Patents

Literature

61results about How to "Prevent from bringing up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

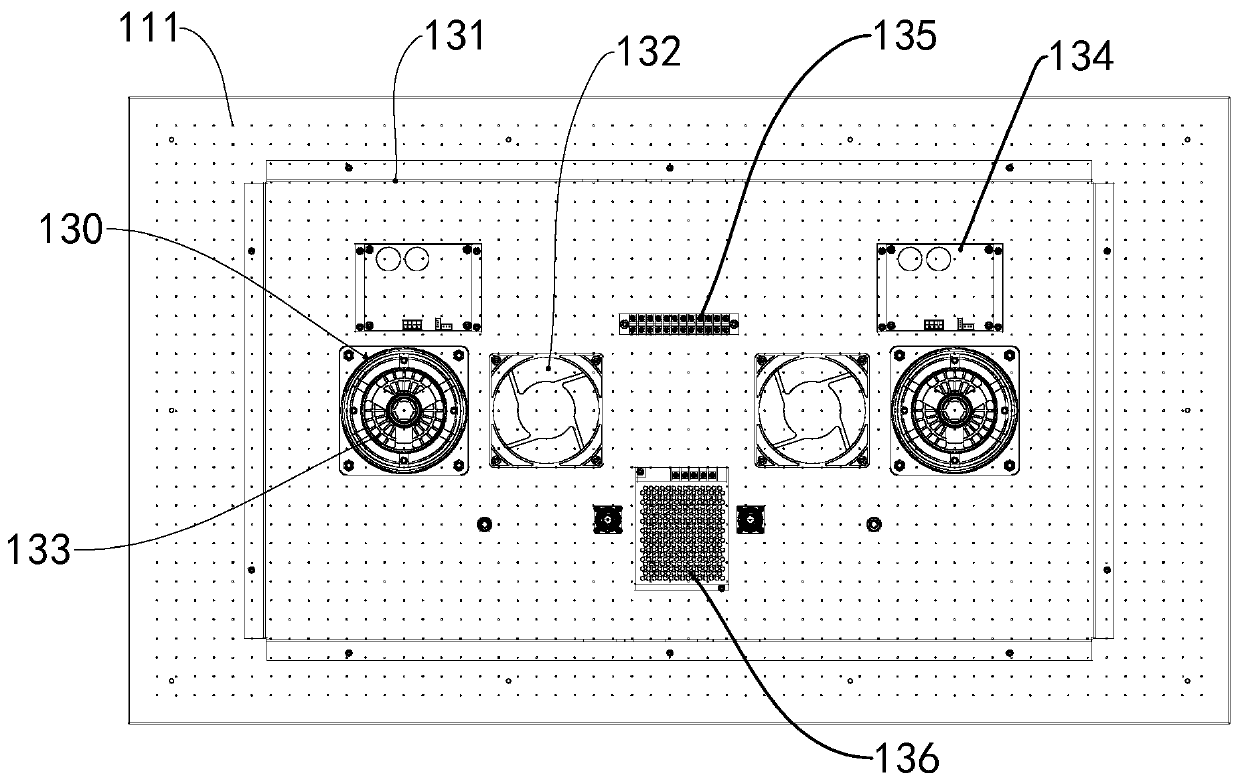

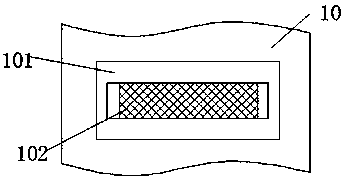

Cushion pad adsorption device and method

InactiveCN101857151APrevent from bringing upAvoid lostGripping headsArticle separationEngineeringCushion

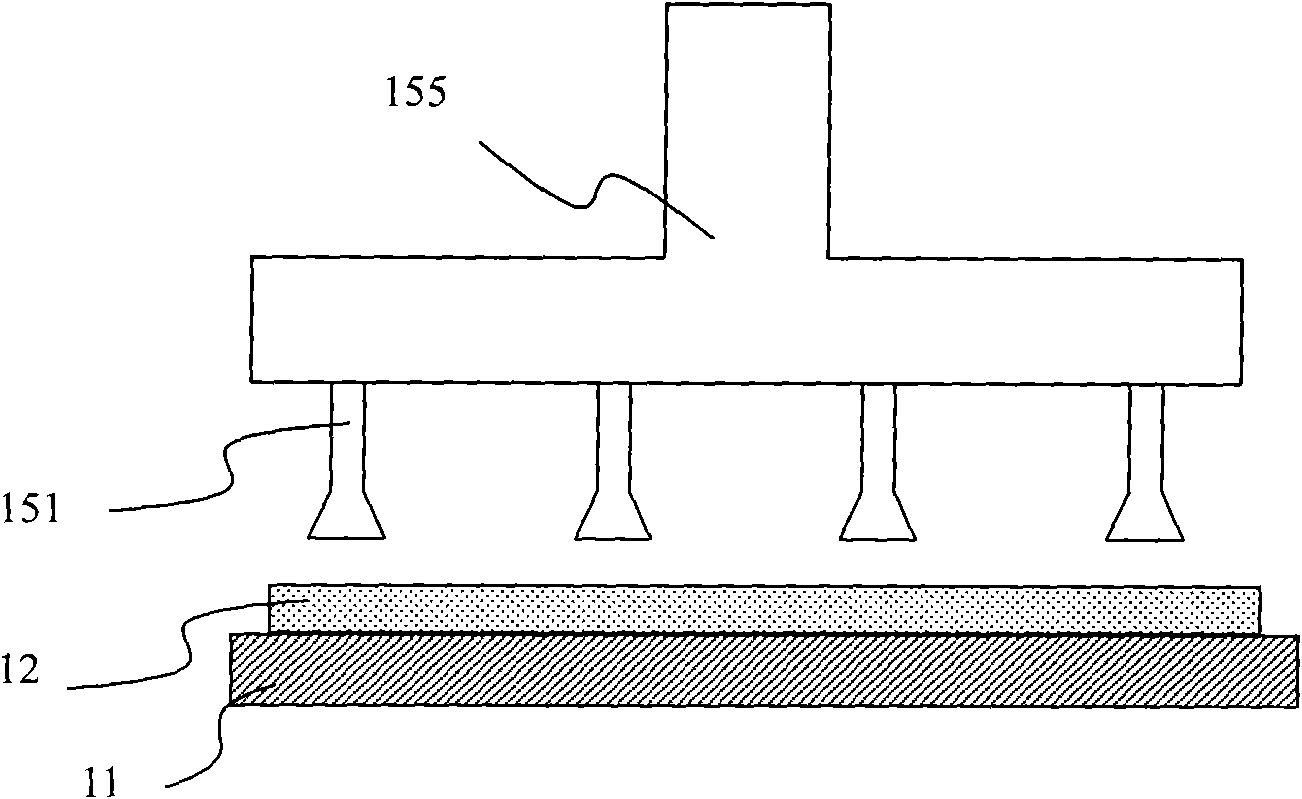

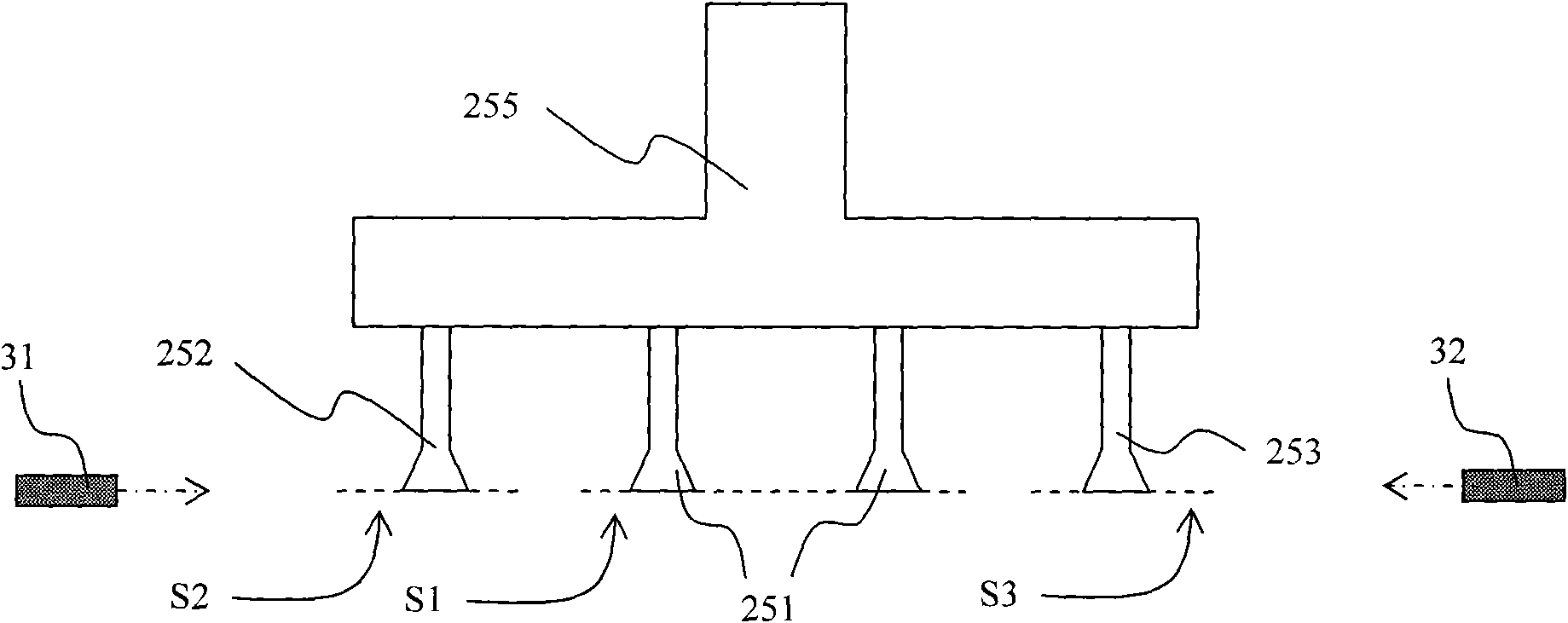

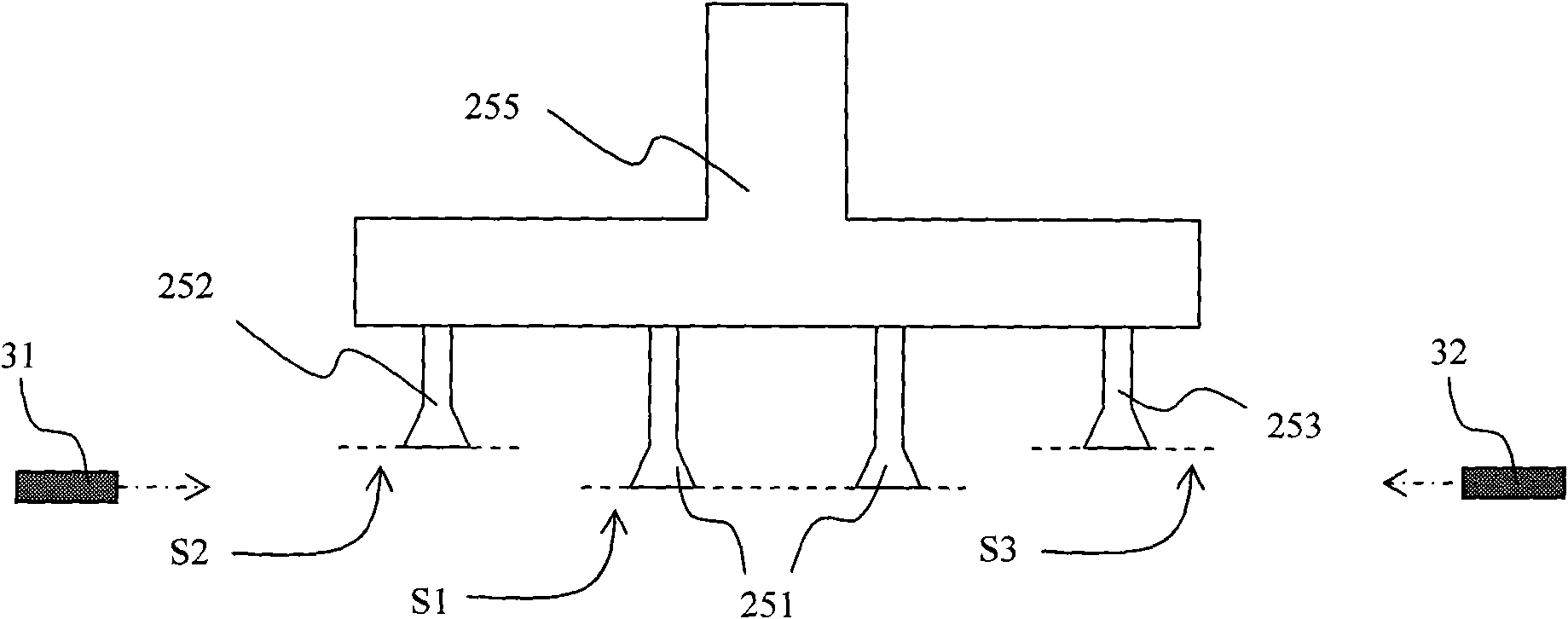

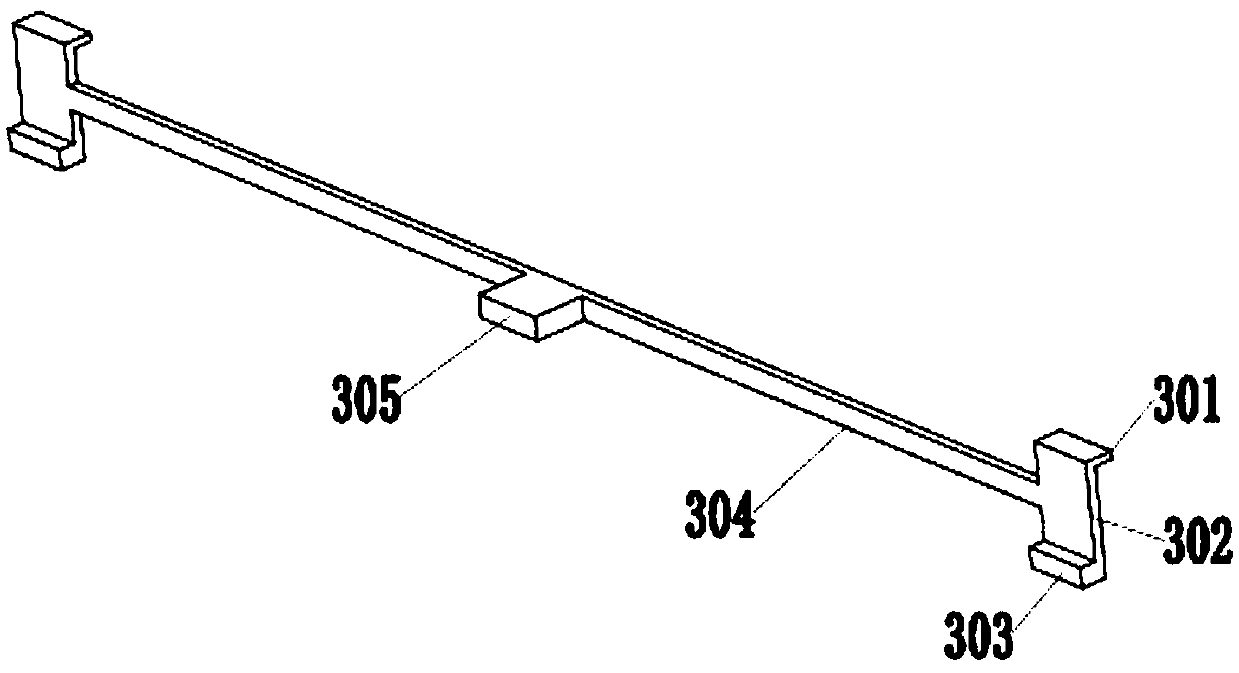

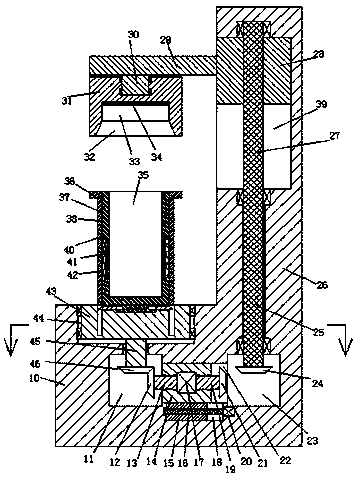

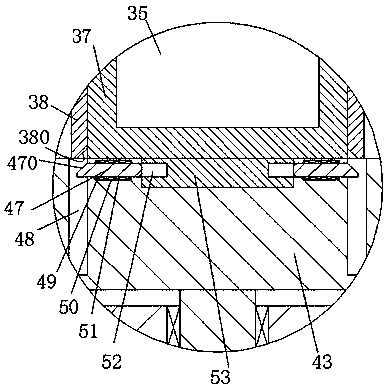

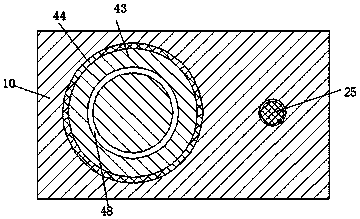

The invention discloses cushion pad adsorption device and method, relating to the adsorption field of a cushion pad. The technical problem to be solved in the invention is to provide a cushion pad adsorption device comprising at least one first suction nozzle and at least one second suction nozzle, wherein the first suction nozzle forms a first adsorption plane; the second suction nozzle is arranged at one side of the first suction nozzle and forms a second adsorption plane; and the first adsorption plane is parallel to the second adsorption plane, and the distance between the first adsorption plane and the second adsorption plane is adjustable and can be adjusted until the first adsorption plane and the second adsorption plane are coincident.

Owner:AU OPTRONICS (XIAMEN) CORP +1

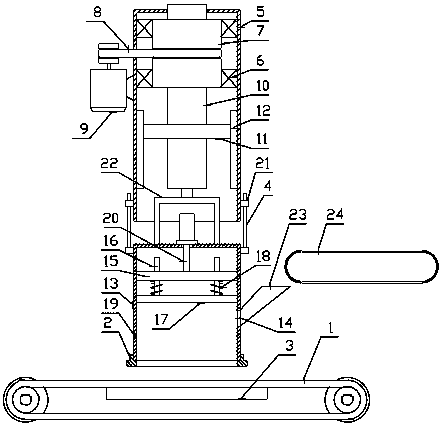

Bag folding method and bag folding device for bag making machine

PendingCN109397754APrevent archingPrevent from bringing upBag making operationsPaper-makingEngineeringPlastic bag

The invention discloses a bag folding method and a bag folding device for a bag making machine. The bag folding device comprises a machine frame, a front corner folding plate, a front folding plate, arear folding plate, an insertion plate and a guiding plate, wherein the front corner folding plate, the front folding plate, the rear folding plate, the insertion plate and the guiding plate are mounted on the upper portion of the front end of the machine frame; an indentation plate is arranged on the front portion of the insertion plate; the lower portion of the indentation plate is translated backwards; a notch is formed in the middle of the translated portion; a longitudinal pressing bar is arranged in the middle of the notch; the indentation plate and the pressing bar are driven by air cylinders arranged on an n-shaped bracket; and a gap corresponding to the pressing bar is arranged in the middle of the front end of the front folding plate. The bag folding device has the advantages that an indentation is pressed at the front folding line by the indentation plate before the front folding plate is operated, the folding line can be effectively prevented from arching when being folded; the pressing bar is pressed downwards to press a folded portion of a plastic bag before the front folding plate is reset after folding, the folded portion of the plastic bag is effectively preventedfrom being taken up when the front folding plate is reset (reversely stretched forwards), and the folding quality and work efficiency are improved.

Owner:王根乐

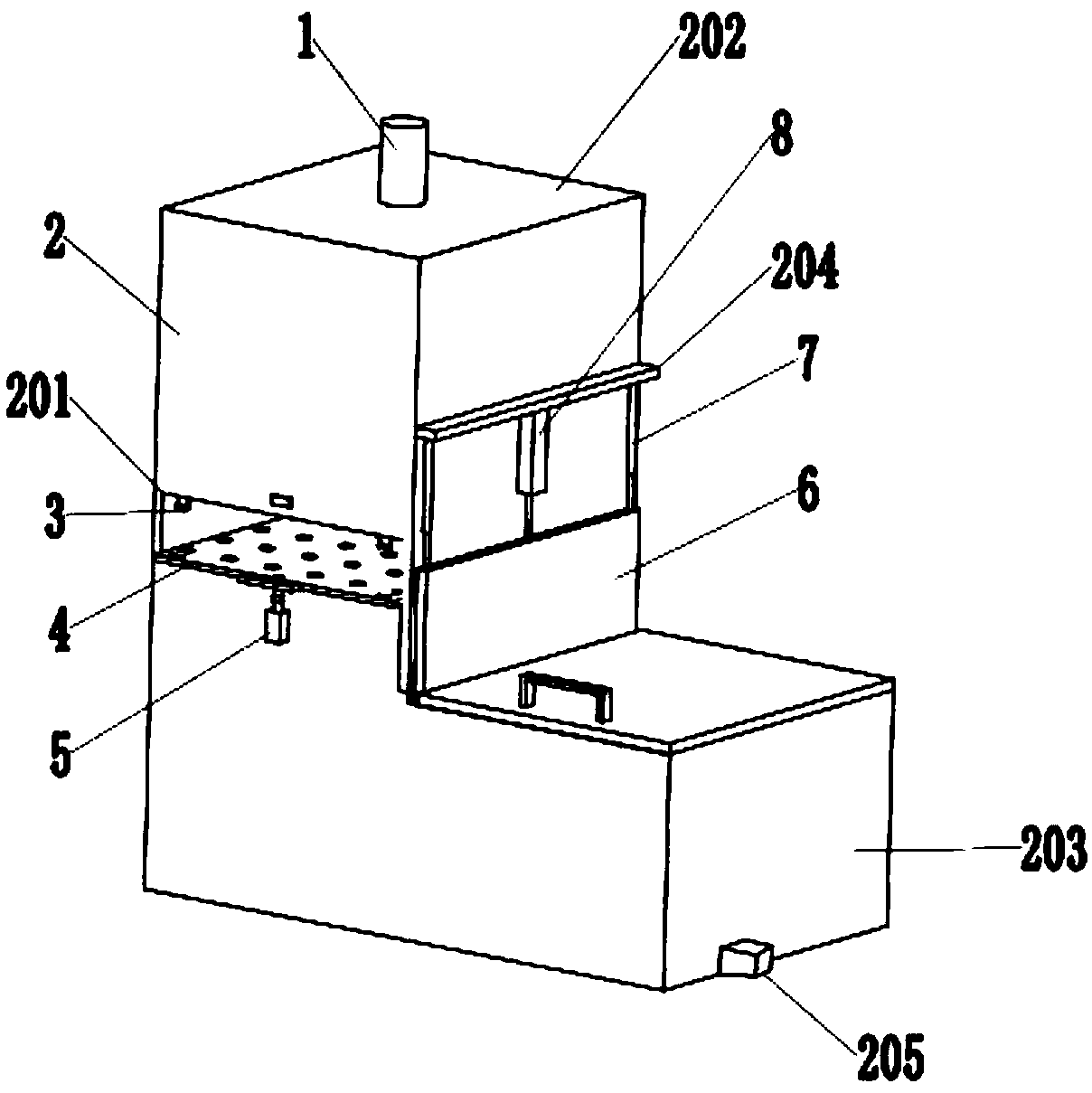

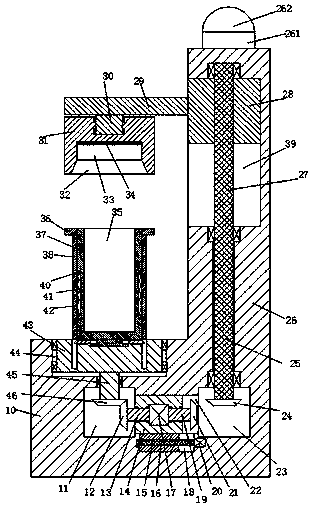

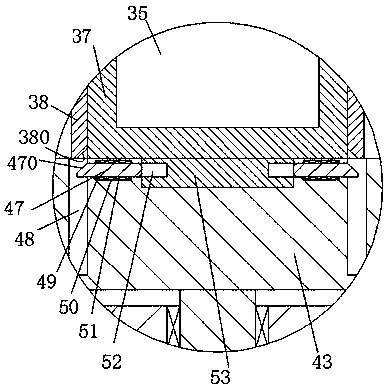

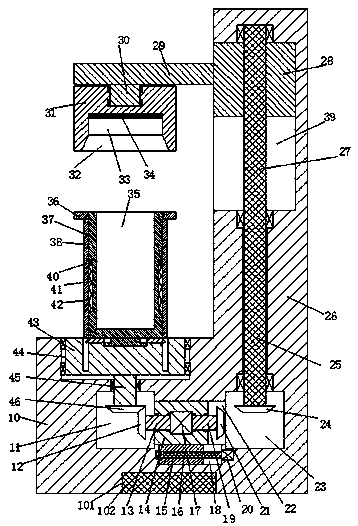

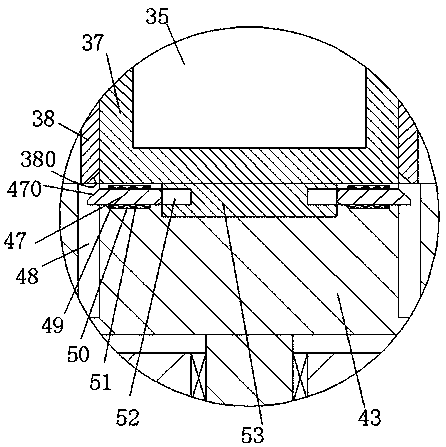

Lithium battery electrolyte cold recovery filter device

ActiveCN109585964APrevent from bringing upWon't pop upWaste accumulators reclaimingStationary filtering element filtersHydraulic cylinderElectrolysis

The invention discloses a lithium battery electrolyte cold recovery filter device. The device comprises a hydraulic cylinder, a chassis, an upper filter plate, a partition plate, a pressure head and acollecting vehicle, the chassis comprises a crushing box and a freezing box, the pressure head is arranged at the upper side of the internal portion of the crushing box, the hydraulic cylinder is arranged at the upper end of the crushing box, the flexible end of the hydraulic cylinder is connected with the pressure head, puncture needles are uniformly arranged at the lower end face of the pressure head, the upper filter plate and the lower filter plate are both provided with jacks which are aligned up and down, the jacks are matched with the puncture needles, the side wall of the crushing boxis provided with a feed port, the upper portion of the feed port is provided with a locking member, the lower portion of the feed port is provided with an unlocking member, the lower portion of the lower filter plate is provided with the collecting vehicle, a sliding rod and a screw rod are arranged between the crushing box and the freezing box, the lower end of the collecting vehicle is connected with the sliding rod and the screw rod, the outer side of the freezing box is provided with a motor, and the partition plate is arranged between the crushing box and the freezing box.

