Solid waste plasma gasification pyrolysis recycle transformation method

A technology of solid waste and plasma, which is applied in the direction of solid treatment gas purification, gasification process, and production of combustible gas. It can solve the problems of extremely high power, no value, and increased operating costs of power consumption, so as to prevent recombination and non-toxic Effect of gas and substance emission and heat reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

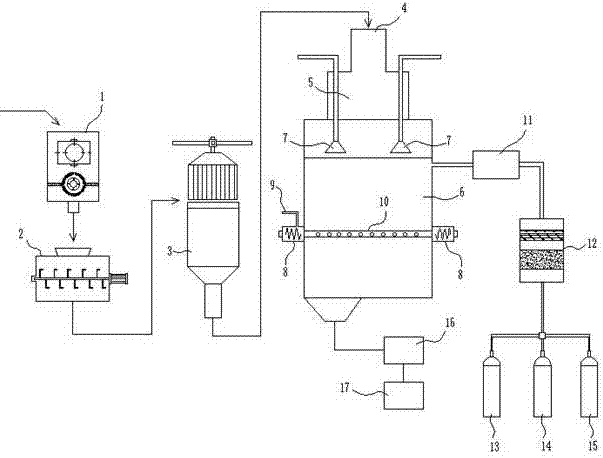

Image

Examples

Embodiment 1

[0025] A method for regeneration and conversion of solid waste by plasma gasification cracking, specifically comprising the following steps:

[0026] (1) Garbage sorting pretreatment: manually screen out the garbage with a size larger than 30cm in the solid garbage that has recycling value, and the remaining small-sized solid garbage uses a conveyor belt at a speed of 0.5m / s to separate metal substances and For non-metallic substances, the non-metallic substances are broken into solid particles with a particle size of 1 cm by a crusher, and the solid particles are extruded into cylindrical blocks with a diameter of 20 cm and a length of 30 cm through an extruder; wherein, the The eddy current magnetic separator described above mainly screens ferrous magnetic metals and copper-aluminum non-magnetic metals. The magnetic field strength of the magnetic system is 200Gs. Compared with single magnetic separation, eddy-current magnetic separation is more superior in performance, and ca...

Embodiment 2

[0031] A method for regeneration and conversion of solid waste by plasma gasification cracking, specifically comprising the following steps:

[0032] (1) Garbage sorting pretreatment: manually screen out garbage with a size larger than 30cm in solid garbage that has recycling value, and use a conveyor belt to separate metal substances and For non-metallic substances, the non-metallic substances are broken into solid particles with a particle size of 2cm by a crusher, and the solid particles are extruded in sections by an extruder into cylindrical blocks with a diameter of 20cm and a length of 30cm; wherein, the The eddy current magnetic separator described above mainly screens ferrous magnetic metals and copper-aluminum non-magnetic metals. The magnetic field strength of the magnetic system is 1500Gs. Compared with a single magnetic separation, the eddy current magnetic separation is more superior in performance, and can screen out more than 60% of copper and aluminum waste. T...

Embodiment 3

[0037] A method for regeneration and conversion of solid waste by plasma gasification cracking, specifically comprising the following steps:

[0038] (1) Garbage sorting pretreatment: manually screen out the garbage with a size larger than 30cm that has recycling value in the solid garbage, and use the conveyor belt to separate the metal substances and For non-metallic substances, the non-metallic substances are broken into solid particles with a particle size of 3cm by a crusher, and the solid particles are extruded in sections by an extruder into cylindrical blocks with a diameter of 20cm and a length of 30cm; wherein, the The eddy current magnetic separator described above mainly screens ferromagnetic metals and copper-aluminum non-magnetic metals. The magnetic field strength of the magnetic system is 2500Gs. The magnetic metal improves the recycling rate, and at the same time prevents the metal from absorbing too much heat and consuming electricity.

[0039] (2) Plasma ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com