Lithium battery electrolyte cold recovery filter device

A filter device and electrolyte technology, which is applied in battery recycling, fixed filter elements, filtration and separation, etc., can solve problems such as environmental hazards, impact on electrolyte recycling, waste of resources, etc., to improve recovery and utilization rates, Increase the sealing and ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

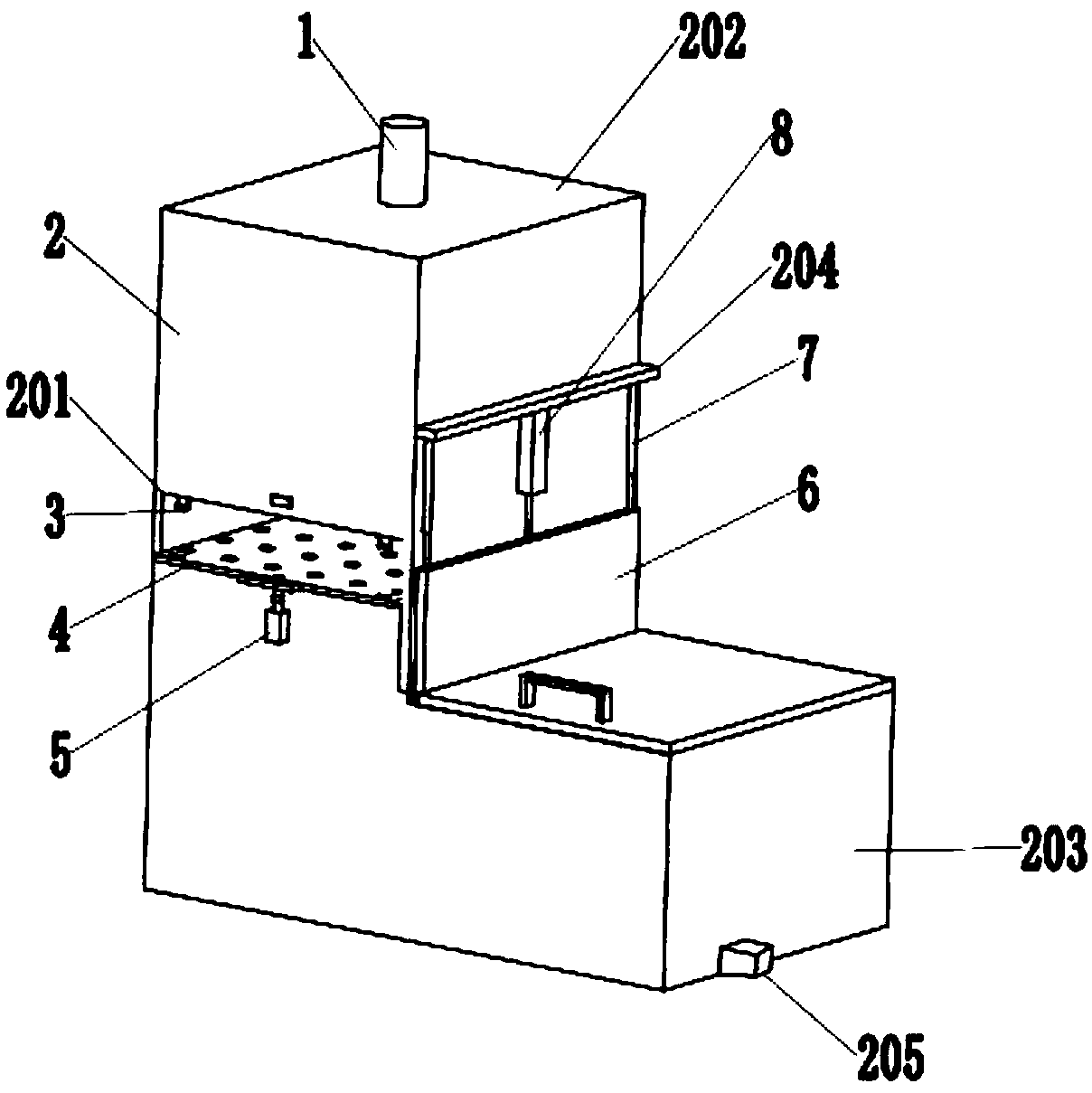

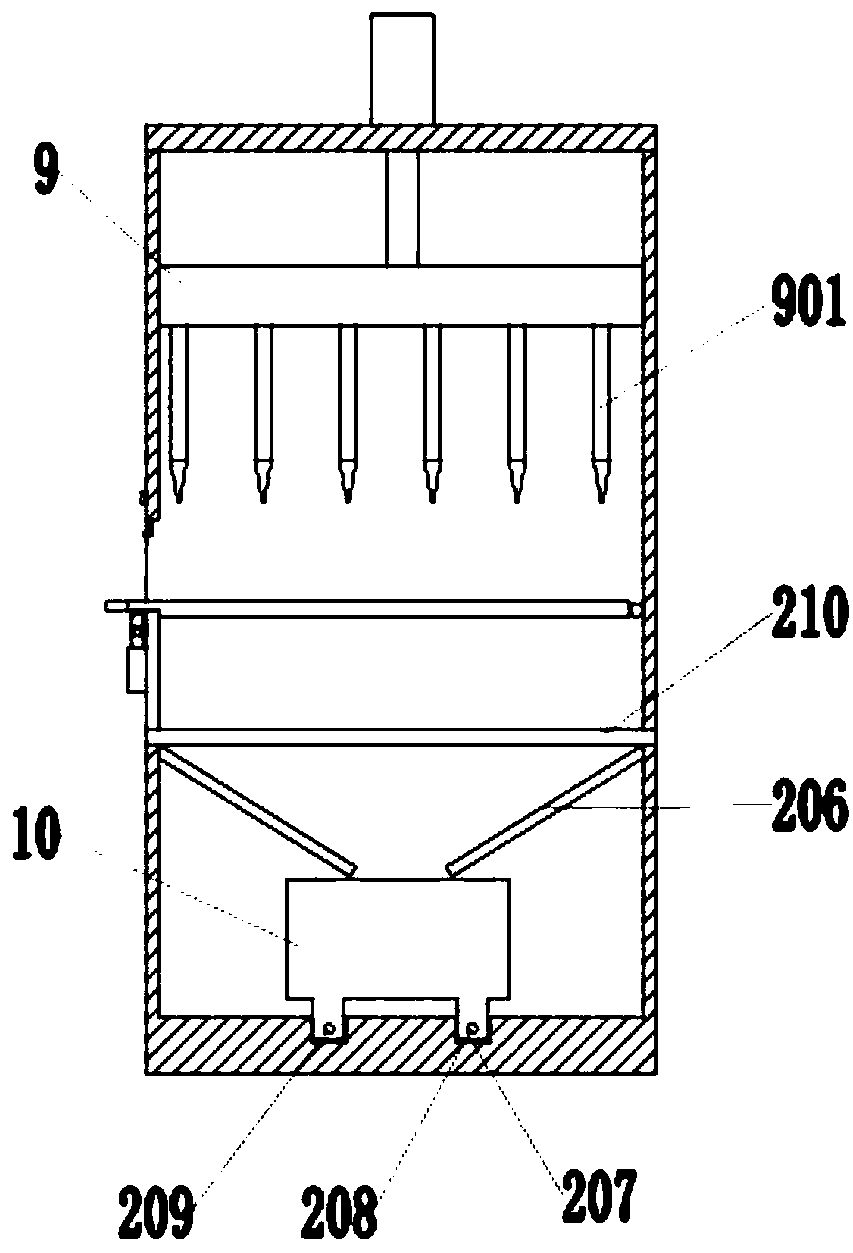

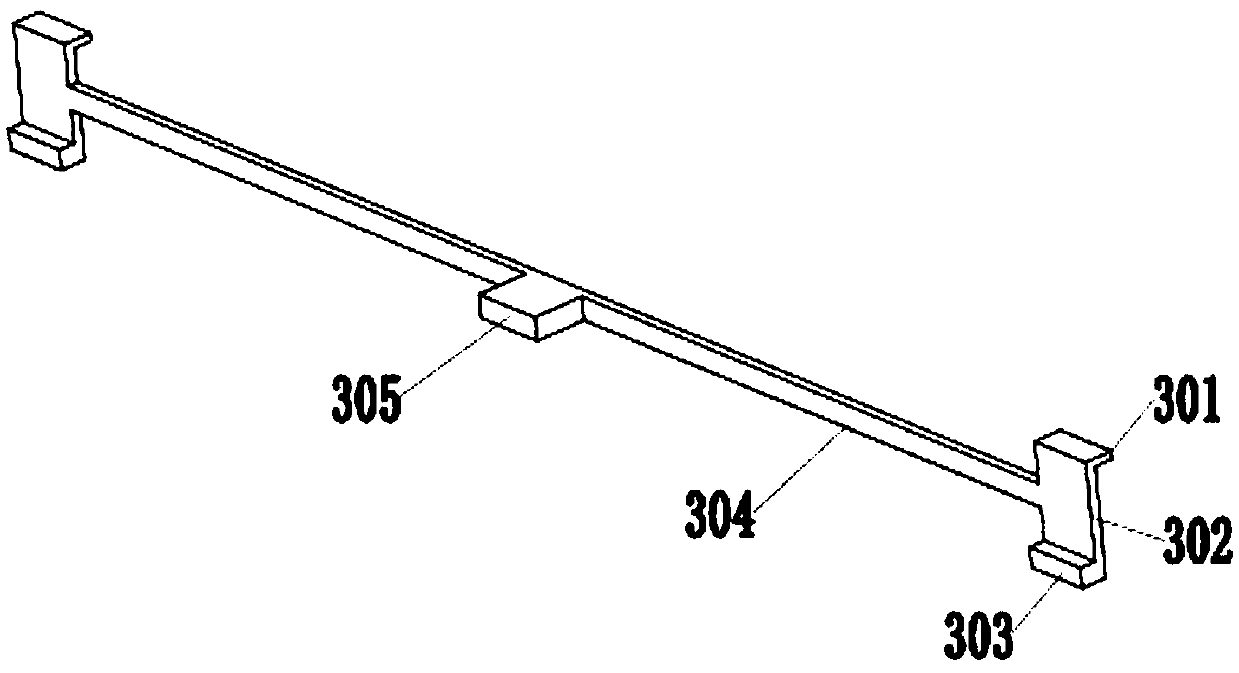

[0028] Such as Figure 1-5 As shown, a lithium battery electrolyte cooling recovery filter device includes a hydraulic cylinder 1, a cabinet 2, an upper filter plate 4, a partition 6, a pressure head 9, and a collection vehicle 10, and the cabinet 2 includes a crushing box 202 and a freezer Box 203, the freezer box 203 communicates with the lower end side of the crushing box 202, the pressure head 9 is located on the upper side of the crushing box 202, the hydraulic cylinder 1 is located at the upper end of the crushing box 202, and the hydraulic cylinder 1 The telescopic end is connected with the indenter 9, and the lower end surface of the