Material dividing and feeding large hopper

A hopper and feeding technology, which is applied in the field of large hoppers for separate feeding, can solve the problems of inflexible and stable control, empty grinding of the next grinding roller, and large installation area, so as to reduce equipment investment and energy consumption, and stabilize material flow rate , the effect of reducing the floor area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

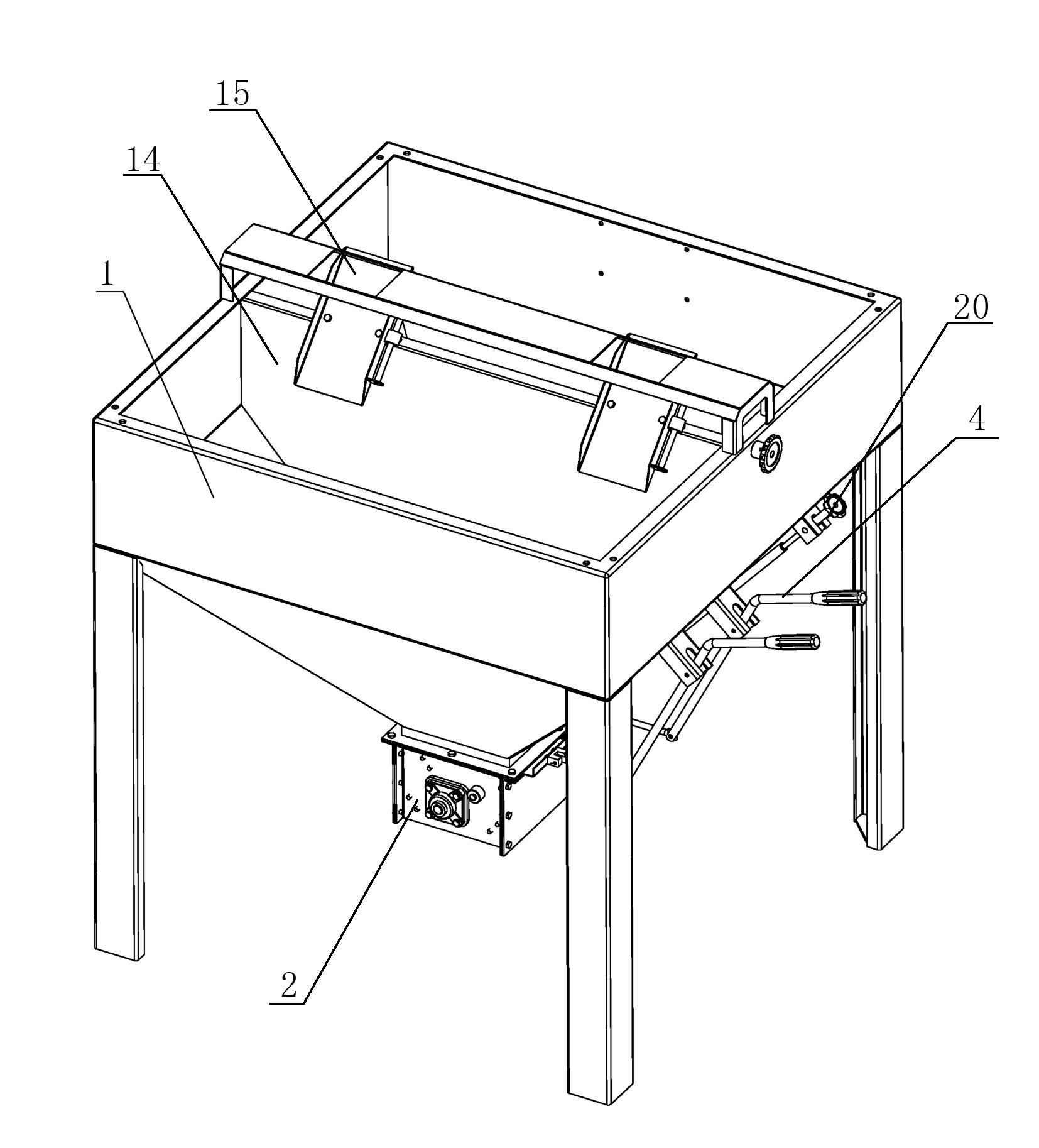

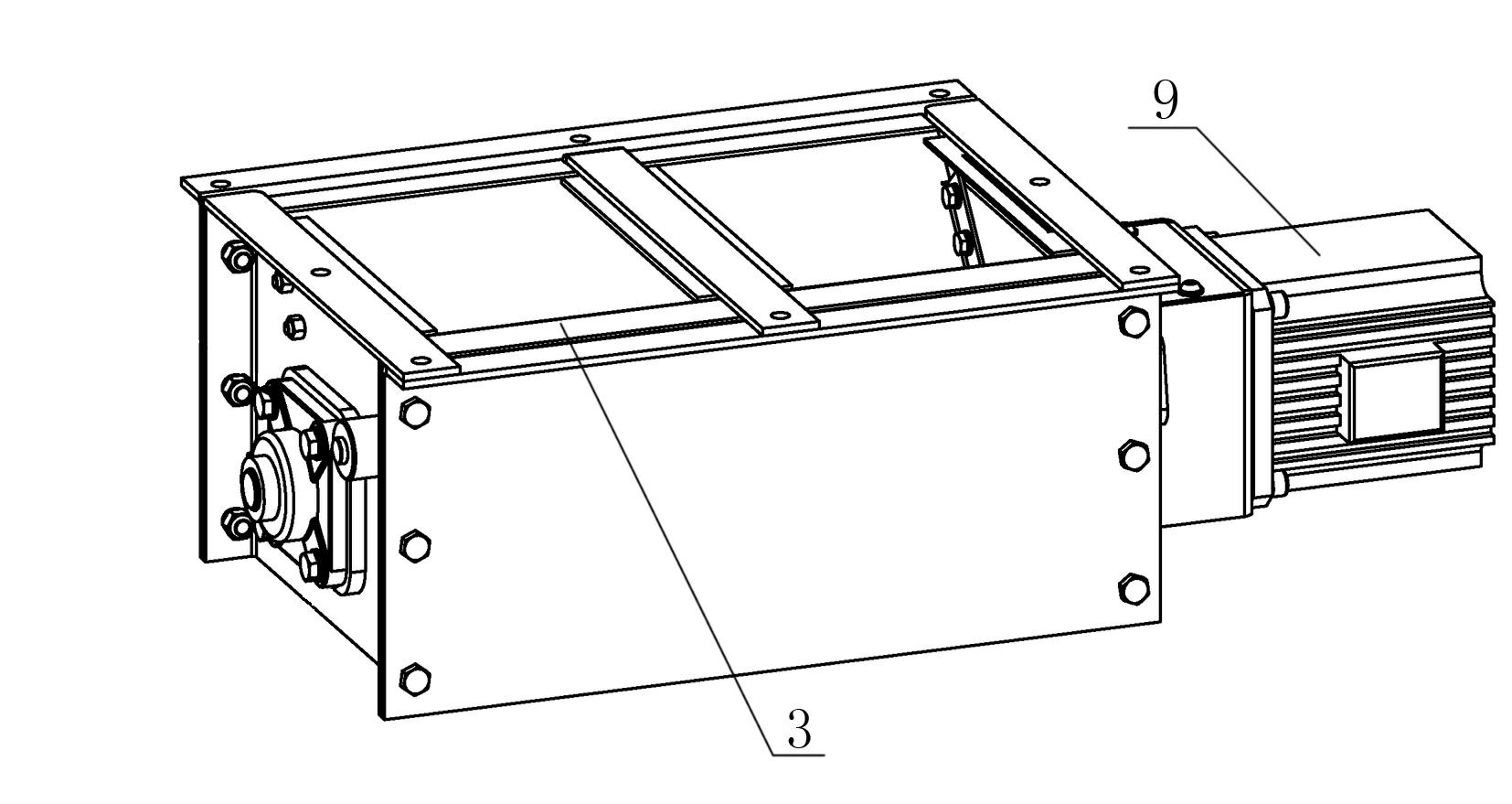

