Room-type cleaning material separation unit and method

A clean and unit technology, applied in conveyors, loading/unloading, transportation and packaging, etc., can solve the problems of inability to achieve clean production, low degree of automation, large dust and smoke, and achieve good dust removal effect, low production cost, and dust removal. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

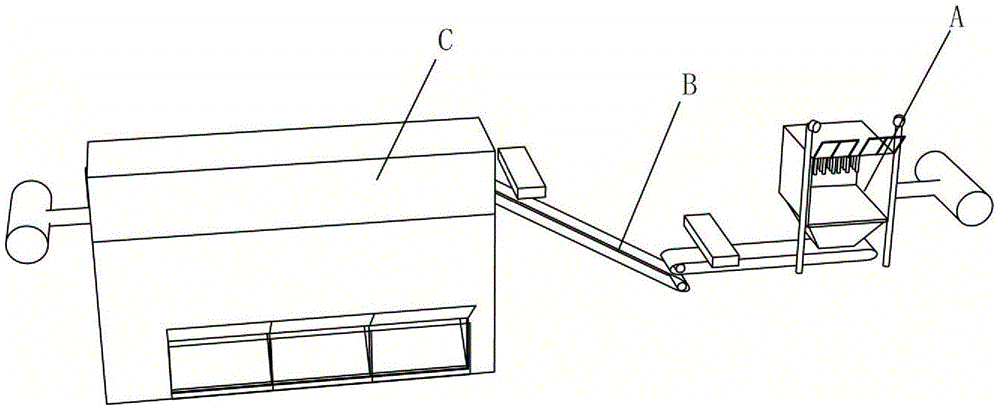

[0039] like figure 1 As shown, the clean belt distribution unit includes a material receiving and dust removal device A, a material transfer mechanism B and a material collection mechanism C.

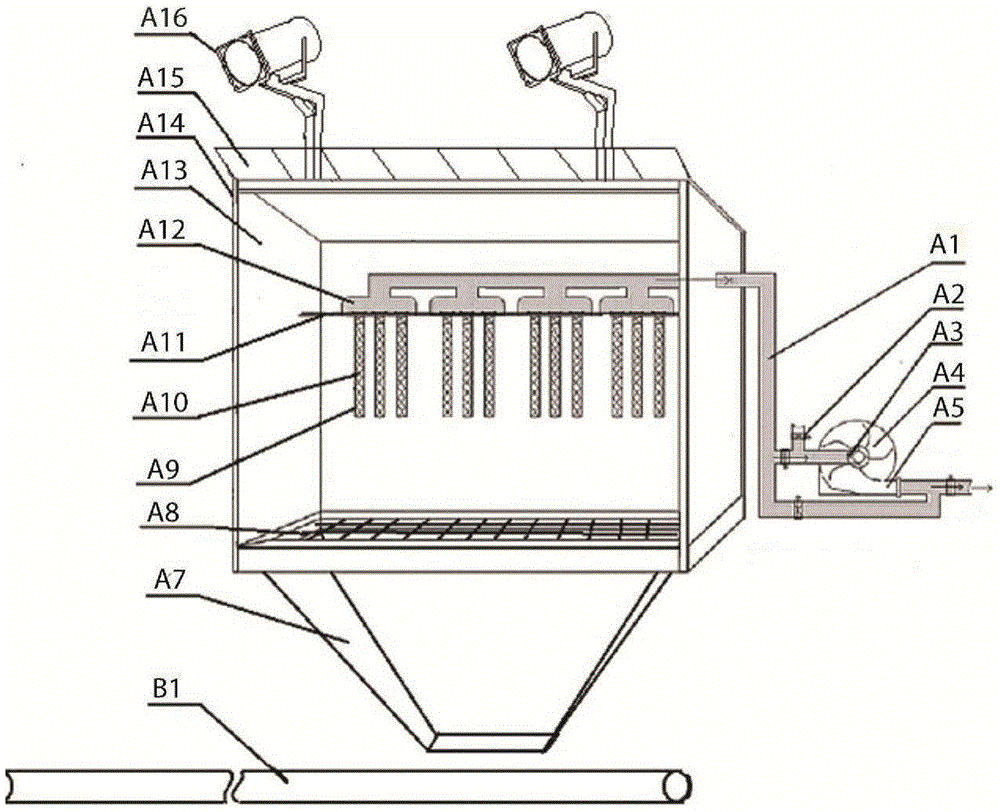

[0040] like figure 2 As shown, the receiving and dedusting device A includes a discharge room A14, a dust removal device for dust removal is provided in the discharge room A14, a suction wind dust removal device is provided at the side of the discharge room A14, and the dust removal device and the suction wind The dust removal device is connected; the dust removal device includes three dust removal bags A9, the dust removal bag A9 is connected through the upper cover A12, and is fixed and suspended inside the discharge room A14 through the support frame A11. A9 is connected to the dust removal device through the pipeline A1; the suction wind dust removal device includes the fan A4, the fan A4 is a positive and negative blower, the air inlet A3 and the air outlet A5 of the fan A4 are r...

Embodiment 2

[0053] In this embodiment, the difference from Embodiment 1 is that the conveyor belt can be replaced with other conveying elements, such as a conveying grid, a conveying net, etc., and the rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com