Owner:贵州中伟资源循环产业发展有限公司

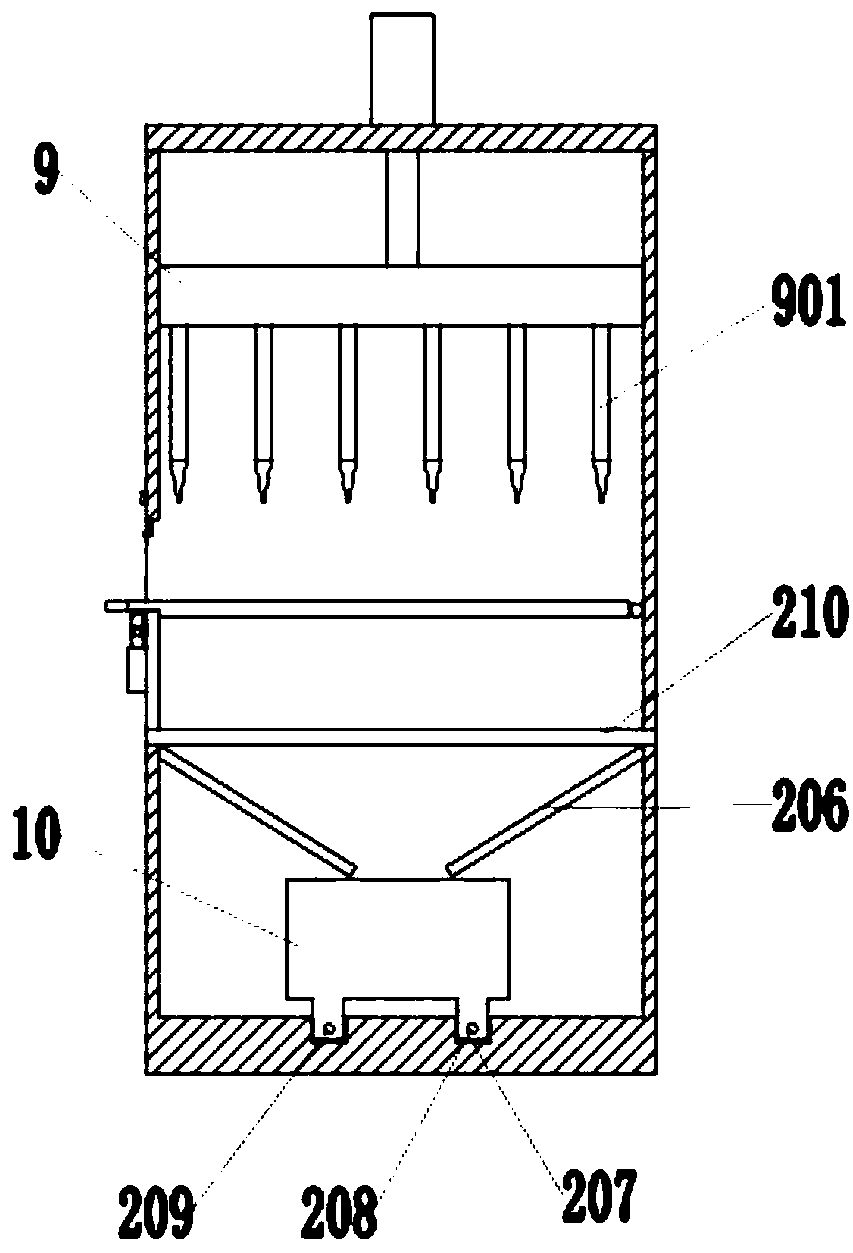

Impact type inertial dust collector for environmental engineer air pollution control

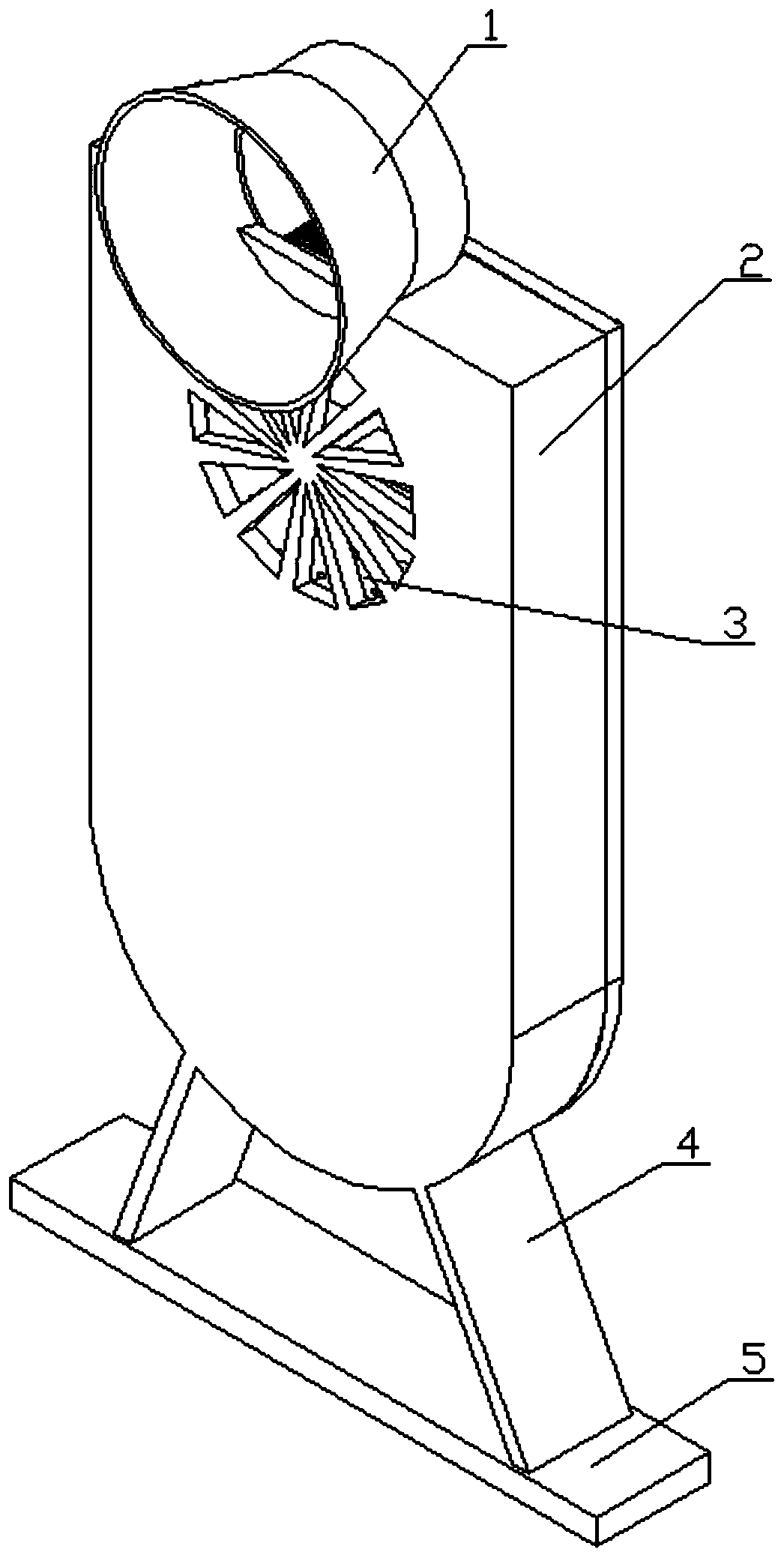

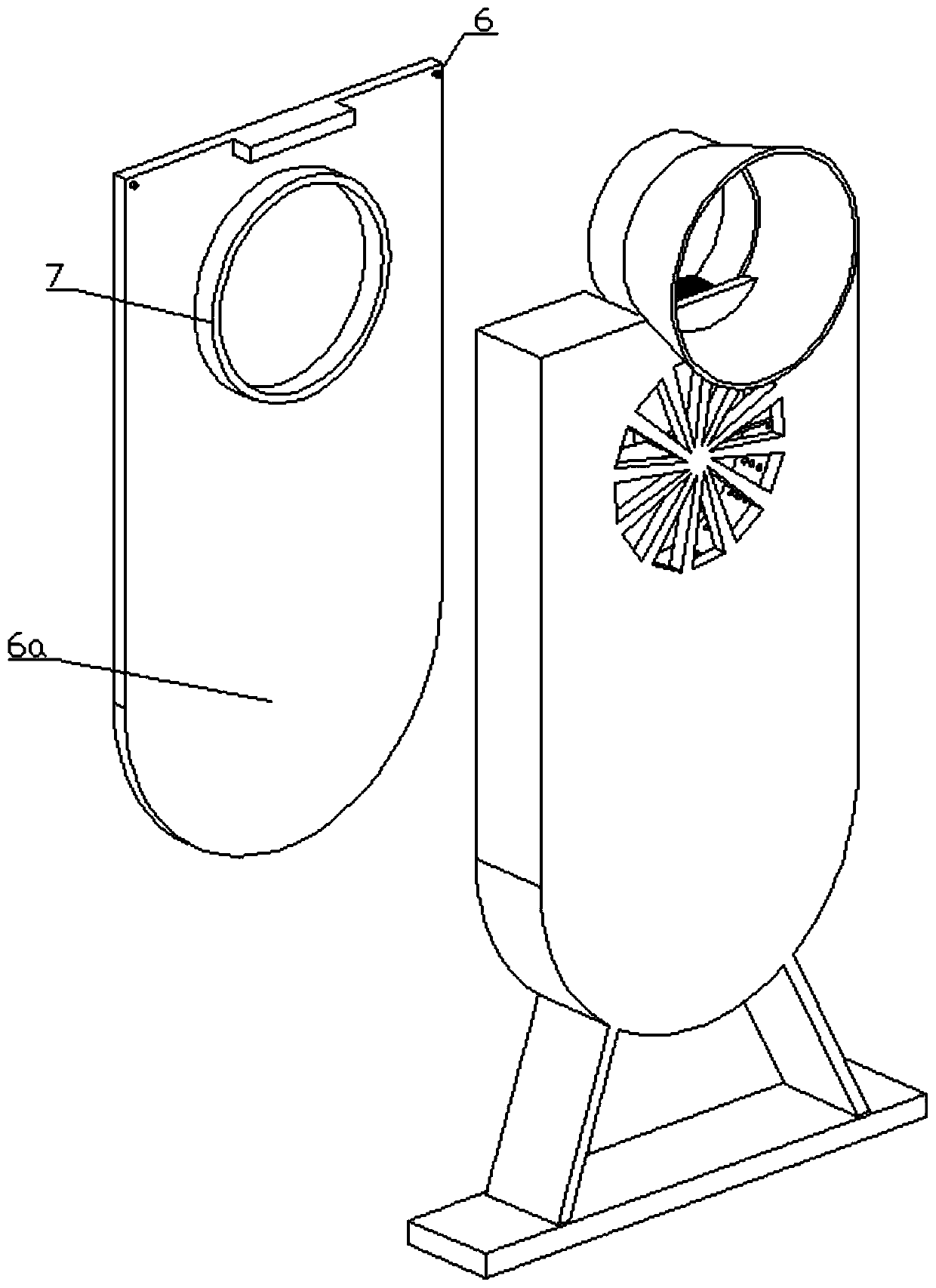

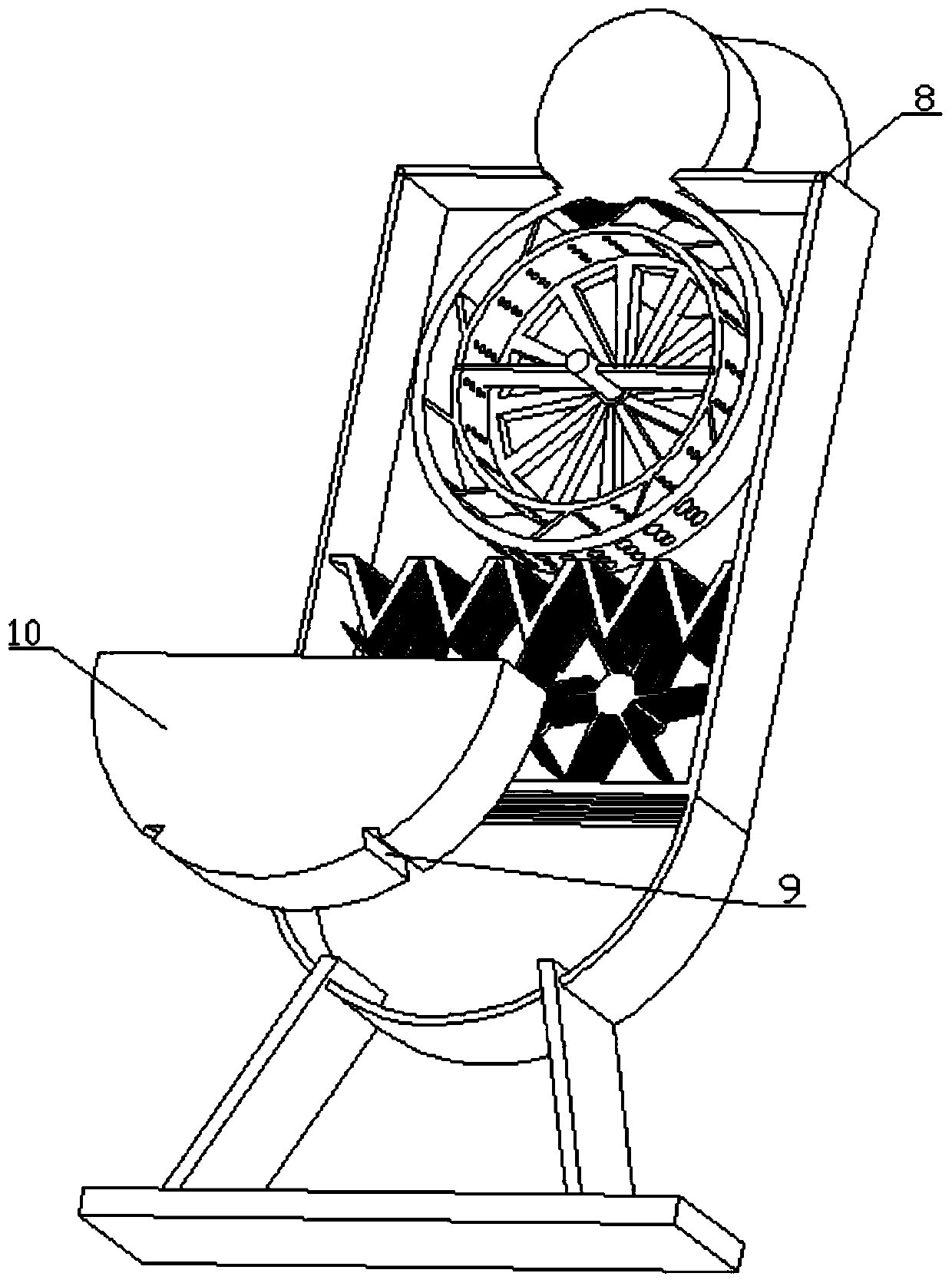

InactiveCN110090496AExtended service lifePrevent from bringing upCombination devicesEngineeringAir pollution

The invention disclose an impact type inertial dust collector for environmental engineering air pollution control, the impact type inertial dust collector comprise a base, and the base is characterized in the two ends on the upper side of the base are respectively fixedly connected with incline supporting rods, the two supporting rods are respectively fixedly connected with the lower side of a shell, the two supporting rods respectively penetrate through the lower side of the shell, threaded holes are respectively arranged at two ends on the upper part of one opening of the shell, and bolts respectively penetrate through the two ends on the upper side of a side plate and are in threaded connection with the corresponding threaded holes. The invention relates to the field of impact dust remover equipment, in particular to the impact type inertial dust collector for environmental engineer air pollution control. The impact type inertial dust collector for environmental engineer air pollution control can purify dust in the air.

Owner:SHANDONG VOCATIONAL COLLEGE OF IND

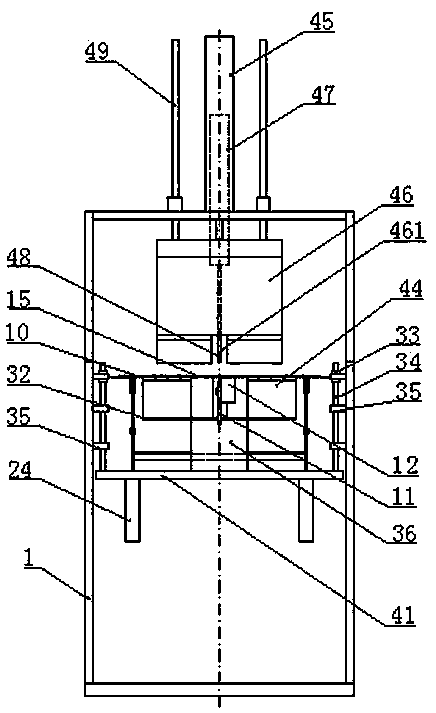

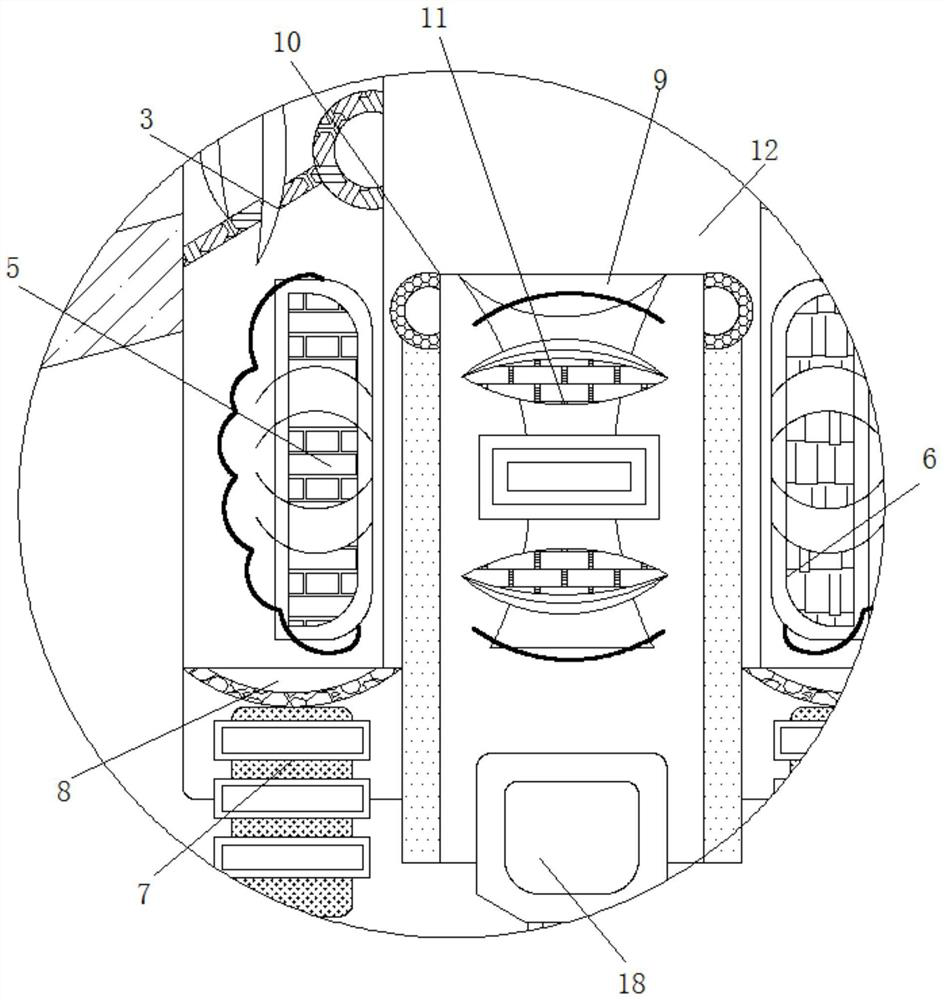

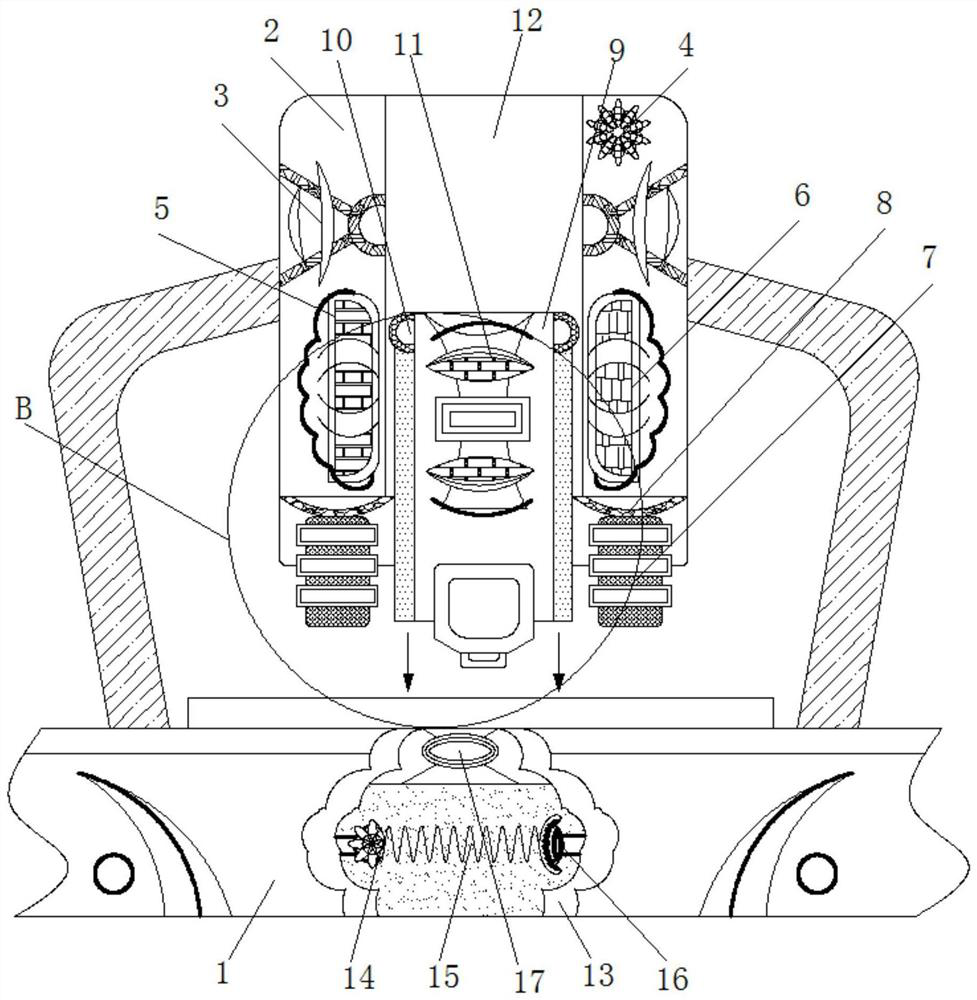

Micro-droplet generating device

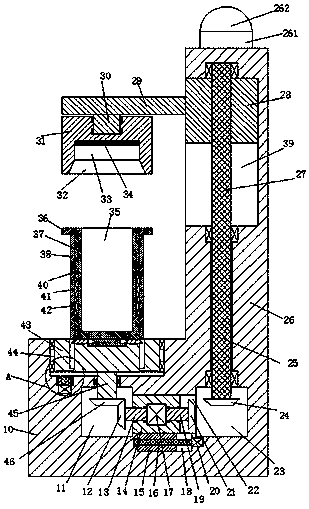

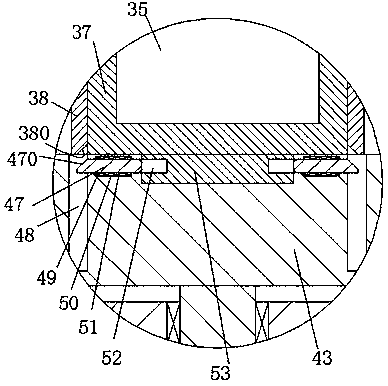

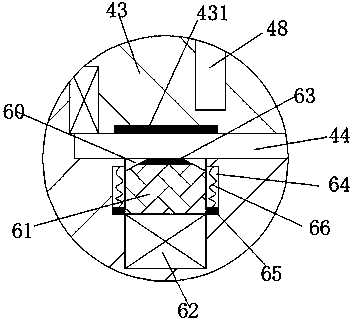

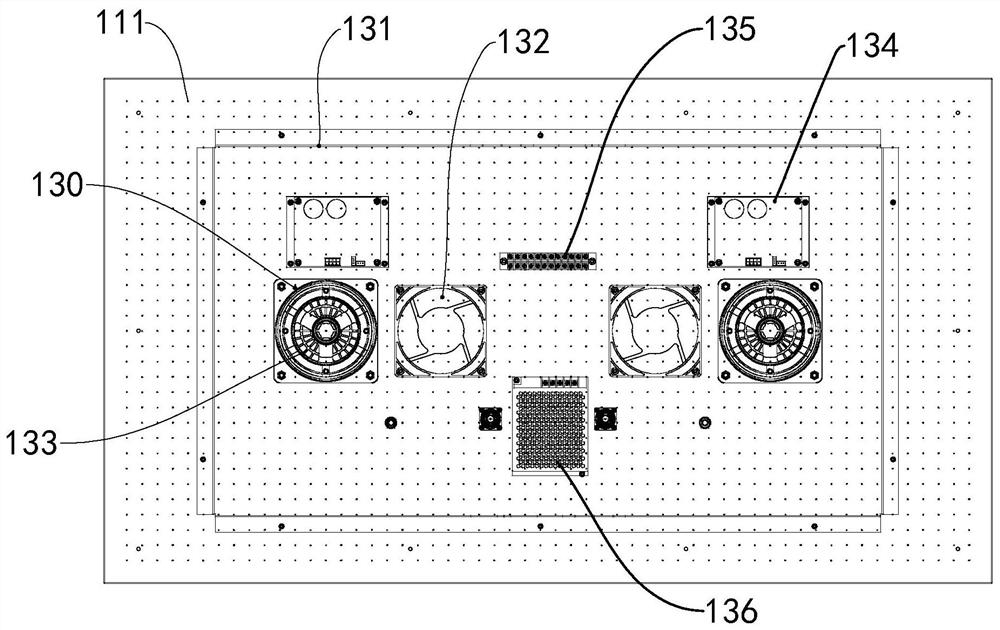

PendingCN112795464AAvoid generatingPrevent from bringing upBioreactor/fermenter combinationsBiological substance pretreatmentsPhysicsChipset