indenter 9 is evenly provided with a puncture needle 901, and an upper filter plate 4 is arranged below the puncture needle 901, and a lower filter plate is arranged below the upper filter plate 4 210, one side of the upper filter plate 4 is rotatably connected with the inner wall of the crushing box 202, and the four sides of the lower fi...

Embodiment 2

[0030] Such as Figure 1-5 As shown, a lithium battery electrolyte cooling recovery filter device includes a hydraulic cylinder 1, a cabinet 2, an upper filter plate 4, a partition 6, a pressure head 9, and a collection vehicle 10, and the cabinet 2 includes a crushing box 202 and a freezer Box 203, the freezer box 203 communicates with the lower end side of the crushing box 202, the pressure head 9 is located on the upper side of the crushing box 202, the hydraulic cylinder 1 is located at the upper end of the crushing box 202, and the hydraulic cylinder 1 The telescopic end is connected with the indenter 9, and the lower end surface of the indenter 9 is evenly provided with a puncture needle 901, and an upper filter plate 4 is arranged below the puncture needle 901, and a lower filter plate is arranged below the upper filter plate 4 210, one side of the upper filter plate 4 is rotatably connected with the inner wall of the crushing box 202, and the four sides of the lower fi...

Embodiment 3

[0034] Such as Figure 1-5 As shown, a lithium battery electrolyte cooling recovery filter device includes a hydraulic cylinder 1, a cabinet 2, an upper filter plate 4, a partition 6, a pressure head 9, and a collection vehicle 10, and the cabinet 2 includes a crushing box 202 and a freezer Box 203, the freezer box 203 communicates with the lower end side of the crushing box 202, the pressure head 9 is located on the upper side of the crushing box 202, the hydraulic cylinder 1 is located at the upper end of the crushing box 202, and the hydraulic cylinder 1 The telescopic end is connected with the indenter 9, and the lower end surface of the indenter 9 is evenly provided with a puncture needle 901, and an upper filter plate 4 is arranged below the puncture needle 901, and a lower filter plate is arranged below the upper filter plate 4 210, one side of the upper filter plate 4 is rotatably connected with the inner wall of the crushing box 202, and the four sides of the lower fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com