Sulfur content removing method and desulfurizer for fluidized bed device

A fluidized bed and desulfurizer technology, applied in the field of desulfurizers, can solve problems such as low utilization rate and achieve good desulfurization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

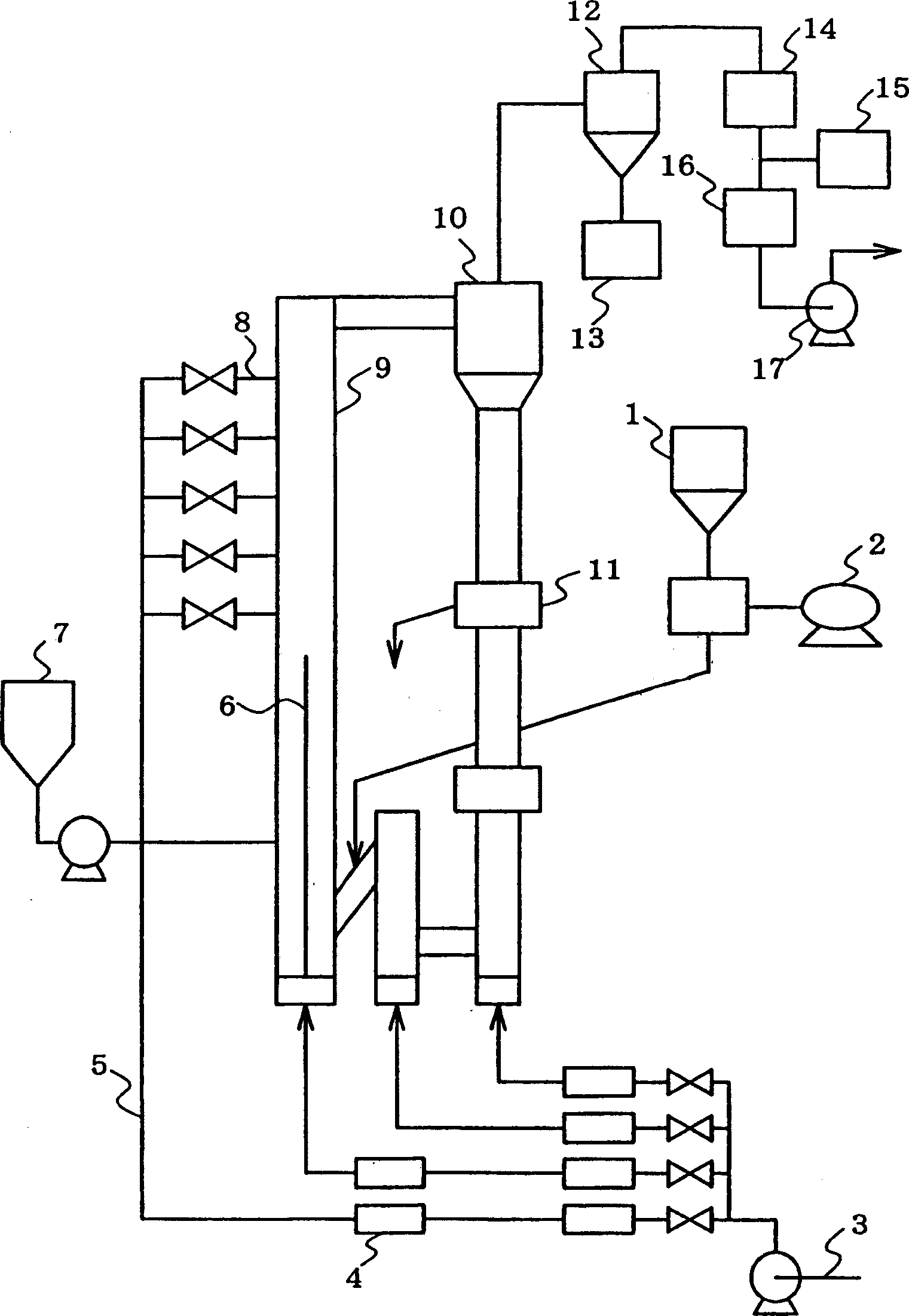

[0058] The lime filter cake manufactured by Nippon Sugar Co., Ltd. having the properties shown in Table 1 was dried, then adjusted to a maximum particle size of 2 mm or less, and the average particle size was 1.2 mm, and the fuel having the properties shown in Table 2 was pulverized into 2 mm or less. coal mix. Four types of mixtures were prepared in which the Ca content in the lime filter cake was 0, 1, 2, and 3 in molar ratio (Ca / S) relative to the sulfur content in the coal. The resulting mixture was burned in a circulating fluidized bed combustion furnace shown in Figure 1, and the SO at the combustion outlet was analyzed. x Concentration, according to the following calculation method to obtain the desulfurization rate, the results are shown in Table 3.

[0059] Desulfurization rate (%)=(a / b)×100

[0060] a=[SO4 when coal is burned alone (Ca / S=0) x Emission concentration]-(SO x discharge concentration)

[0061] b = SO during combustion alone (Ca / S=0) x Exhaust concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com