The invention provides a micro-droplet generating device. The micro-droplet generating device comprises a chip assembly, a pressing mechanism and a first driving mechanism, wherein the first driving mechanism drives the pressing mechanism to move in the vertical direction; the pressing mechanism comprises a puncture needle, a chip pressing plate, a first elastic piece and a second elastic piece; when the chip assembly moves to the position under the pressing mechanism, the pressing mechanism is pressed downwards, and air is communicated through the puncture needle to guide the air pressure into the chip assembly so as to generate micro-droplets. In the downward pressing process of the pressing mechanism, the pressing mechanism is firstly driven by the first driving mechanism, and then the pressing mechanism is driven by the elastic force applied by the first elastic piece to press the chip assembly, so that the functions of puncturing a silica gel film and pressing the microdroplet generation card are realized, and the microdroplet generation card can be protected from being crushed by rigid impact; in the process that the pressing mechanism leaves the chip assembly, the second elastic piece applies reverse elastic force to the chip pressing plate, and in the process that the puncture needle leaves the silica gel film, the chip pressing plate downwards presses the chip assembly, so that the microdroplet generation card is prevented from being taken up.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

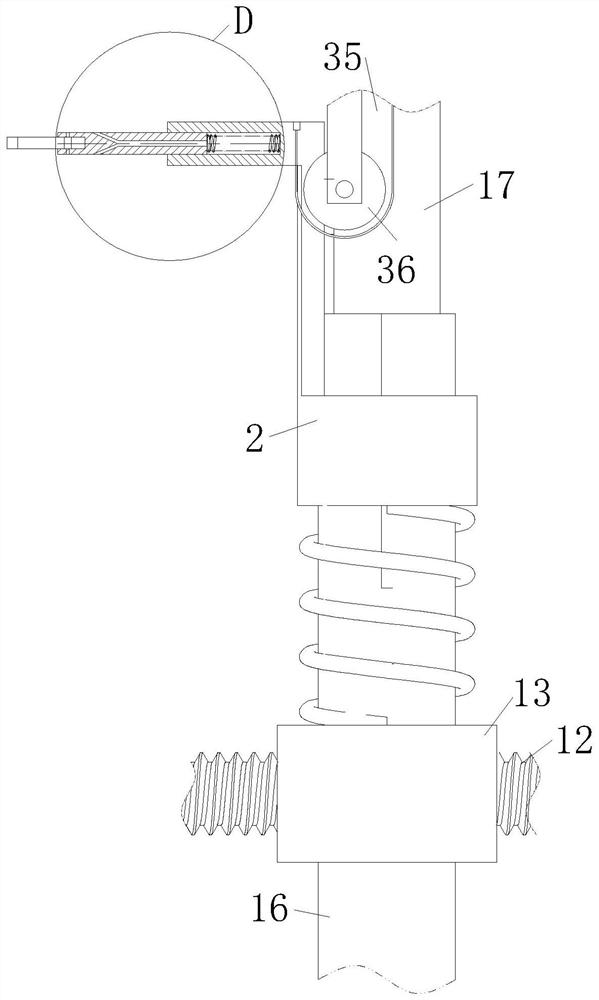

Small carton packing machine

ActiveCN111674601AImprove packaging efficiencyImprove protectionPaper article packagingPaper recyclingCartonScrew thread

The present invention belongs to the technical field of carton packing machines, particularly to a small carton packing machine. The small carton packing machine comprises a frame, and a conveying apparatus for conveying corner protection papers; a screw rod is rotatably connected to the frame at the middle of the conveying apparatus; a forward thread and a reverse thread are provided at both endsof the screw rod, respectively; a pair of slide blocks sleeves the screw rod; the slide blocks are in threaded connection to the screw rod; a cylinder is fixedly connected to the slide blocks, and isconnected with a high-pressure air source by means a controller and a pipe; a pressing rod is provided at the top of a piston rod of the cylinder; a slide ring is slidably connected to the outer periphery of the cylinder at the tops of the slide blocks; a limiting groove is formed in the outer periphery of the cylinder; the position, corresponding to the limiting groove, of the slide ring is fixedly connected to a limiting block; a slide cylinder is fixedly connected to the top of the slide ring by means of a bracket; a slide rod is slidably connected into the slide cylinder; and a spring isprovided between the slide rod and the bottom of the slide cylinder. In the present invention, the corner protection papers are ejected by the slide rod, so that the fall of the corner protection papers at the bottom is reduced, and the packing efficiency of the packing machine is further improved.

Owner:湖南景呈包装有限公司

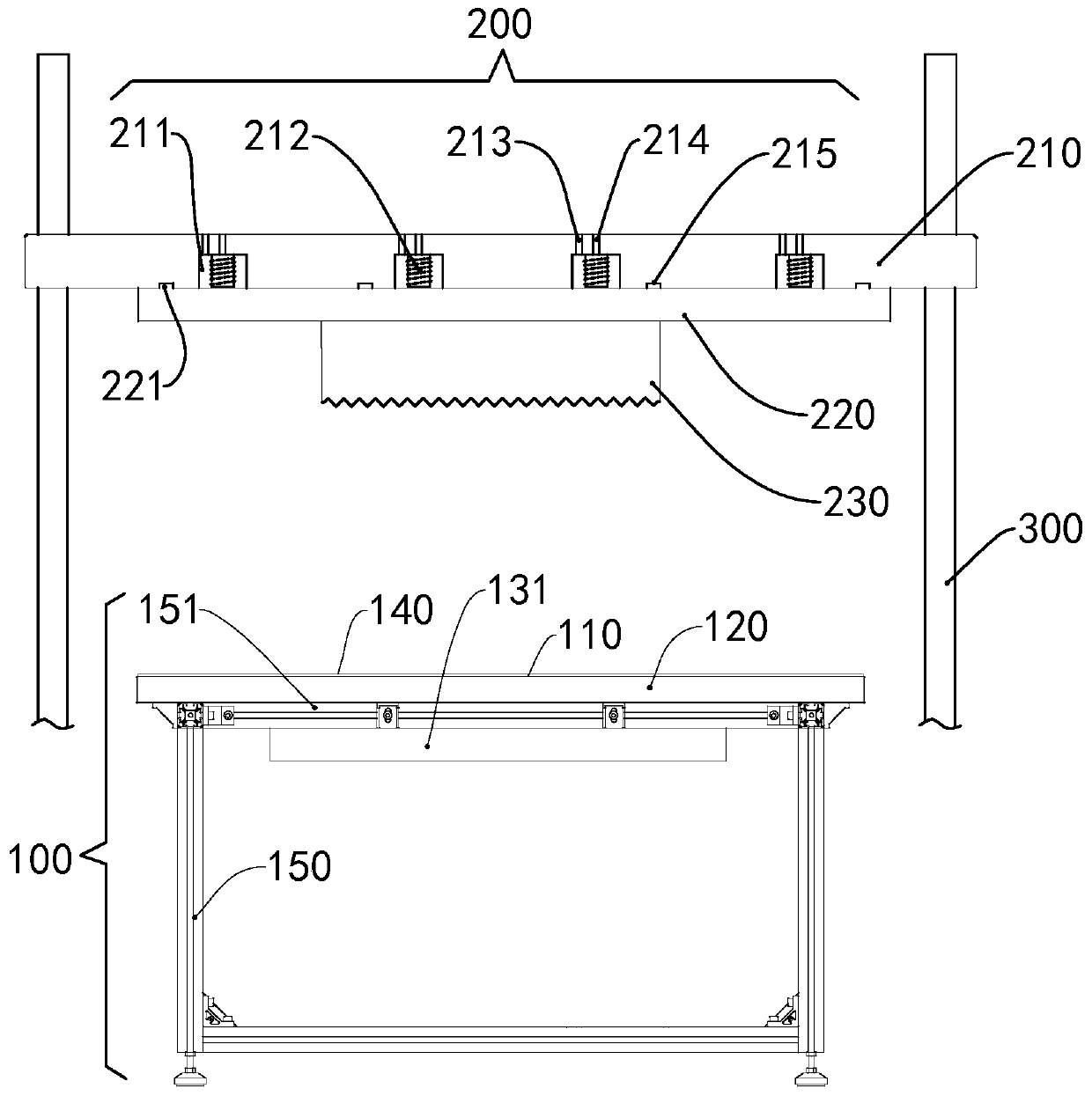

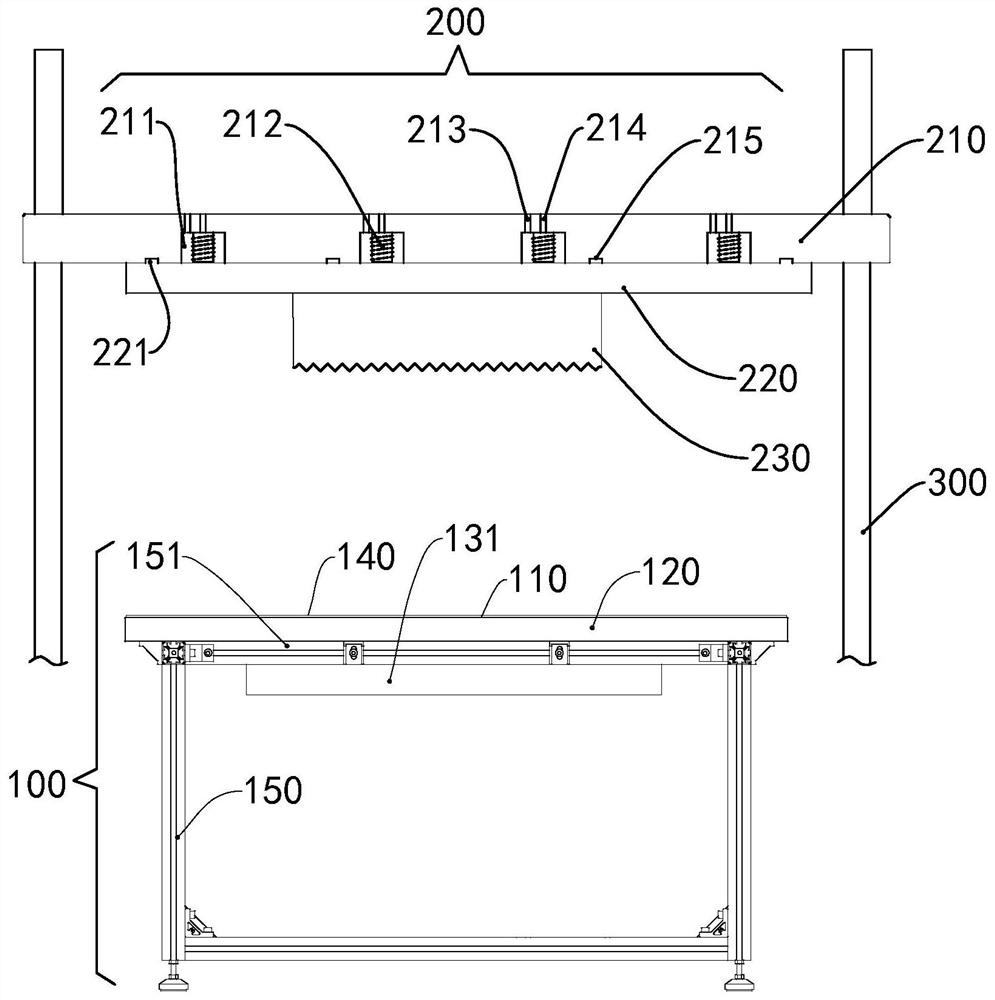

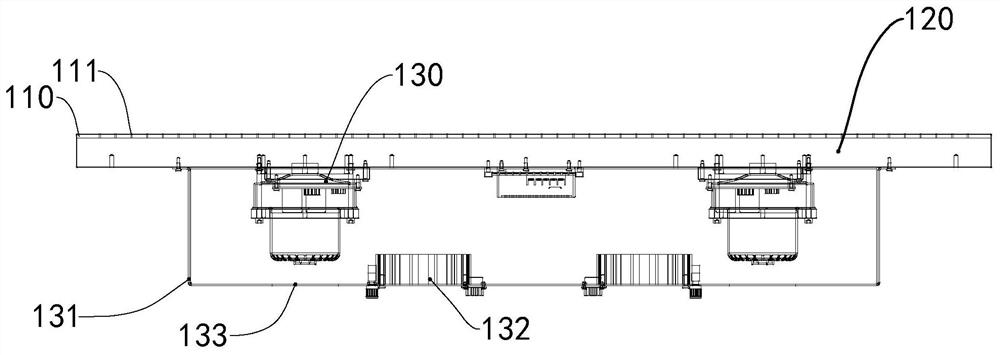

Light soft material blanking device

InactiveCN111571720APrevent from bringing upImprove positioning accuracyMetal working apparatusSoft materialsWorkbench

The invention relates to a light soft material blanking device which comprises a workbench and a cutting die above the workbench and capable of moving up and down relative to the workbench. The workbench comprises a tabletop plate and at least one air suction device. First air suction holes run through the tabletop plate. The air suction devices communicate with the first air suction holes. The cutting die comprises a positioning piece, an installing piece and a tool. The tool is connected with the installing piece. The positioning piece is connected with an electromagnet. By powering on or off the electromagnet, the installing piece is released or attracted. The positioning piece is provided with a first limiting part, and the installing piece is provided with a second limiting part. Thesecond limiting part is used in cooperation with the first limiting part for preventing the installing piece from moving relative to the positioning piece in at least one direction perpendicular to amagnetic attraction direction. The light soft material blanking device can prevent a light soft material from being taken up during cutting, the tool can be conveniently replaced, and production efficiency is improved.

Owner:丁卫兵

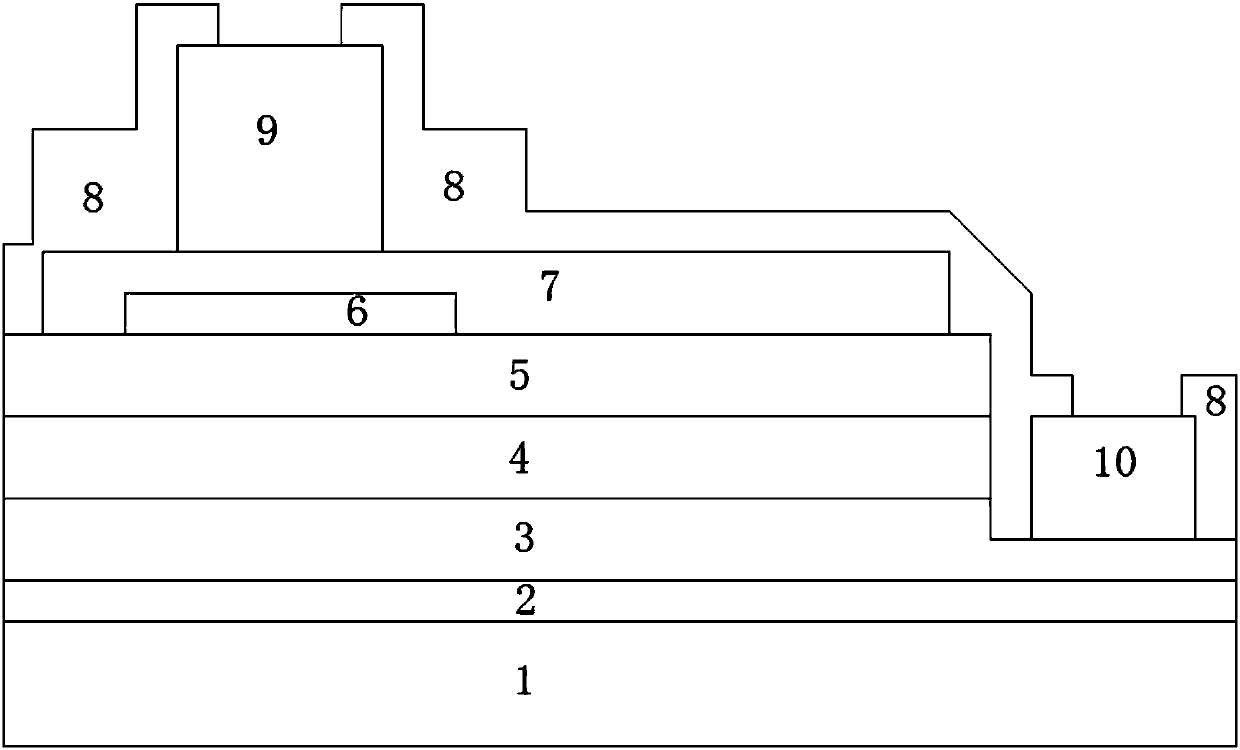

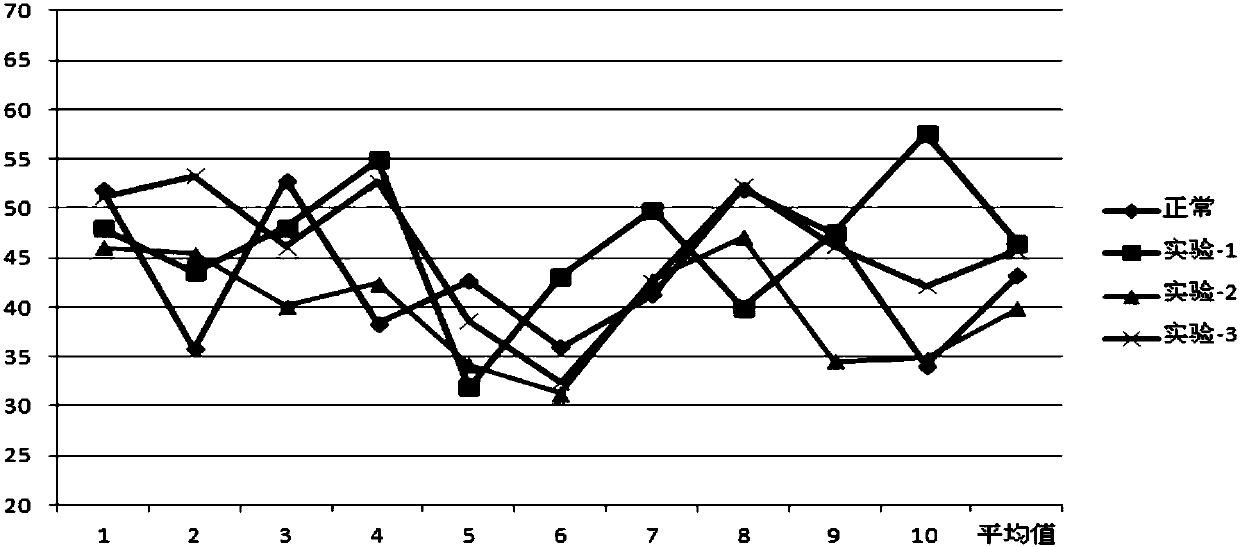

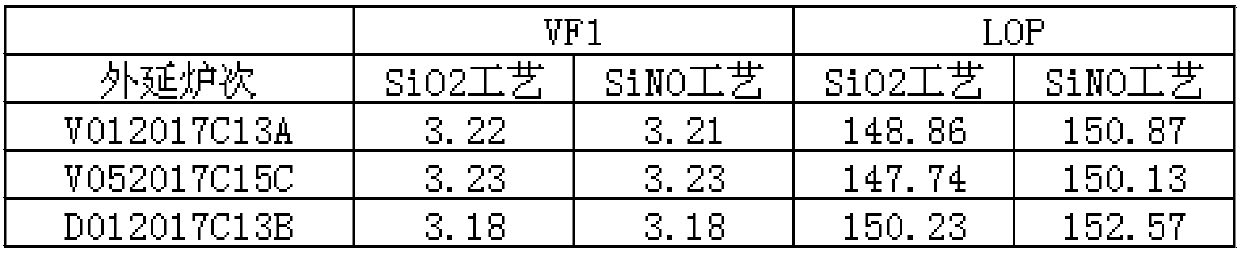

PV film layer for improving electrode ring adhesion and adhesion improvement method

InactiveCN108321276AGuard electrodeImprove the drop problemSemiconductor devicesSolder ballOptoelectronics

The invention provides a PV film layer for improving electrode ring adhesion and an electrode ring adhesion improvement method. The PV film layer is characterized in that a SiNO thin film layer is deposited outside the ITO ring of an epitaxial wafer and is taken as a transparent insulating layer. The SiNO thin film layer can completely cover the external surface of an electrode, a crack phenomenonis not generated, the electrode is effectively protected, a solder ball is prevented from being picked up, and a probability for a PAD to fall off on the ITO ring during heating is reduced.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

