Technology for producing cooled coal gas with no discharge of phenolic water

A technology of cold gas and phenol water, which is applied in the direction of gas dust removal, petroleum industry, and the manufacture of combustible gas, etc. It can solve the problems of non-compliance with environmental protection and energy saving, huge gas cooling system, and poor heat exchange effect of bare tubes, so as to improve the effect of dust removal and heat exchange efficiency, optimize the dust removal and heat exchange process, and increase the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

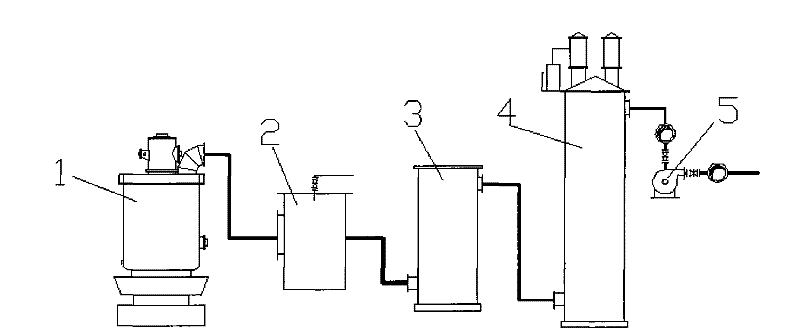

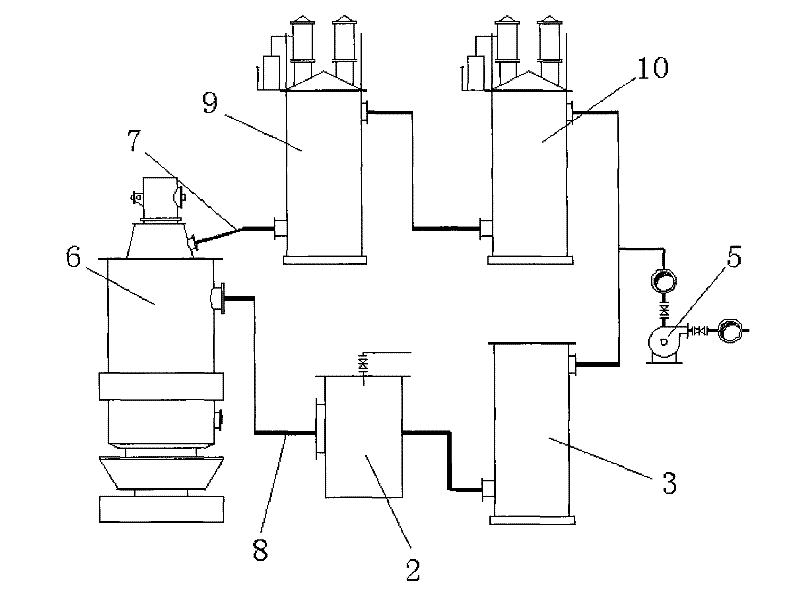

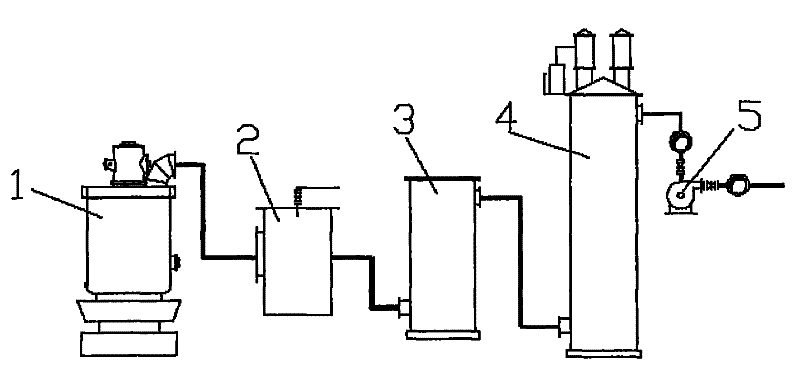

[0018] It can be seen from the prior art that the standpipe cooling widely used in the current gas cooling process, the washing tower and other methods all use cooling water to directly contact the gas to achieve the purpose of cooling and purifying the gas, but at the same time, the phenol in the gas Phenolic compounds are very soluble in water, forming a large amount of highly toxic phenolic water. Therefore, in order to avoid producing a large amount of phenol water, indirect cooling must be adopted, so that the gas and the cooling medium can exchange heat in separate circulation pipes to avoid direct contact between gas and water. However, during the gas cooling process, the gas itself will still condense a small amount of phenolic water. In order to realize the "zero discharge" of phenolic water, this process proposes to use this small amount of phenolic water as a cooling medium to absorb the heat of the gas and evaporate it into steam. The bottom of the furnace is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com