Collecting and dedusting device

A dust removal device and material technology, applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, can solve the problems of reduced dust removal efficiency, poor dust removal effect, difficulty in cleaning fine dust in bag filter, etc., and achieve dust removal efficiency High, good dust removal effect, reduce dust flying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

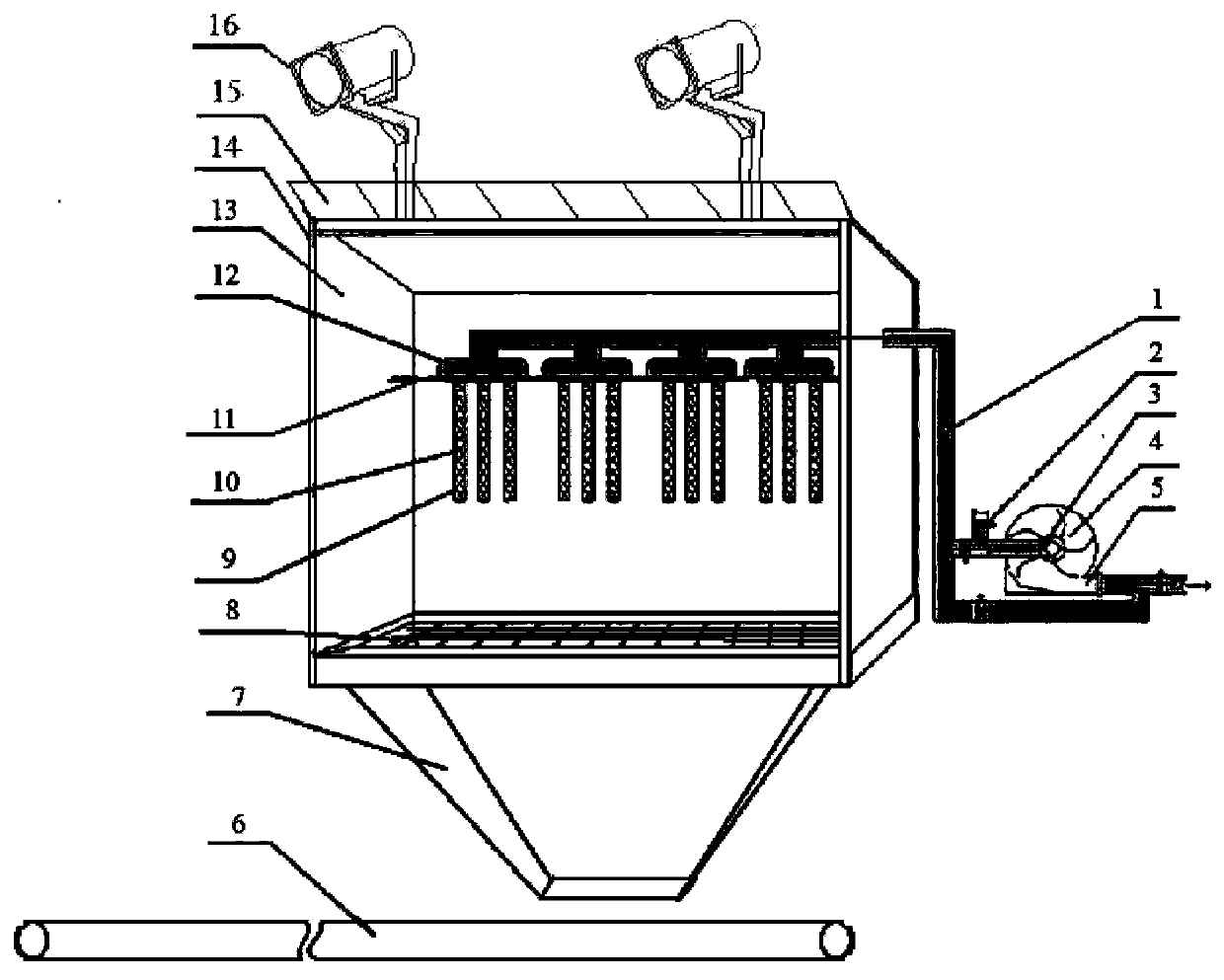

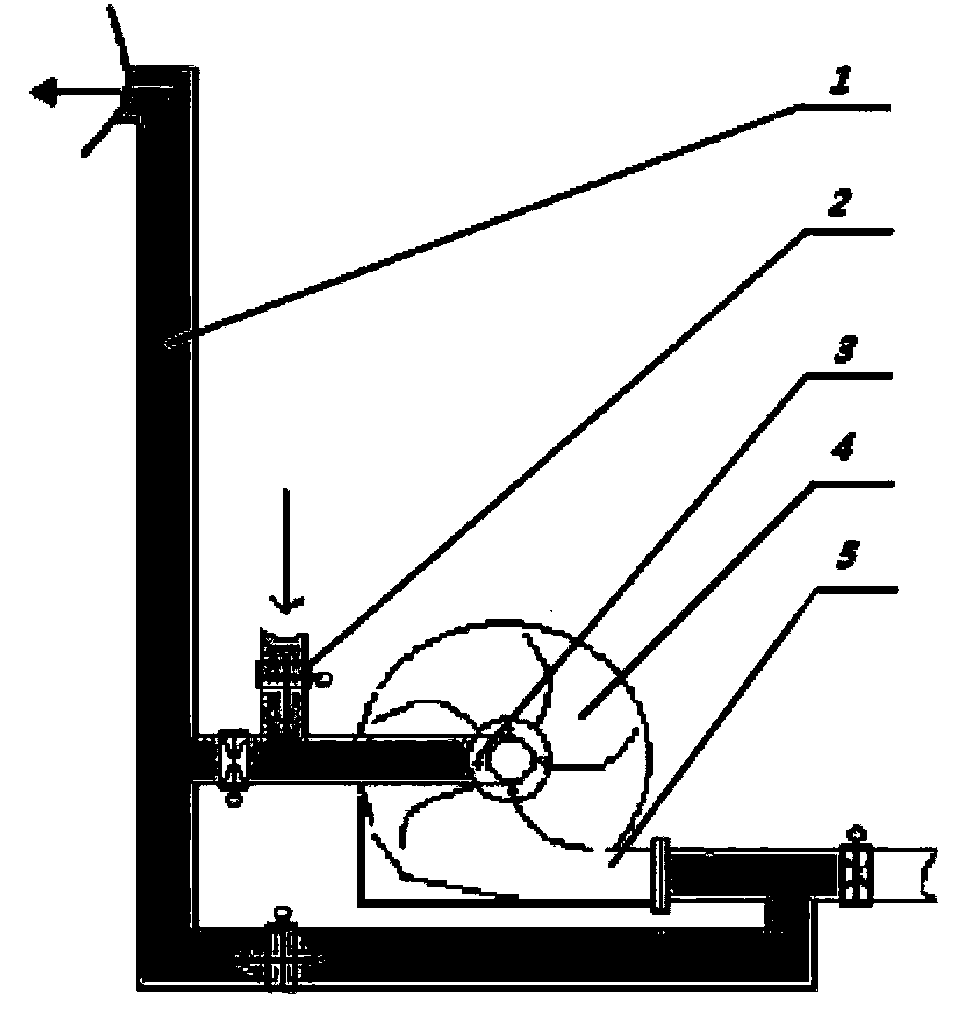

[0034] Such as Figure 1~4 Shown, a kind of collection dust removal device comprises discharge room 14, is provided with the dust removal device that is used for dust removal in the discharge room 14, is provided with suction wind dust removal device at the side position of discharge room 14, dust removal device and suction wind The dust removal device is connected; the dust removal device includes three dust removal bags 9, the dust removal bag 9 is connected by the upper cover 12, and is fixed and suspended inside the discharge room 14 through the support frame 11, and the inner side of the dust removal bag 9 is also provided with a winding piece 10, the dust removal bag 9 is connected to the dust removal device through the pipeline 1; the suction wind dust removal device includes a fan 4, the fan 4 is a positive and negative blower, and the air inlet 3 and the air outlet 5 of the fan 4 are respectively connected to the pipeline 1 to form an intercommunication circuit, and th...