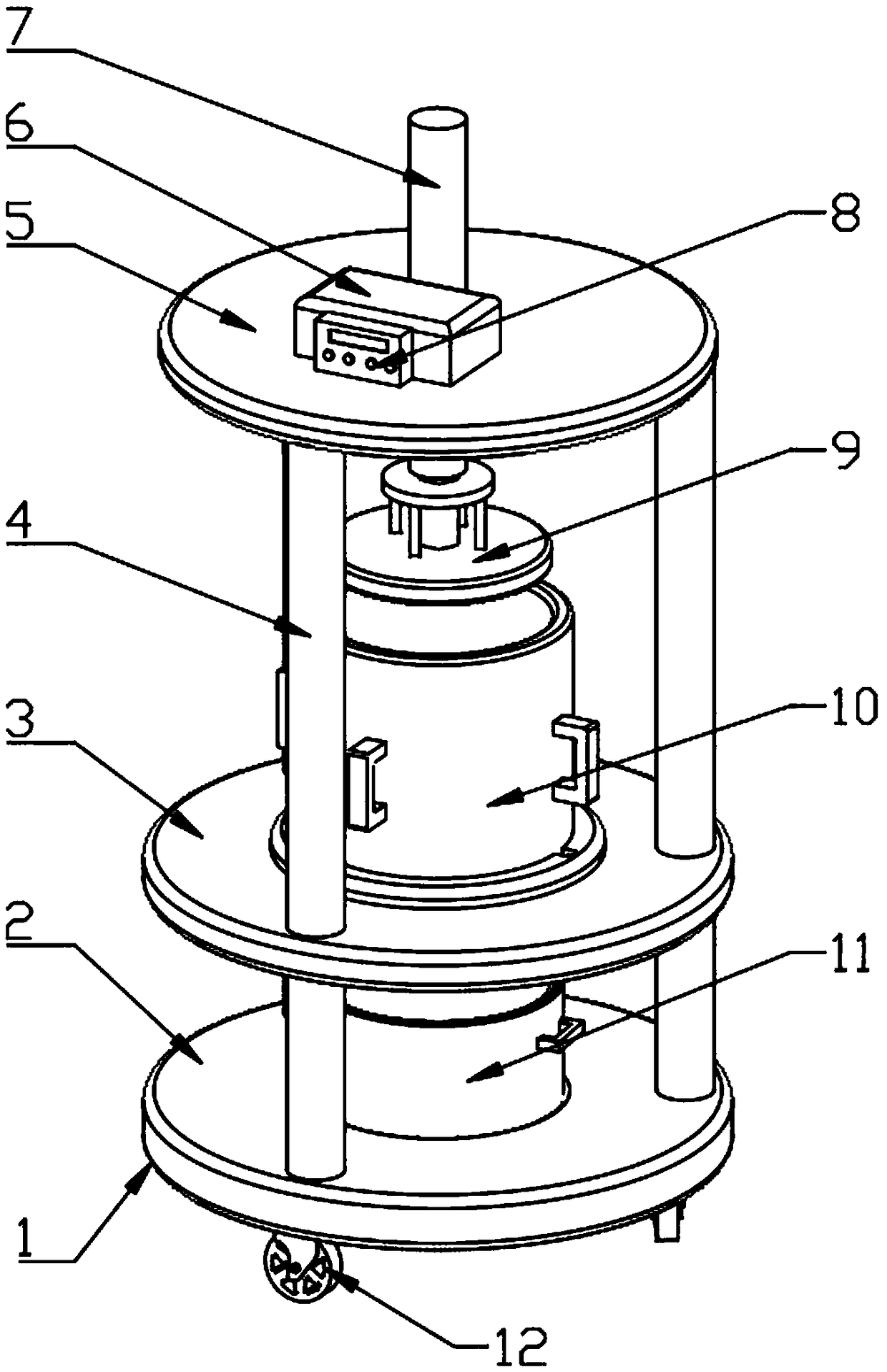

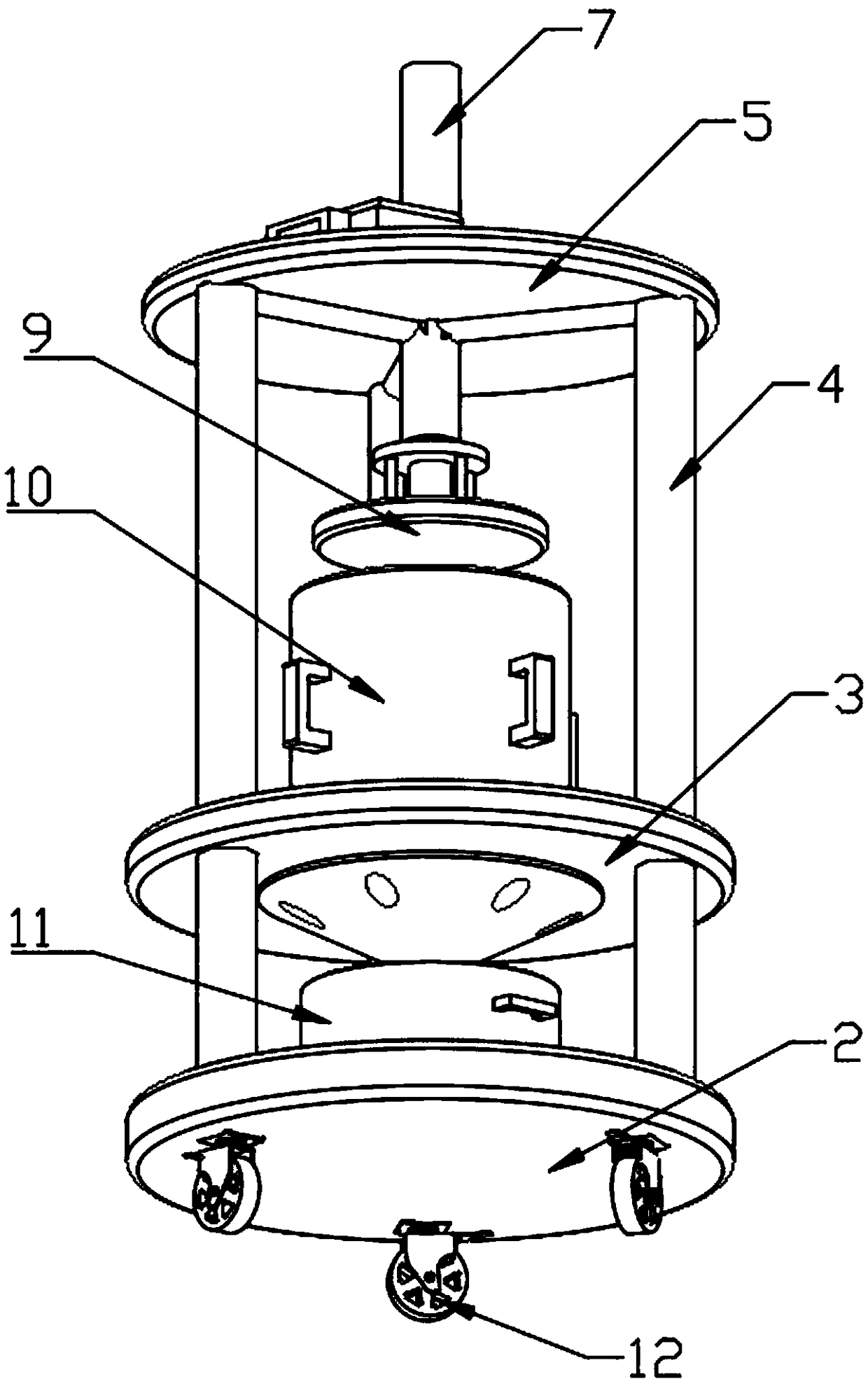

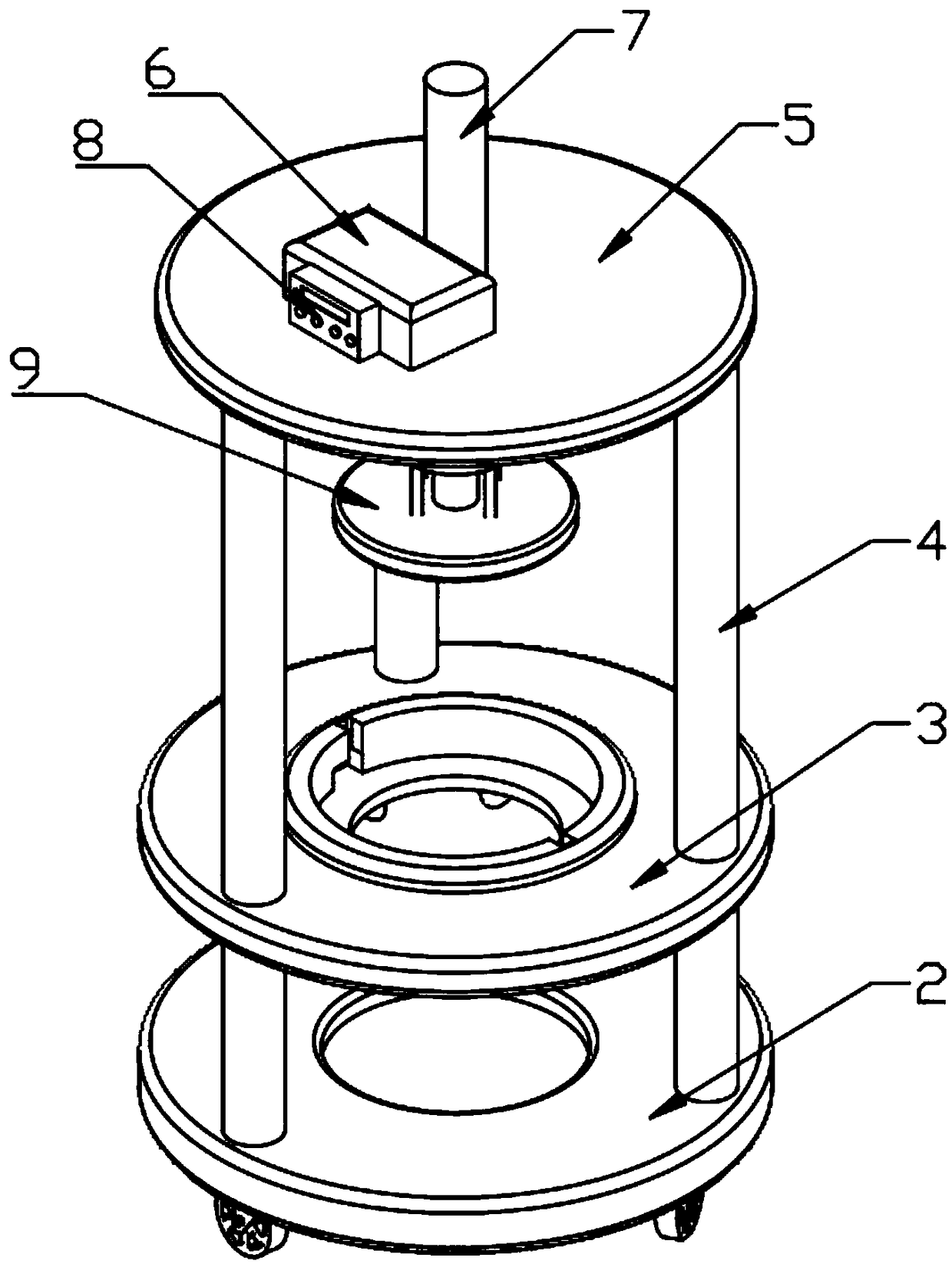

Basket pressing device for food processing

ActiveCN108790247AImprove placement stability and accuracyImprove placement accuracyPressesEngineeringMechanical engineering

The invention provides a basket pressing device for food processing. The device comprises limiting grooves, a pressing cylinder and a liquid holding cylinder; three movable wheels are symmetrically arranged on the bottom side of a fixed base plate; the liquid holding cylinder is arranged in the middle position of the upper side of the fixed base plate; a middle fixed plate is arranged on the upperside of the fixed base plate; the pressing cylinder is clamped and mounted on the upper side of the middle fixed plate; a top fixed plate is arranged on the upper side of the pressing cylinder; a pneumatic hydraulic cylinder is loosely mounted in the middle position of the top fixed plate by a bolt; a pressing plate is fixedly mounted on the bottom side of the pneumatic hydraulic cylinder; and anair pump is mounted at the top end of the top fixed plate. The basket pressing device for food processing is symmetrically provided with two L-shaped limiting grooves on the inner side wall with a pressing cylinder fixed groove; and the limiting grooves are convenient to fix the pressing cylinder in the pressing cylinder fixed groove, so that the phenomenon of incapability of pulling up caused bytaking of the pressing cylinder during ascending of the pressing plate is prevented.

Owner:ANHUI TIANHE FOOD

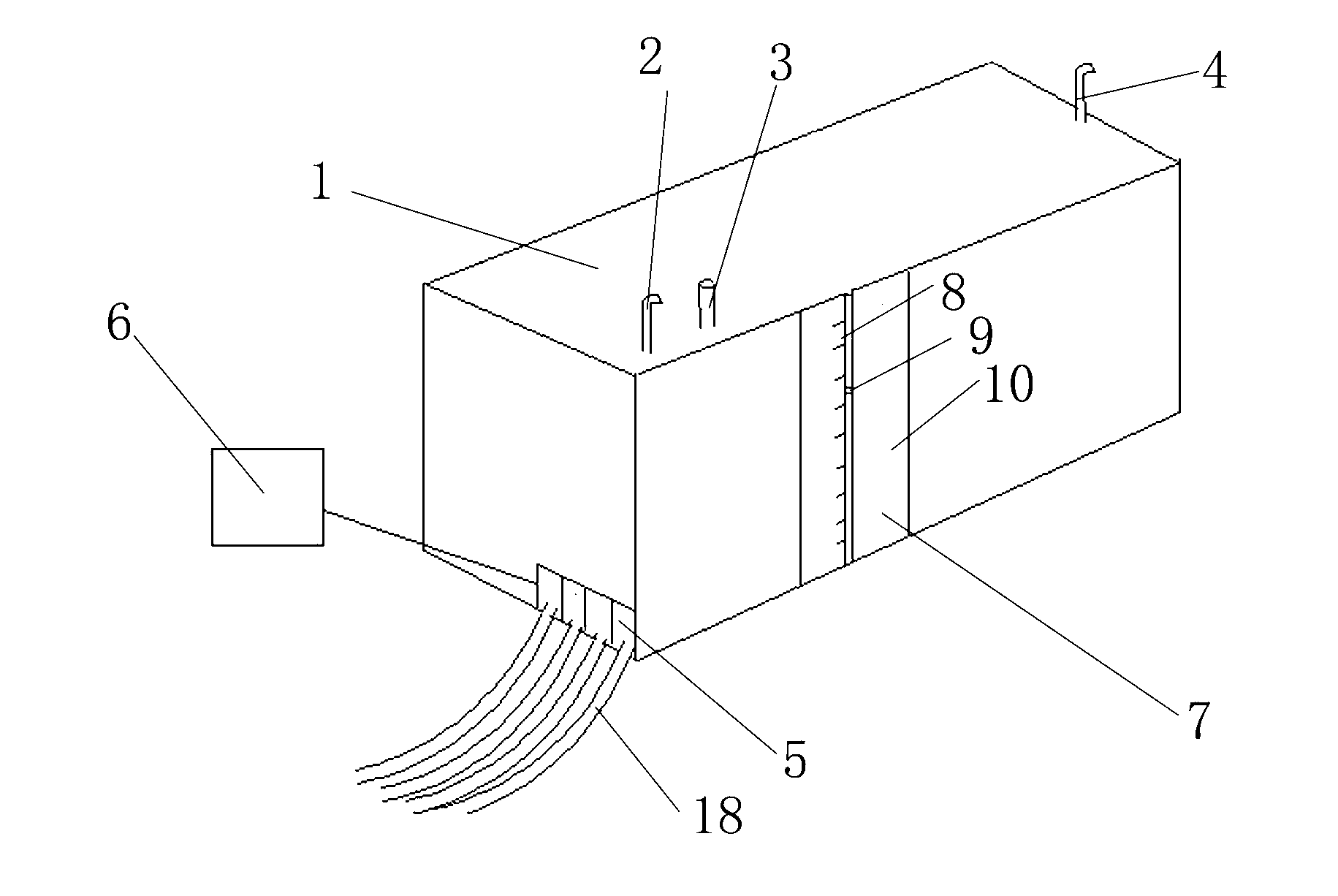

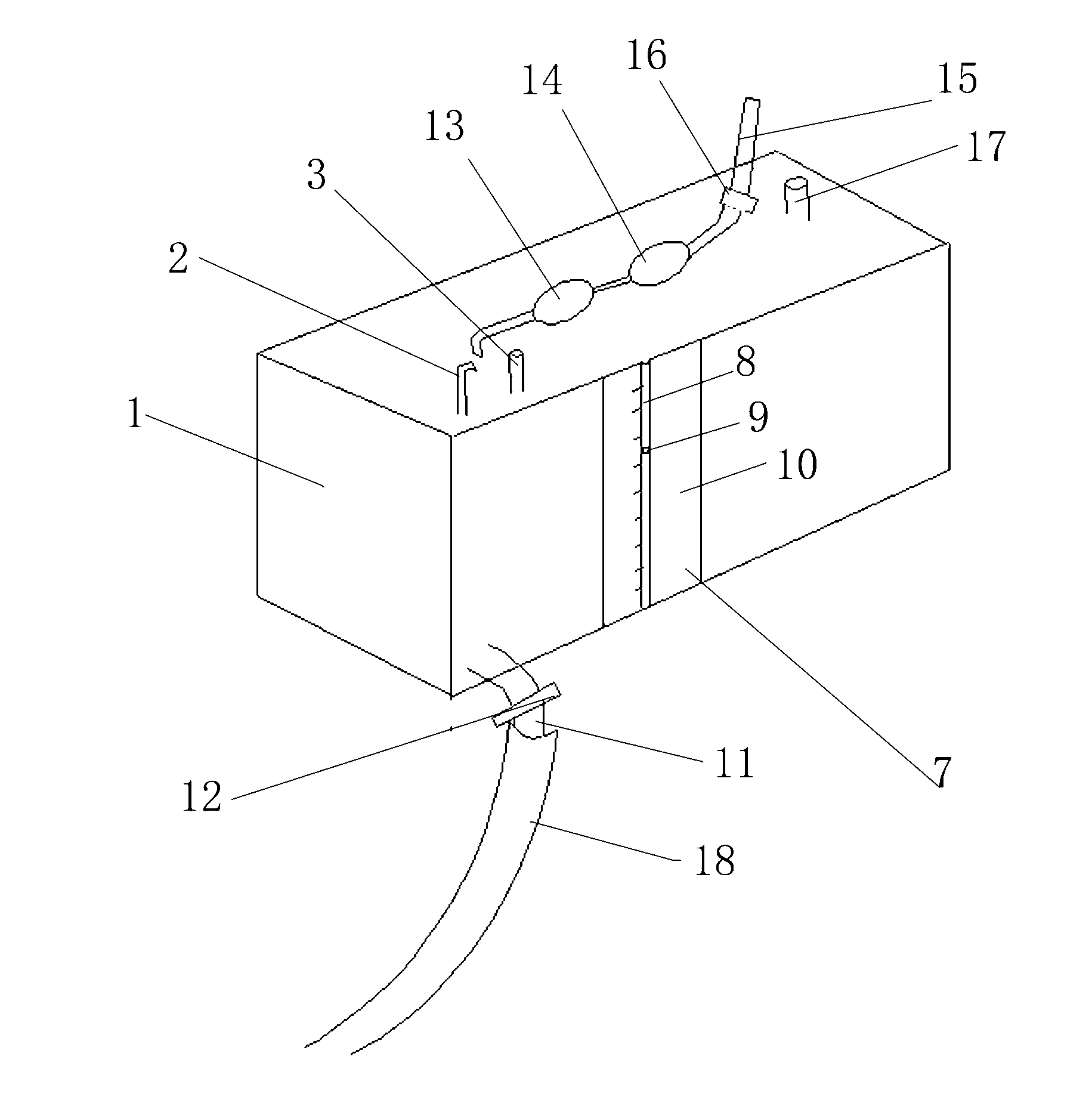

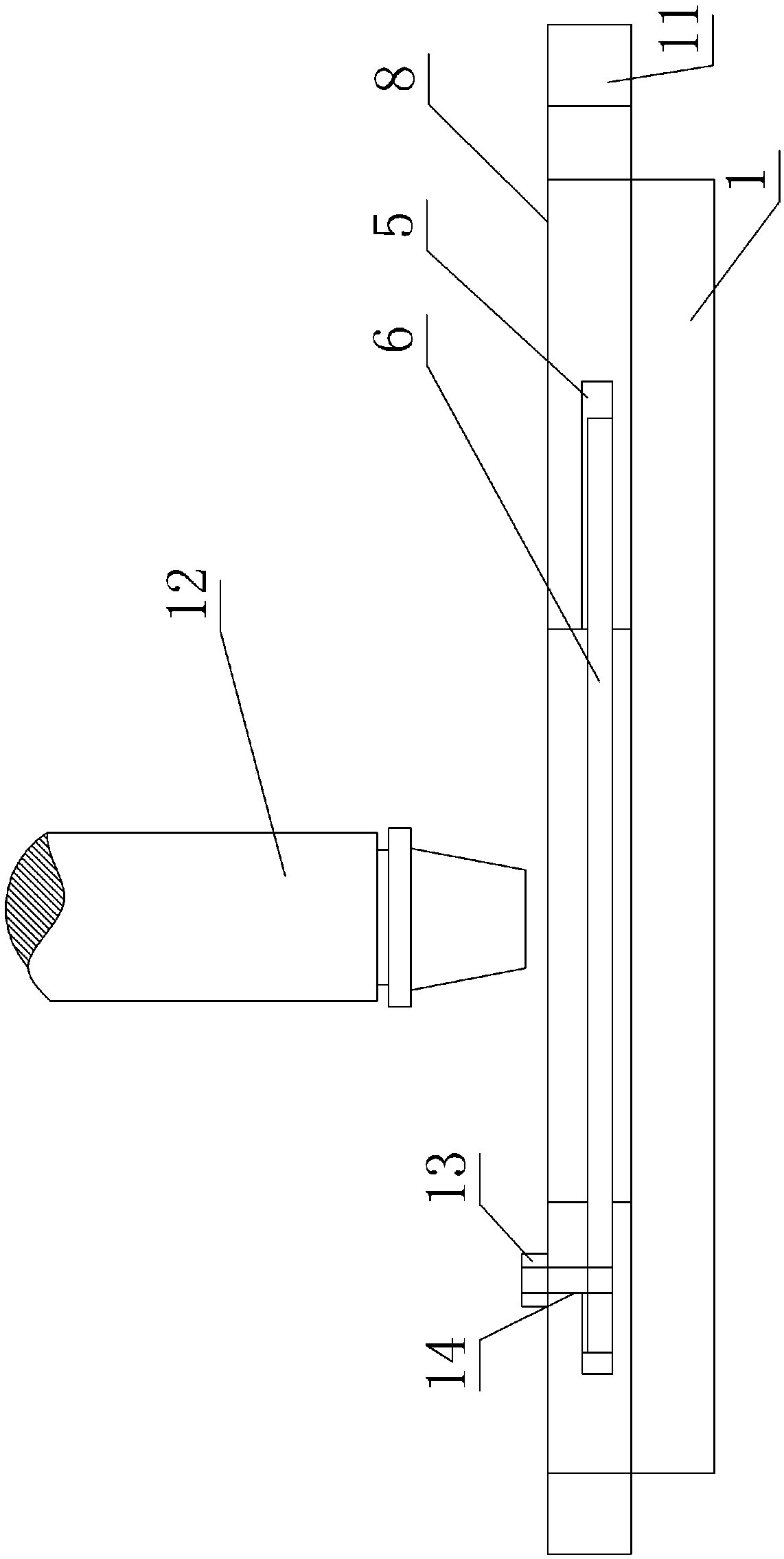

Dustproof system for automobile

InactiveCN102849036APrevent from bringing upSolve the problem of dust removalVehicle cleaningRoad surfaceWaste management

The invention discloses a dustproof system for an automobile. The dustproof system comprises a water tank (1), a water feeding pipe (2) and a ventilation pipe (3), wherein the water tank (1) is hung on a girder of the automobile or is erected in front of a carriage; water in the water tank (1) is guided and sprayed on tire through a pipeline; the pipeline comprises a hose arranged along the girder and a hard pipe arranged on a front axle, an intermediate axle or a rear axle of the automobile; spray heads are arranged on hard pipes; the hose is connected with the hard pipe; and a metering device (7) is arranged on one side of the water tank (1) and is used for indicating the weight of residual water in the water tank (1). According to the dustproof system of the automobile, which is disclosed by the invention, the water is sprayed on the tire, so that the dust caused by the tire is prevented, the problem in dust removal in a factory area, a harbor area and a mine area can be effectively solved, the dust can be reduced by 80-90 percent and the pavement temperature can be reduced by 2-5 degrees.

