C-shaped pole shoe one-die eight-element continuous manufacturing method and continuous die

A technology of eight pieces in one mold and pole shoes, which is applied to the continuous mold preparation method of C-shaped pole shoes and the field of continuous molds, can solve the problems of restricting production demand, processing time, and waste of human resources, so as to improve labor utilization and shorten processing. Time, productivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

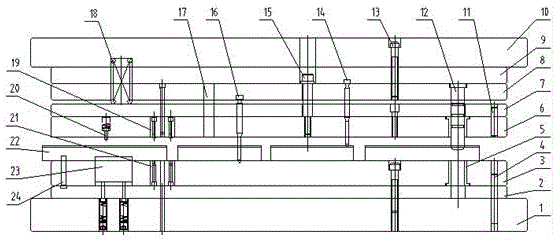

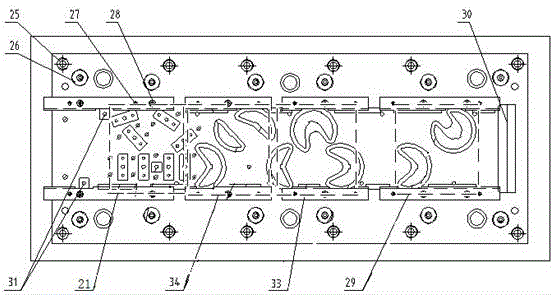

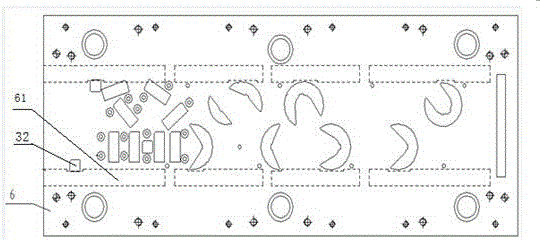

[0029] Embodiment of the present invention: a continuous mold of a C-shaped pole shoe mold eight pieces continuous preparation method, such as Figure 1-8 As shown, the die set plate 3 is included, the die set plate 3 is fixed on the lower die base 1, and the lower die backing plate 2 is also provided between the lower die base 1 and the die set plate 3, the die set plate 3 and the The lower mold base 1 is fixed by the pin A4 and the pin E25, and the die fixing plate 3 is successively provided with punching and enclosing convex die inserts 21 and 8 blanking die inserts of different shapes. The insert 21 is provided with a punching and punching die 212 and a punching die 211; an upper mold base 10 is provided above the die fixing plate 3, and a guide sleeve 5 is provided between the upper die base 10 and the lower die base 1. Positioned with the guide post 12, the bottom of the upper die base 10 is provided with a special-shaped punch 17 corresponding to the blanking die insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com