Patents

Literature

128results about How to "Small insertion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

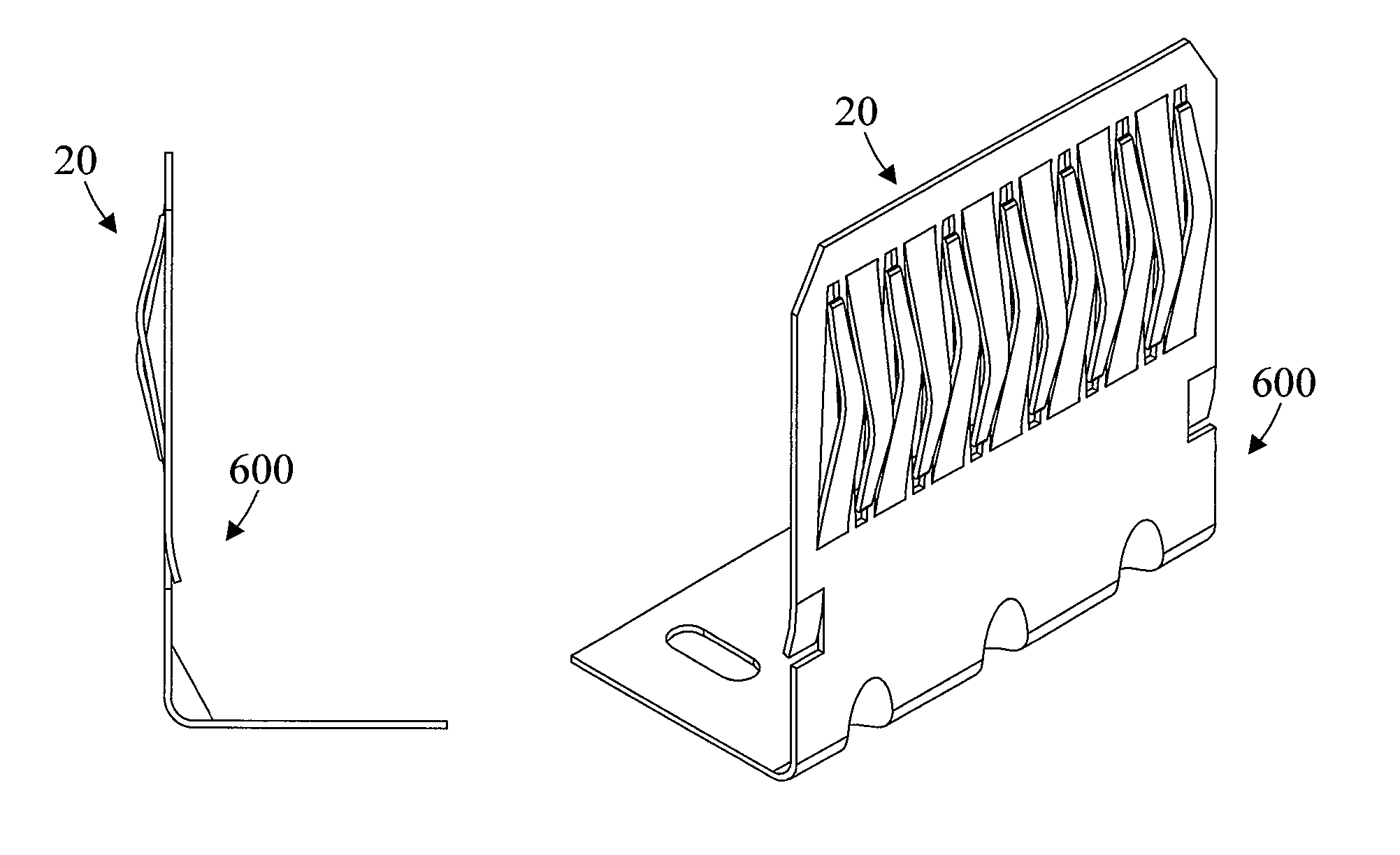

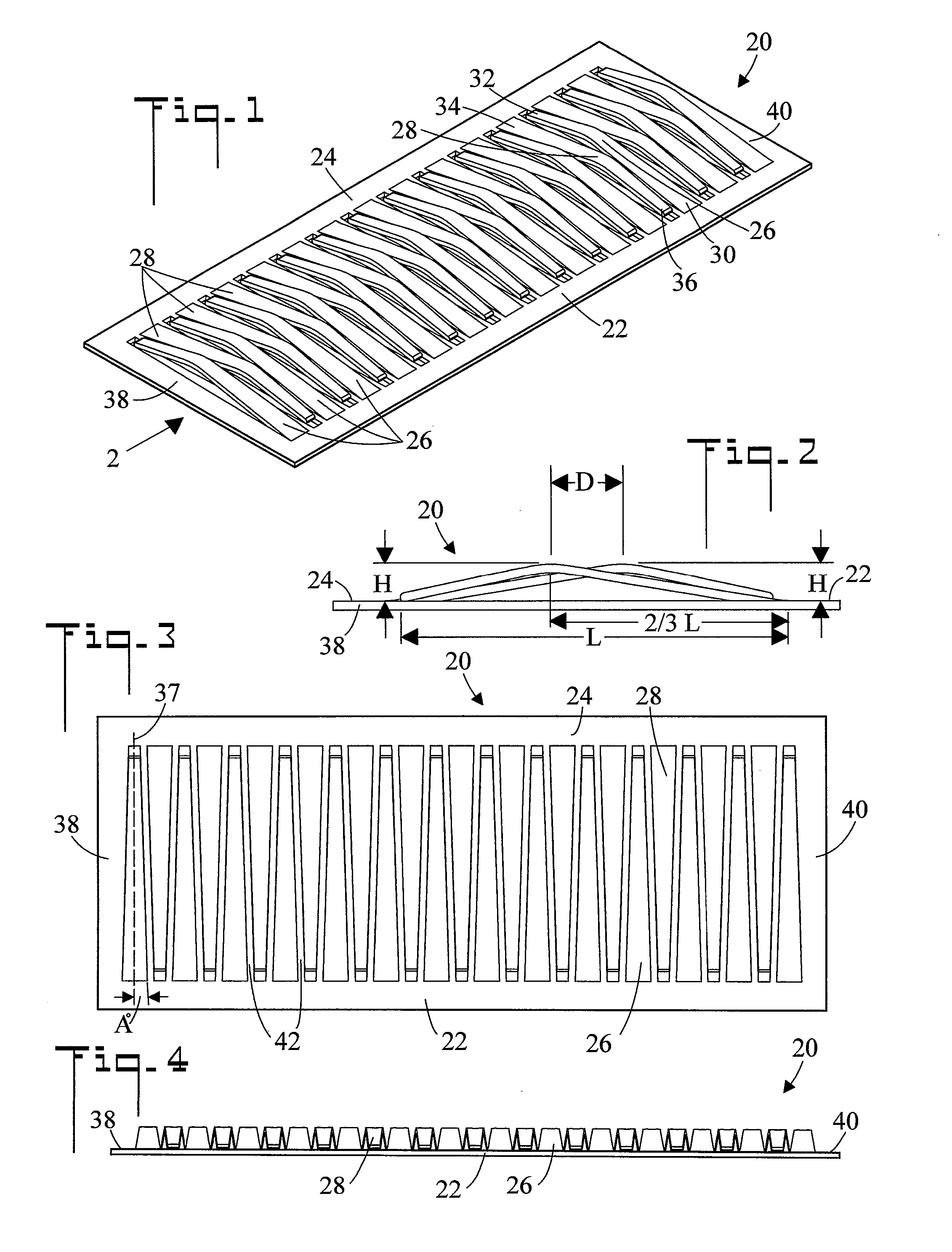

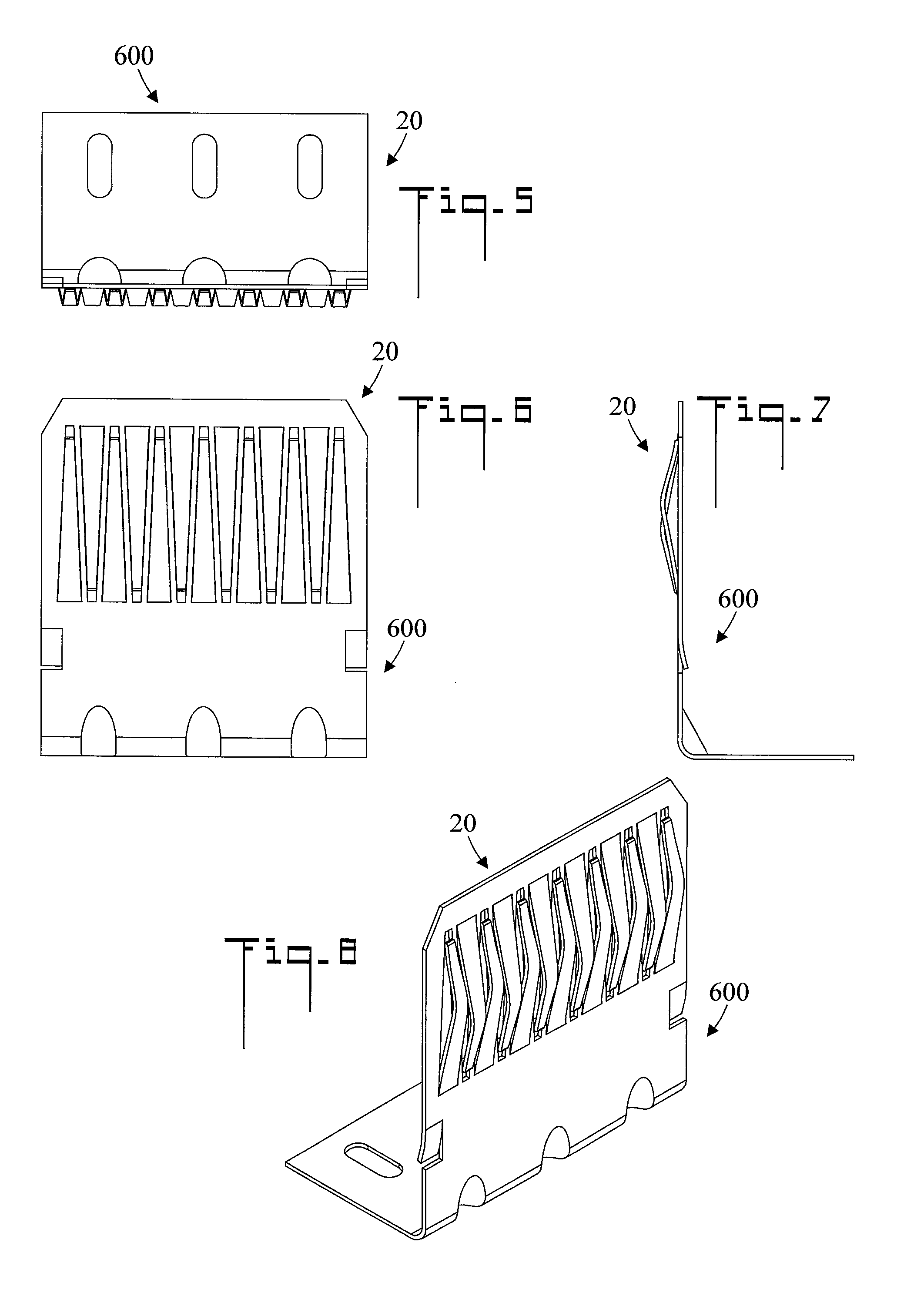

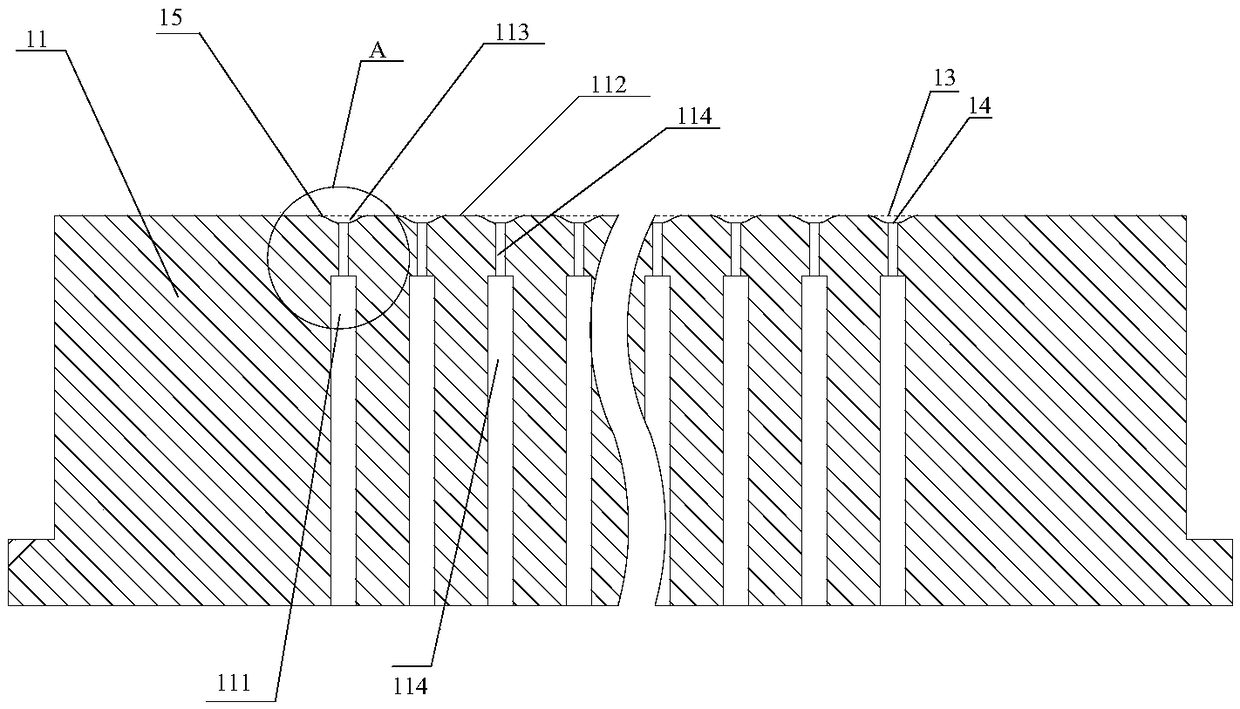

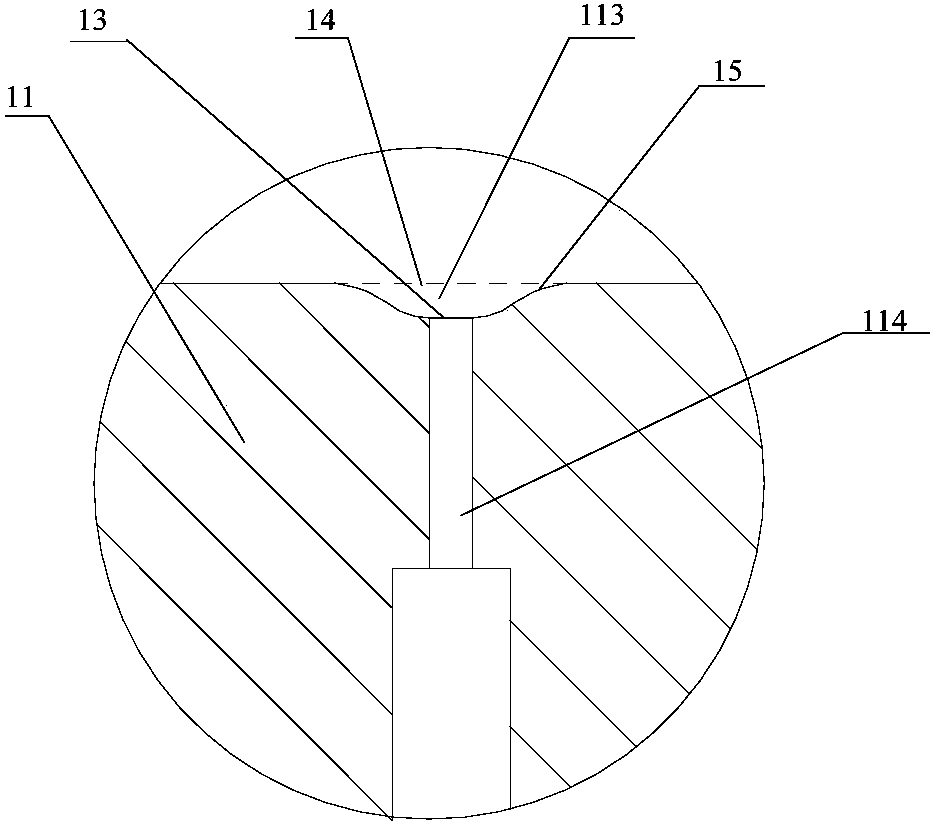

Electrical contact having multiple cantilevered beams

ActiveUS8821170B1Small insertion forceHigh currentElectrically conductive connectionsCoupling device detailsCantilevered beamEngineering

An electrical contact includes a first set of spaced apart cantilevered beams connected to a first rail, and a second set of cantilevered beams connected to a second rail. The first set of cantilevered beams project toward the second rail, and the second set of cantilevered beams project toward the first rail, wherein the first and second sets of cantilevered beams reside in alternating relationship. Each cantilevered beam is bowed and is outwardly tapered from its connected proximal to its unconnected distal end.

