Demisting system with dedusting, demisting and water recovery functions

A water recovery and functional technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of demister blockage, uncontrolled, affecting slurry density and pH value, etc., to increase workload, Uniform and stable flow field, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

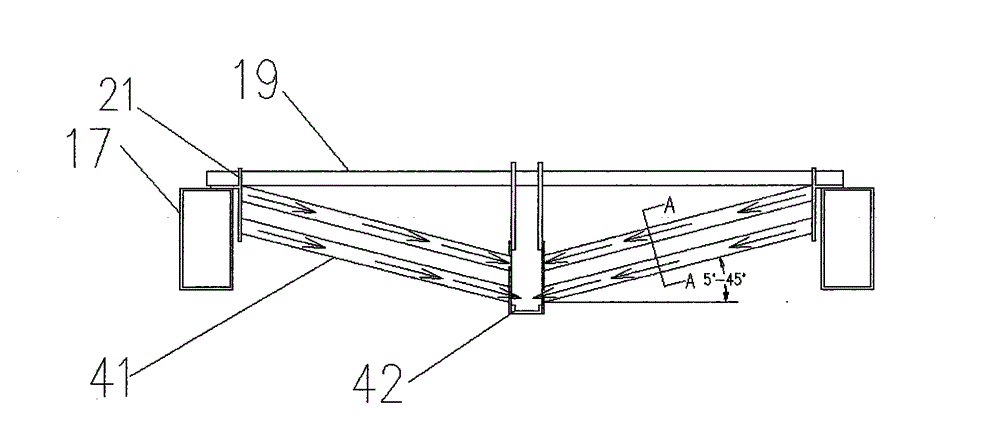

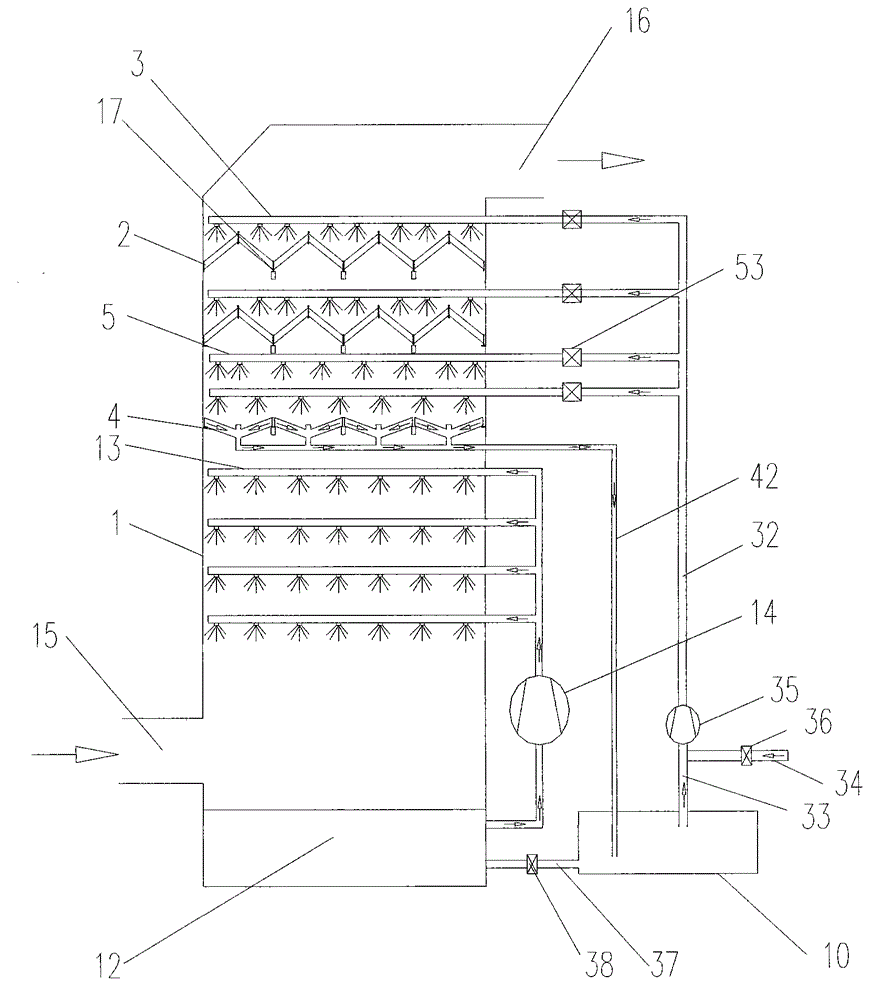

[0050] Such as image 3 As shown, a demister system with functions of dust removal, mist removal and water recovery is installed in the absorption tower 1 to remove dust and mist droplets in saturated flue gas and realize the purpose of flushing water recycling, including setting in the absorption tower 1 The mist eliminator 2 in the tower 1 and the flushing device 3 for flushing the mist eliminator 2 . The absorption tower 1 is provided with a raw flue gas inlet 15 and a clean flue gas outlet 16, and a slurry pool 12 is provided at the bottom of the tower, and the slurry is transported to the spray system 13 above the slurry pool 12 by a slurry pump 14 for removing smoke. SO in air 2 gas. The mist eliminator 2 is installed at the upper end position in the absorption tower 1, and a flushing device 3 is arranged above it. A spray device 5 is provided below the demister 2 for spraying dust into the flue gas. A flushing water recovery device 4 is provided below the spraying d...

Embodiment 2

[0060] Such as Figure 6 As shown, in this embodiment, on the basis of Embodiment 1, the spray device 5 is reduced, and it is used in application fields that do not need dust removal in some cases. The demister 2 is installed at the upper end of the absorption tower 1, and a flushing device 3 is arranged above it. A flushing water recovery device 4 is provided below the demister 2, and the flushing water recovery device 4 is arranged above the slurry spray system 13 to receive the flushing water generated by the flushing device 3 and discharge it out of the tower to prevent the flushing water from Fall directly into the slurry pool 12, causing the slurry to dilute. A sedimentation tank 10 for receiving flushing water is provided outside the absorption tower 1 , and the sedimentation tank 10 supplies water to the flushing device 3 through a water pump 35 to realize the recycling of flushing water.

[0061] Preferably, the flushing device 3 is provided with two water inlet pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com