Owner:邱万

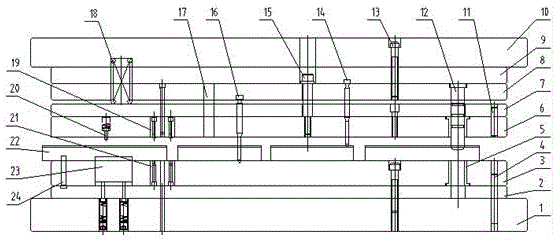

C-shaped pole shoe one-die eight-element continuous manufacturing method and continuous die

PendingCN106270159AImprove productivityPromote safe productionShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a C-shaped pole shoe one-die eight-element continuous manufacturing method and a continuous die. Eight groups of convex hulls and through holes are stamped in a strip by means of convex hull stamping male die inserts, and then C-shaped pole shoes corresponding to the eight groups of convex hulls and through holes are subjected to blanking and die stripping sequentially through blanking female die inserts and special-shaped male dies in the strip moving process. The continuous die comprises a female die fixing plate, the convex hull stamping male die inserts and the eight blanking female die inserts different in shape are sequentially arranged on the female die fixing plate, and each convex hull stamping male die insert is provided with a convex hull stamping male die and a punching female die; an upper die base is arranged above the female die fixing plate, the special-shaped male dies corresponding to the blanking female die inserts and convex hull stamping female die inserts corresponding to the convex hull stamping male die inserts are arranged below the upper die base, and each convex hull stamping female die insert is provided with a convex hull stamping female die and a punching male die. The method and the continuous die have the advantages that production efficiency is high, machining time is short, and manpower resources are saved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

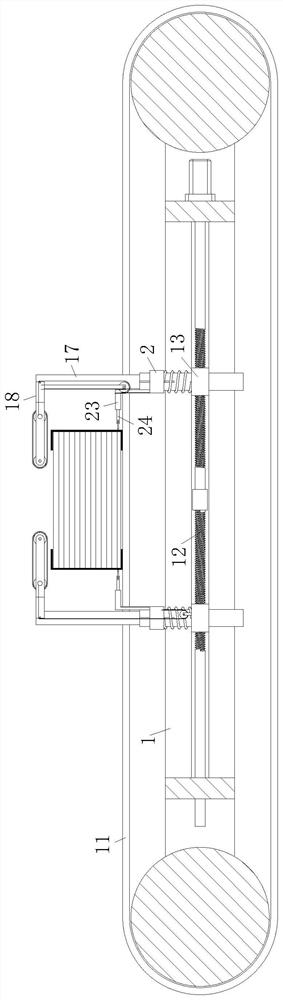

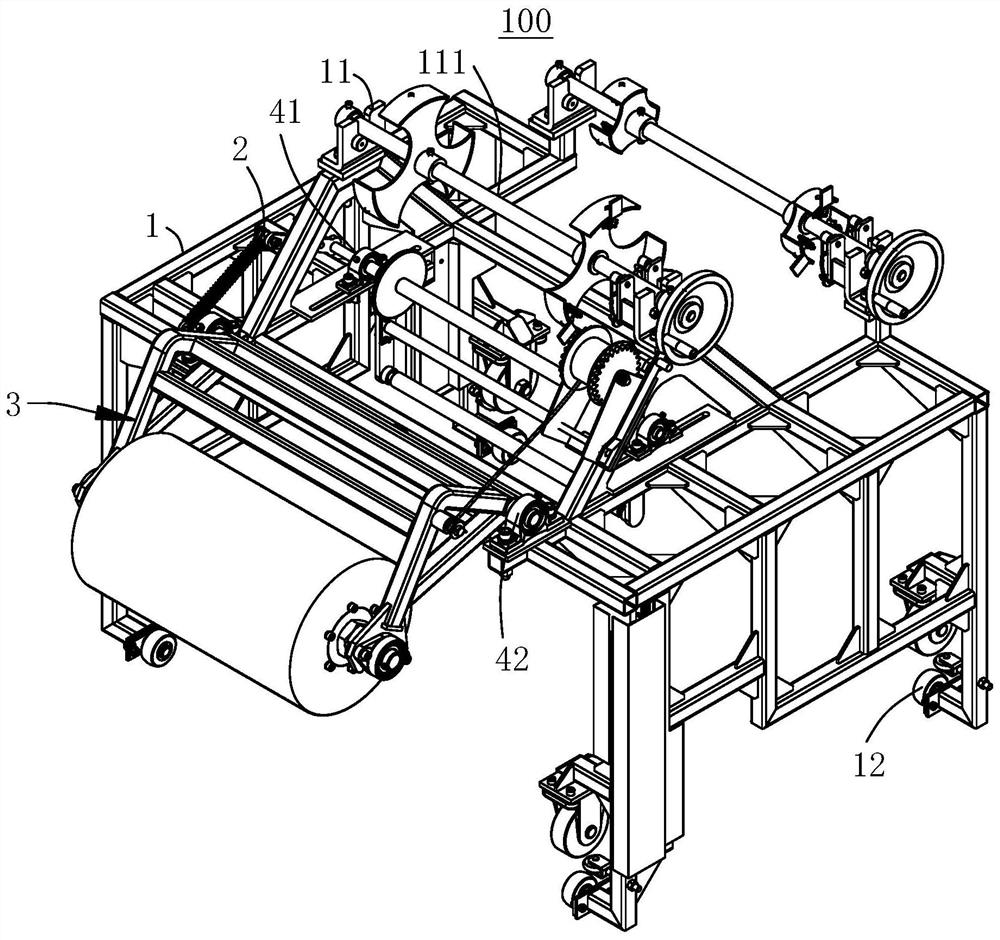

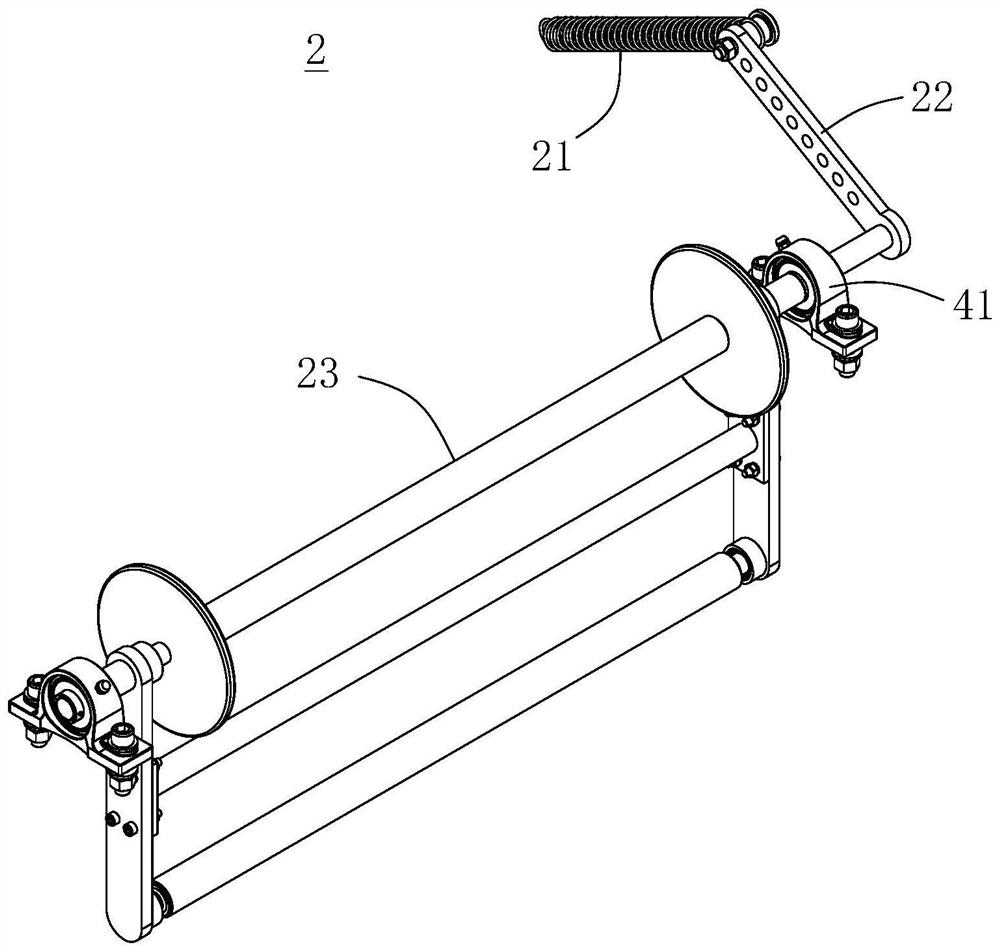

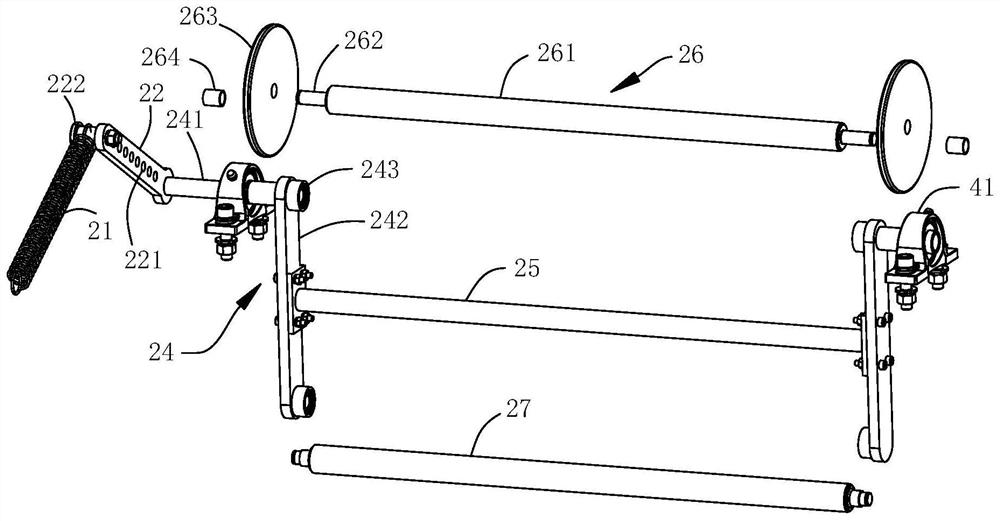

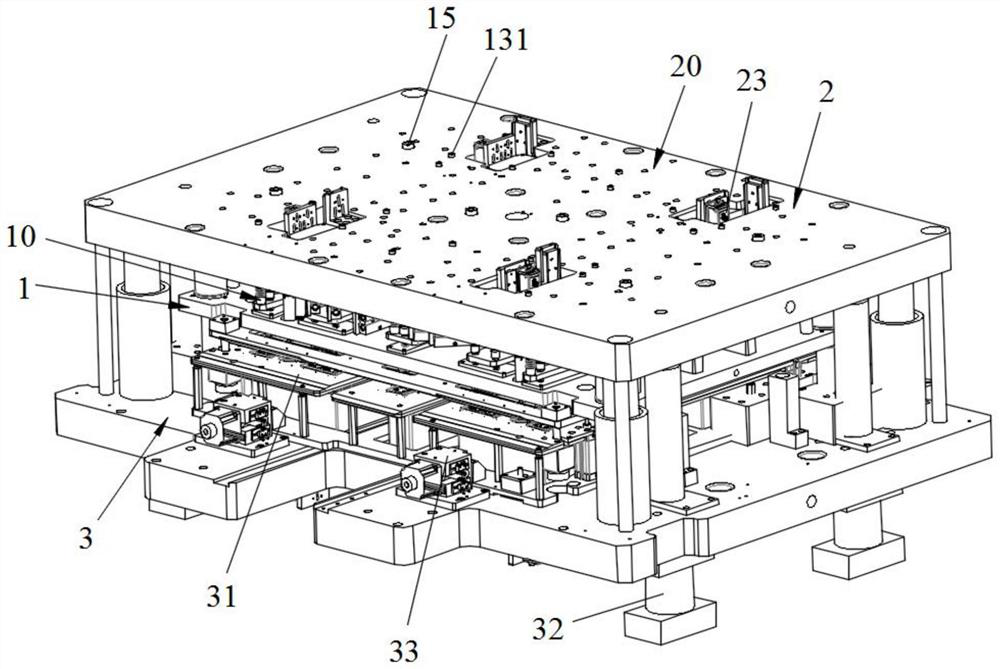

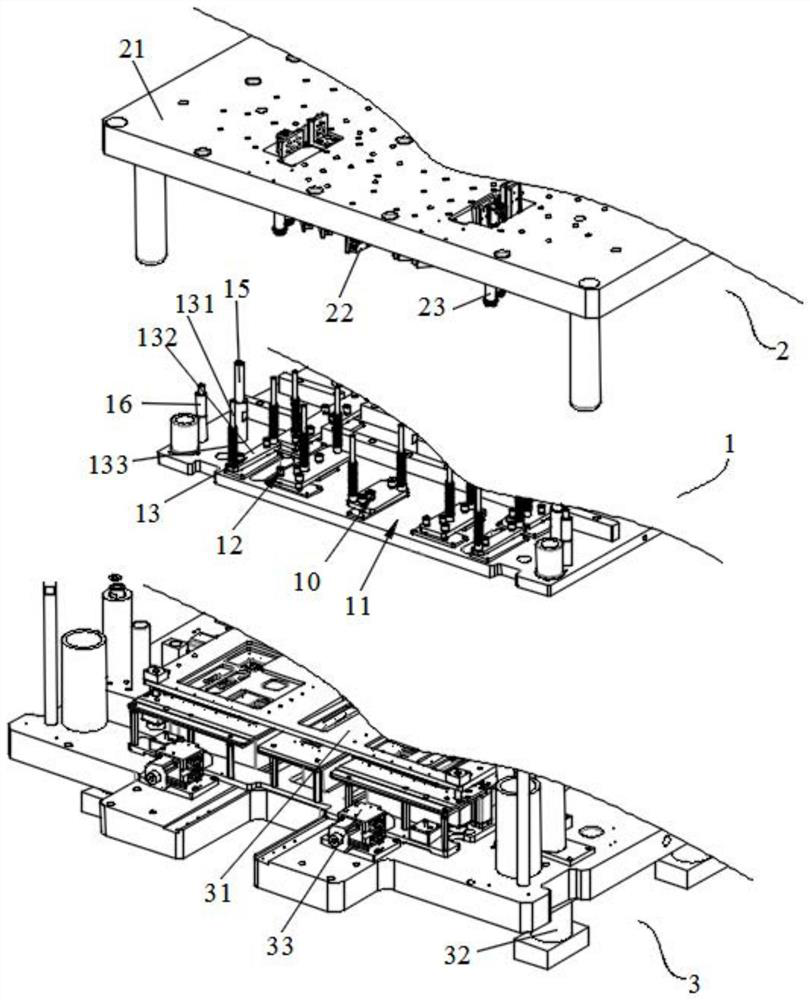

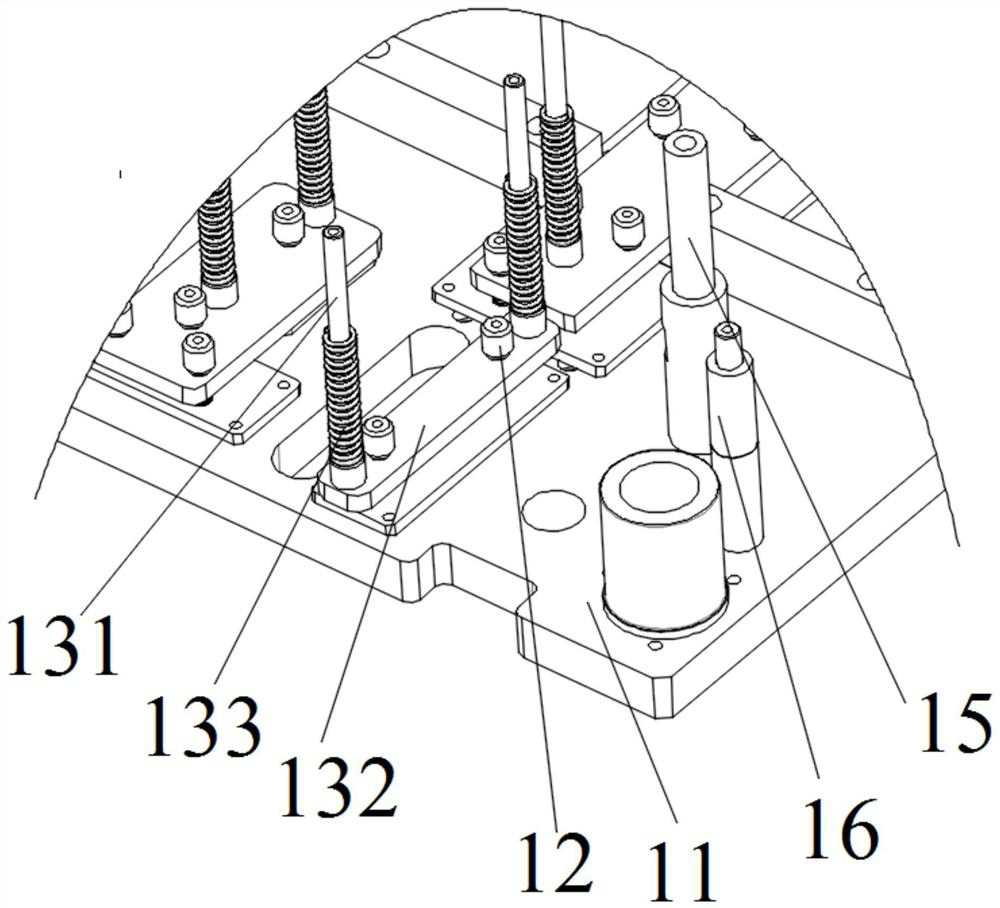

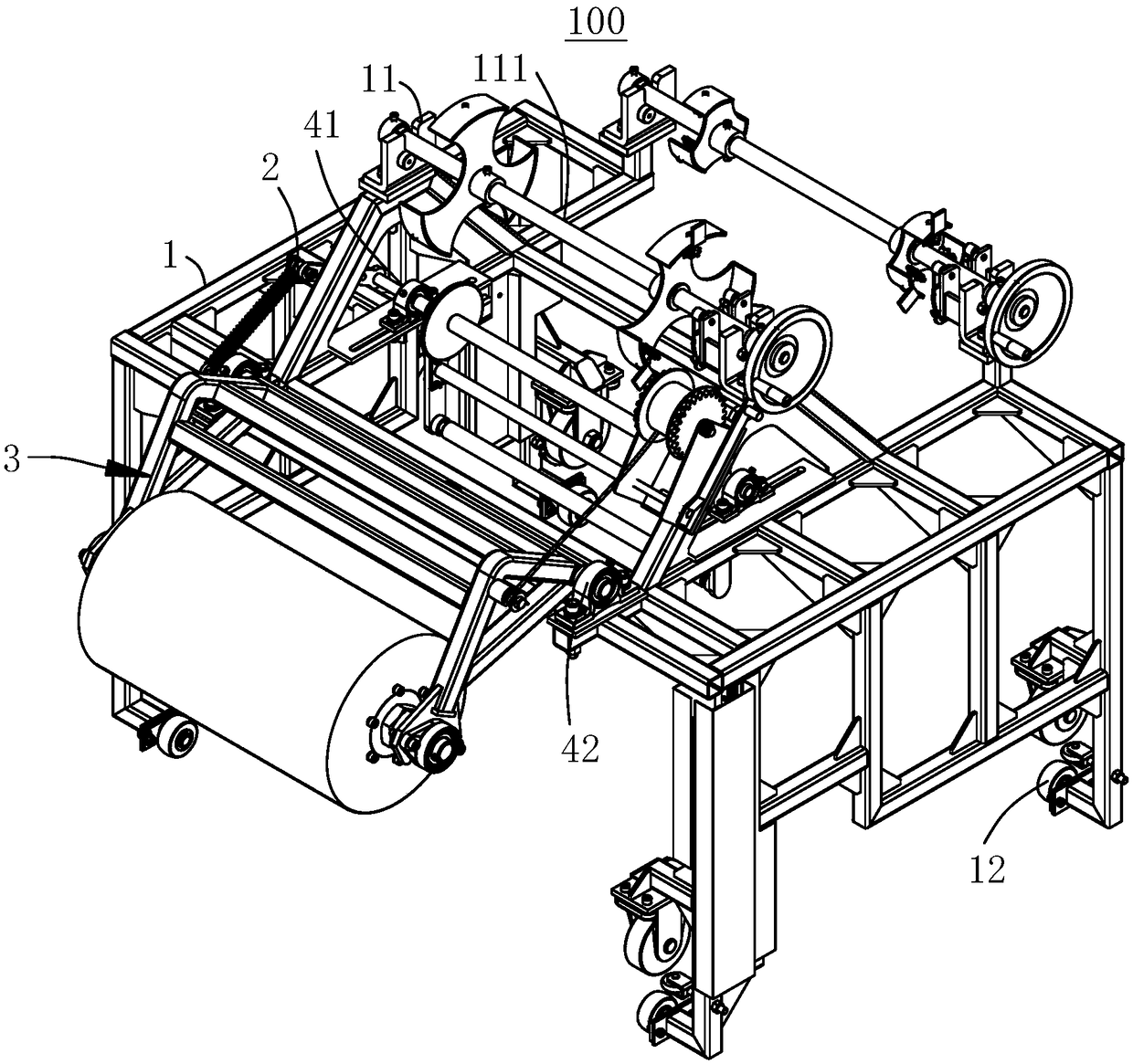

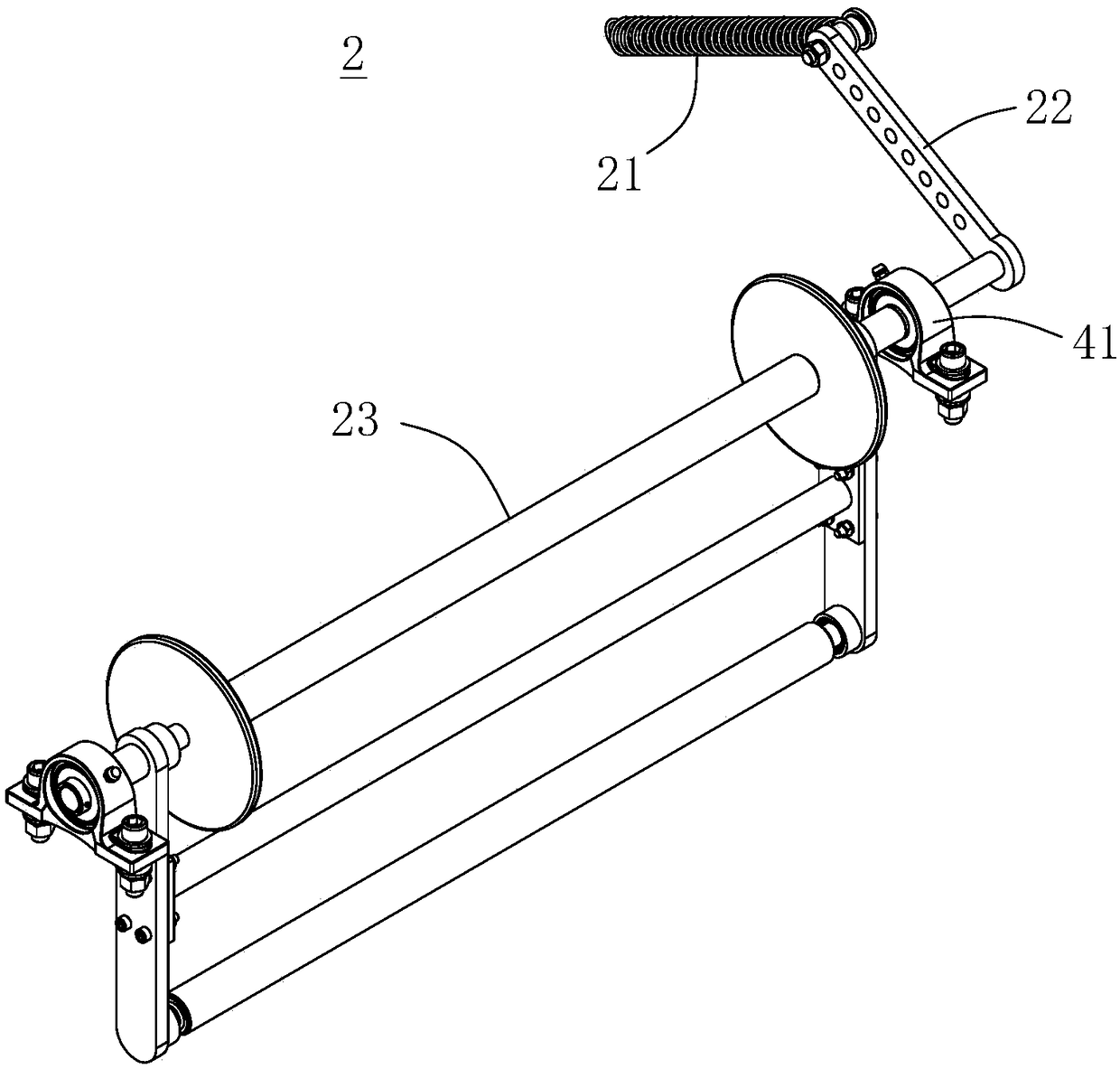

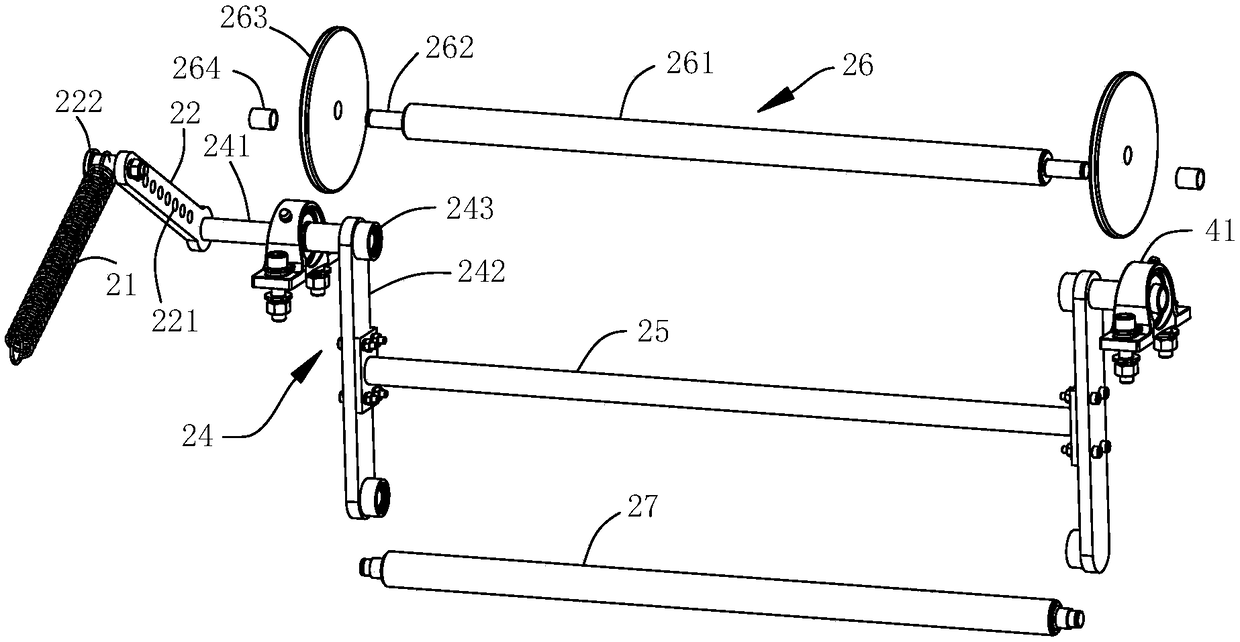

Blade beam cap spreading trolley

ActiveCN108584526BEasy tension adjustmentUniform spin tensionUnfolding thin materialsWebs handlingEngineeringStructural engineering

The invention relates to a blade beam cap laying trolley, and belongs to the technical field of laying trolleys. A tension spring is detachably connected with an adjusting swing arm, the adjusting swing arm is in transmission connection with a tension adjusting assembly, the tension adjusting assembly is rotatably connected with a frame, a cloth pressing roll swing frame is rotatably connected with the frame, a cloth pressing roll is rotatably connected with the cloth pressing roll swing frame, and a winching assembly is installed on the frame and connected with the cloth pressing roll swing frame; the tension spring can drive the adjusting swing arm to rotate relative to the frame, so that cloth arranged on the tension adjusting assembly in a penetrating mode is tensioned; and the winching assembly is used for driving the cloth pressing roll swing frame to rotate relative to the frame, so that the cloth pressing roll presses the cloth. According to the blade beam cap laying trolley, the tension of the cloth can be conveniently adjusted, the uniformity of the rotating tension of cloth layers can be guaranteed, the flatness of the cloth layers is kept, the internal stress among thecloth layers is eliminated, the condition that the laid cloth layers are lifted up in the cloth laying process is prevented, cloth layer folds are eliminated, and the cloth laying quality and the cloth laying efficiency are improved.

