Multiple stage pulsant ash removal equipment in bag typed dust removal for blast furnace gas, and method

A gas bag and blast furnace technology, which is applied in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., can solve problems such as inability to reach the cleaning effect of bag cleaning, achieve quantity reduction, and ease production scale Effect of expansion and reduction of equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

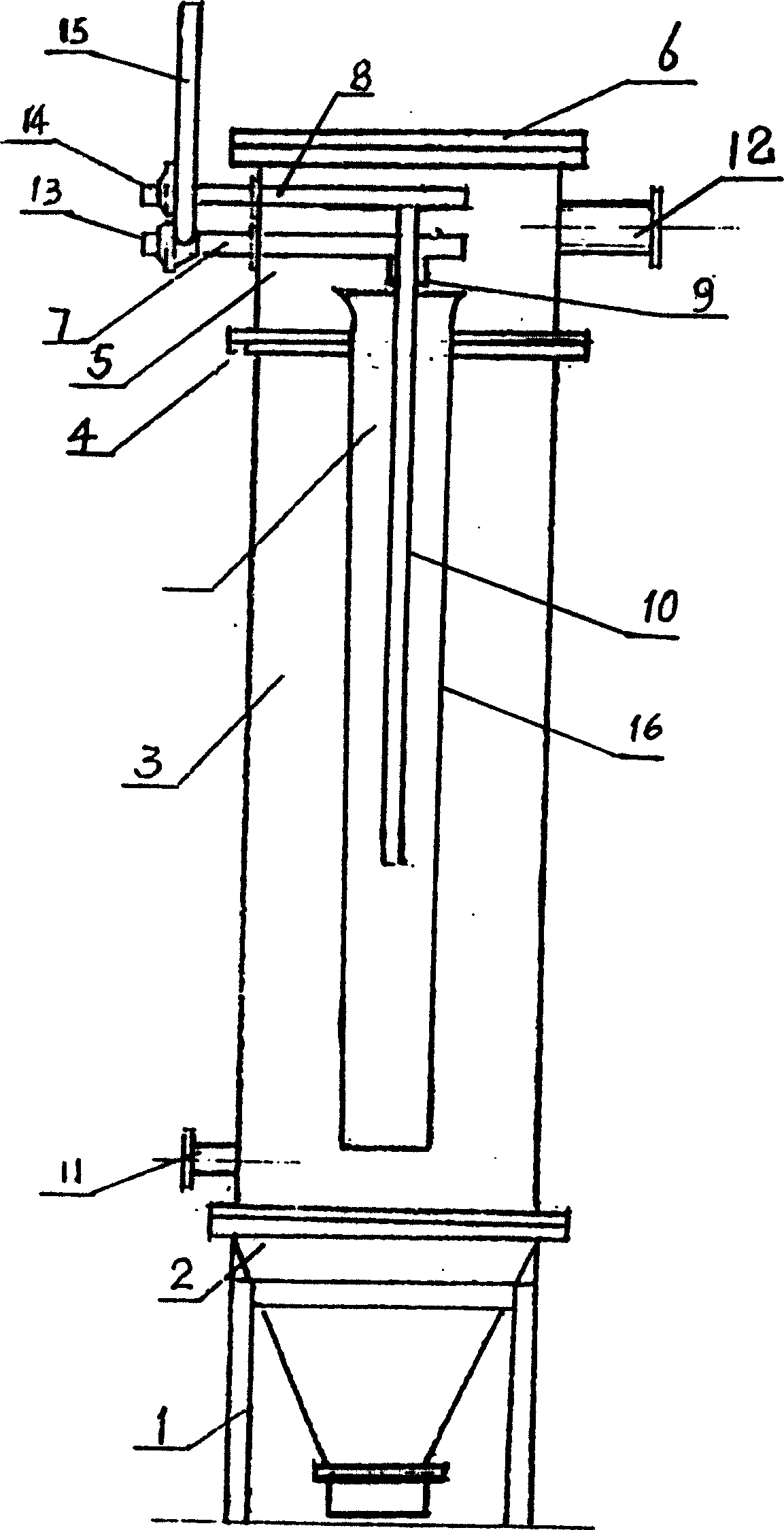

[0026] Using the device and method of the present invention, at 300 meters 3 On the gas bag type dust removal device of the blast furnace, 3 tests of gas bag dust removal and bag dust removal were carried out. The gas dust removal device of the blast furnace has 4 bag type dust removal boxes, and each box is equipped with 119 filter bags. The length of the bag is 16m, bag diameter Φ125mm, total area of dust removal and filtration 2869.5m 2 .

[0027] Firstly, the raw gas to be dust-removed is input into the dust-removing box from the gas inlet, and the raw gas passes through the dust-removing bag at a certain flow rate. After dust-removing, the clean gas goes out from the bag mouth and enters the clean-gas conveying pipeline for output. When the working resistance reaches a certain level, it means that the adsorption layer on the periphery of the dust bag has reached a certain thickness, which affects the penetration of the gas. It is necessary to stop the dust removal proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com