Blast furnace gas dust removal system

A dust removal system and blast furnace gas technology, applied in the direction of gas dust removal, combustible gas purification, combustible gas purification/transformation, etc., can solve problems such as gas explosion and safety hazards, reduce burden, reduce equipment resistance, and solve safety hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

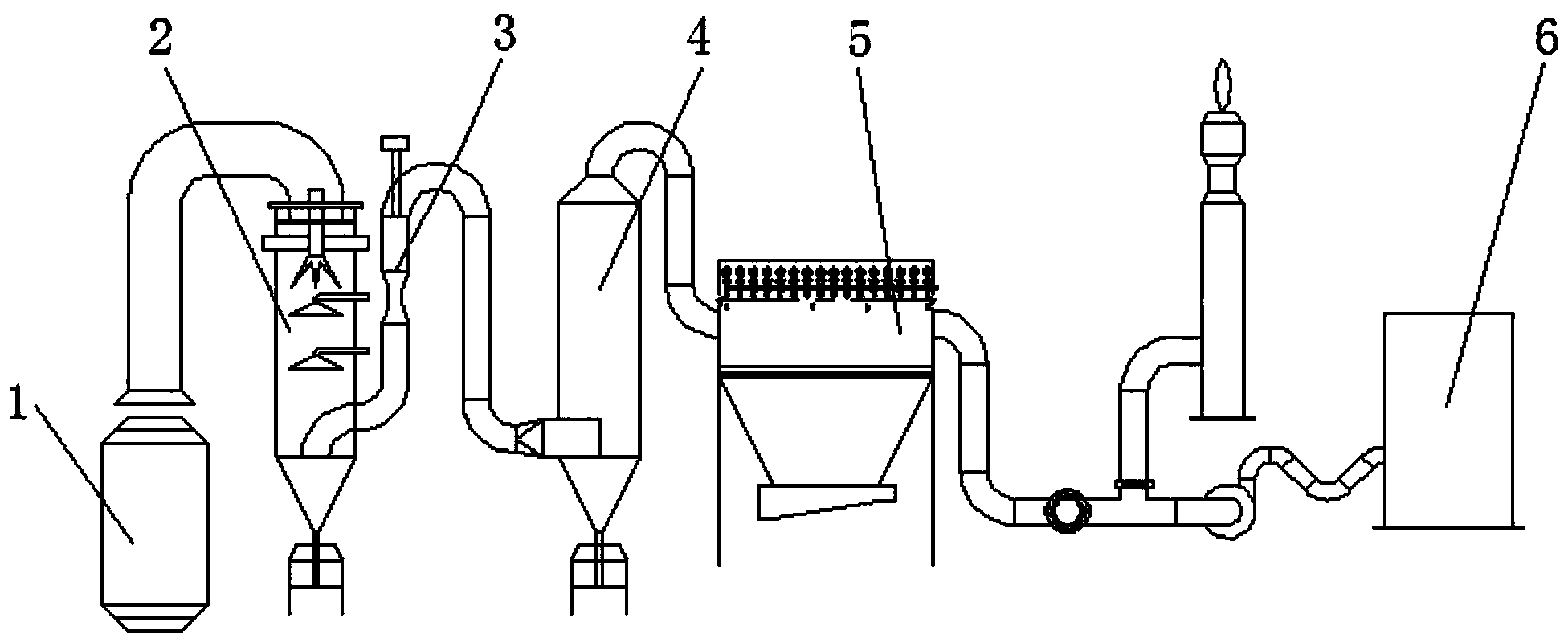

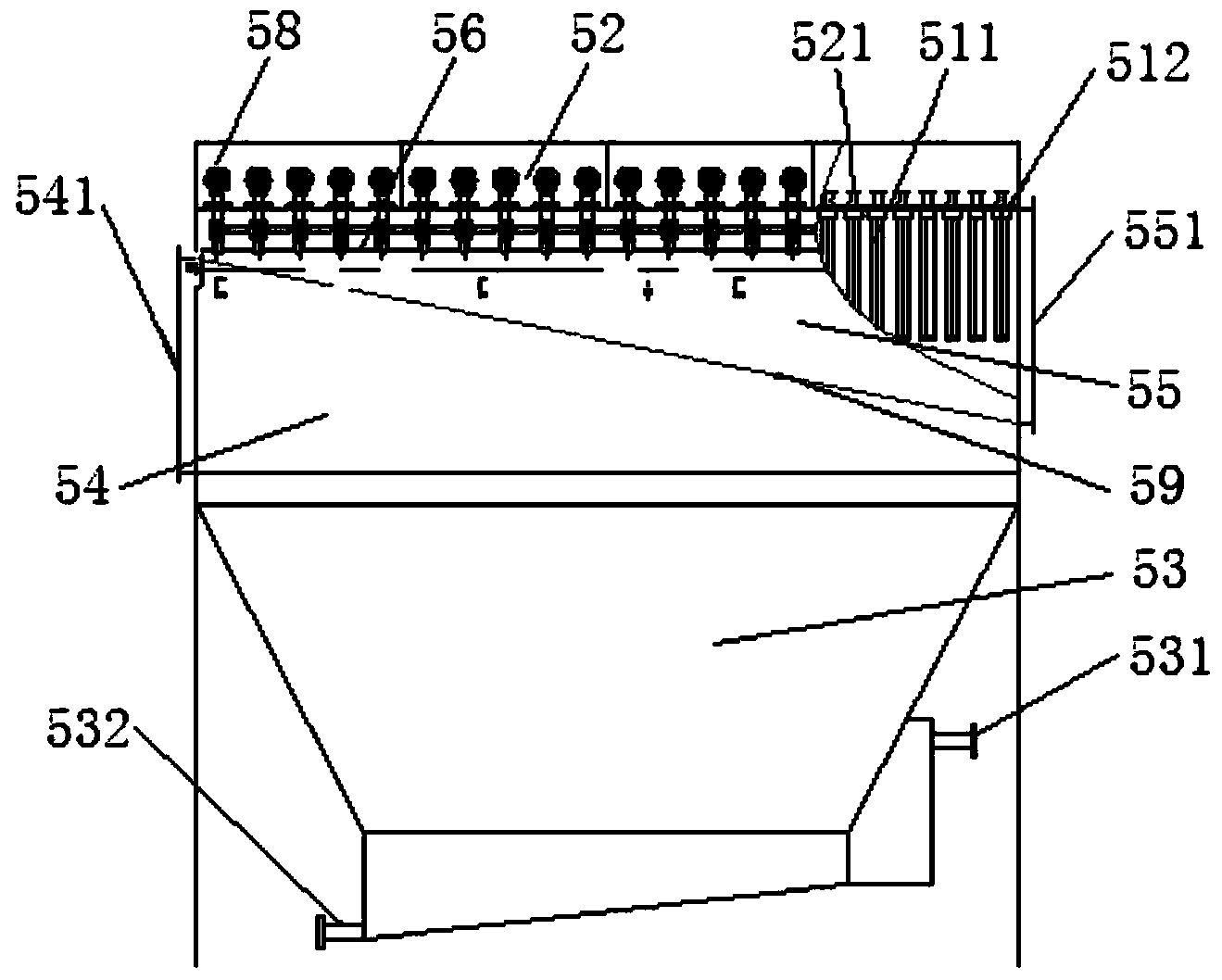

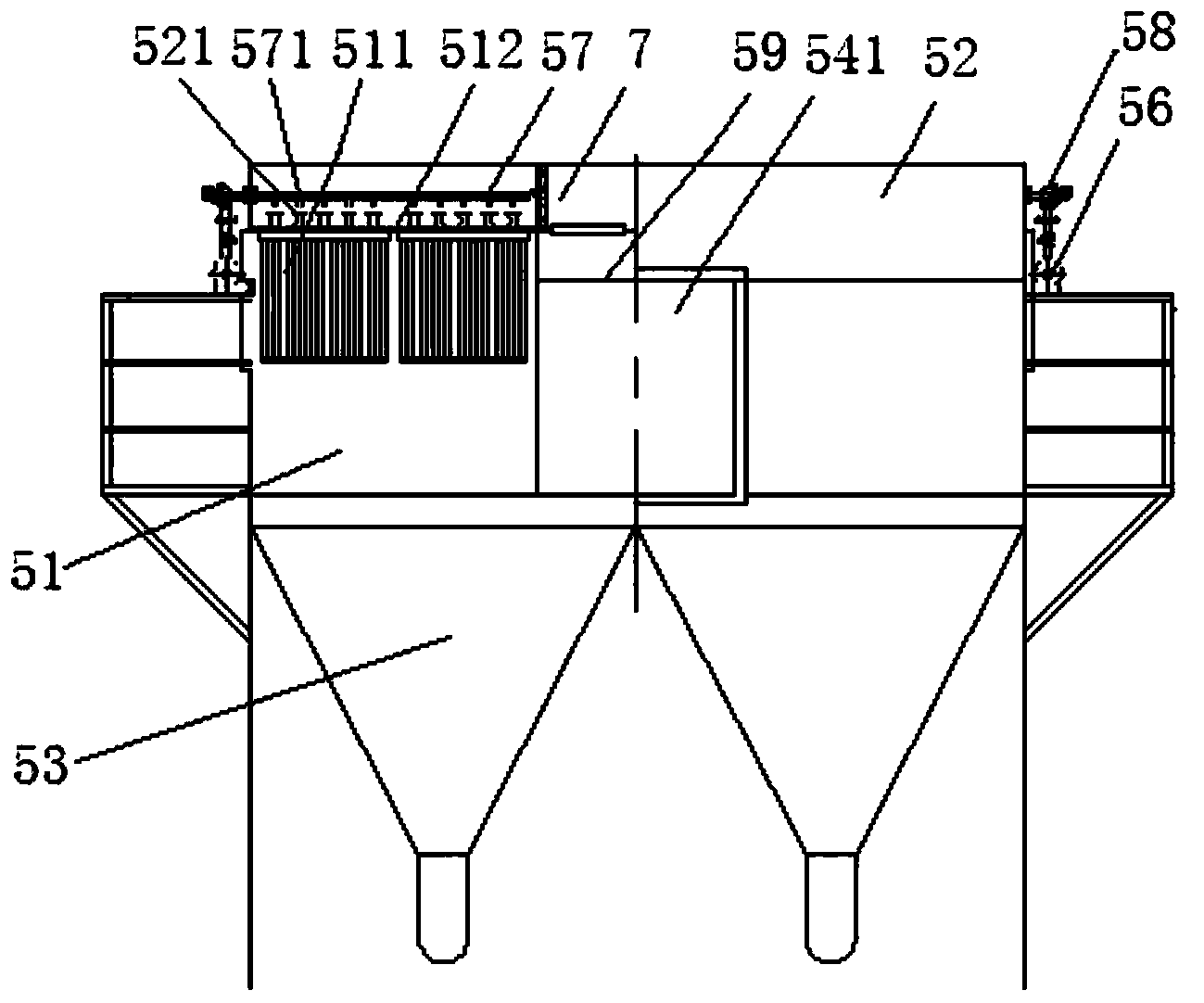

[0026] This embodiment provides a blast furnace gas dedusting system, such as Figure 1 to Figure 3 As shown, the blast furnace gas dust removal system includes a converter 1, a spray tower 2, a wetting dust collector 3, a cyclone dehydration device 4, and a plastic-fired plate dust collector 5, which are sequentially connected through pipelines in accordance with the gas flow sequence.

[0027] The gas discharged from the converter 1 first passes through the pipeline and enters the spray tower 2 for cooling. The gas temperature drops from 1300°C to 900°C, and the initial dust concentration reaches 116g / nm 3 above; then enter the wet dust collector 3 for coarse dust removal, most of the coarse dust will be discharged with water, the gas temperature will be further reduced to below 80 ℃, and the dust concentration will be reduced to 20g / nm 3 Below; After entering the cyclone dehydration device 4 for dehydration, through the rotation of the swirl plate, the saturated mist-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com