Owner:重通成飞风电设备江苏有限公司 +1

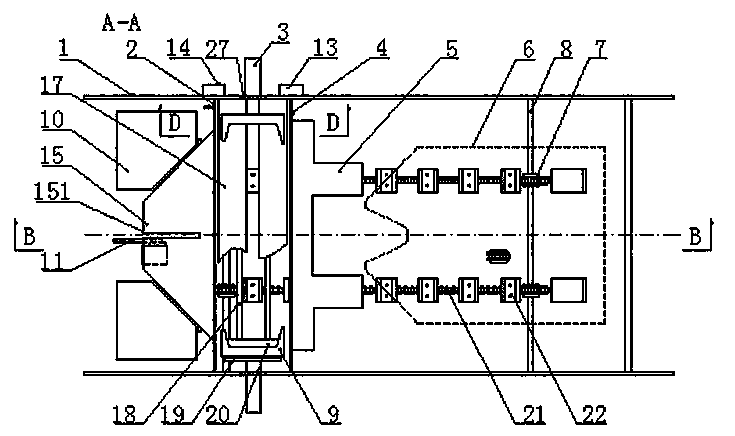

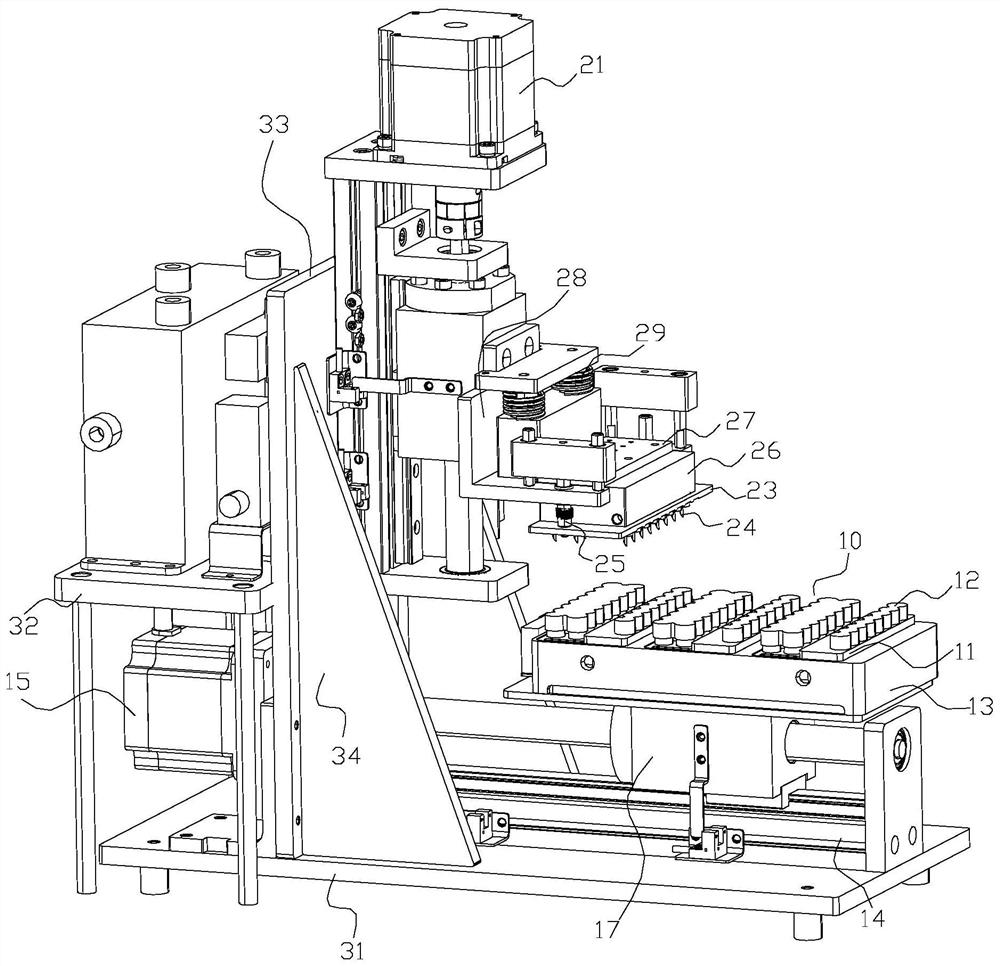

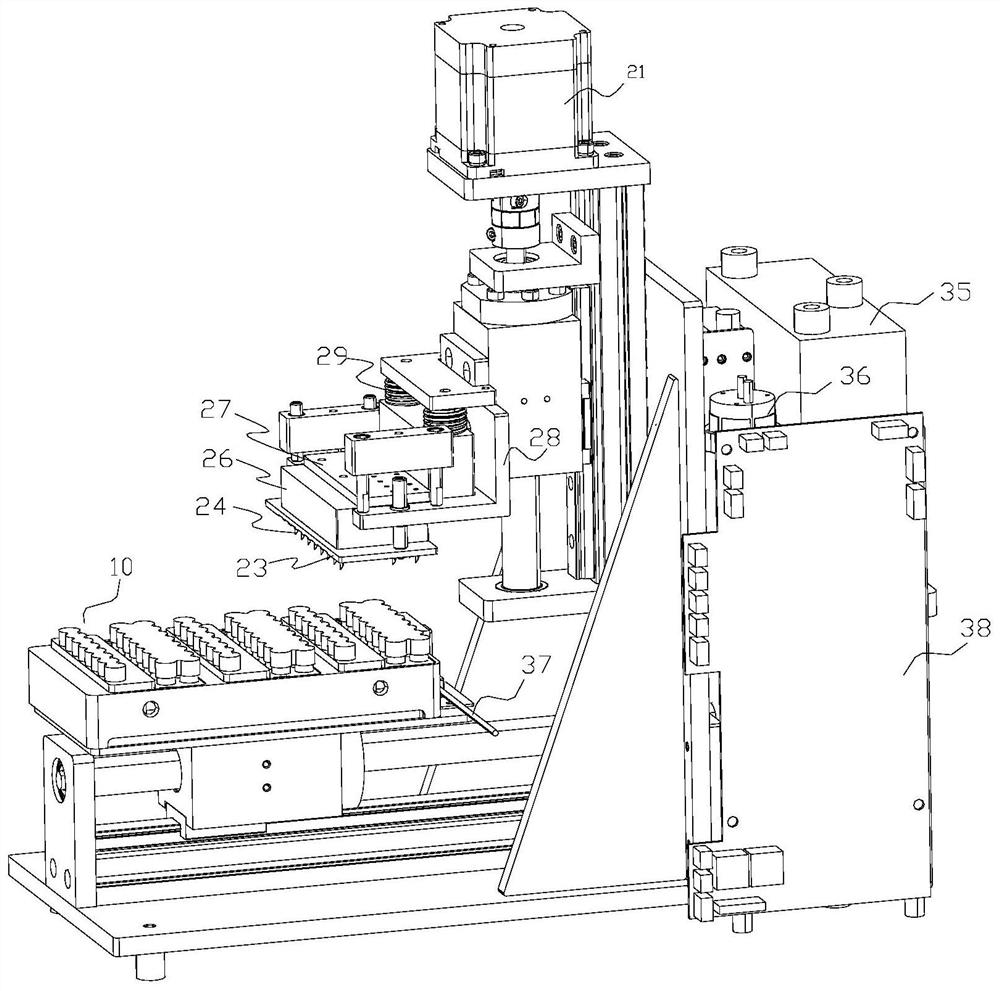

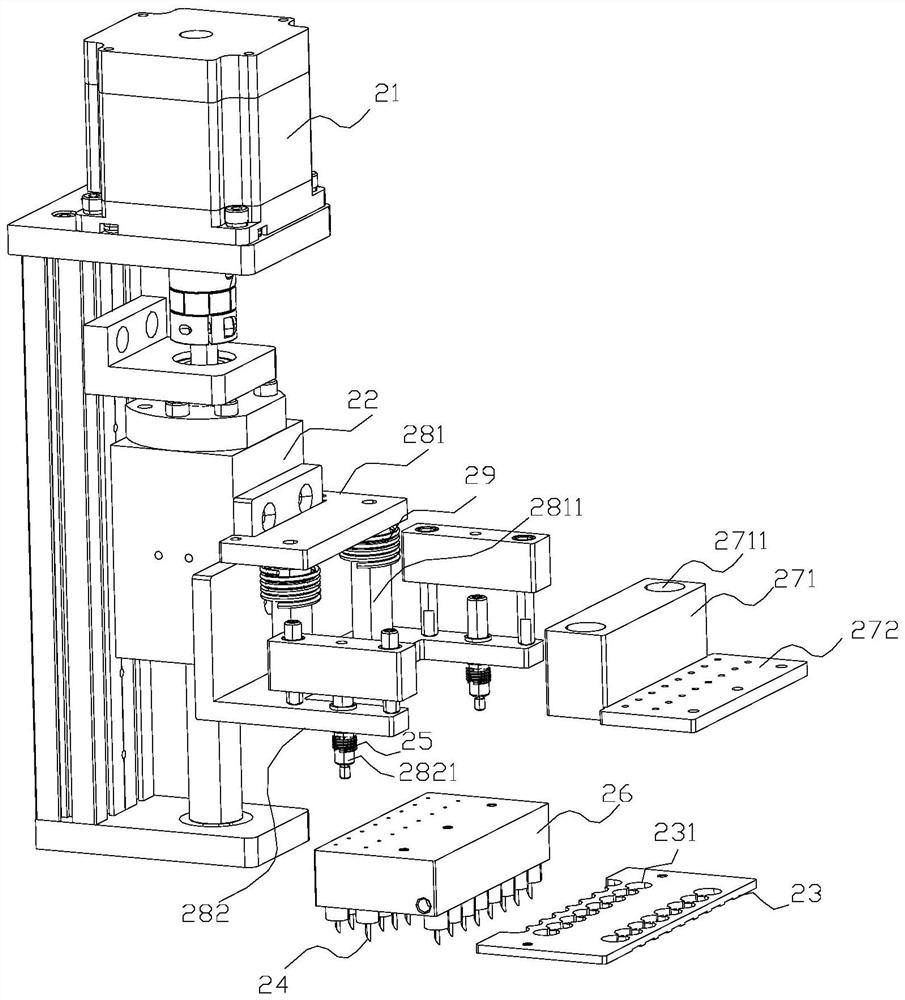

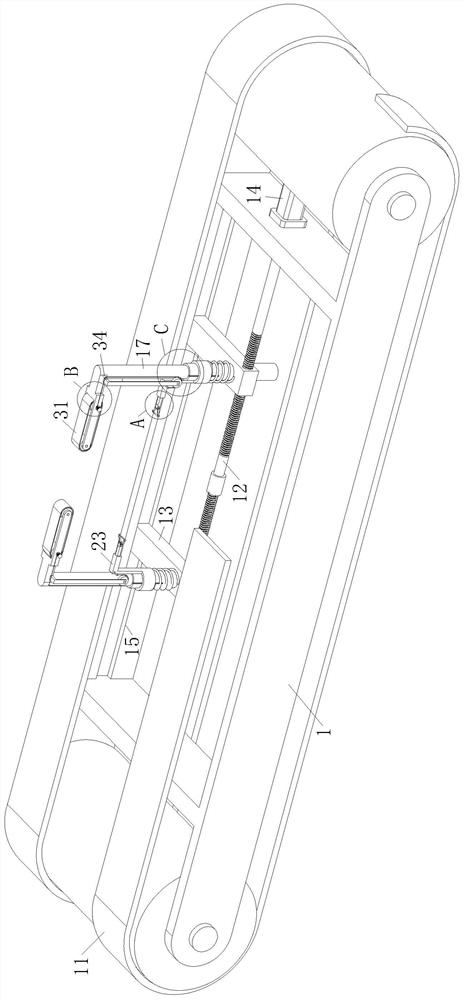

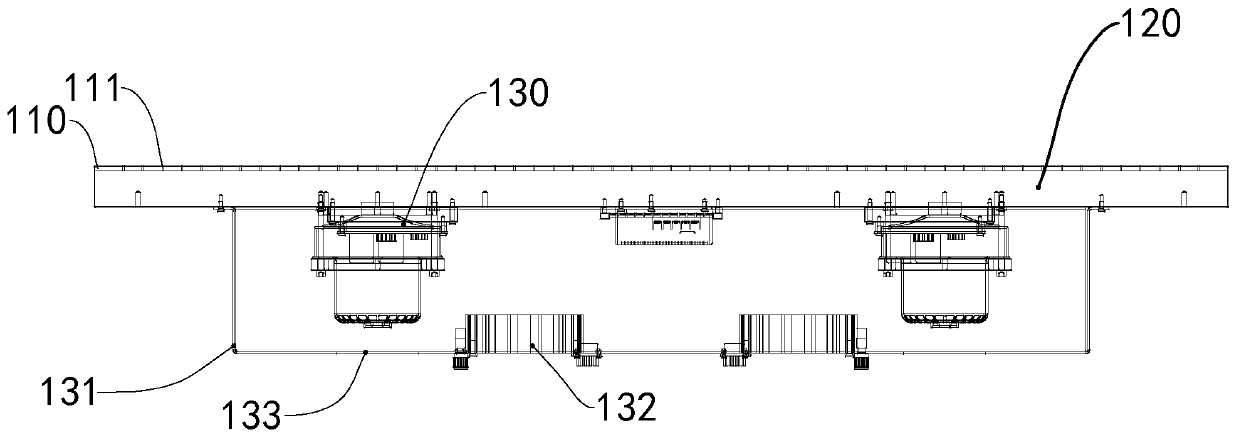

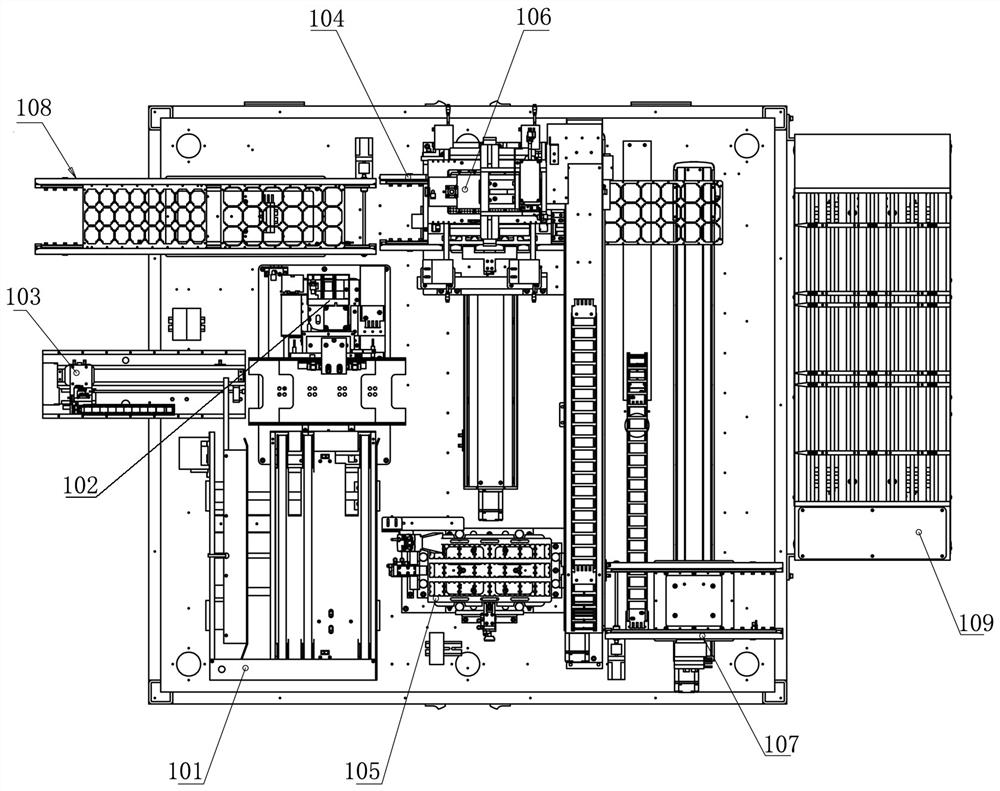

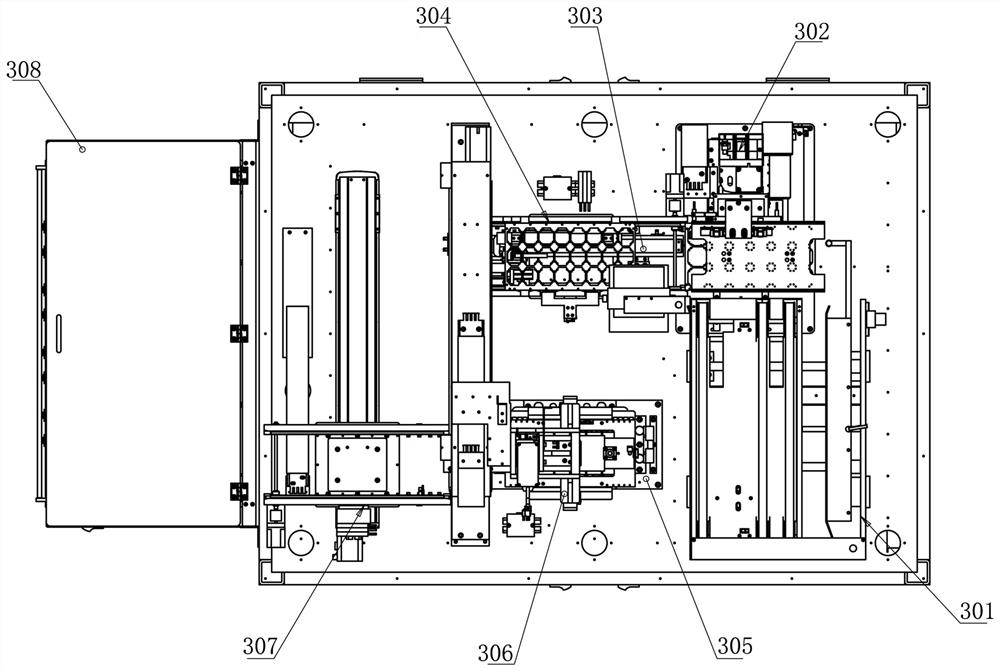

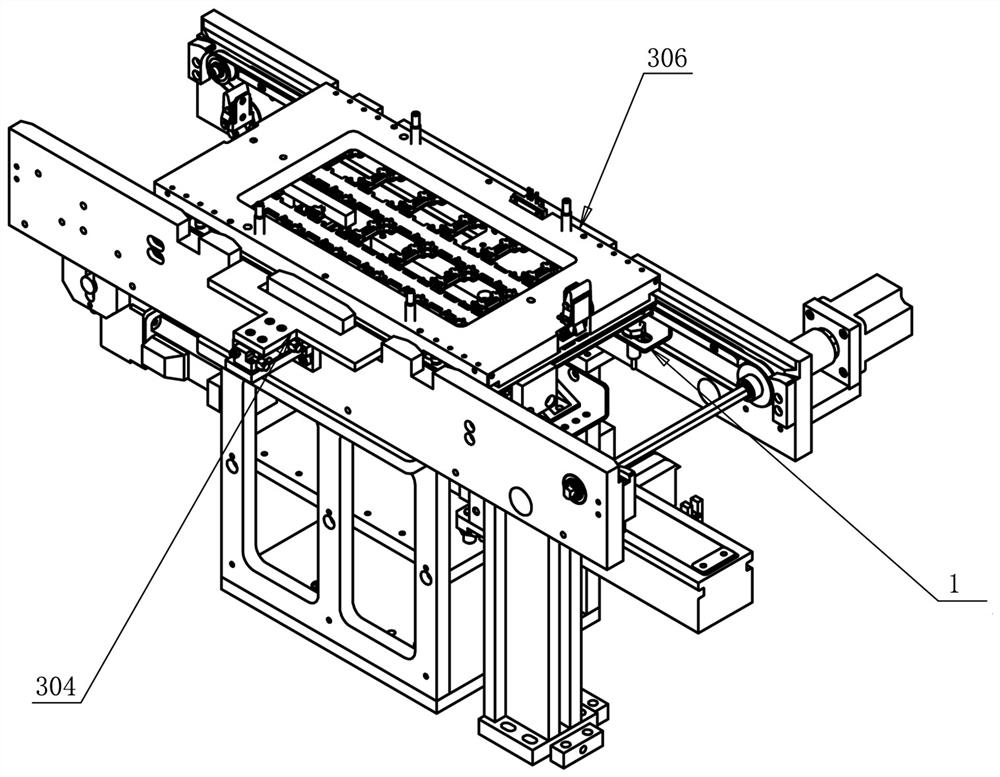

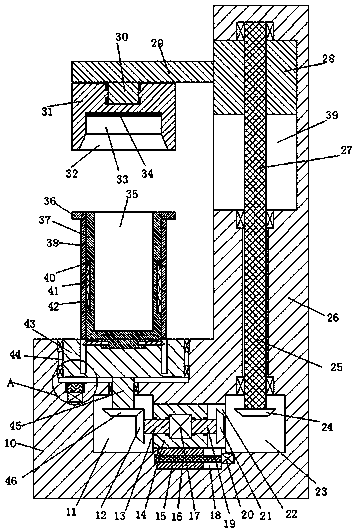

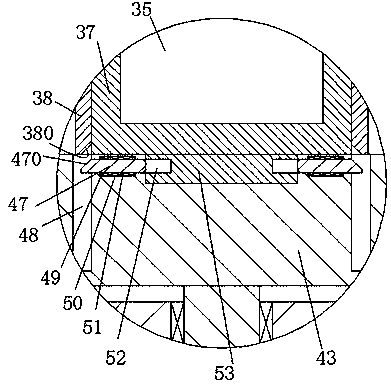

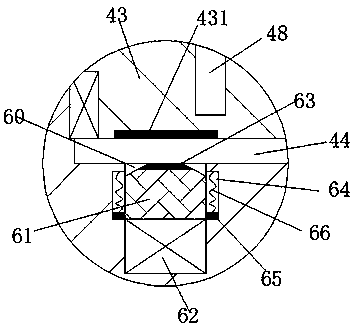

Machine for feeding, cover adding, discharging and cover removing of semiconductor substrate

ActiveCN113213121APrevent from bringing upSolve this phenomenonConveyor partsEngineeringSemiconductor

The invention discloses a machine for feeding, cover adding, discharging and cover removing of a semiconductor substrate. The machine comprises a feeding part, a washing machine and a discharging part, wherein the front part and the rear part of the washing machine are connected with the feeding part and the discharging part respectively; and the feeding part comprises a material box feeding conveying belt, a material box clamping jaw, a push rod, a supporting plate positioning rail, a cover plate feeding area, a cover plate adsorption area and a first material distribution guide rail, and the discharging part comprises a washing flow channel, a second material distribution guide rail, a positioning guide rail, a cover plate discharging area, a material box discharging area, a cover plate adsorption mechanism, a push rod part and a material box clamping part. On the basis of a common feeding machine, the function of additionally arranging a cover plate on a supporting plate is added, the function of preventing the situation of chips from being flushed out of the supporting plate by water flow and causing chip scrapping is achieved, and the supporting plate is positioned on the guide rails, so that the situation that the when the supporting plate deforms, the supporting plate is taken up when the cover plate is taken out is prevented, and the phenomenon that the supporting plate is taken up when the cover plate is added and taken out is avoided.

