High-effective dust-removing coke quenching tower

A coke quenching tower and high-efficiency technology, applied in the field of high-efficiency dust removal and coke quenching tower, can solve the problems such as the influence of the surrounding environment, achieve good dust removal effect, overcome difficult cleaning, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

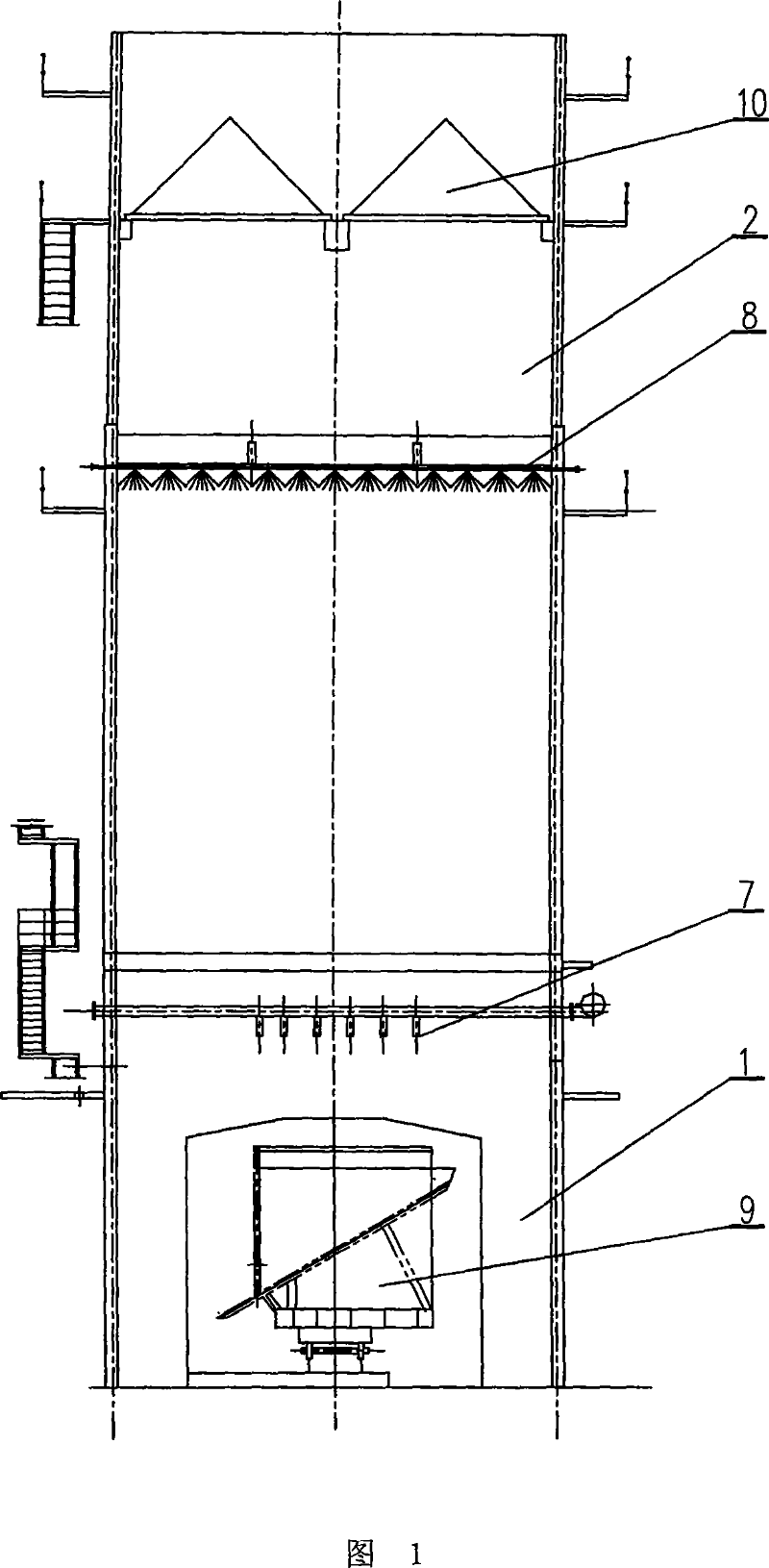

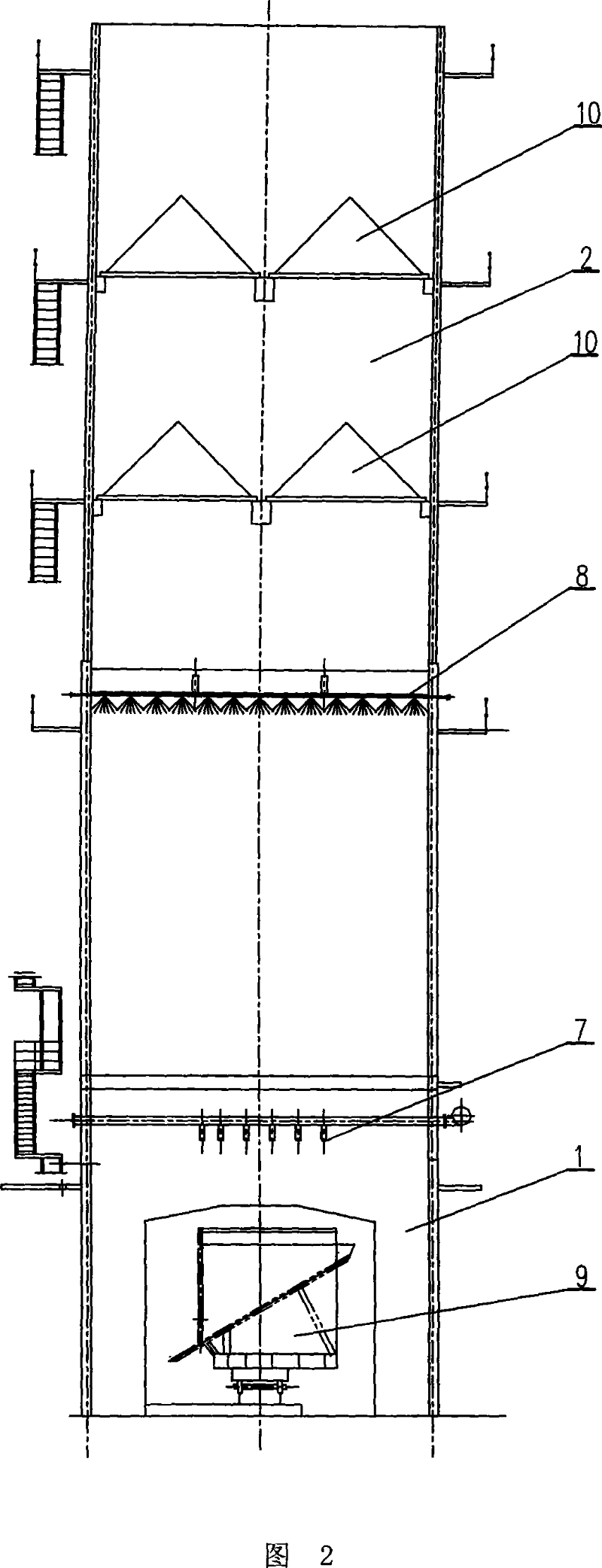

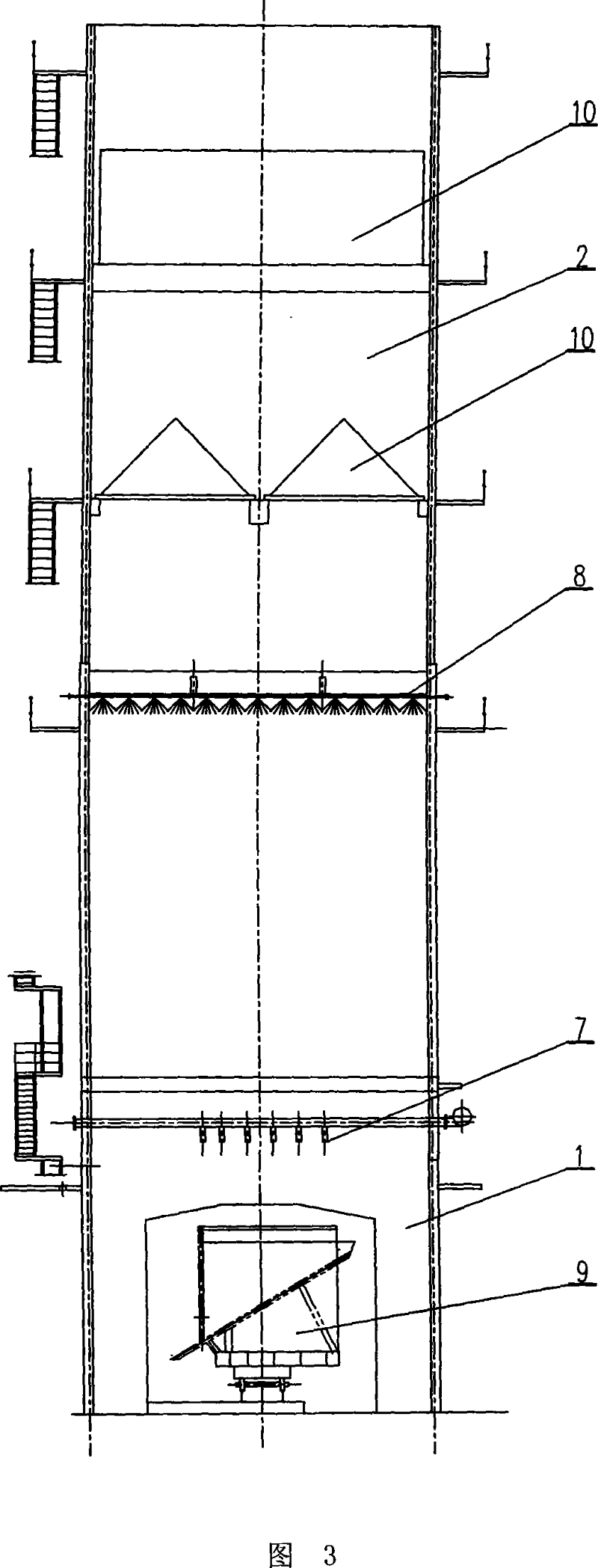

[0018] The high-efficiency dust removal and coke quenching tower of the present invention is realized in this way, and will be described in detail below in conjunction with the accompanying drawings. The coke quenching section 1 is provided with a coke quenching injection pipe 7, and above the coke quenching injection pipe 7 and at the entrance of the dust removal section 2, a group of washing and cooling devices 8 are arranged, and a dust removal device 10 is arranged above the washing and cooling device 8. The layout direction can be parallel to or perpendicular to the 9 tracks of the coke quenching car. See Fig. 4, Fig. 5, Fig. 6, Fig. 7, dust removal device 10 is made up of structural frame 3, dust removal plate 4, dust removal pipe 5 and nozzle 6, dust removal plate 4 is arranged on structural frame 3, and dust removal plate 4 is multiple, Both ends of each dust removal plate 4 are connected with the structural frame 3 through studs 12, and placed at an angle of 45-60° to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com