Device for guiding airflow to impact liquid level in tangential direction for forming moisture-containing airflow

A technology of airflow and liquid level, applied in the direction of using liquid separating agent, liquid fuel supply/distribution, combustion method, etc., can solve the problems of low dust removal efficiency of dust removal device, increased motor power of induced draft fan, low dust removal efficiency, etc., and achieves compact structure. , The effect of improving thermal efficiency and convenient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

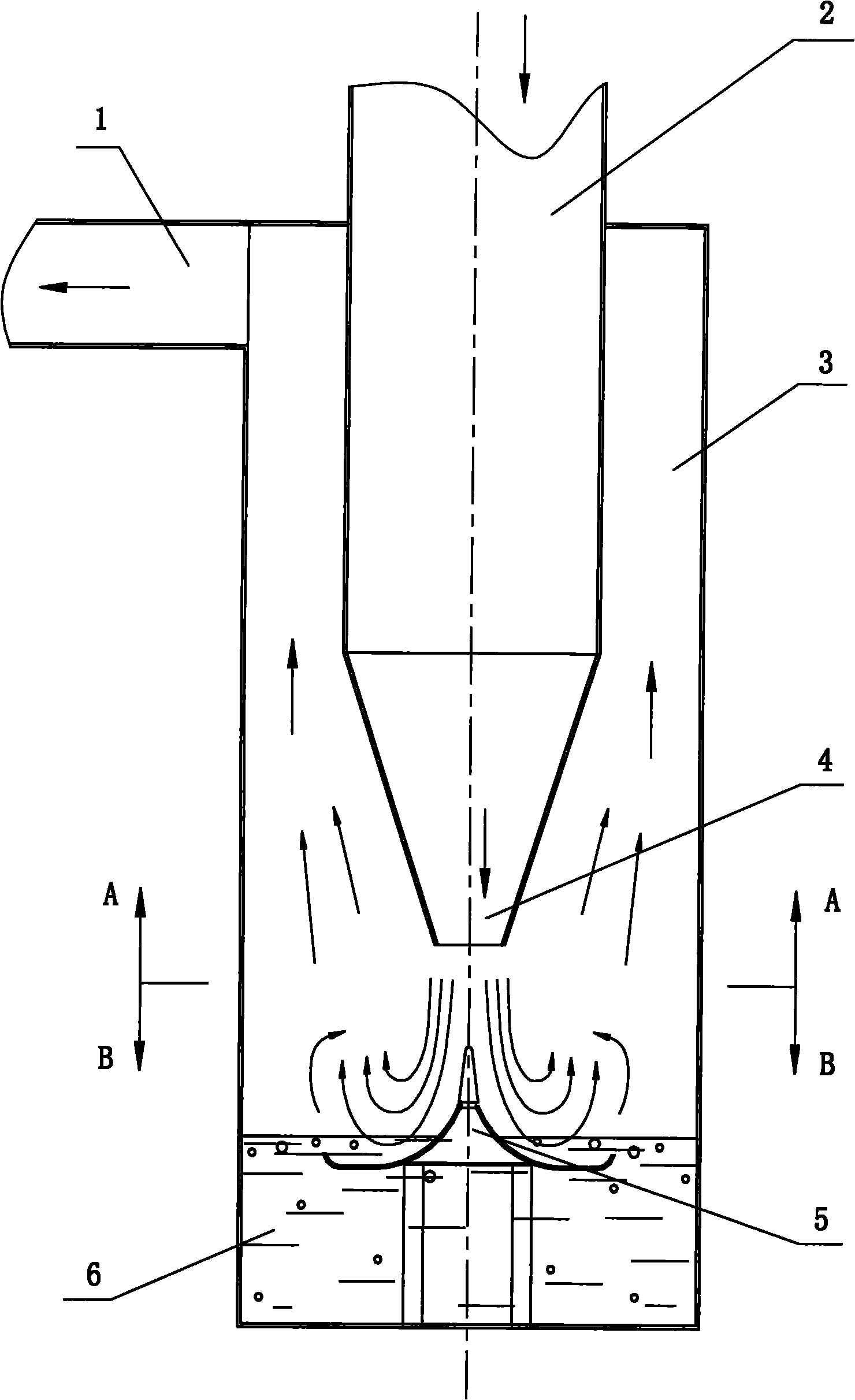

[0033] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

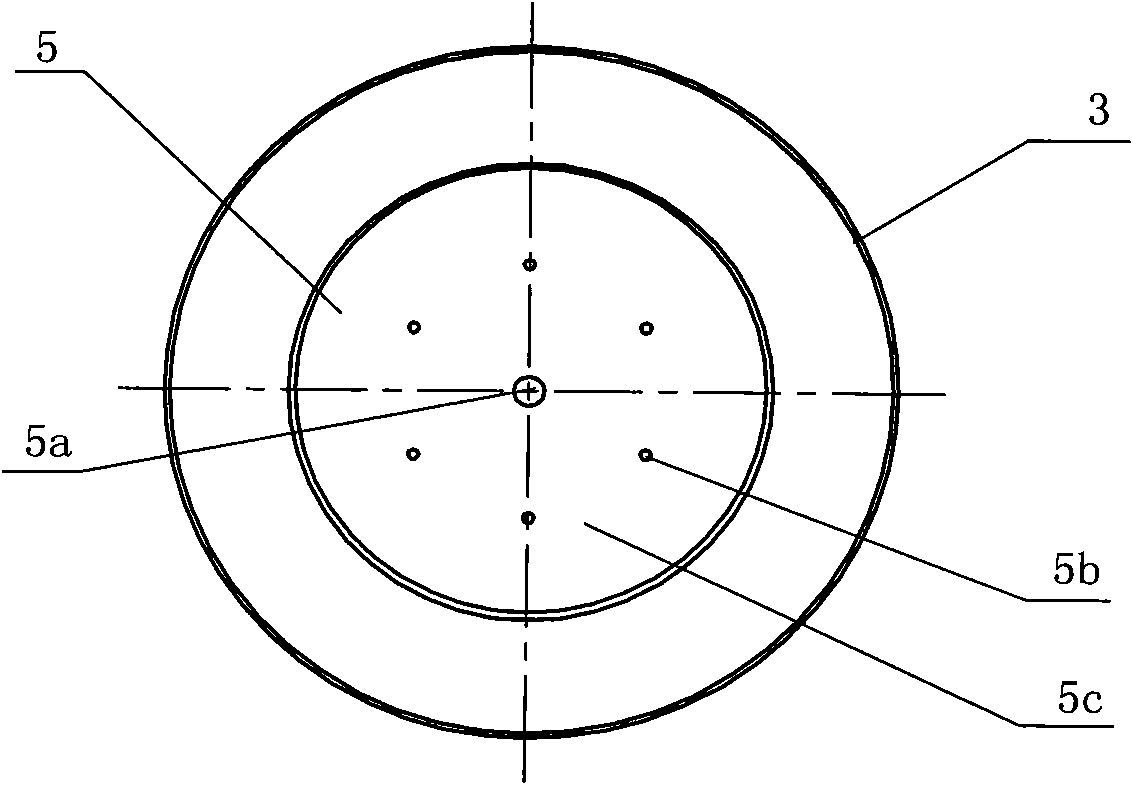

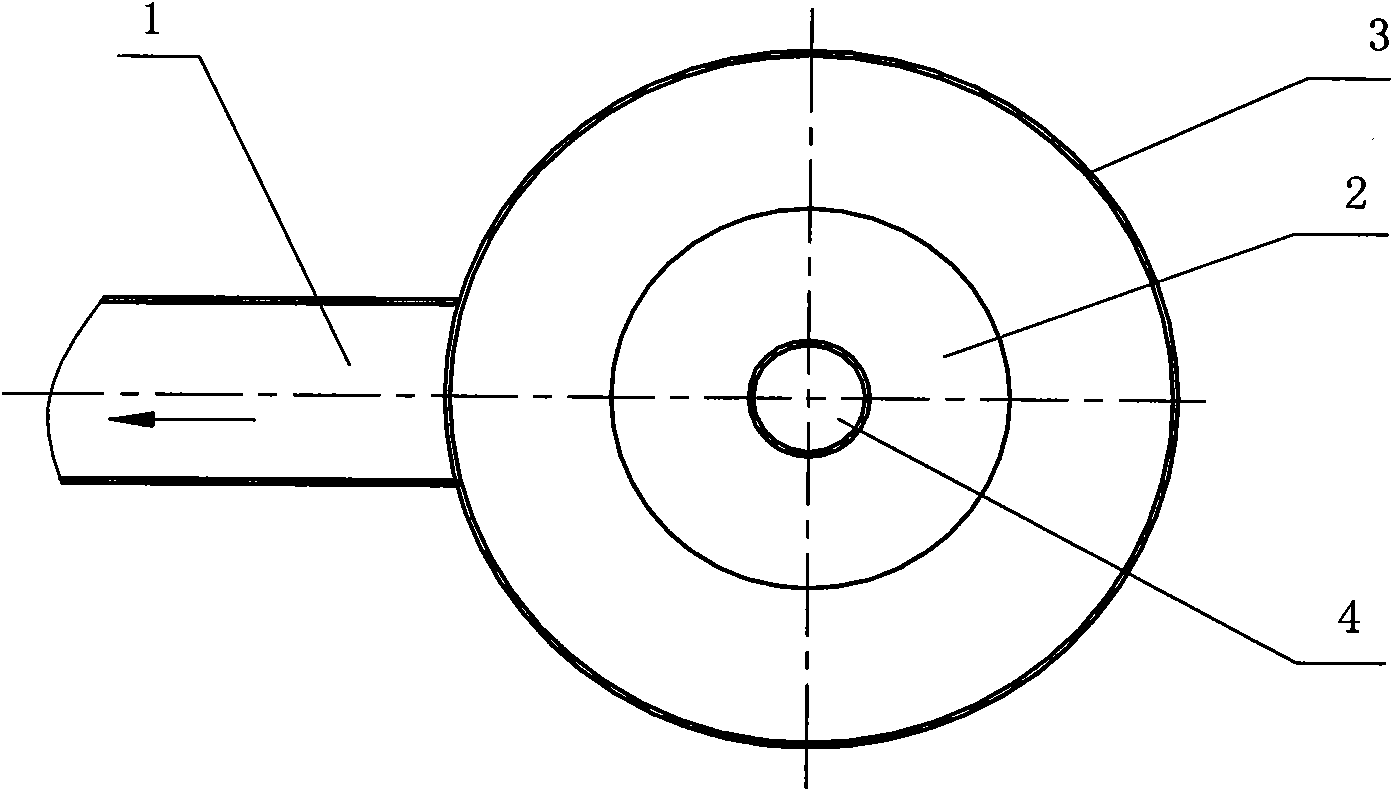

[0034] A device that guides the airflow to impact the liquid surface tangentially to form a wet airflow. A conical spout 4 connected to the vertically downward air inlet pipe 2 is set in the container 3. The liquid 6 is below the spout 4, which is in the shape of an inverted umbrella. The lower part of the airflow cyclone 5 is immersed in the liquid level of the liquid 6, and an air outlet 1 is drawn on the passage between the inner wall of the container 3, the air inlet pipe and the outer wall of the spout 4; the middle of the airflow cyclone 5 protrudes upwards Spire 5a, then be the arc-shaped surface 5c that is extended to the edge with a certain curve shape first down to the edge and then slightly upwards; Consistent shape, round or polygonal. When the airflow hits the airflow cyclone 5 downward, under the guidance of the curved surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com