Cloth and yarn cutting-off machine with dust removal function

A cutting machine and fabric technology, which is applied in the field of fabric and yarn fiber processing and dust removal, can solve the problems of harm, pollute the environment, human body, and no dust removal by the rag machine, and achieve the effect of simple and practical structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

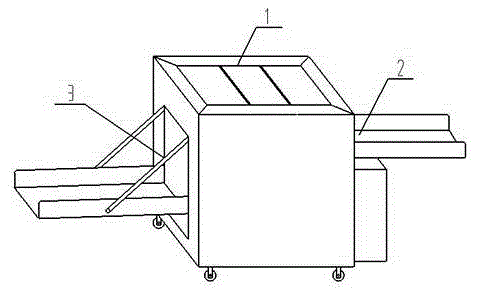

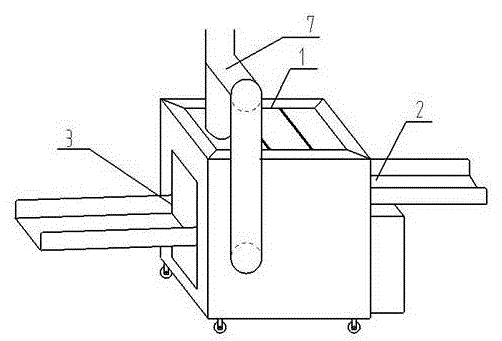

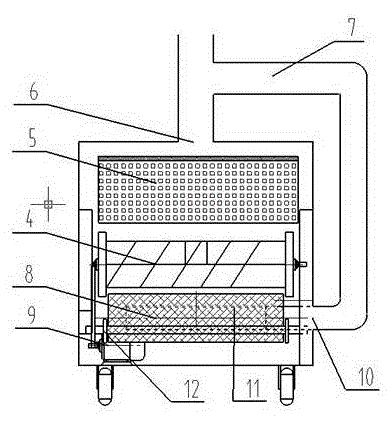

[0021] Such as Figure 2-4 A cloth and yarn cutting machine with dust removal function shown includes a cutting machine casing 1, a feeding port 2, a discharging port 3 and a rotary hob 4, and the feeding port 2 is arranged at the front end of the cutting machine casing 1. The discharge port 3 is arranged on the rear end of the cutting machine casing 1, the rotary hob 4 is arranged in the cutting casing 1, and a dust filter plate 5 is arranged in the cutting machine casing 1 above the rotary hob 4, and a dust filter plate 5 is arranged on the top of the dust filter plate 5 The top dust discharge port 6 is arranged on the cutting machine box body 1, and the top dust discharge port 6 is connected with a dust discharge pipe 7; the cloth and yarn enter the cutting machine box body 1 through the feed port 2, and are continuously cut by the rotating hob 4 Next, the cloth and yarn will be cut or crushed into small pieces. At the same time, the dust generated during the crushing proce...

Embodiment 2

[0023] Such as Figure 2-5 A cloth and yarn cutting machine with dust removal function is shown, on the basis of Embodiment 1, in order to more effectively discharge the dust in the cut cloth and yarn under the rotary hob 4, the bottom of the rotary hob 4 A drum-type dust cage 8 is provided in the cutting machine box 1, and the drum-type dust cage 8 is placed on two rotating shafts 12 to roll, and the drum-type dust cage 8 is supported by the two rotating shafts 12, and the two rotating shafts 12 are in the motor 9 is driven to rotate, and the rotation of the two rotating shafts 12 drives the drum-type dust cage 8 to rotate. The drum-type dust cage 8 is provided with a dust-absorbing inner tank 11, and the dust-absorbing inner tank 11 is connected with the dust-absorbing pipeline 7 is connected and fixed, and the drum-type dust cage 8 is driven by two rotating shafts 12 to rotate continuously. The dust-absorbing liner 11 in the drum-type dust cage 8 remains fixed. The side du...

Embodiment 3

[0026] Such as Figure 2-4 A cloth and yarn cutting machine with dust removal function shown, on the basis of Embodiment 1, the side dust discharge port 10 is connected with a dust discharge pipe 7, and the dust discharge pipe 7 and the top dust discharge port 6 pass through The three-way pipe connection is convenient for dust discharge, and the structure is practical and simple. The top dust discharge port 6 and the side dust discharge port 10 are used to discharge through a main pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com