Light soft material blanking device

A soft material and blanking technology, applied in the field of light soft material processing equipment, can solve the problems of lower production efficiency, difficulty in meeting production needs, and difficult positioning of cutting dies, etc., and achieve simple and light structure and good negative pressure suction effect , Improve the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

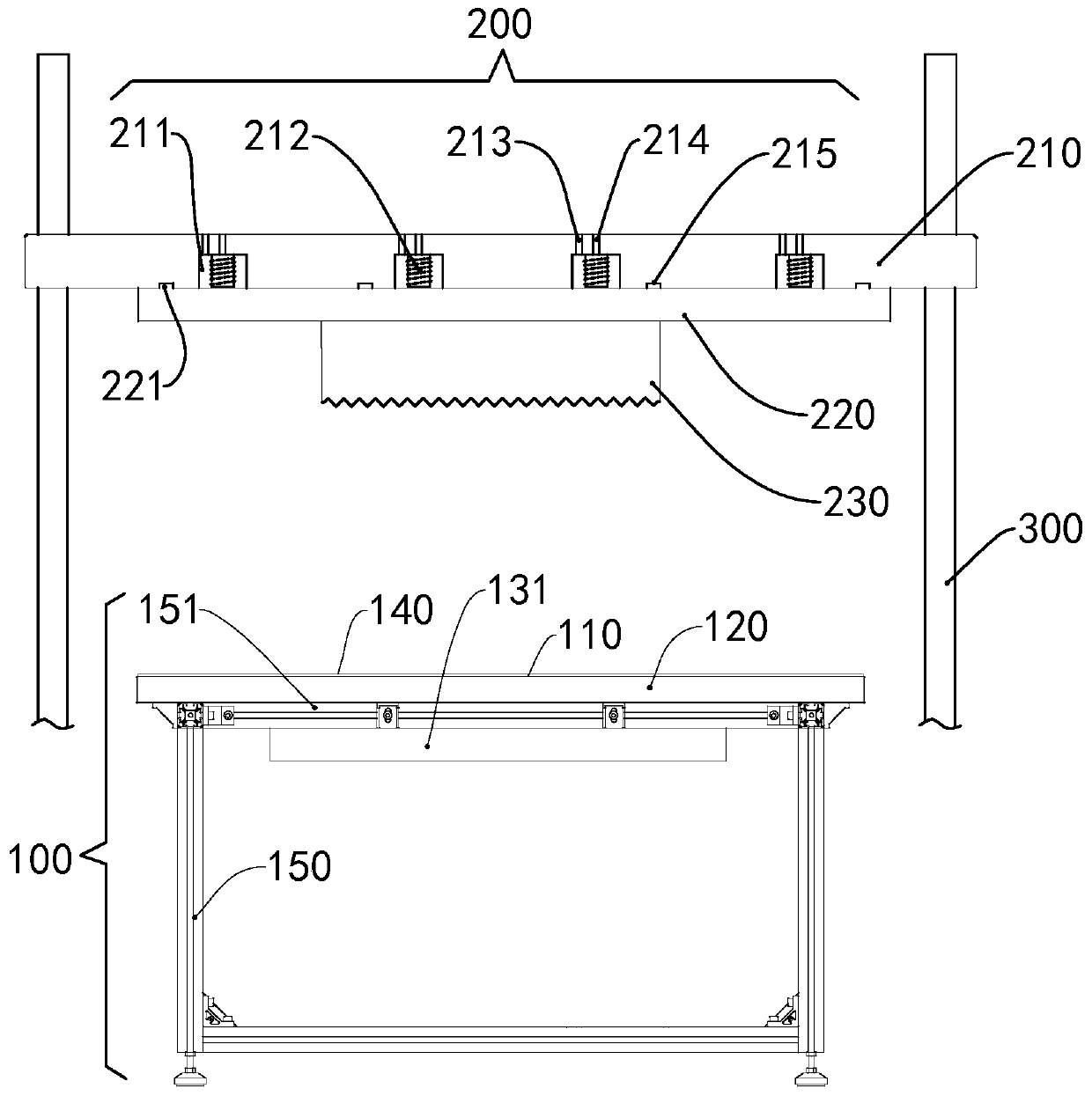

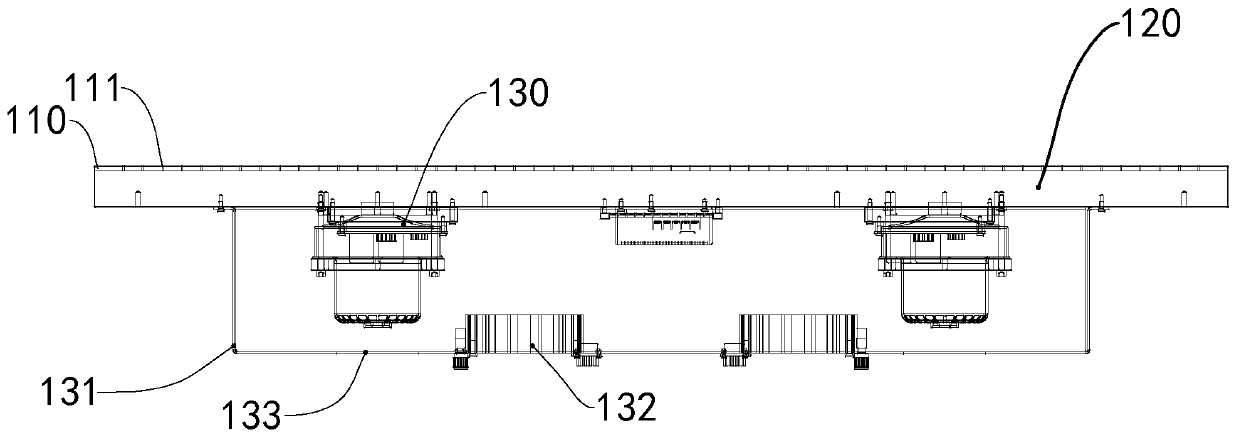

[0053] Such as Figure 1 to Figure 11 As shown, the lightweight soft material blanking device of this embodiment includes a worktable 100 and a die 200 , the die 200 is arranged above the workbench 100 and can move up and down relative to the workbench 100 . For example, the light-duty soft material blanking device may further include a guide column 300 , the guide column 300 is arranged vertically, and the cutting die 200 is slidably connected with the guide column 300 . The light-duty soft material blanking device may also include a driving member such as an oil cylinder, an air cylinder or a motor, etc., for pushing the knife die 200 to move up and down. The guide column 300 can be connected to an adjustment device, and the adjustment device is used to move the guide column 300 and the connected die 200 in a horizontal direction, such as front, rear, left, and right, so as to adjust the position of the die die 200 relative to the horizontal plane of the workbench 100 .

[...