Owner:BELLWETHER ELECTRONIC CORP

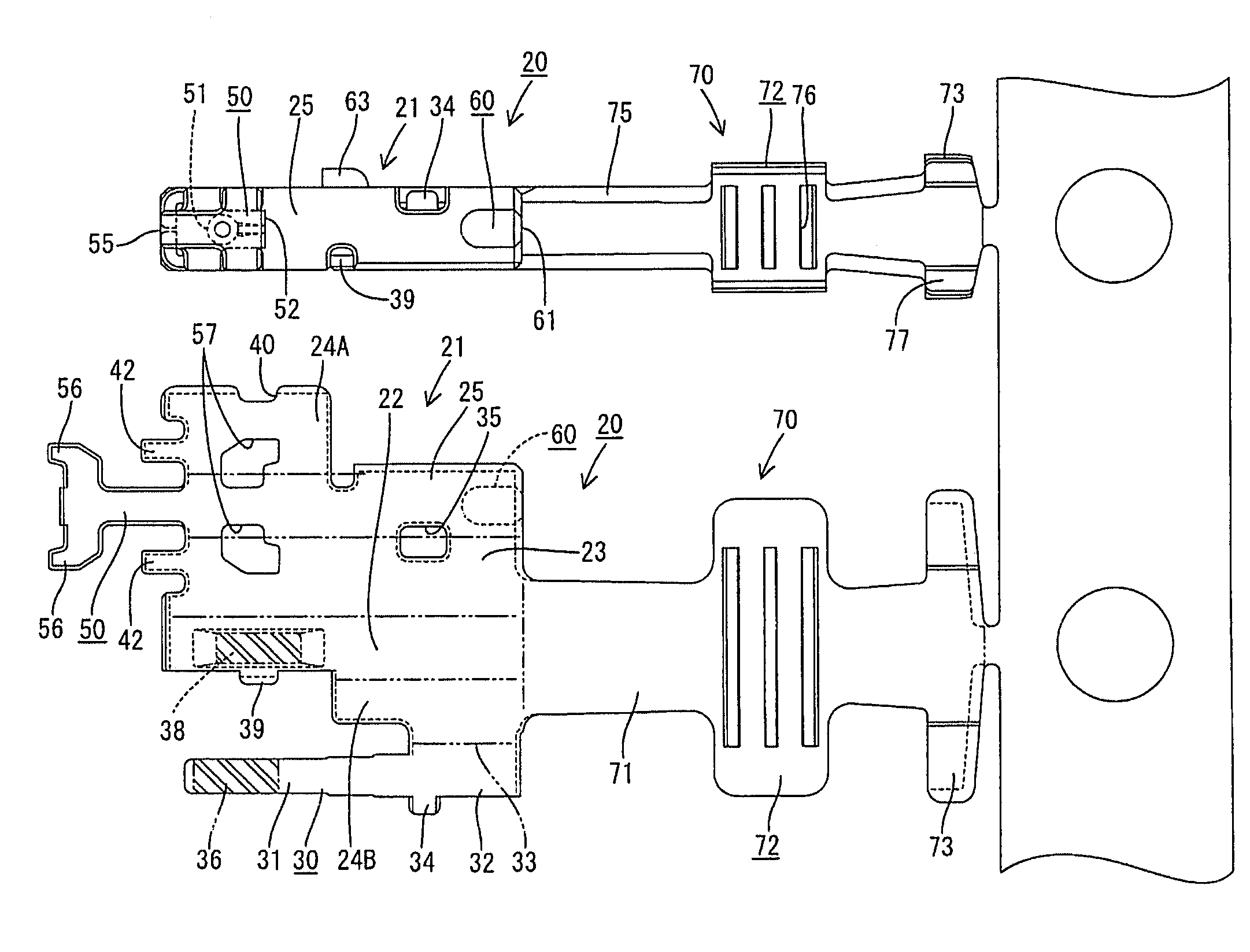

