A multi-bridge connection, small-pitch edge-wrapped printed circuit board and its manufacturing method

A technology for printed circuit boards and manufacturing methods, which is applied in the directions of printed circuit components, electrical connection printed components, and the formation of electrical connections of printed components, etc., and can solve the problem of edge-wrapping copper skin warping, too small bridge connection, poor milling defects, etc. Problems, to achieve the effect of good bonding force of gold-clad board edge, prevent warping and falling off, and enhance the bonding force of gold-clad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

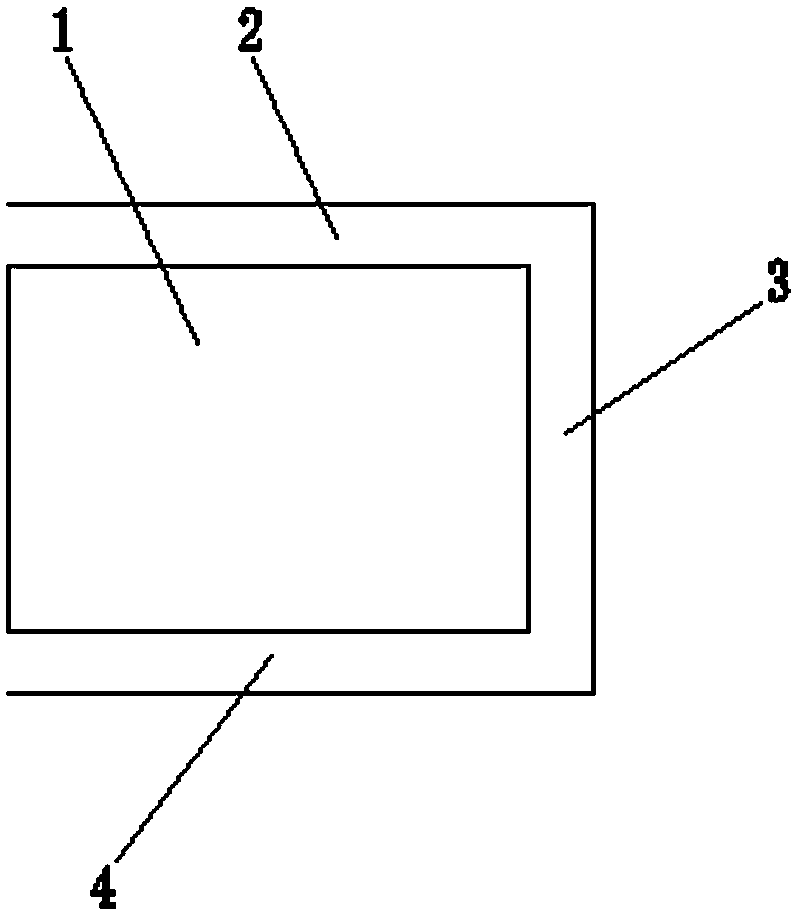

[0042]Such as figure 1 As shown, a printed circuit board with multi-bridge connection and small-pitch edging is mainly composed of a circuit board 1, the side of the circuit board 1 is provided with a metal edging 3, and the upper end surface of the metal edging 3 is connected to the top The surface graphics 2 are connected, and the lower end surface of the metal wrapping 3 is connected with the bottom surface graphics 4. The present invention connects the upper end surface of the metal edging 3 with the top surface graphic 2, and the edging design of the connection between the lower end surface of the metal edging 3 and the bottom surface graphic 4 can effectively enhance the binding force of the plate edge gold coating and prevent the edge edging during the forming process. The copper skin is lifted, falling off, etc., to ensure that the drill bit is in clockwise contact with the wrapping when drilling, effectively ensuring that the drill bit does not lift the copper belt wh...

Embodiment 2

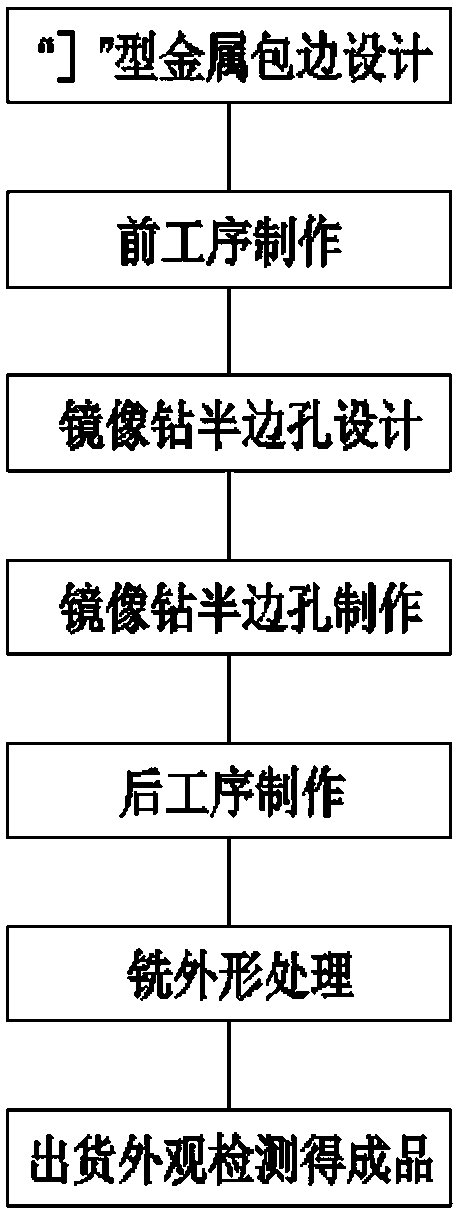

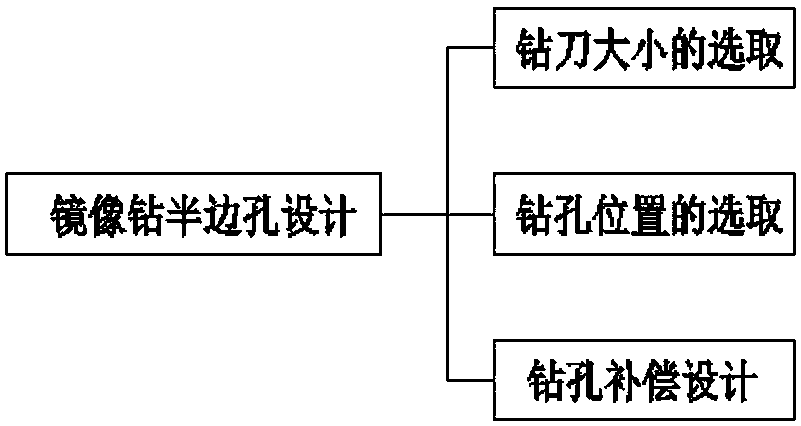

[0044] The structure and principle of this embodiment and embodiment 2 are basically the same, the difference is: as figure 2 As shown, when the upper end surface and the lower end surface of the metal edging 3 are not connected with the top figure 2 and the bottom figure 4, the metal edging 3 is designed as a "]" type metal edging 3 (such as image 3 shown), when the metal edging 3 is a "]" type metal edging 3, the distance between the "]" type metal edging 3 and the circuit pattern is greater than or equal to 3mil. When the metal edging 3 is a "]" type metal edging 3, the length of the edging corners 5 at the top and bottom of the "]" type metal edging 3 is greater than or equal to 3 mils, which effectively ensures the stability of the edging and prevents the edging fall off. The multi-bridge connection and small-pitch edge-wrapping printed circuit board of the present invention adopts the design of "]" type metal edge wrapping 3, which can effectively enhance the bonding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com