Exhaust frame of density plate pre-pressing machine

A pre-press, MDF technology, applied in household components, flat products, household appliances, etc., can solve the problems of belt deviation, uncontrollable impact on the health of clean production personnel, and affecting the continuous operation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

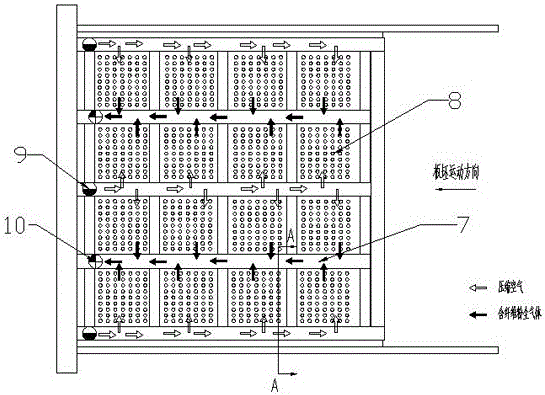

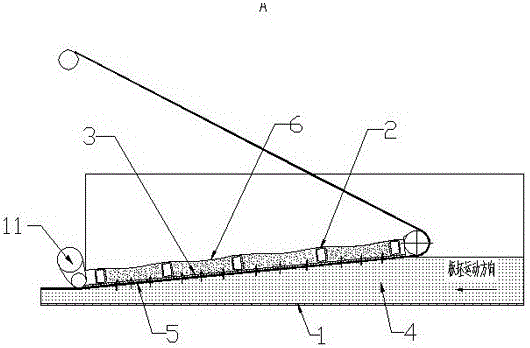

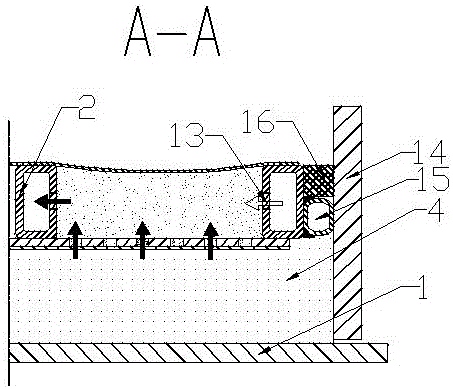

[0014] The exhaust rack of the density plate pre-pressing machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] As shown in the figure, the density board pre-pressing machine exhaust rack of the present invention includes a horizontally arranged conveyor belt 1 and an introduction frame 2 with an inclined angle between the conveyor belt and the conveyor belt. The introduction frame is a frame structure, and the introduction The bottom end of the frame 2 is provided with a rotating shaft 11, and the introducing frame 2 can be flipped around the rotating shaft to adjust the angle. There is a breathable mesh belt 5 that can run synchronously with the conveyor belt under the blank 4 and the mesh plate 3. When in use, the blank 4 moves forward under the drive of the conveyor belt 1, and the guide frame 2 can turn up and down around the rotating shaft 10 , adjust the inclination ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com