Tapping jig capable of avoiding dragging product

A product and fixture technology, applied in the field of mechanical processing, can solve problems such as damaged products and taps, product surface pinching, complex fixture structure, etc., to achieve the effects of increased friction, easy processing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

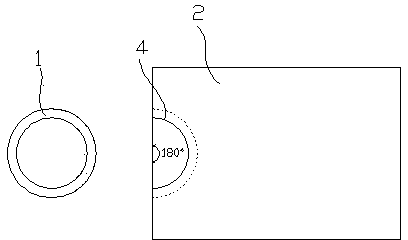

[0023] Such as Figure 1-3 As shown, a tapping jig to prevent products from following, wherein the product 1 is in the shape of a circular table, the jig includes a plate-shaped base 2, the base 2 is provided with an opening upward, and its internal shape is similar to that of the product 1 on one side of the circumference. Cooperating accommodation groove 4.

[0024] Specifically, the tank body of the accommodating tank 4 is small at the top and large at the bottom, the cross section is fan-shaped, and the central angle of the fan is 180°. The vertical distance from the bottom of the accommodation tank 4 to the bottom of the base 2 is greater than the height of the housing tank 4 to ensure the strength of the accommodation tank 4 .

[0025] When in use, the base 2 is fixed, and the small end of the product 1 faces upwards and the large end faces downwards, and the product 1 is aligned at the same height as the accommodating groove 4 and inserted into the accommodating groove...

Embodiment 2

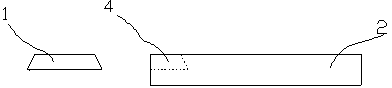

[0027] Such as Figure 4 As shown, a tapping jig to prevent products from following, wherein the product 1 is in the shape of a circular table, the jig includes a plate-shaped base 2, the base 2 is provided with an opening upward, and its internal shape is similar to that of the product 1 on one side of the circumference. Cooperating accommodation groove 4.

[0028] Specifically, the tank body of the accommodating tank 4 is small at the top and large at the bottom, the cross section is fan-shaped, and the central angle of the fan is 180°. The vertical distance from the bottom of the accommodation tank 4 to the bottom of the base 2 is greater than the height of the housing tank 4 to ensure the strength of the accommodation tank 4 . More specifically, the base 2 is provided with a mounting groove, and the strip-shaped elastic member 6 is embedded in the mounting groove 8 to form the accommodating groove 4 , that is, the inner wall of the elastic member 6 is the groove wall of t...

Embodiment 3

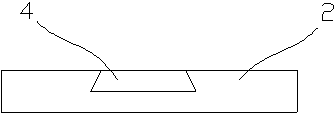

[0031] Such as Figure 5 As shown, a tapping jig to prevent products from following, wherein the product 1 is in the shape of a circular table, the jig includes a plate-shaped base 2, and the base 2 is provided with a container with an opening upward and an internal shape that matches the shape of the product 1. Slot 4.

[0032] Specifically, the tank body of the accommodating tank 4 is small at the top and large at the bottom, and is in the shape of a circular frustum with a circular cross section. The vertical distance from the bottom of the accommodation tank 4 to the bottom of the base 2 is greater than the height of the housing tank 4 to ensure the strength of the accommodation tank 4 . The base 2 is composed of a first part 22 and a second part 24. The first part 22 is provided with a first groove 42 with a semicircular cross section, and the second part 24 is provided with a second groove 44 with a semicircular cross section. The first groove 42 and the second groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com