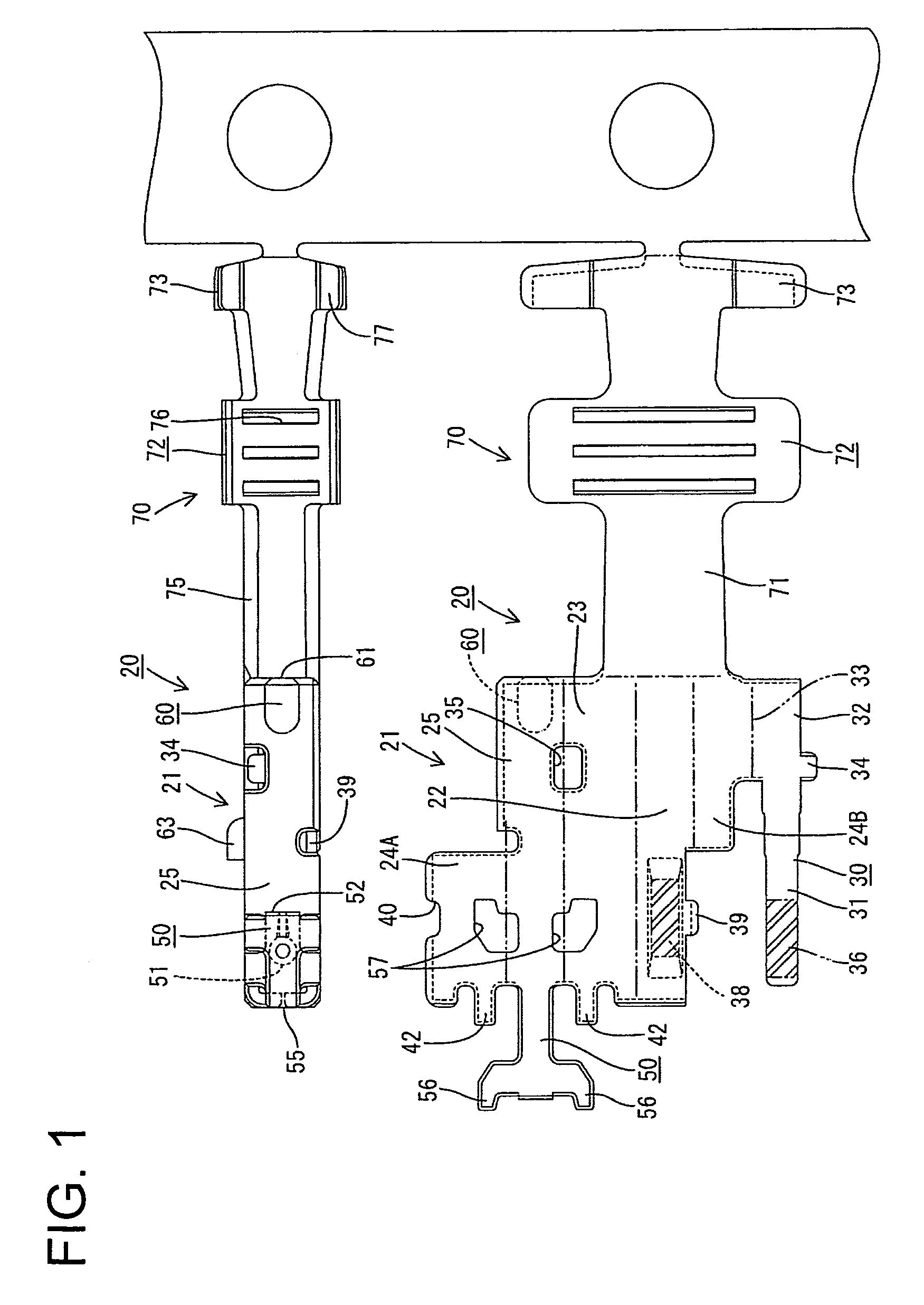

