Bag folding method and bag folding device for bag making machine

A bag-making machine and bag-folding technology, applied in bag-making operations, transportation and packaging, packaging, etc., can solve problems affecting folding quality and work efficiency, folding failure, plastic bag unraveling, etc., to improve folding quality and The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

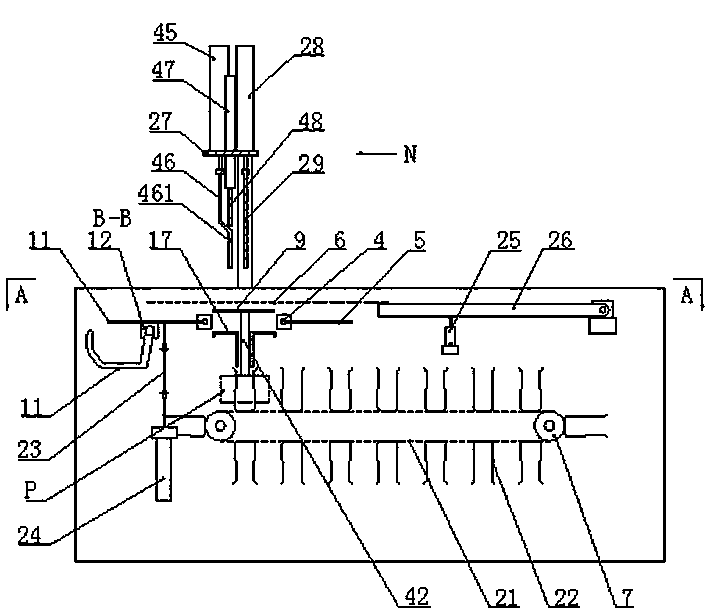

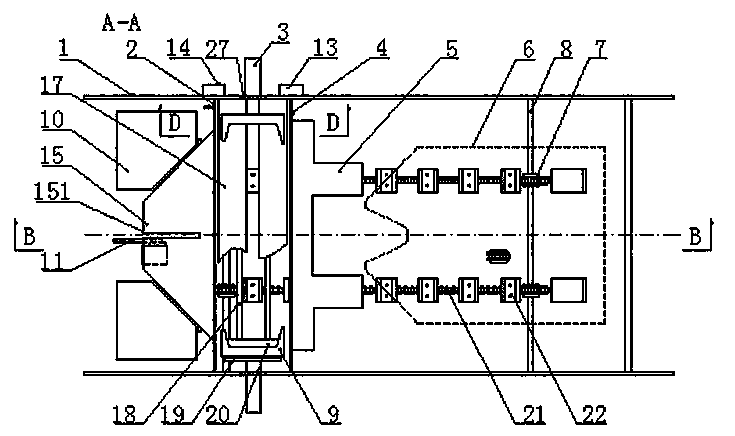

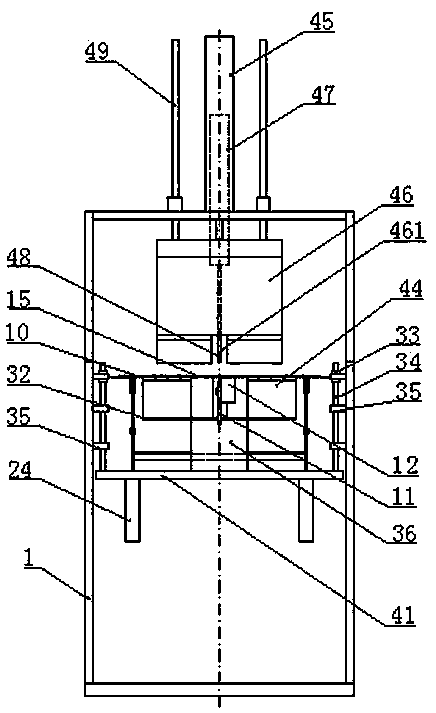

[0025] see Figure 1-Figure 5 , a basic embodiment of a bag folding device for a bag making machine in the present invention, comprising a frame 1 and a front corner folding mechanism installed on the upper front end of the frame 1 (in the present invention, referred to as figure 1 The left end is the front end, and the right end is the back end. The front end is the feed end, the rear end is the discharge end), the front angle folding mechanism includes the front angle folding plate 10 and the front angle folding cylinder 24, the hypotenuses of the two front angle folding plates 10 are hinged to the frame through the hinge shaft 1 on the connecting piece (the oblique vertical plate 44), the bottom surface of the front corner folding plate 10 is hinged with the piston rod of the front corner folding cylinder 24 through the hinge fork and the connecting rod 23, and the front corner folding cylinder 24 (cylinder body) Installed on the beam 41 of the connector. Between the hypo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com