Preparing system and method of PMMA light-guide-stage transparent membranes

A preparation system and technology of transparent film, applied in the preparation system and field of PMMA light guide grade transparent film, can solve the requirement that the appearance quality of the optical grade PMMA ultra-thin light guide plate cannot be met, the appearance of the product is crushed, and the dust removal effect is average. and other problems, to achieve perfect optical quality, solve the requirements of appearance quality, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

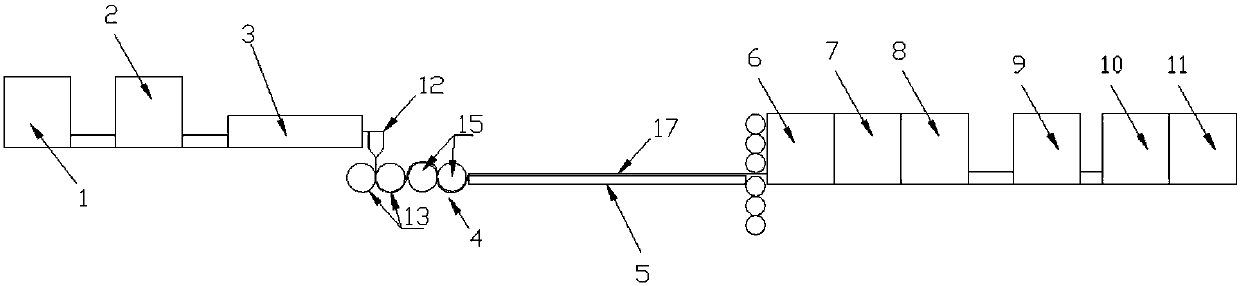

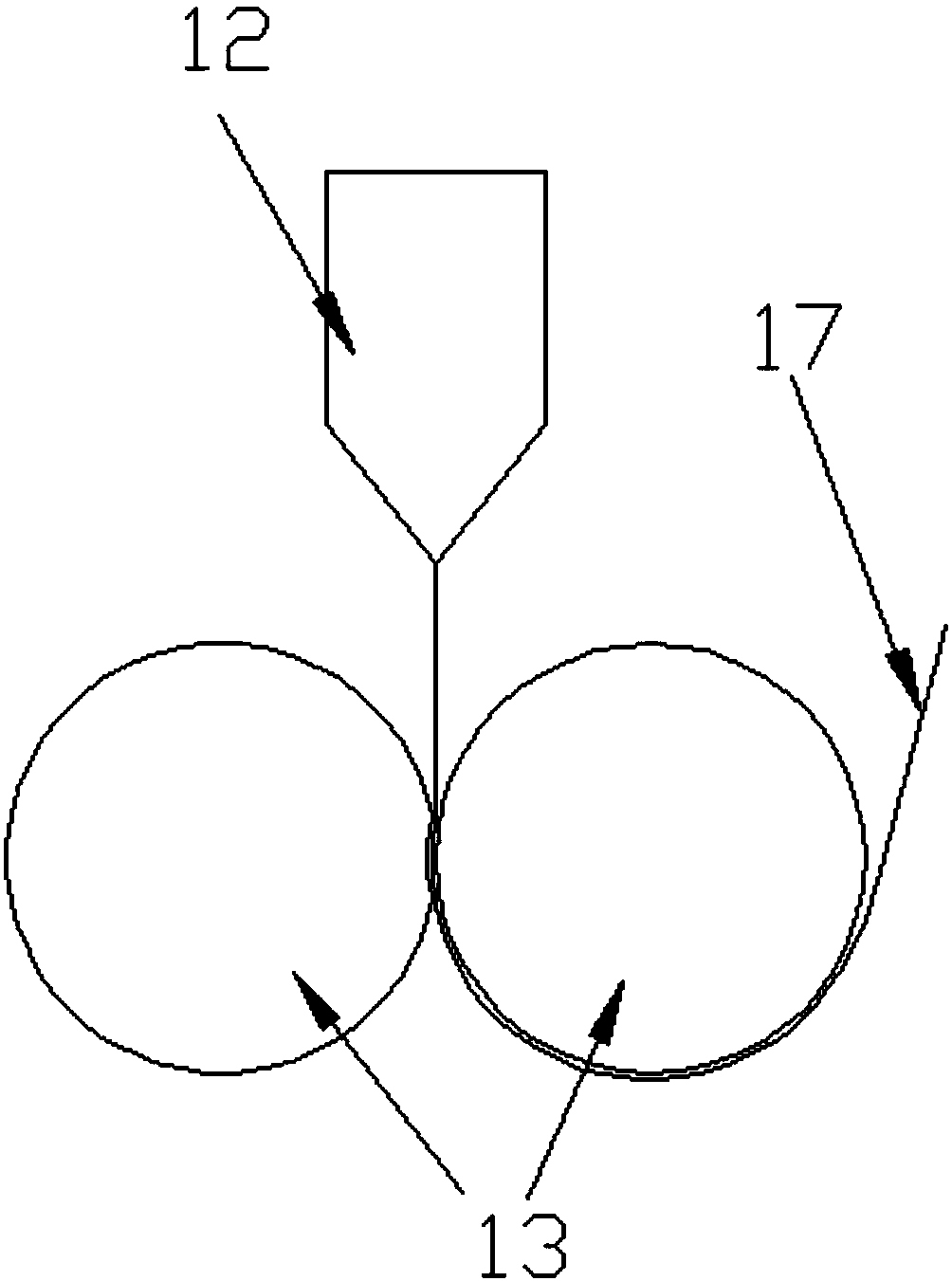

[0032] Such as Figure 1 to Figure 6 As shown, the present invention is a preparation system for PMMA light-guiding grade transparent film, including a cleaning device 1, a drying device 2, an extruding device 3, a polishing roller unit 4, a roller conveying table 5, and a relay-type diaphragm arranged in sequence. Surface dust removal device, film laminating machine 6, first cutting machine 7, tractor 8, edge trimming machine 9, second cutting machine 10 and sheet loading machine 11; Negative pressure chip suction device on the discharge side of side machine 9 and second cutting machine 10; Extrusion device 3 (extrusion device 3 includes a single-shaft extruder, a gear pump, a polymer filter and a die 12 arranged in sequence , the single-screw extruder uniformly melts, kneads and extrudes the resin particles, the gear pump delivers the molten resin quantitatively, and the polymer filter is used to filter the molten resin. In most cases, it can remove foreign matter and crysta...

Embodiment 2