Embodiment 2

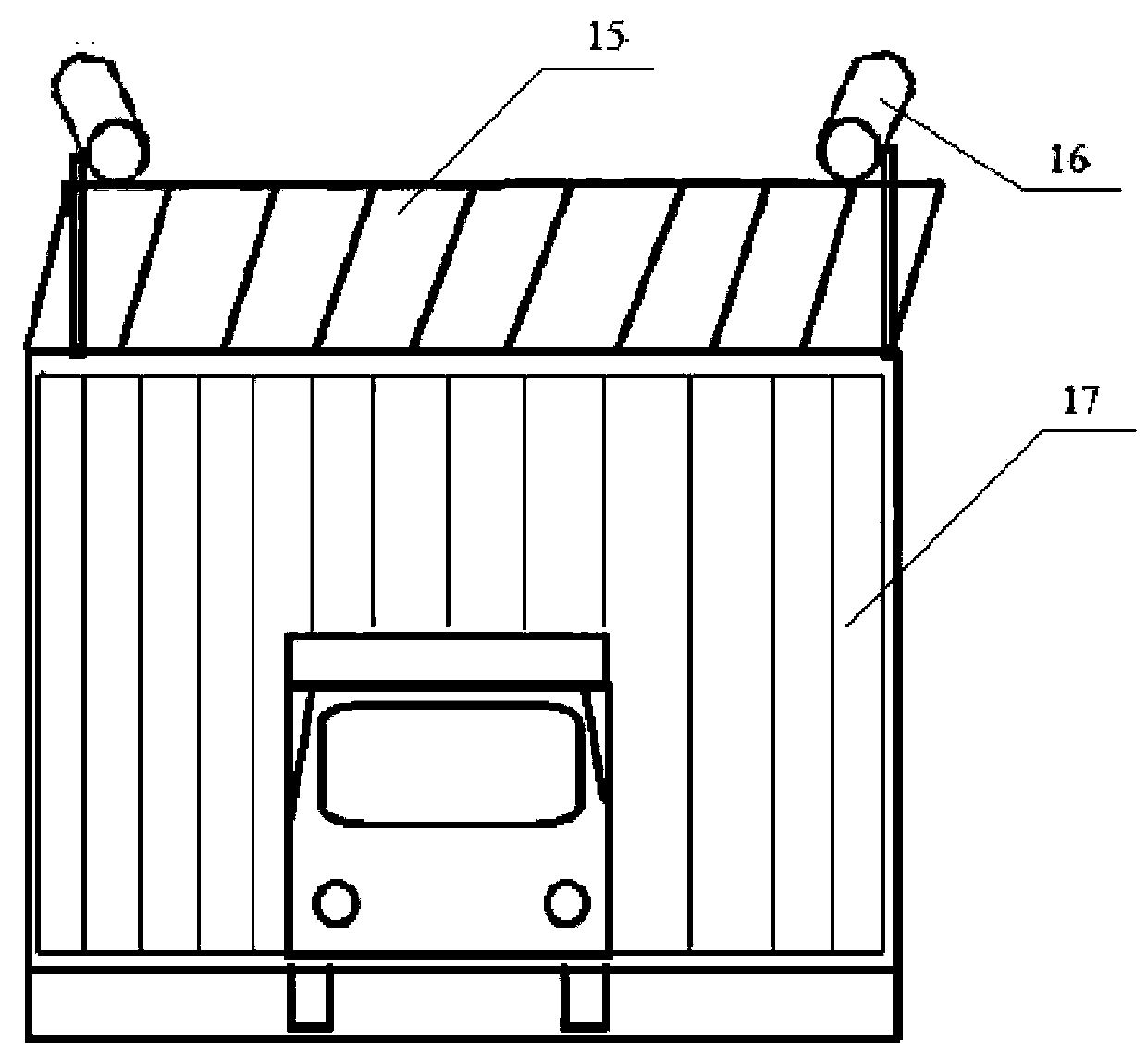

[0038] The difference between this embodiment and Embodiment 1 is that a dust bag 9 is provided at the lower end of each upper cover 12, the power of the fan 4 is 2.5KW, the rotating speed of the fan 4 is 1400r / min, and the flow rate of the wind is 3500m 3 / h, the wind pressure is 560Pa; the dustproof nozzle includes two sets of water mist spray nets 15 and spray blower 16. Each parameter of dust bag 9, blower fan 4 and the number of groups of dust-proof nozzles can be set according to the present invention, so no other drawing is indicated.

[0039] In addition, the partition net 8 is a double-layer grid 8 in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com