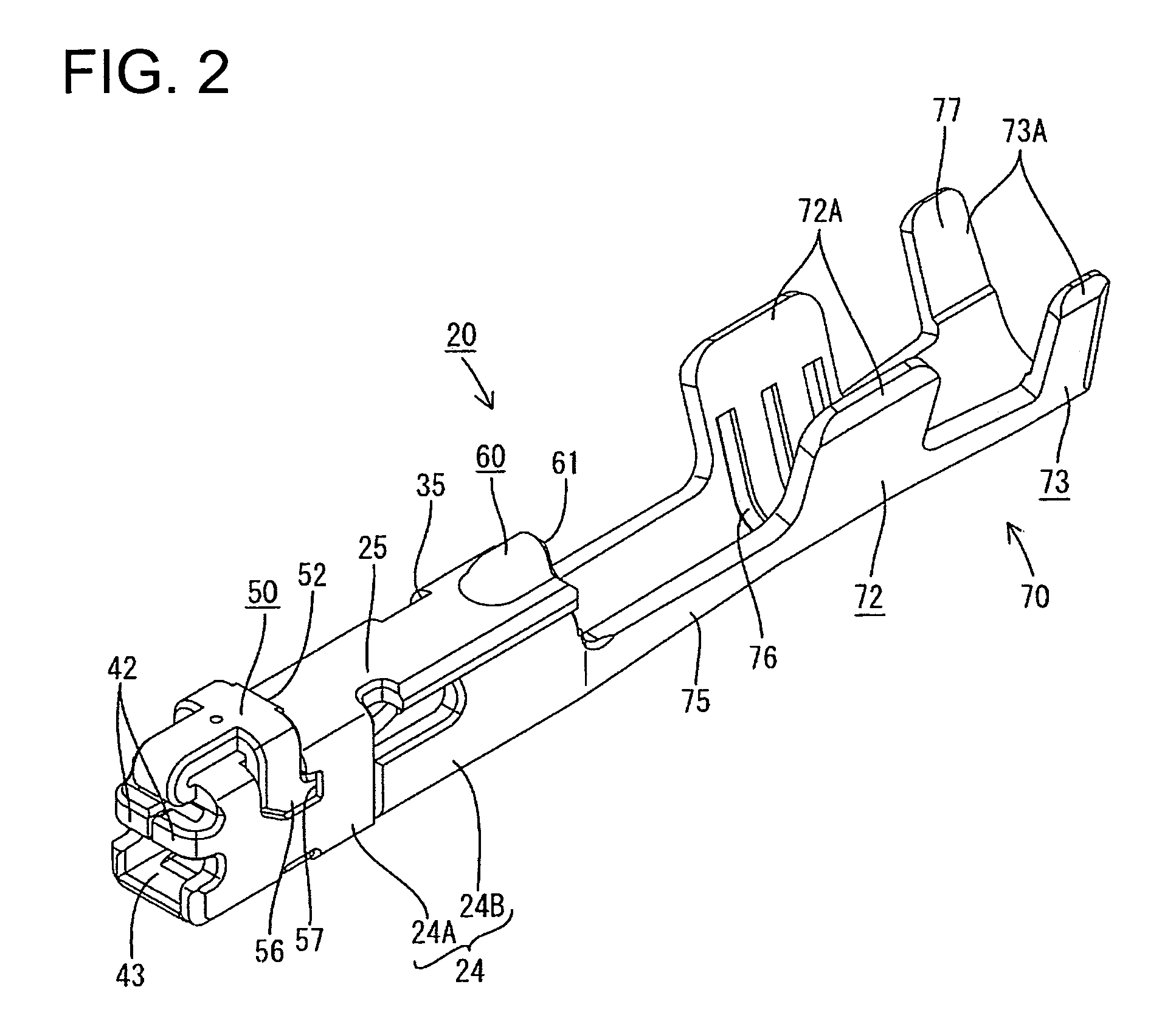