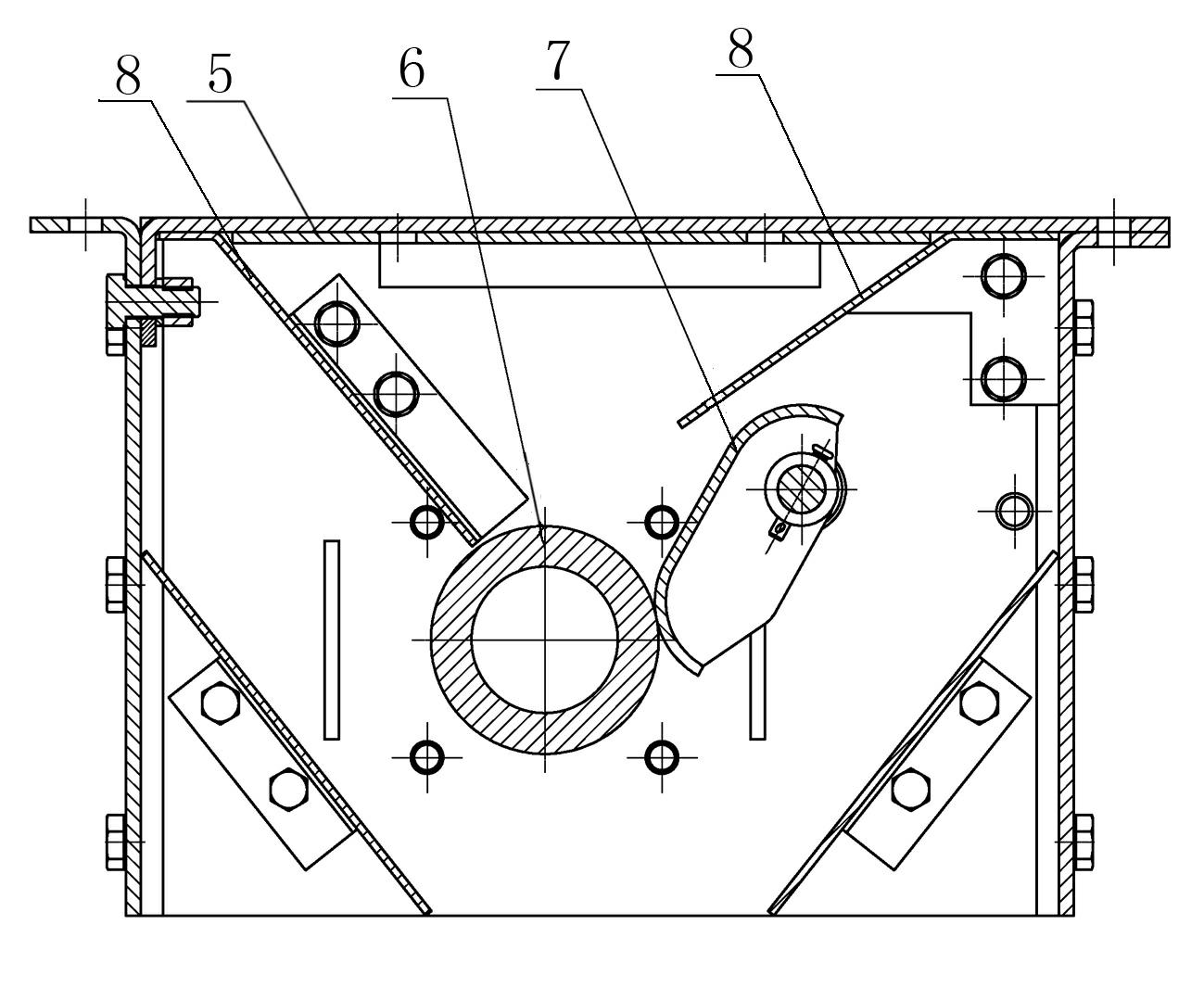

[0021] as attached figure 1 , 2-1 , 2-2, and 3, the present invention consists of a feeding and distributing device 2 with a hopper housing 1 arranged in the hopper housing 1, and the feeding and distributing device 2 is composed of a storage channel with more than two The feeding box 3 and the drawer type material door 4 used to control the opening and closing of the storage channel, the upper end of the feeding box 3 is provided with an intermediary plate 14 for dividing the storage channel, and the feeding box 3 includes a feeding box shell Body 5, the feeding mechanism that is arranged on the feeding box housing 5 by the feeding roller 6 and the pressing knife 7, the guide plate 8 that is arranged on the upper end of the feeding mechanism and the motor 9 for the feeding roller 6; The pumping plate type material door 4 comprises a pumping plate material door 10, a pumping plate connecting rod 11 fixedly connected with the pumping plate material door 10, a control bar 12 hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com