Biogas filter

A biomass gas and biomass gas technology, which is used in dispersed particle filtration, gas dust removal, combustible gas purification, etc. Good filtering effect and avoid coagulation and precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

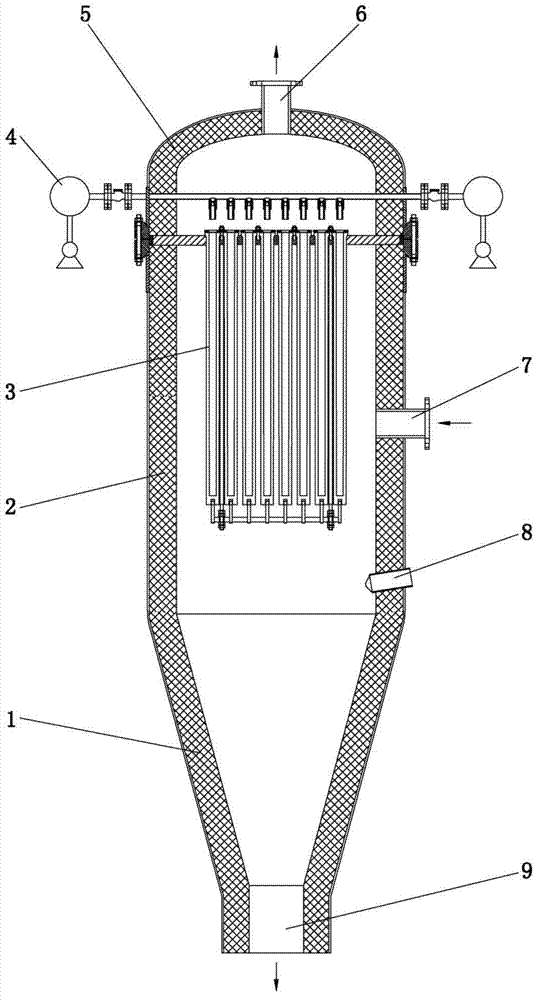

[0020] Such as figure 1 As shown, the main body of the filter is a cylinder, and a filter unit 3 and a blowback device 4 are assembled inside the cylinder. The cylinder is composed of a head 5, a cylinder 2 and a cone 1. The top of the head 5 is provided with an air outlet 6 , the side of the cylinder 2 is provided with an air inlet 7 , and the bottom of the cone 1 is provided with an ash outlet 9 .

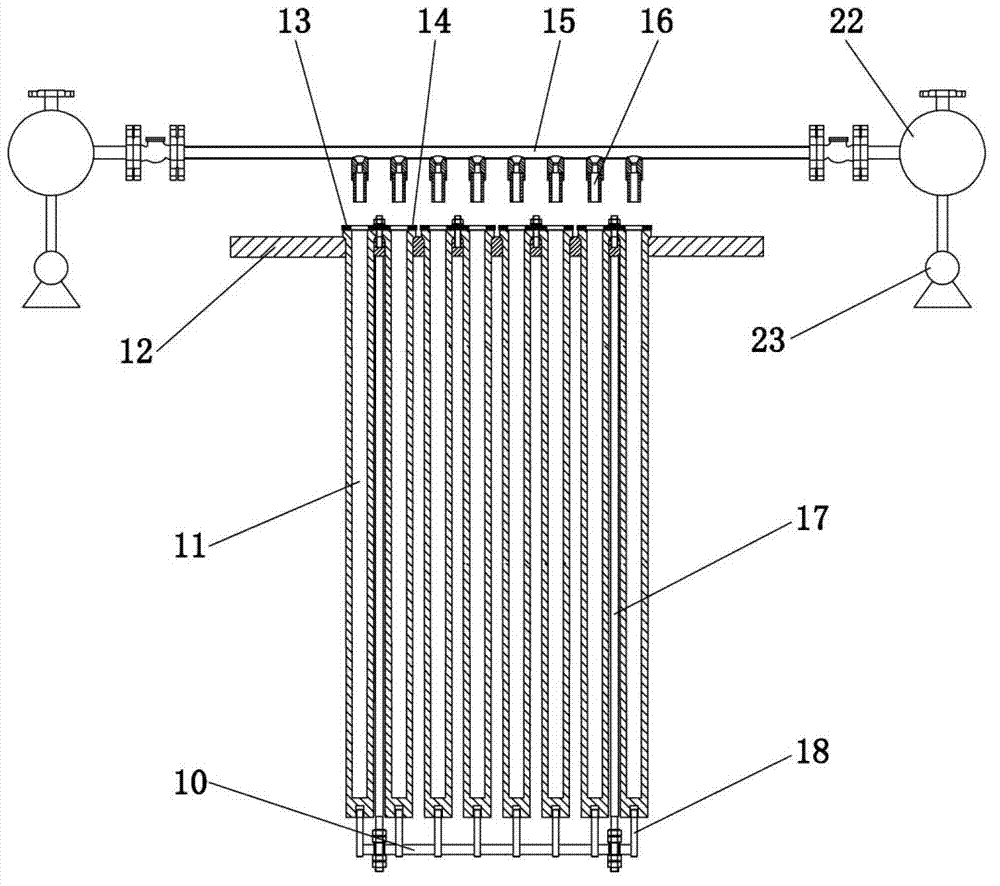

[0021] Such as figure 2 As shown, the filter unit 3 is composed of an orifice plate 12, 48 ceramic filter elements 11, a bracket and a suspension rod 17. The orifice plate 12 is fitted at the contact of the head 5 and the cylinder 2 . The orifice plate is provided with 8 rows × 6 columns = 48 through holes, and the ceramic filter element is inserted in the through holes. In order to prevent the lower part of the filter element from shaking, the orifice plate 12 is vertically connected to the suspension rod 17, and the suspension rod is used to lift a bracket, and the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com