Owner:上海世禹精密机械有限公司

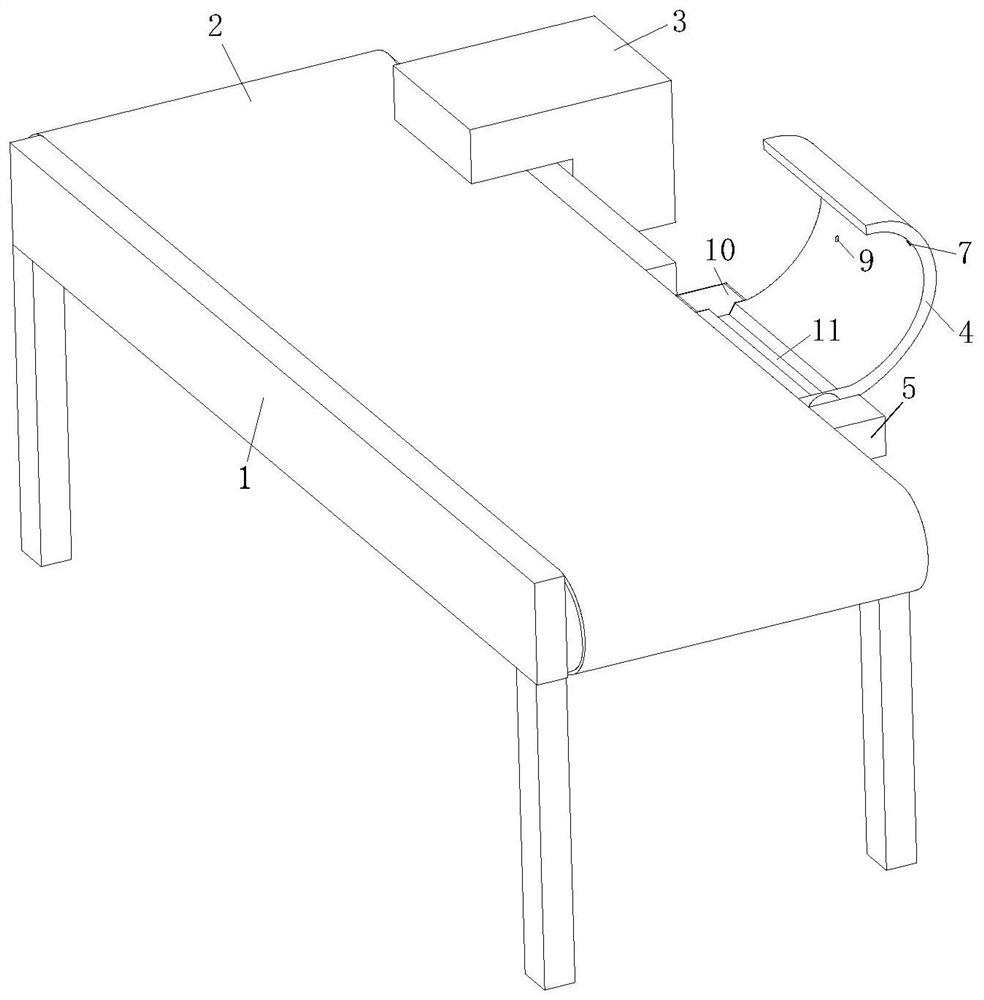

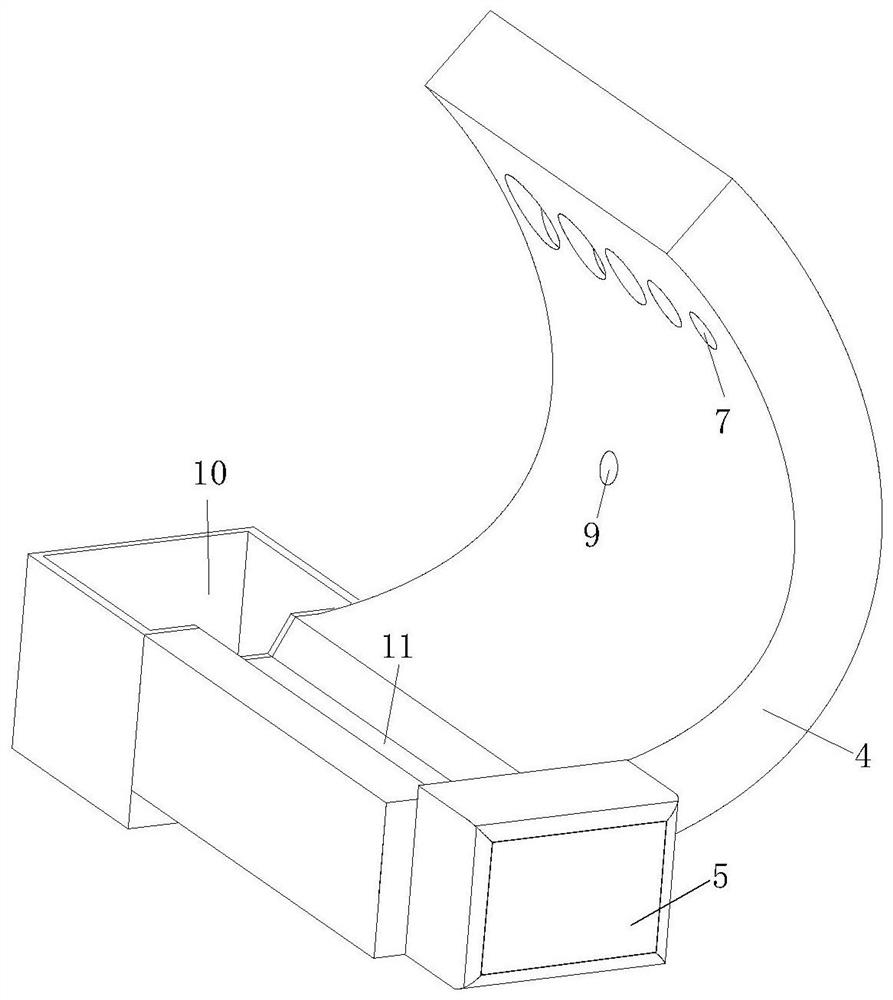

Woven bag covering machine

ActiveCN113756016AEasy to sewPrevent from bringing upSewing-machine elementsSack sewingStructural engineeringIndustrial engineering

The invention relates to the technical field of packaging equipment, in particular to a woven bag covering machine. The woven bag covering machine comprises a machine frame, a conveying module, an edge covering module and a controller. The edge covering module and the conveying module are fixedly connected to the machine frame. An arc-shaped plate is fixedly connected with one side of the conveying module; the arc-shaped plate and the edge covering module are located on the same side of the conveying module; a circular groove is formed in the face, facing the conveying module, of the arc-shaped plate; a brightness sensor is installed on the face, away from the circular groove, of the arc-shaped plate; an oil pump is arranged on the side, away from the edge covering module, of the arc-shaped plate; an air channel is formed in the oil arc-shaped plate; and the air channel penetrates through the interior of the arc-shaped plate to be attached to the groove bottom of the circular groove in the arc-shaped plate. Lubricating oil does not need to be smeared on the woven bag subjected to edge covering treatment manually, so that time and labor are saved when the lubricating oil is smeared automatically, and edge covering sewing of the woven bag by the woven bag covering machine is more convenient.

Owner:温州隆庆塑业有限公司

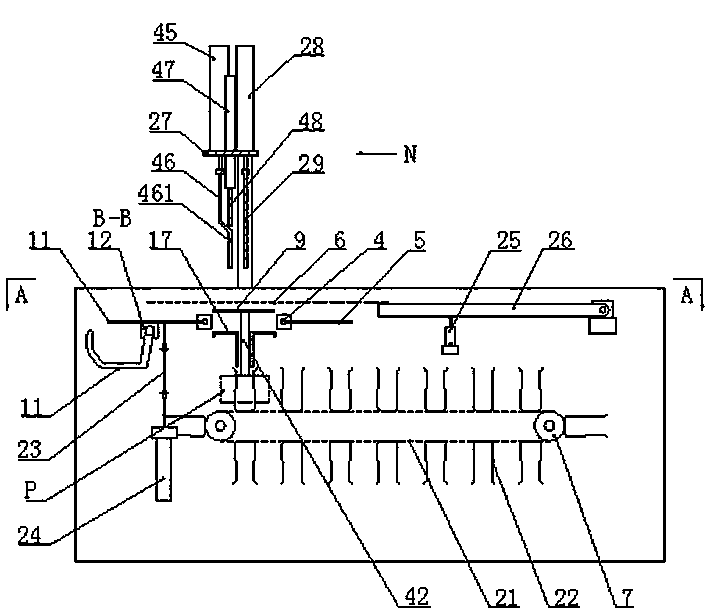

Punching device, punching platform and punching method

PendingCN113547582APrevent from bringing upAvoid damagePrinted circuit manufactureMetal working apparatusStructural engineeringMechanical engineering

A punching device comprises a pressing plate structure, a punching needle structure and a needle supporting structure; the pressing plate structure is connected to a stamping device and moves along with the stamping device; the punching needle structure is movably connected to the pressing plate structure; one end of the needle punching structure is connected to the stamping device and moves along with the stamping device; the other end of the needle punching structure supports the punching needle structure, and the stamping device drives the pressing plate structure, the needle supporting structure and the punching needle structure to move towards a workpiece; the pressing plate structure presses the workpiece; the punching needle structure penetrates through the pressing plate structure and completes punching on the workpiece; the stamping device drives the needle supporting structure to move by deviating from the workpiece, and the needle supporting structure supports the punching needle structure to be separated from the workpiece; and the pressing plate structure continues to press the workpiece, and after the punching needle structure moves to a preset distance by deviating from the workpiece, the stamping device drives the pressing plate structure to be separated from the workpiece. Through the arrangement of the needle supporting structure, the stamping device can drive the pressing plate structure to be separated from the workpiece only after the punching needle structure moves to the preset distance by deviating from the workpiece, and therefore the workpiece is effectively prevented from being taken up, damage to the workpiece is effectively avoided, and follow-up conveying of the workpiece is facilitated.

Owner:东莞王氏港建机械有限公司

Tea oil cake-making mechanism

InactiveCN107779257ARealize automated productionEasy to produceFatty-oils/fats productionConveyor beltPulp and paper industry

The invention discloses a tea oil cake making mechanism. A conveyor belt is provided under the cake pressing mechanism, and a support plate is provided under the conveyor belt; the cake pressing mechanism includes a drive unit, which is connected to the forming unit via a vertical guide rail; the drive unit includes a sleeve, and the drive unit above the sleeve A lead screw nut is connected through a bearing, the lead screw nut is connected to the motor through a drive belt, the lead screw nut is also connected to the lead screw, the lead screw is connected to the slider, and the slider is connected to the slide rail; the forming unit includes a forming cover, There is a material inlet on the forming cover, and a base plate is arranged in the forming cover, the base plate is connected to the pressing plate through the forming guide rail, and a spring is provided on the forming guide rail between the base plate and the pressing plate, and a material level is also provided on the side wall of the forming cover. The sensor is provided with a cake pressing oil cylinder on the top surface of the forming cover, and the cake pressing oil cylinder is connected with the base plate; the lead screw is connected with the forming cover through a connecting frame. The invention has the characteristics of convenient production and high production efficiency.

Owner:贵州金狗生态茶油有限责任公司

Blade beam cap laying trolley

ActiveCN108584526AUniform tensionMaintain the flatness of the cloth layerUnfolding thin materialsWebs handlingInternal stressTextile

The invention relates to a blade beam cap laying trolley, and belongs to the technical field of laying trolleys. A tension spring is detachably connected with an adjusting swing arm, the adjusting swing arm is in transmission connection with a tension adjusting assembly, the tension adjusting assembly is rotatably connected with a frame, a cloth pressing roll swing frame is rotatably connected with the frame, a cloth pressing roll is rotatably connected with the cloth pressing roll swing frame, and a winching assembly is installed on the frame and connected with the cloth pressing roll swing frame; the tension spring can drive the adjusting swing arm to rotate relative to the frame, so that cloth arranged on the tension adjusting assembly in a penetrating mode is tensioned; and the winching assembly is used for driving the cloth pressing roll swing frame to rotate relative to the frame, so that the cloth pressing roll presses the cloth. According to the blade beam cap laying trolley, the tension of the cloth can be conveniently adjusted, the uniformity of the rotating tension of cloth layers can be guaranteed, the flatness of the cloth layers is kept, the internal stress among thecloth layers is eliminated, the condition that the laid cloth layers are lifted up in the cloth laying process is prevented, cloth layer folds are eliminated, and the cloth laying quality and the cloth laying efficiency are improved.

Owner:重通成飞风电设备江苏有限公司 +1

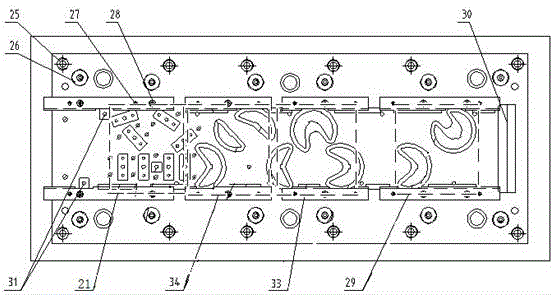

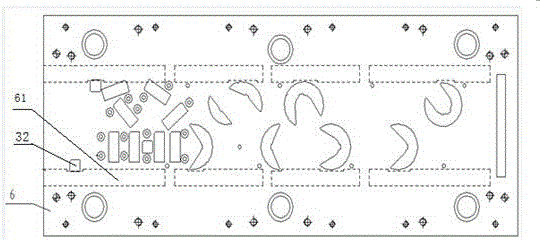

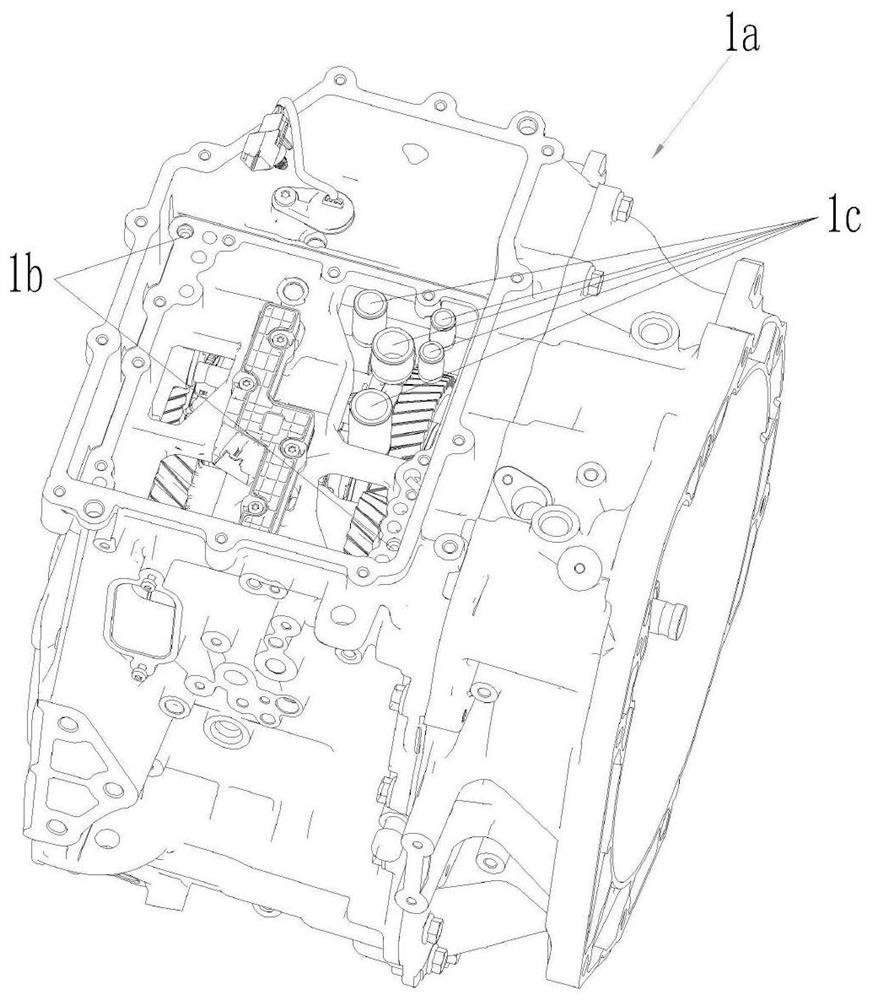

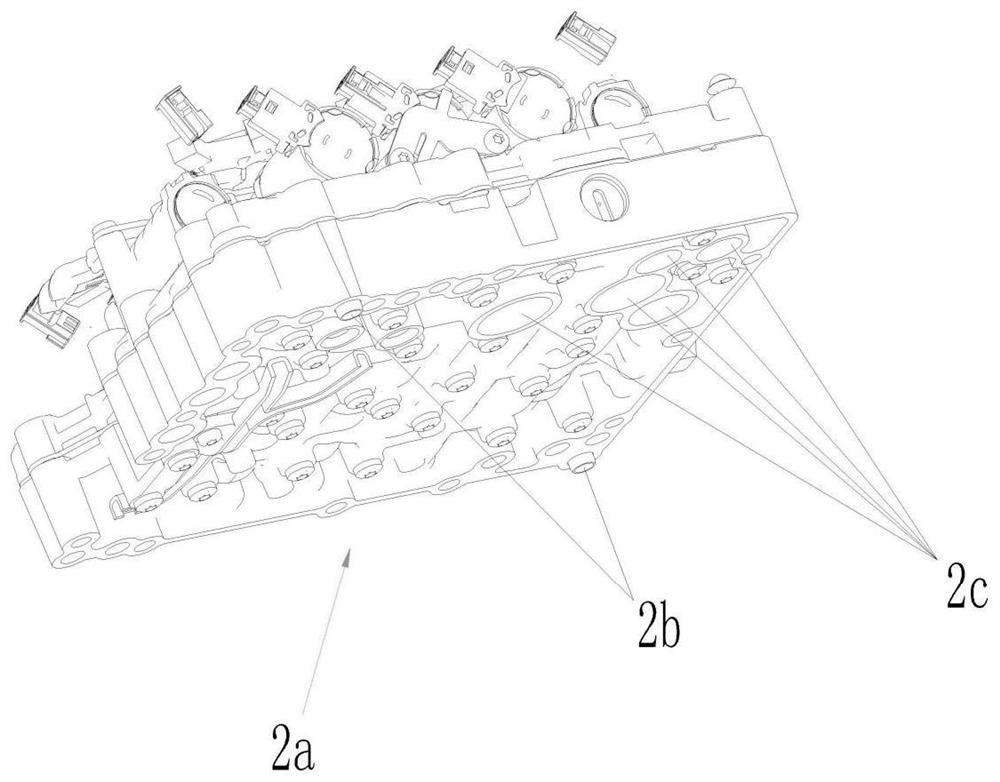

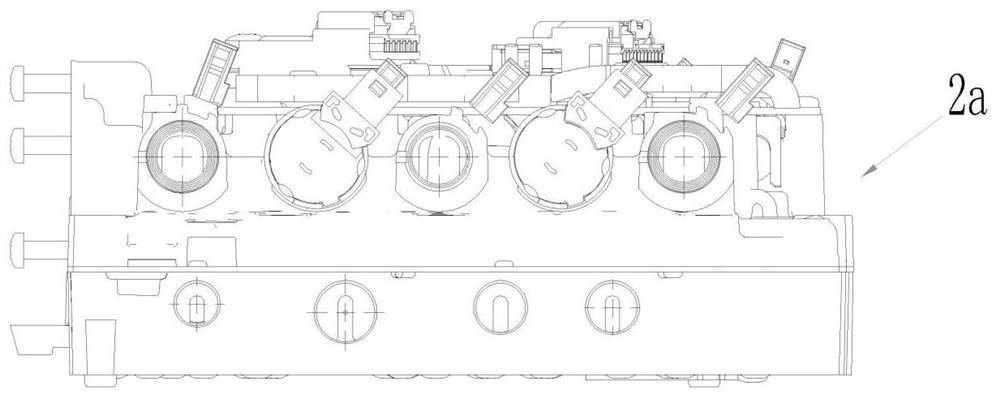

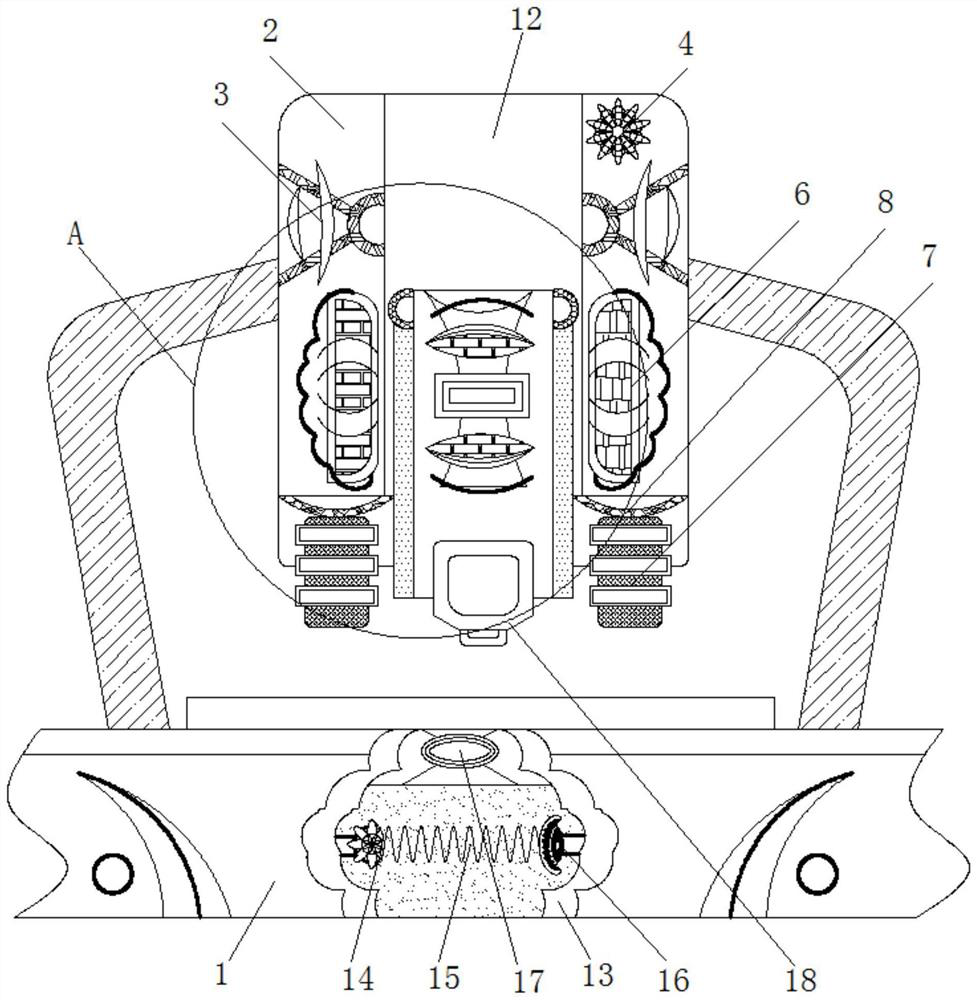

Automatic grabbing device for DCT gearbox valve body friction force

ActiveCN111687612ARealize automatic crawlingPrevent from bringing upMetal working apparatusClassical mechanicsStructural engineering

The invention provides an automatic grabbing device for DCT gearbox valve body friction force. The automatic grabbing device for the DCT gearbox valve body friction force comprises two sets of drivingassemblies arranged at the top of a mounting plate, a pair of linear guide rail assemblies, four sets of friction clamping pin assemblies, four sets of adjusting mechanisms, three sets of counter-force supporting column assemblies, two positioning pins, two sets of pressing block assemblies and three sets of laser displacement sensor assemblies, the pair of linear guide rail assemblies, the foursets of friction clamping pin assemblies, the four sets of adjusting mechanisms, the three sets of counter-force supporting column assemblies, the two positioning pins, the two sets of pressing blockassemblies and the three sets of laser displacement sensor assemblies are arranged at the bottom of the mounting plate; and a friction force structure formed by the four sets of friction clamping pinassemblies, the pair of linear guide rails and the two sets of driving assemblies automatically grabs a valve body by utilizing the friction force, the two positioning pins are used for positioning the position of the valve body on the automatic friction force grabbing device, the three counter-force supporting columns are used as pressing heads for transmitting the valve body box closing press-fitting force and can play a role in end face positioning, the three laser displacement sensors cooperatively work at three positions to detect the levelness and the in-place state of the valve body, and the two pressing block assemblies are used for preventing the valve body from being lifted when the device is reset after the valve body is closed. The automatic grabbing device for the DCT gearboxvalve body friction force can provide a new simple and effective idea for closing the valve body.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Anti-adhesion device for wood board punching

InactiveCN113001699APrevent from bringing upIncrease the areaWood working safety devicesWood punching outPunchingWood machining

The invention relates to the technical field of wood processing, and discloses an anti-adhesion device for wood board punching. The device comprises a base and a supporting table; an electric rail is fixedly connected in the supporting table; a piezoresistor is fixedly connected in the supporting table; a positive plate is fixedly connected in the supporting table; a negative plate is fixedly connected in the supporting table; a magnetic movable rod is movably connected with the bottom of the supporting table; and a magnetic plate is fixedly connected with the interior of the supporting table. According to the anti-adhesion device for wood board punching, the supporting table and the base are fixed through a supporting rod, when a punching base moves downwards and the interior of the punching base is movably connected with an insulating plate, the insulating plate moves downwards, so that the relative area between the positive plate and the negative plate is increased, the piezoresistor is switched on, the magnetic plate is powered on, the magnetic movable rod is located in a magnetic field environment, and the magnetic movable rod extends to press wood, so that a punch is prevented from lifting up a wood board, operation is easy, the punching quality is improved, and the machining cost is saved.

