Closed circulation dust removal device of impact crusher

An impact crusher, closed-circuit technology, applied in the direction of climate change adaptation, climate sustainability, human health protection, etc. The effect of the dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

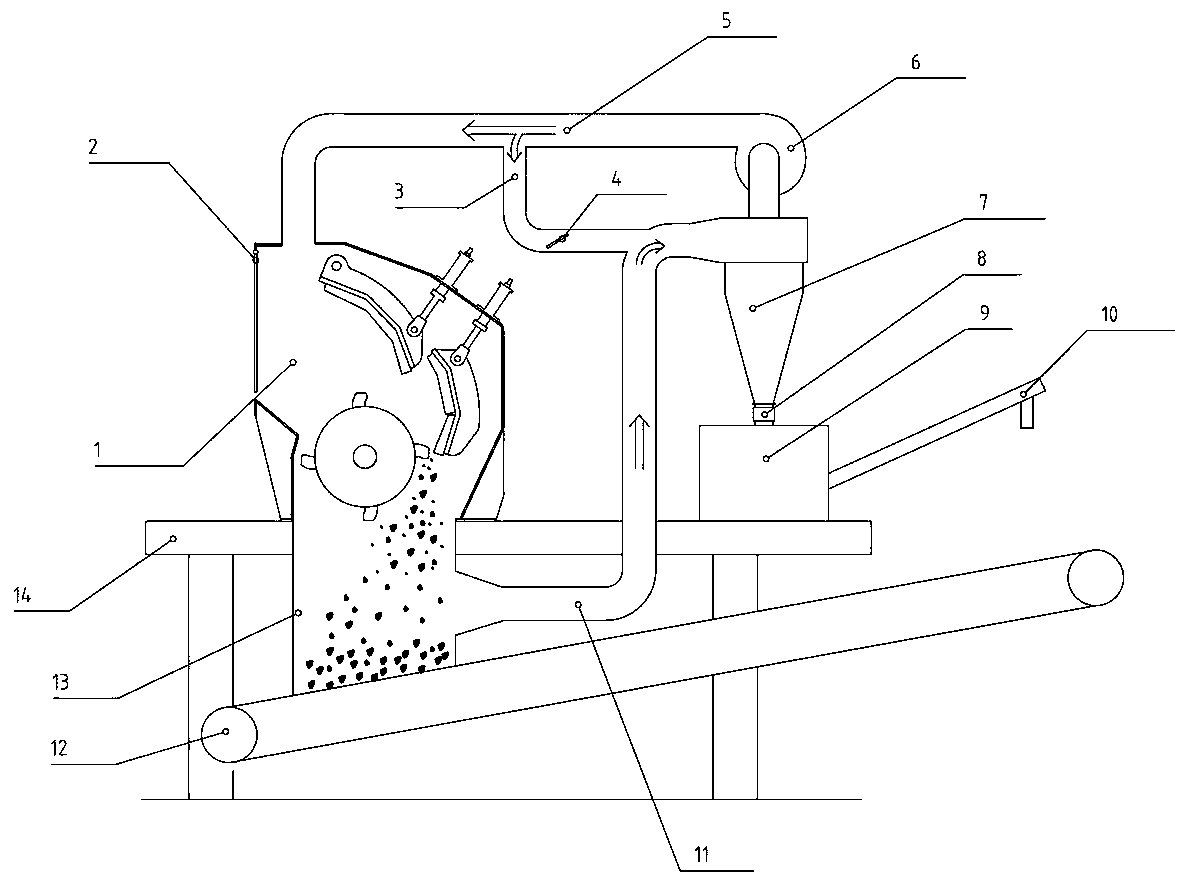

[0014] Such as figure 1 As shown, a closed-circuit circulation dust removal device for an impact crusher includes an impact crusher 1 fixed on a base 14. The feed port of the impact crusher 1 is hinged with a feed port curtain 2. The discharge port of the impact crusher is connected with a discharge hopper 13, and a conveyor belt 12 is laid under the discharge hopper 13. An air inlet is left on the casing above the feed port of the impact crusher, and one side of the discharge hopper 13 is provided with an air outlet. The air outlet is connected with a suction pipe 11, the outlet of the suction pipe 11 is connected with a cyclone powder collector 7, the air inlet of the cyclone powder collector 7 is connected to the outlet of the suction pipe 11, and the air outlet of the cyclone powder collector 7 is connected There is a centrifugal fan 6, the air outlet of the centrifugal fan 6 is connected with an exhaust pipe 5, the other end of the exhaust pipe 5 is connected with the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com