no. 2 example

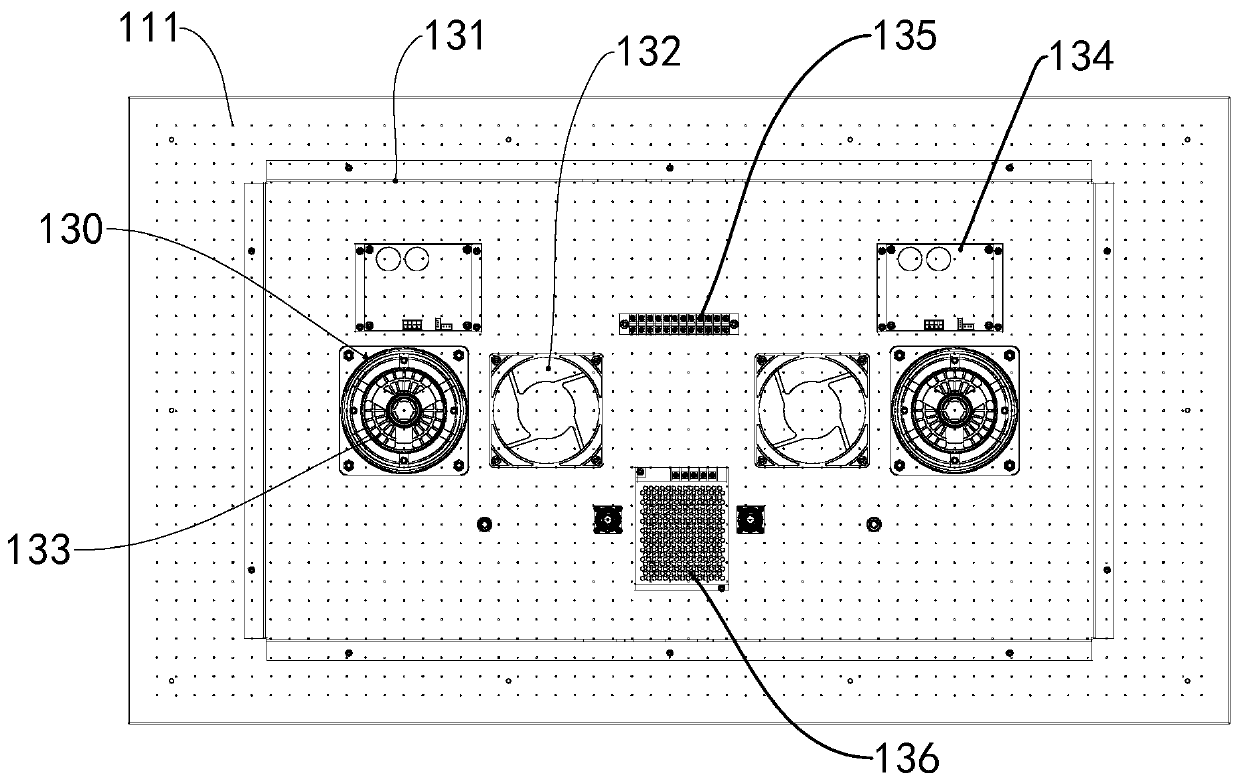

[0075] Such as Figure 12 to Figure 13 As shown, the structure of this embodiment is similar to that of the above-mentioned first embodiment, and the difference is that the table top 110 can be divided into a plurality of work areas, each work area is provided with a first air extraction hole 111, and the air groove 112 is formed on the upper surface of the table top 110. Connect the adjacent first air suction holes 111 in the same working area. An air extraction device is connected below each working area, and each air extraction device includes a chamber, a cover body, at least one blower fan and at least one instrument fan. Different chambers corresponding to different air extraction devices may be separated by a single integral chamber, and the different chambers are respectively connected to the cover body, the blower fan and the instrument fan.

[0076] In this embodiment, on the basis of the first embodiment, the countertop 110 is partitioned, and the negative pressure...

no. 3 example

[0078] Such as Figure 14 As shown, the structure of this embodiment is basically the same as that of the above-mentioned first embodiment, the difference is that the first limiting part in the die is the first limiting hole 216, and the second limiting part is the second limiting hole 222, that is, the positioning The board 210 is provided with a first limiting hole 216 , and the mounting plate 220 is provided with a second limiting hole 222 . The first limiting hole 216 is aligned with the second limiting hole 222 , and the limiting member 240 connects the first limiting hole 216 and the second limiting hole 222 . For example, the first limiting hole 216 and the second limiting hole 222 may be tapered through holes whose diameter decreases from top to bottom, and the limiting member 240 may be a conical pin. For example, one of the first limiting hole 216 and the second limiting hole 222 can be a threaded hole, the other can be a through hole, and the limiting member 240 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com