Owner:杨珂腾

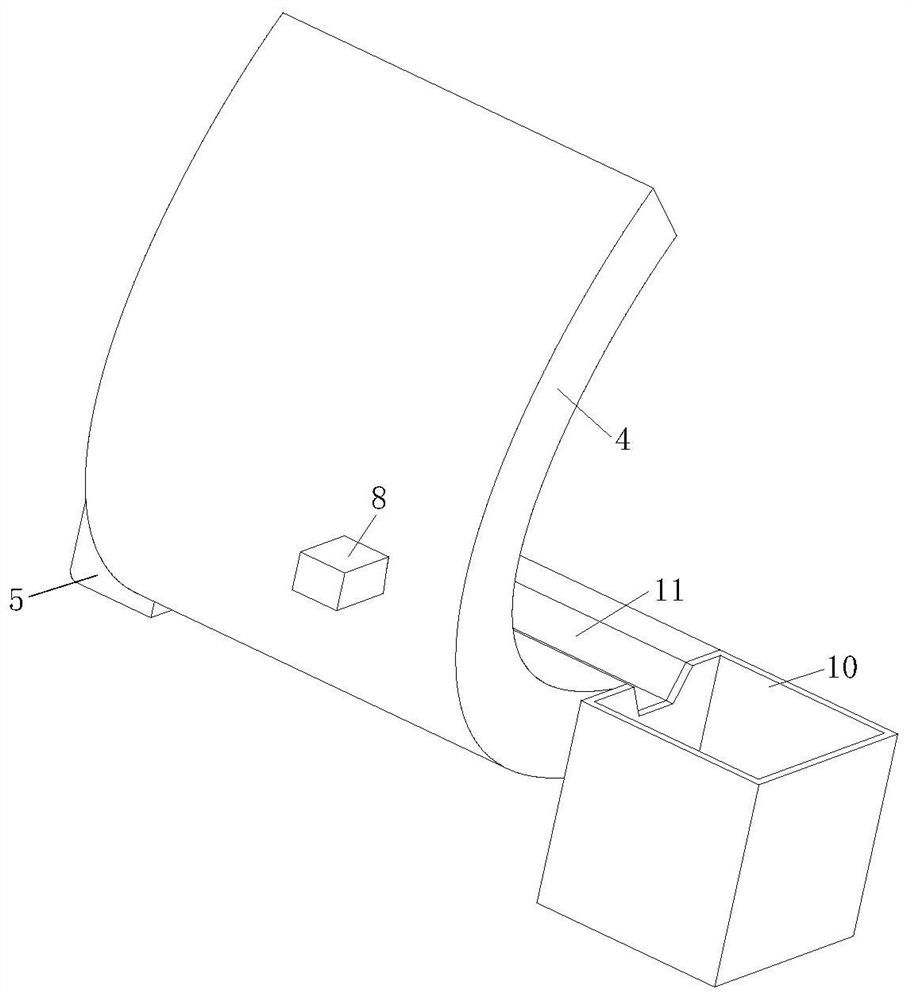

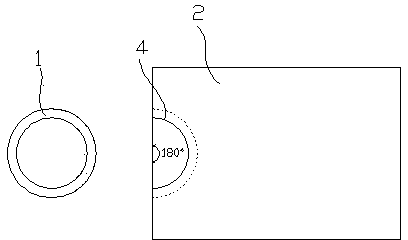

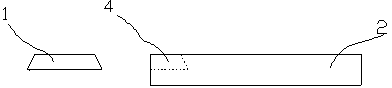

Tapping jig capable of avoiding dragging product

InactiveCN104002152AAvoid damageSimple structureThread cutting machinesPositioning apparatusBiochemical engineering

The invention discloses a tapping jig capable avoid dragging a product. The product is in the shape of a circular truncated cone. The tapping jig comprises a plate-shaped base and is characterized in that the base is provided with an accommodating slot opened upwards, and the internal shape of the accommodating slot is matched with one circumferential side of the product or the entire product in appearance. The tapping jig fixes the product through the accommodating slot matched with the circular truncated cone-shaped product in appearance, thereby being simple in structure, easy to machine, low in cost and convenient to use, and meanwhile fixing the product firmly without damaging the product and effectively avoid damage to the product or tapped screws due to the fact of dragging the product out when exiting the tapping process.

Owner:SUZHOU CHUANGFENG PRECISION HARDWARE

Enzyme preparation device for textile industry

InactiveCN108300644AAvoid accidentsImprove securityBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringEnzyme

The invention discloses an enzyme preparation device for textile industry. The enzyme preparation device comprises a machine base and a frame body which is fixedly arranged on the right side of the upper end face of the machine base; a first rotating groove and a second rotating groove are formed in the machine base; a first sliding groove communicated with the first rotating groove and the secondrotating groove is formed between the first rotating groove and the second rotating groove; a third rotating groove which is provided with an upward groove opening and is positioned above the first rotating groove is formed in the upper end face of the machine base; a rotating seat is rotationally arranged in the third rotating groove by a bearing; a first rotating pin shaft is fixedly arranged at the middle end of the bottom end face of the rotating seat; the lower end of the first rotating pin shaft downwards penetrates through the bottom wall of the third rotating groove, extends into thefirst rotating groove and is fixedly provided with a first cone wheel; in addition, the first rotating pin shaft is rotationally matched with the bottom wall of the third rotating groove; a first sliding block which can slide leftwards and rightwards is arranged in the first sliding groove; a first electric motor is fixedly arranged in the first sliding block; a second rotating pin shaft and a third rotating pin shaft which penetrate through the first sliding block are in power connection with the left side and the right side of the first electric motor.

Owner:张鑫祥

Improved textile industry purpose enzyme preparation device

InactiveCN108165459AAvoid accidentsImprove securityBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringEnzyme

The invention discloses an improved textile industry purpose enzyme preparation device. The improved textile industry purpose enzyme preparation device comprises an engine base and a frame body, the frame body is fixedly installed on the right side of the upper end face of the engine base and extends upwards, the engine base is internally provided with a first rotating groove and a second rotatinggroove, a communicated first slippage groove is arranged between the first rotating groove and the second rotating groove, a third rotating groove is arranged in the upper end face of the engine base, a notch of the third rotating groove faces upwards, the third rotating groove is located above the first rotating groove, a rotating seat is rotatably installed in the third rotating groove througha bearing, a first rotating pin shaft is fixedly installed at the middle end of the bottom end face of the rotating seat, the lower end of the first rotating pin shaft penetrates downwards through thebottom wall of the third rotating groove, extends into the first rotating groove and is fixedly provided with a first cone wheel, the first rotating pin shaft and the bottom wall of the third rotating groove are rotatably matched, a first slippage block capable of slipping left and right is installed in the first slippage groove, a first electromotor is fixedly installed in the first slippage block, and a second rotating pin shaft and a third rotating pin shaft which penetrate through the first slippage block are in power connection to the left side and the right side of the first electromotor.

Owner:郭林惠

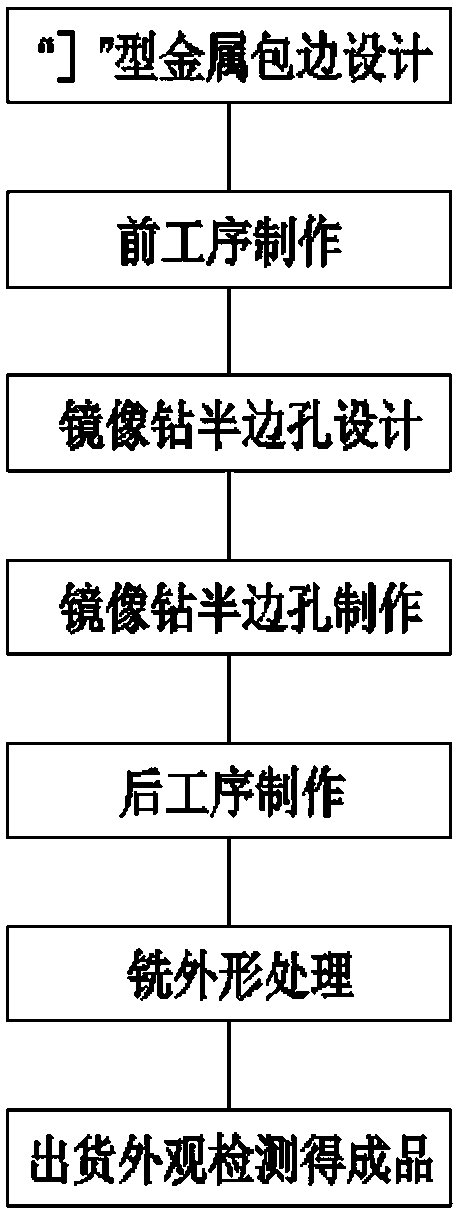

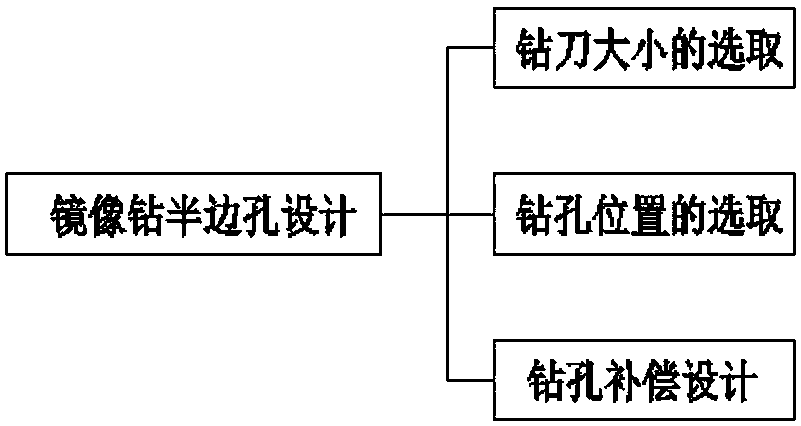

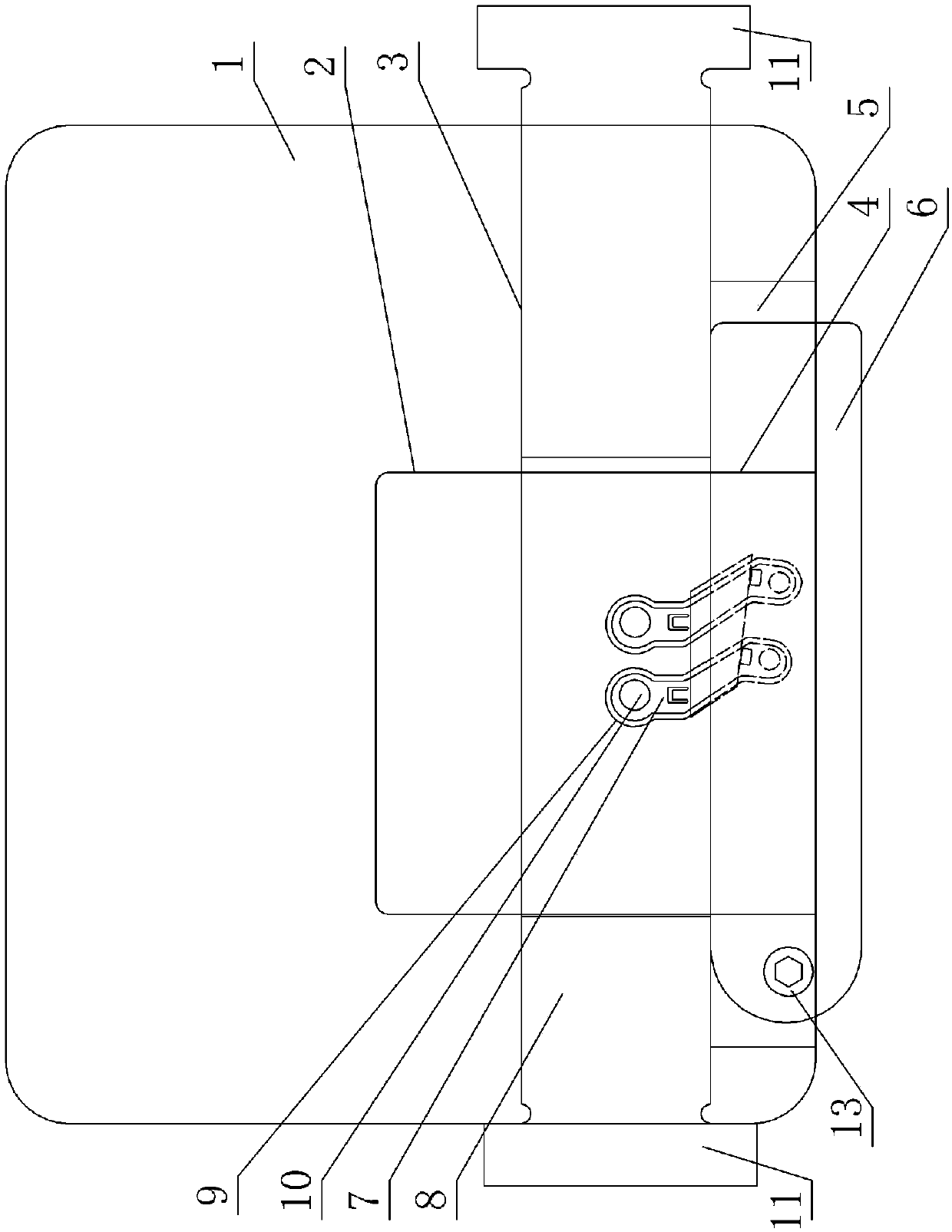

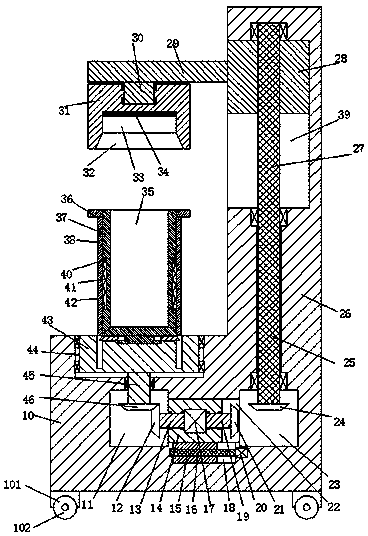

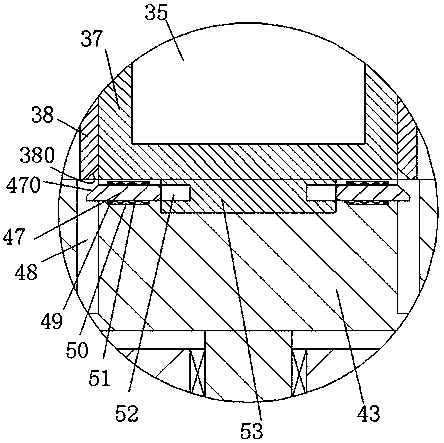

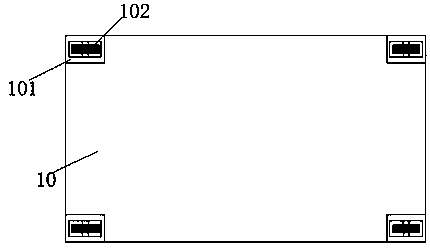

A multi-bridge connection, small-pitch edge-wrapped printed circuit board and its manufacturing method

ActiveCN106102314BImprove bindingAvoid liftingElectrical connection printed elementsPrinted element electric connection formationBridging positionCopper

Disclosed is a multi-bridging position and small-spacing edge-wrapped printed circuit board, which is mainly composed of a circuit plate (1). A side face of the circuit plate (1) is provided with a metal wrapping edge (3). The metal wrapping edge (3) is "]"-shaped, or the upper end face of the metal wrapping edge (3) is connected to a top face pattern (2) and the lower end face of the metal wrapping edge (3) is connected to a bottom face pattern (4). Further disclosed is a manufacturing method for the multi-bridging position and small-spacing edge-wrapped printed circuit board, comprising the following steps: a first step of wrapping edge design, in which a "]"-shaped metal wrapping edge (3) is designed at a side face of a circuit plate (1); a second step of mirroring half hole drilling design, in which drilling tool diameter selection is carried out firstly, drilling location selection is carried out secondly, and finally drilling compensation design is carried out; and a third step of mirroring half hole drilling manufacture, which comprises steps of drilling file manufacture, drilling positioning and board loading for half hole drilling. The present application is applicable to a multi-bridging position and small-spacing edge-wrapped printed circuit board, having advantages such that when hole drilling is carried out, copper sheets will not be raised; and when board milling is carried out, copper sheets at small bridging positions will not tilt and fall off.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

A light-duty soft material punching device

The invention relates to a light-duty soft material blanking device, which comprises a workbench and a cutting die above the workbench that can move up and down relative to the workbench; the workbench includes a workbench and at least one air extraction device; There is a first air extraction hole, and the air extraction device is connected to the first air extraction hole; the knife mold includes a positioning piece, a mounting piece and a knife, and the knife is connected to the mounting piece; the positioning piece is connected to an electromagnet, which is loosened by turning on and off the electromagnet Or adsorption mounting parts; the first limiting part is provided on the positioning part, and the second limiting part is provided on the mounting part, and the second limiting part is used to cooperate with the first limiting part to prevent the mounting part from moving relative to the positioning part. Move in at least one direction perpendicular to the direction of magnetic attraction. The light-duty soft material punching device of the present invention can prevent the light-duty soft material from being lifted up during punching, and can conveniently replace knives to improve production efficiency.

Owner:丁卫兵

Jig for welding double nuts to busbar

PendingCN107552938AAchieve weldingRealize free switchingResistance welding apparatusBusbarSpot welding

The invention provides a jig for welding double nuts to a busbar. According to the jig, after a product is fed at a time, spot welding of the two nuts is achieved through the movable jig, the production efficiency is improved, the production cost is reduced, and free switching of single-welding-spot welding and double-welding-spot welding of the same machine can be achieved. The jig comprises a base; the upper end face of the base is provided with a downwards concave groove which comprises a die seat installation cavity and a material covering plate installation cavity; and the positions, close to the edges, of the material covering plate installation cavity are provided with inwards concave positioning grooves which extend towards the two sides, the two sides of a material covering plateare inserted into the positioning grooves correspondingly, and the material covering plate presses the tail portion of the busbar. The jig further comprises a movable die seat which is of a long-strip-shaped structure, the movable die seat is provided with a set of inwards concave positioning die cavities which are used for storing the busbar and the corresponding two nuts, and the two ends, in the length direction, of the movable die seat outwards protrude from the corresponding two side edges of the base.

Owner:SUZHOU ANJIE TECH

Improved paint color mixing device

InactiveCN108371924APrevent from bringing upImprove operational stabilityRotating receptacle mixersTransportation and packagingColor mixingBogie

The invention discloses an improved paint color mixing device, comprising a base and a post fixedly mounted at the right side of the upper end face of the base and extends upwards. A first turning cavity and a second turning cavity are formed in the base, and a feed-through first slide slot is formed between the first turning cavity and the second turning cavity; a third turning cavity with upwards opening and disposed above the first turning cavity is formed in the upper end face of the base, a turning rack is rotationally mounted in the third turning cavity through a bearing, a first turningshaft is fixedly mounted at the center point of the bottom end face of the turning rack, the lower end of the first turning shaft penetrates downwards the bottom wall of the third turning cavity to extend into the first turning cavity and is fixedly provided with a first conical pulley, and the first turning shaft is in rotational fit with the bottom wall of the third turning cavity; a first slider capable of sliding left and right horizontally is mounted in the first slide slot, a first motor is fixedly mounted in the first slider, and a second turning shaft and a third turning shaft both penetrating the first slider are in power connection with the left and right sides of the first motor respectively.

Owner:何杨波

Novel environmentally-friendly coating device

InactiveCN108452729APrevent from bringing upImprove operational stabilityRotating receptacle mixersTransportation and packagingSlide plate

The invention discloses a novel environmentally-friendly coating device. The device comprises a bearing seat and a vertical frame, wherein the vertical frame is fixedly arranged at the right side of the upper end face of the bearing seat and extends upward, a counterweight groove is formed in the end face of the bottom of the bearing seat, a counterweight block is arranged in the counterweight groove, a first rotating bin and a second rotating bin are arranged in the bearing seat above the counterweight block, a communicated first sliding cavity is formed between the first rotating bin and thesecond rotating bin, a third rotating bin with an upward opening is arranged in the upper end face of the bearing seat and located above the first rotating bin, a rotating table is rotationally arranged in the third rotating bin through a bearing, a first rotating rod is fixedly arranged at the center of the bottom end face of the rotating table, the lower end of the first rotating rod penetratesthrough the bottom wall of the third rotating bin downward, stretches into the first rotating bin and is fixedly provided with a first cone helical wheel, the first rotating rod is rotationally matched with the third rotating bin, a first sliding plate is laterally and movably arranged in a first sliding cavity, a first motor is fixedly arranged in the first sliding plate, and the left and rightsides of the first motor are dynamically connected with a second rotating rod and a third rotating rod which penetrate through the first sliding plate.

Owner:韦健敏

Method of reducing broken drilled plug holes

ActiveCN109760135BReduce resistanceReduce breakageMetal working apparatusStructural engineeringDrill hole

The invention relates to a method for reducing broken drilled plug holes, comprising the following steps: S1, according to the positions of the positioning holes on the base plate, correspondingly drill positioning holes on the bottom plate and the cover plate, and according to the positions of the functional holes on the base plate, drill out positioning holes on the base plate and the cover plate Corresponding via holes are drilled on the board, S2, a cylindrical positioning pin is set at the position corresponding to the positioning hole on the base plate on the drilling platform of the drilling machine, and the diameter of the positioning pin is consistent with the diameter of the positioning hole; S3, the bottom plate, the base plate Put the cover plate on the positioning pin, and make the bottom plate, base plate and cover plate close to each other, and then fix the cover plate on the drilling platform; S4, use the drill to drill the base plate through the via hole on the cover plate , when drilling to half the thickness of the substrate, the drill bit is lifted up and separated from the substrate, hovering in the air for 5‑20 seconds and then continues to drill until the substrate is drilled through. The invention can effectively reduce broken drilled plug holes.

Owner:惠州市骏亚精密电路有限公司

Novel fruit juice beverage blending equipment

InactiveCN108525577APrevent from bringing upImprove operational stabilityRotating receptacle mixersTransportation and packagingFruit juiceEngineering

The invention discloses novel fruit juice beverage blending equipment. The novel fruit juice beverage blending equipment comprises a frame seat and a bracket which is fixedly mounted at the right sideof an upper end face of the frame seat and stretches upward, wherein the frame seat is internally provided with a first rotary connection cavity and a second rotary connection cavity; a communicatedfirst sliding connection groove is formed between the first rotary connection cavity and the second rotary connection cavity; the upper end face of the frame seat is provided with a third rotary connection cavity, which is provided with an upward through hole and is located above the first rotary connection cavity; a rotary connection frame is rotatably mounted in the third rotary connection cavity through a bearing; a first rotary connection shaft is fixedly mounted at the middle of a bottom end face of the rotary connection frame; the lower end of the first rotary connection shaft downwardpenetrates through a bottom wall of the third rotary connection cavity ad stretches into the first rotary connection cavity, and a first tapered wheel is fixedly mounted; the first rotary connection shaft is in rotatable matching with the bottom wall of the third rotary connection cavity; a first sliding connection block, which can be in left-right sliding connection, is mounted in the first sliding connection groove; a first electric rotary machine is fixedly mounted in the first sliding connection groove; a second rotary connection shaft and a third rotary connection shaft, which penetrate through the first sliding connection block, are in power connection with the left and right sides of the first electric rotary machine.

Owner:莫宇

Novel gene engineering medicine device

InactiveCN108330055APrevent from bringing upImprove operational stabilityBioreactor/fermenter combinationsBiological substance pretreatmentsFixed frameDrive motor

The invention discloses a novel gene engineering medicine device. The novel gene engineering medicine device comprises a base and a fixed frame, wherein the fixed frame is fixedly arranged at the right side of the upper end surface of the base and extends up; the interior of the base is provided with a first rotary cavity and a second rotary cavity; a first slide groove is communicated between thefirst rotary cavity and the second rotary cavity; the interior of the upper end surface of the base is provided with a third rotary cavity with an upward opening, and the third rotary cavity is positioned above the first rotary cavity; a rotary frame is rotationally arranged in the third rotary cavity through a bearing; a first rotary shaft is fixedly arranged at the center of the bottom end surface of the rotary frame; the lower end of the first rotary shaft downwards penetrates through the bottom wall of the third rotary cavity, and extends into the first rotary cavity, and a first bevel gear is fixedly arranged at the lower end of the first rotary shaft; the first rotary shaft is rotationally matched with the bottom wall of the third rotary cavity; a first slide block is arranged in the first slide groove and slides left and right; a first drive motor is fixedly arranged in the first slide block; the left side and right side of the first drive motor are connected with a second rotary shaft and a third rotary shaft in a power way, and the second rotary shaft and the third rotary shaft penetrate through the first slide block.

Owner:陈旭东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com