Adhesive composition for semiconductor, semiconductor device using the same and method for producing semiconductor device

一种半导体、组合物的技术,应用在半导体/固态器件制造、粘合剂类型、半导体器件等方向,能够解决半导体芯片和电路基板粘合力不充分、粘合片材发泡、连接可靠性降低等问题,达到简化安装到电路基板的工序、高速切断、减少溢出量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] The present invention will be explained by citing the following examples and the like, but the present invention is not limited to the exemplified examples. In addition, the evaluation of the adhesive composition for semiconductors in an Example was performed by the following method.

Synthetic example 1

[0114] Synthesis Example 1 Synthesis of Organic Solvent-soluble Polyimide A

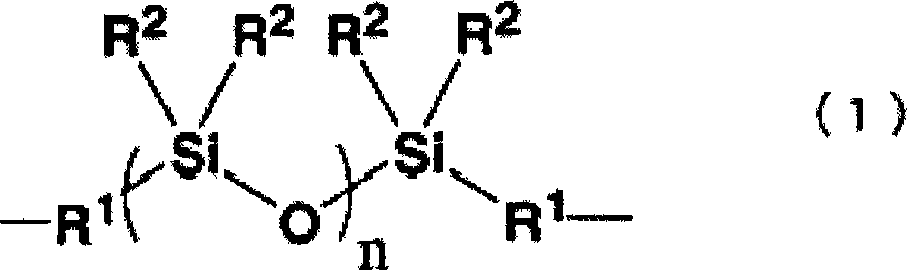

[0115] Under a stream of dry nitrogen, dissolve 24.54g (0.067mol) of 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane (hereinafter referred to as BAHF) and 1,3-bis(3-amino) in 80g of NMP Propyl) tetramethyldisiloxane (hereinafter referred to as SiDA) 4.97 g (0.02 mol), and blocking agent 3-aminophenol (hereinafter referred to as 3-Aph) 2.18 g (0.02 mol). Then, 31.02g (0.1mol) of bis(3,4-dicarboxyphenyl)ether dianhydride (hereinafter referred to as ODPA) and 20g of NMP were added to it, reacted at 20°C for 1 hour, and then stirred at 50°C 4 hours. Then, 15 g of xylene was added to azeotrope water and xylene while stirring at 180°C for 5 hours. After the stirring, the solution was poured into 3L of water to obtain a white precipitated polymer. The precipitate was filtered, recovered, washed with water three times, and dried at 80°C for 20 hours with a vacuum dryer. The obtained polymer solid was measured ...

Synthetic example 2

[0116] Synthesis Example 2 Synthesis of Organic Solvent-soluble Polyimide B

[0117] Under a stream of dry nitrogen, 18.31 g (0.05 mol) of BAHF, 7.46 g (0.03 mol) of SiDA, and 4.37 g (0.04 mol) of 3-Aph were dissolved in 150 g of NMP. Add 52 g (0.1 mol) of 2,2-bis(4-dicarboxyphenoxy) phenyl) propane dianhydride (hereinafter referred to as BSAA) and 30 g of NMP, and react at 20°C for 1 hour, and then Stir at 50°C for 4 hours. Next, it was stirred at 180°C for 5 hours. After the stirring, the solution was poured into 3L of water to obtain a white precipitated polymer. The precipitate was filtered, recovered, washed with water three times, and dried at 80°C for 20 hours with a vacuum dryer. The obtained polymer solid was measured by infrared absorption spectroscopy, at 1780cm -1 Nearby, 1377cm -1 An absorption peak derived from the imide structure of polyimide was detected nearby. In this way, an organic solvent-soluble polyimide B having a functional group capable of reacting with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com