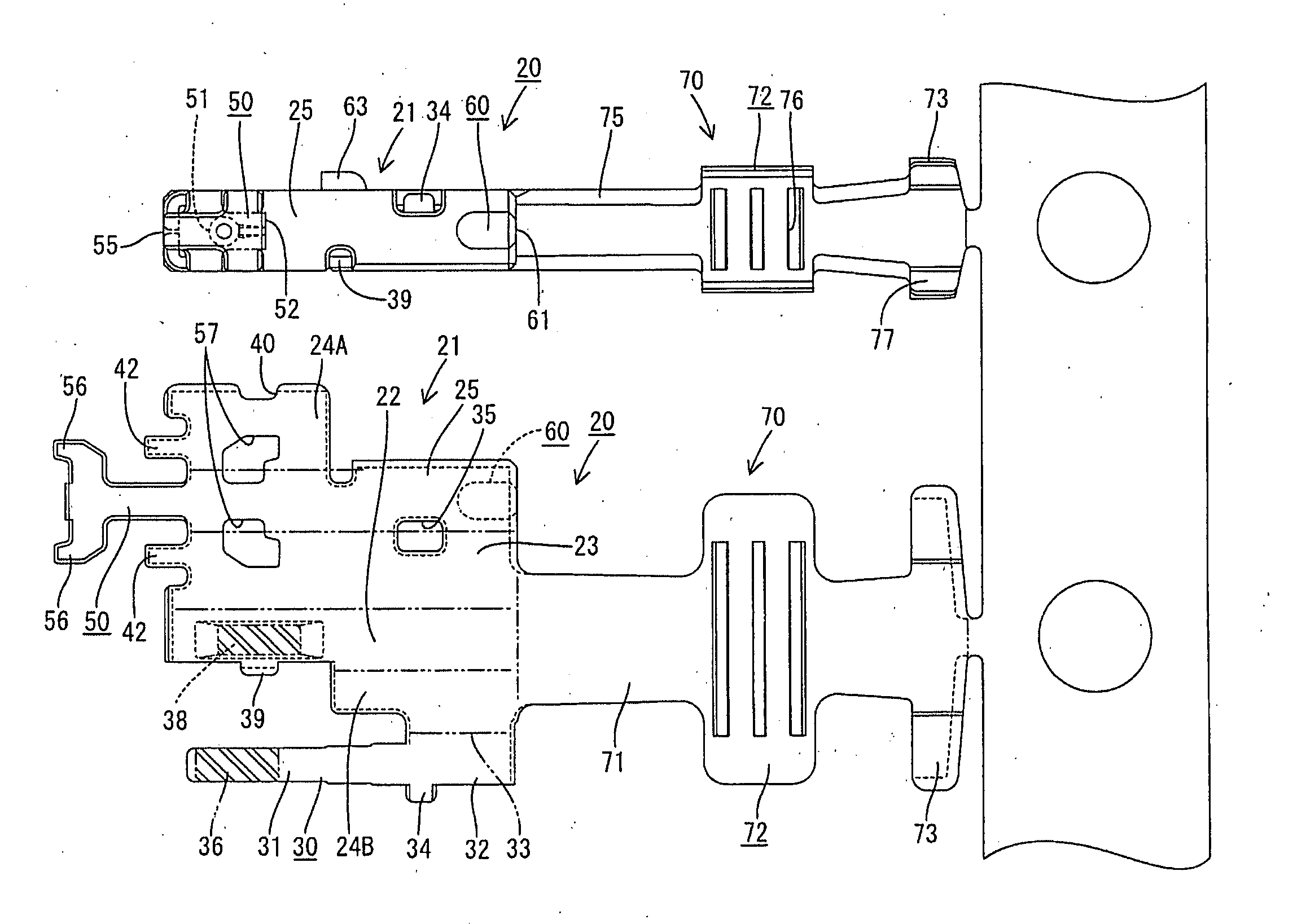

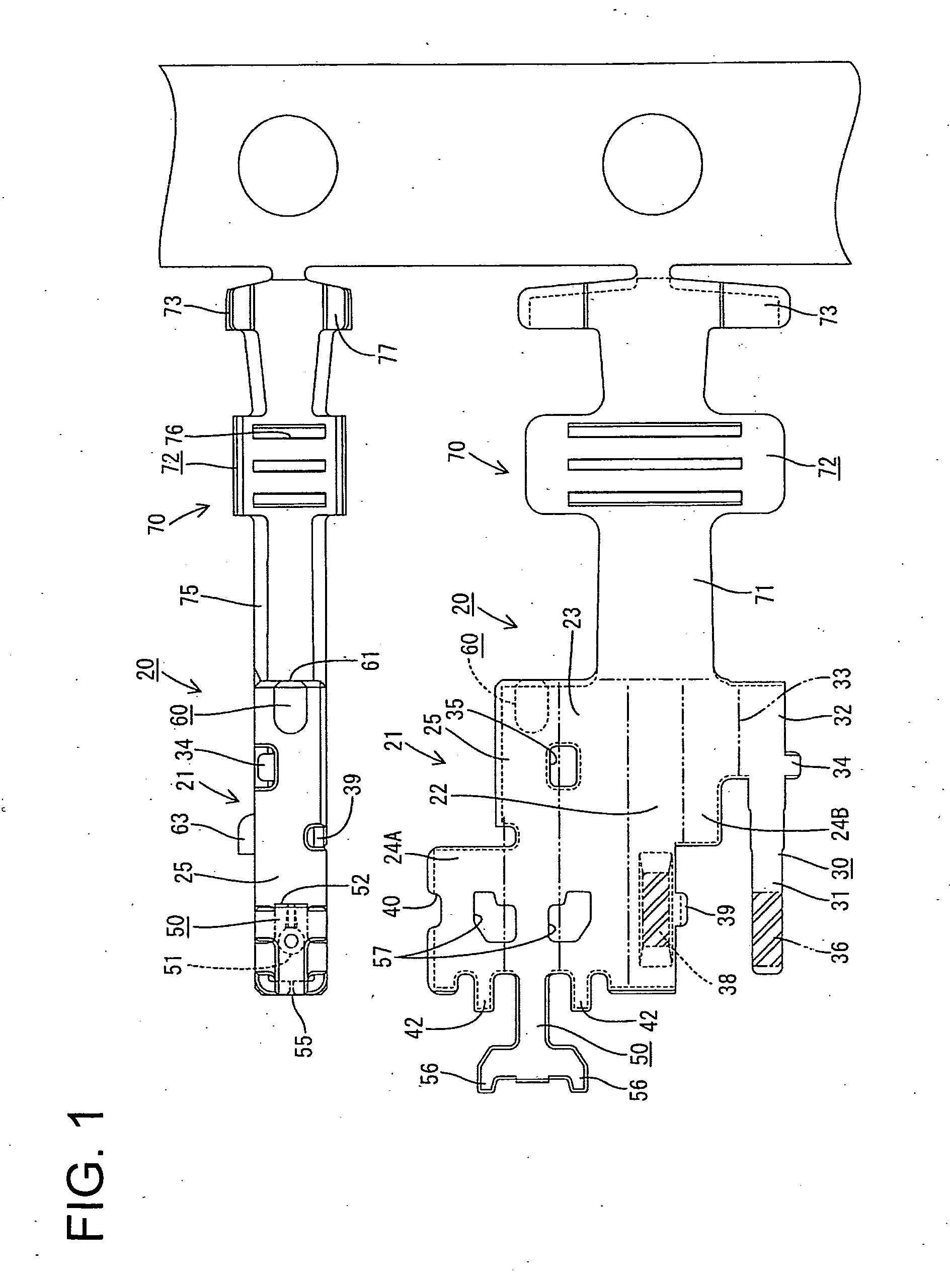