[0037] The difference from Embodiment 1 is that, as Figure 7 , Figure 8 As shown, a pair of squeeze rollers 13 with a flexible surface is composed of an inner metal roller 18 and a flexible layer 16 coated on the outside of the metal roller 18; the flexible layer 16 is a rubber layer, and the surface of the rubber layer is coated with polytetrafluoroethylene. vinyl film. The upper dust removal roller group and the lower dust removal roller group are respectively provided with two groups along the conveying direction. The upper dust removal roller group and the lower dust removal roller group of the first group are respectively equipped with three dust removal rollers. There are two dust removal rollers respectively. They are respectively high viscosity dust removal roller 20, medium viscosity dust removal roller 21 and low viscosity dust removal roller 22; the second group includes two dust removal rollers respectively arranged on both sides of the PMMA film; respectively ...

Embodiment 3

[0039] The difference from Embodiment 1 is that, as Figure 9 As shown, a pair of squeeze rollers 13 with flexible surfaces includes an inner metal roller 18 and an outer flexible layer 16, and also includes a pressure regulator between the metal roller 18 and the flexible layer 16 for adjusting the hardness of the flexible layer 16. Layer 19, the pressure regulating layer 19 is hollow, and the hollow part is filled with fluid, and the side of the squeeze roller 13 is provided with a fluid inlet; the flexible layer 16 is a rubber layer, and the surface of the rubber layer is covered with a polytetrafluoroethylene film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com