Intelligent transformer overhaul integration device

A transformer, intelligent technology, applied in switchgear, electrical components, etc., can solve the problems of inability to cool and dedust the transformer online, and inability to monitor the oil temperature of the transformer cooling oil online.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

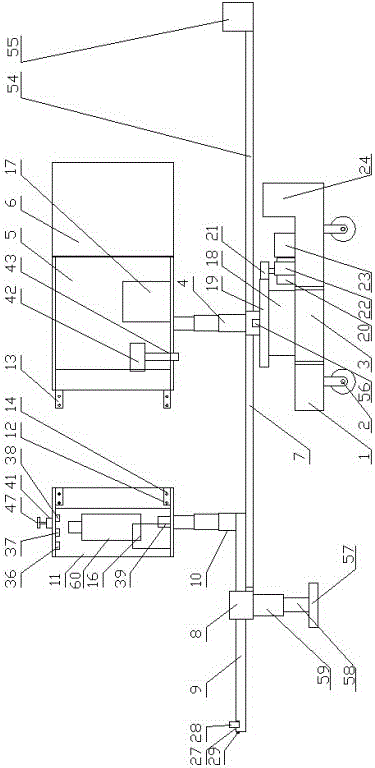

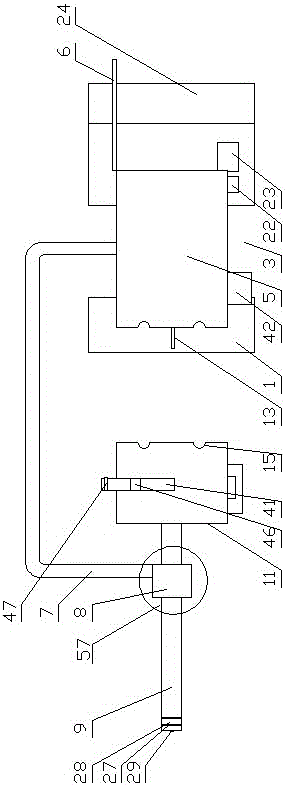

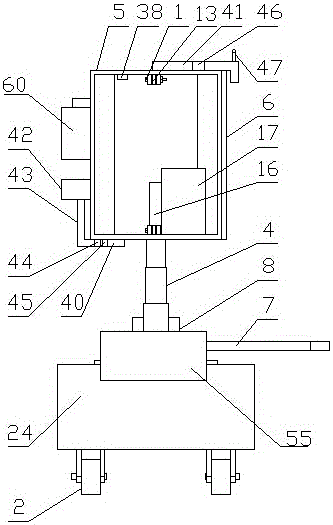

[0050] Embodiment 1: An intelligent transformer maintenance integrated device, including a platform 1, a slewing mechanism arranged on the upper part of the platform 1, and a running mechanism 2 arranged at the bottom of the platform 1, and the left and right sides of the platform 1 are provided with There is a groove 3, the upper part of the slewing mechanism is provided with a right elevating rod 4, the top of the right elevating rod 4 is provided with a right inspection box 5, and the right end of the right inspection box 5 is rotated to install a sealing door 6, and the upper part of the slewing mechanism is close to A semi-frame support frame 7 is arranged at the edge, and a fixed sleeve 8 is provided at the end of the semi-frame support frame 7. A cantilever 9 is slidably arranged in the fixed sleeve 8, and a left elevating rod 10 is fixedly arranged on the upper surface of the right end of the cantilever 9. A left inspection box 11 is arranged on the top of the left elev...

Embodiment 2

[0068] Embodiment 2: An intelligent transformer maintenance integrated device, including a platform 1, a slewing mechanism arranged on the upper part of the platform 1 and a running mechanism 2 arranged on the bottom of the platform 1, and the left and right sides of the platform 1 are provided with There is a groove 3, the upper part of the slewing mechanism is provided with a right elevating rod 4, the top of the right elevating rod 4 is provided with a right inspection box 5, and the right end of the right inspection box 5 is rotated to install a sealing door 6, and the upper part of the slewing mechanism is close to A semi-frame support frame 7 is arranged at the edge, and a fixed sleeve 8 is provided at the end of the semi-frame support frame 7. A cantilever 9 is slidably arranged in the fixed sleeve 8, and a left elevating rod 10 is fixedly arranged on the upper surface of the right end of the cantilever 9. A left inspection box 11 is arranged on the top of the left eleva...

Embodiment 3

[0076] Embodiment 3: The difference between it and Embodiment 1 and Embodiment 2 is that: both the left elevating rod 10 and the right elevating rod 4 are hydraulic elevating rods.

[0077] The right end of the platform 1 is provided with a draw bar 25 , and a draw hole 26 is provided on the draw bar 25 .

[0078] An elastic layer 48 is provided on the right end surface of the left inspection box 11 and the left end surface of the right inspection box 5 .

[0079] The elastic layer 48 is made of wear-resistant rubber, and the wear-resistant rubber is composed of the following components in parts by weight: 40 parts of polyurethane rubber, 23 parts of acrylic rubber, 15 parts of nitrile rubber, 250 parts of styrene-butadiene rubber, brominated butyl 16 parts of acrylic rubber, 8 parts of polypropylenediene siloxane, 6 parts of urethane, 6 parts of polyethylene wax, 2 parts of carbon fiber, and 13 parts of polytetrafluoroethylene; due to the use of polyethylene wax as an anti-ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com