Basket pressing device for food processing

A food processing and basket-type technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of inconvenient operation, complicated use steps, and poor mobility, so as to improve the stability and accuracy of placement, improve the strength of support and fixation, The effect of improving placement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

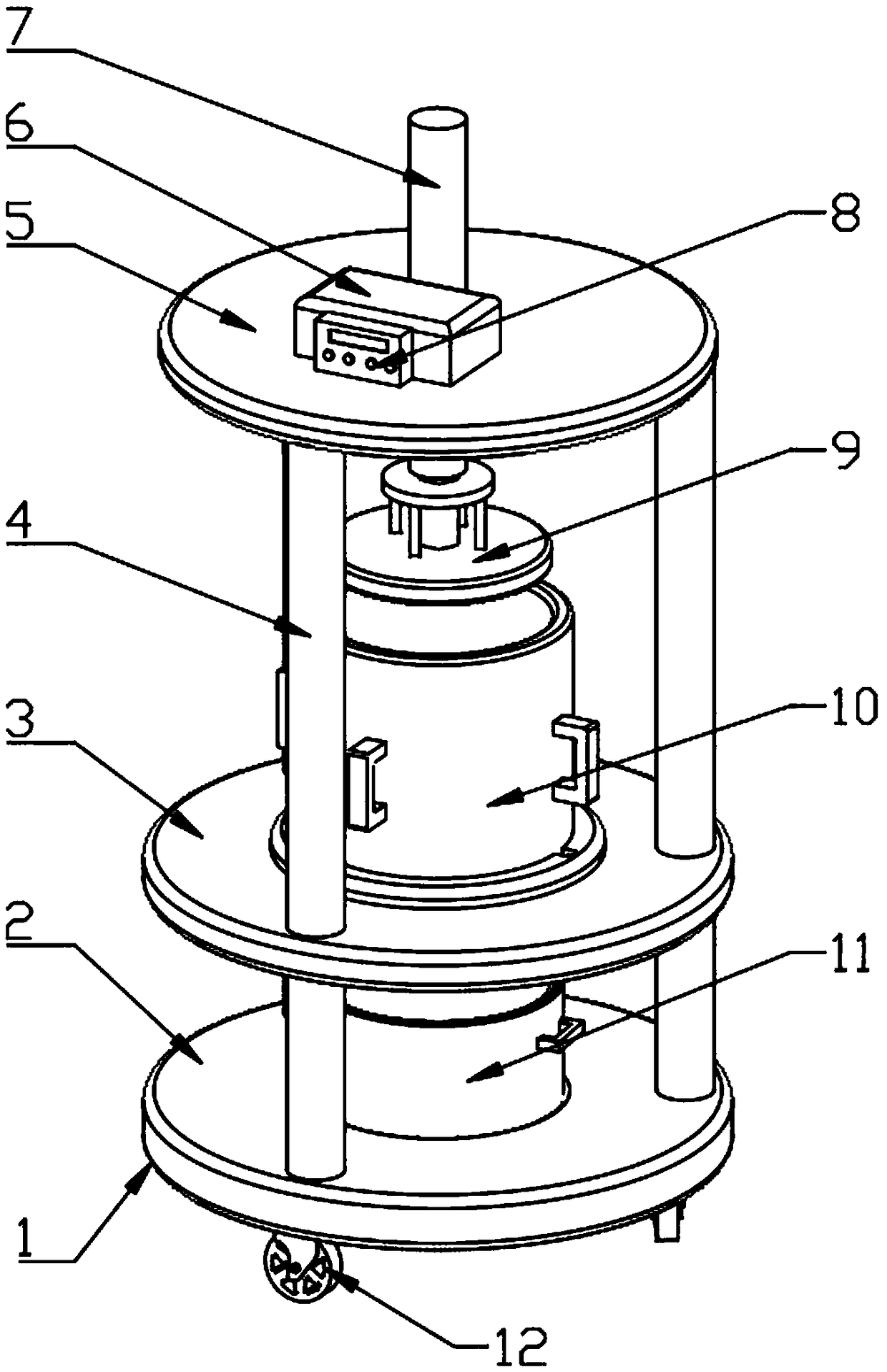

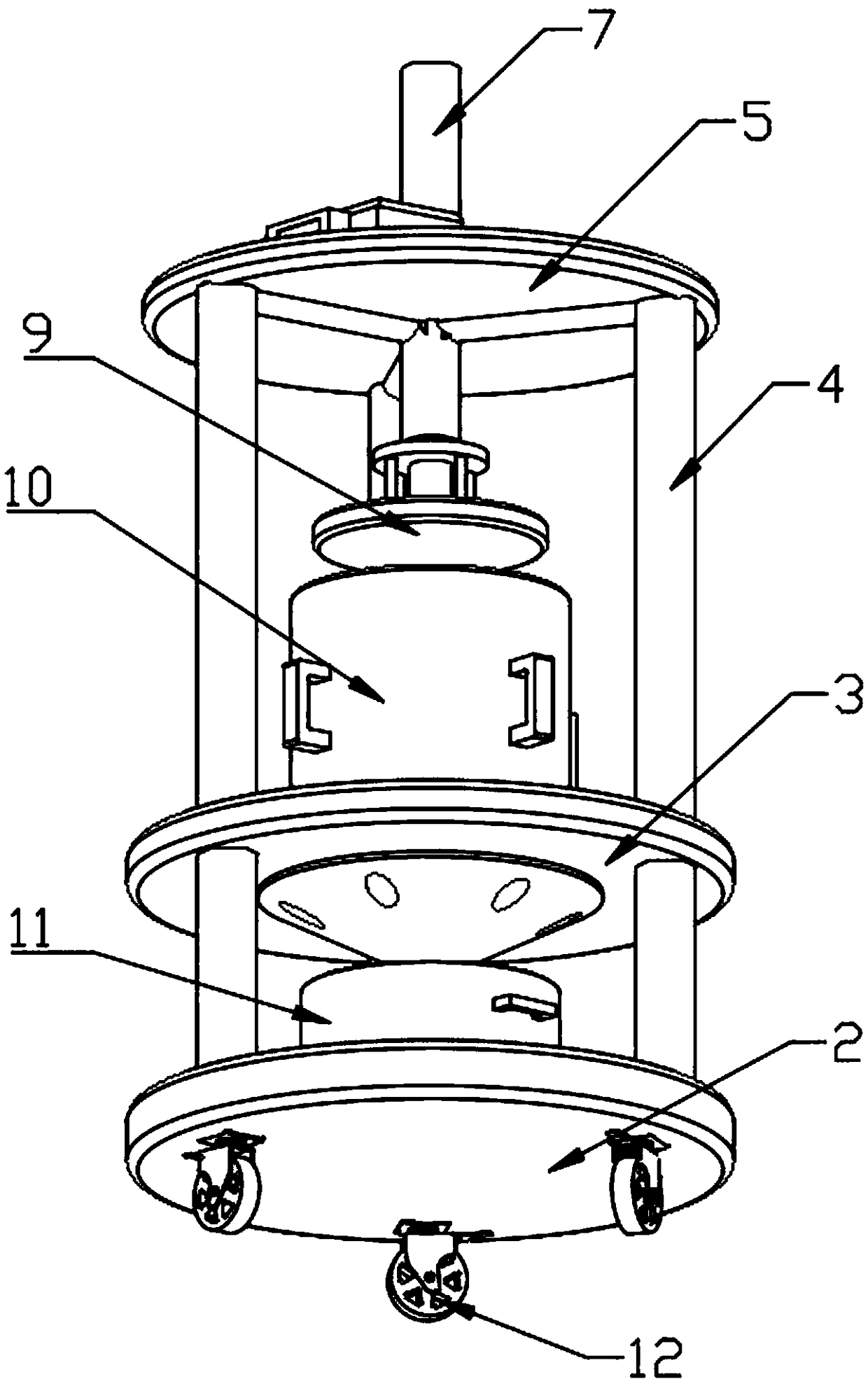

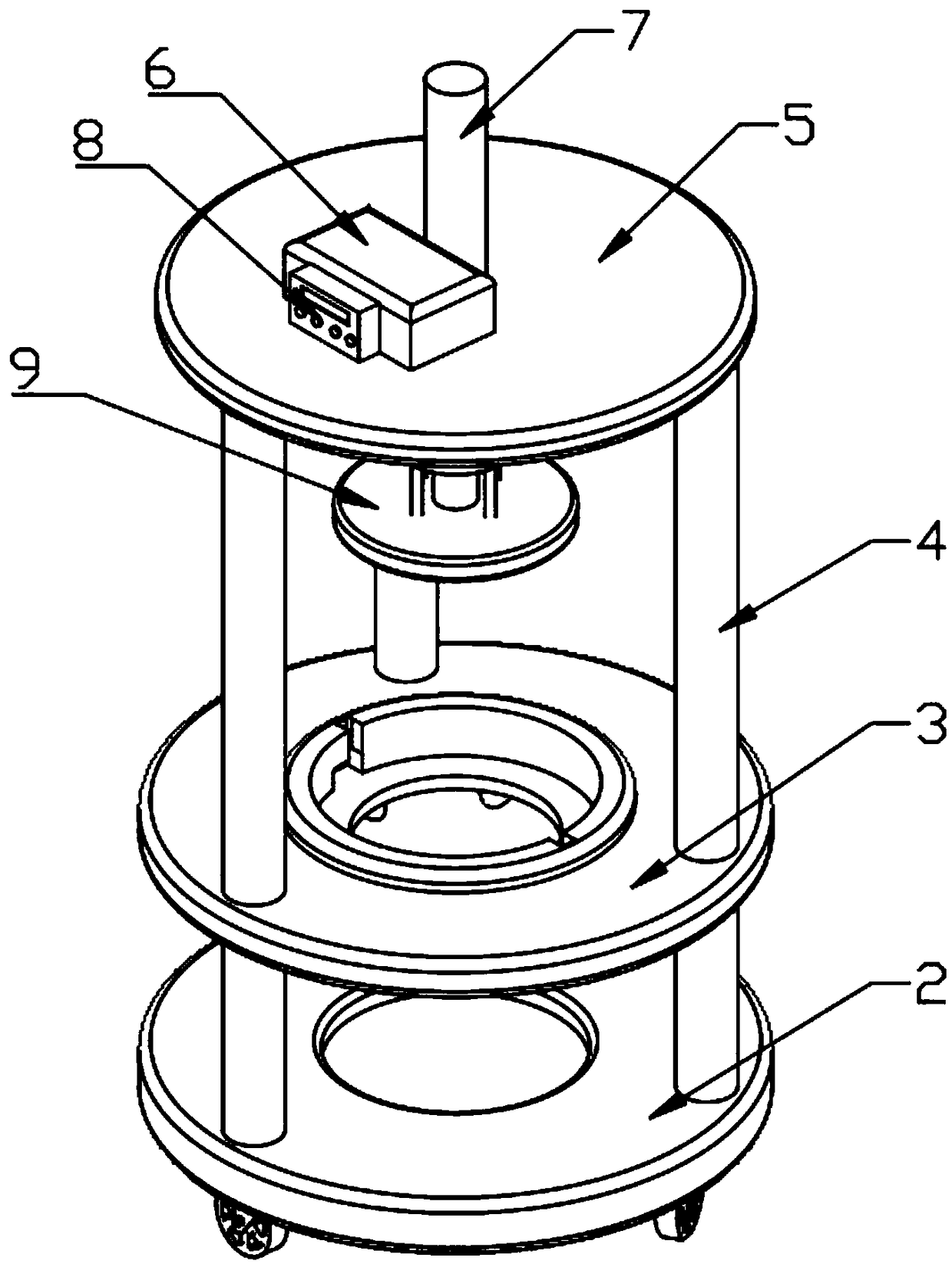

[0038] as attached figure 1 to attach Figure 8 Shown:

[0039]The present invention provides a basket press device for food processing, which includes: a device body 1, a fixed bottom plate 2, a middle fixed plate 3, a press cylinder fixing groove 301, a limit groove 301a, a liquid collection tank 302, and a reinforcement column 302a , support column 4, top fixed plate 5, air pump 6, pneumatic hydraulic cylinder 7, controller 8, pressure plate 9, squeeze cylinder 10, turning handle 1001, limit block 1002, liquid outlet 1003, liquid storage cylinder 11 and moving wheel 12; the bottom of the device body 1 is provided with a fixed base plate 2; the bottom side of the fixed base plate 2 is symmetrically provided with three moving wheels 12; the upper middle position of the fixed base plate 2 is provided with a liquid containing cylinder 11; The upper side of the fixed bottom plate 2 is provided with a middle fixed plate 3; the upper side of the middle fixed plate 3 is locked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com