodium bicarbonate enters the expansion device 2 quantitatively from the sodium bicarbonate storage tank 1, and heats up in the expansion device at a heating rate of 10°C / min. At this time, the decomposition acceleration slope (i.e. decomposition rate / heating rate) is 1.63. When the internal pressure of the device is stable at 0.3MPa and does not change, open the switching valve to release the pressure instantly to form explosive atomized powder and spray it into the buffer tank. The buffer tank is a normal pressure device and communicated with the atmosphere. After entering the grinding system for grinding, it is sprayed into the desulfurization system. After grinding, the powder agglomeration is solved and the specific surface area of the powder is further increased.

Embodiment 3

[0029] Embodiment 3: adopt same system with embodiment 1, pretreatment method step is:

[0030] Sodium bicarbonate enters the expansion device 2 quantitatively from the sodium bicarbonate storage tank 1, and heats up in the expansion device at a heating rate of 20°C / min. At this time, the decomposition acceleration slope (i.e. decomposition rate / heating rate) is 1.73. When the internal pressure of the device is stable at 0.3MPa and does not change, open the switching valve to release the pressure instantly to form explosive atomized powder and spray it into the buffer tank. The buffer tank is a normal pressure device and communicated with the atmosphere. After entering the grinding system for grinding, it is sprayed into the desulfurization system. After grinding, the powder agglomeration is solved and the specific surface area of the powder is further increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com