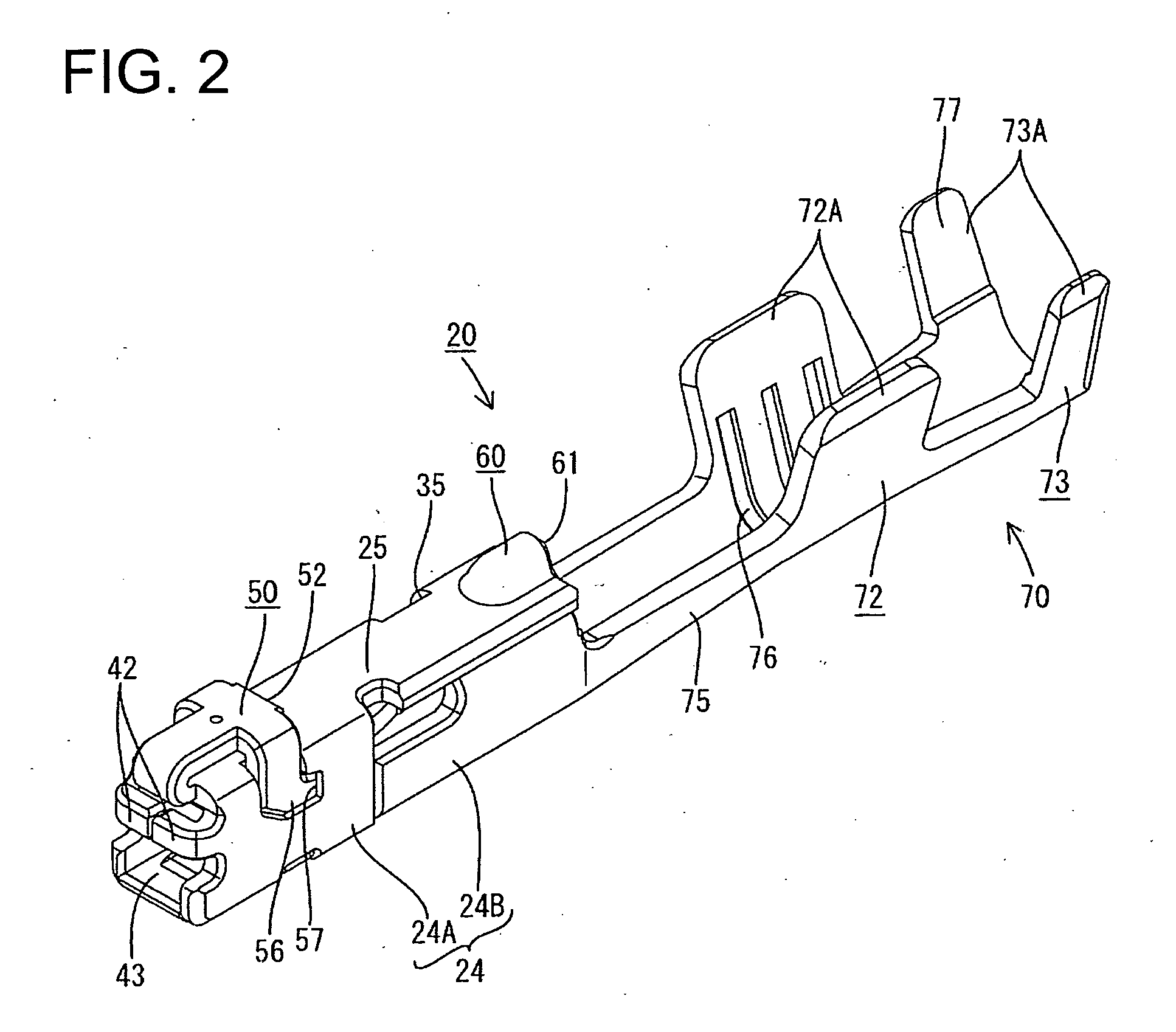

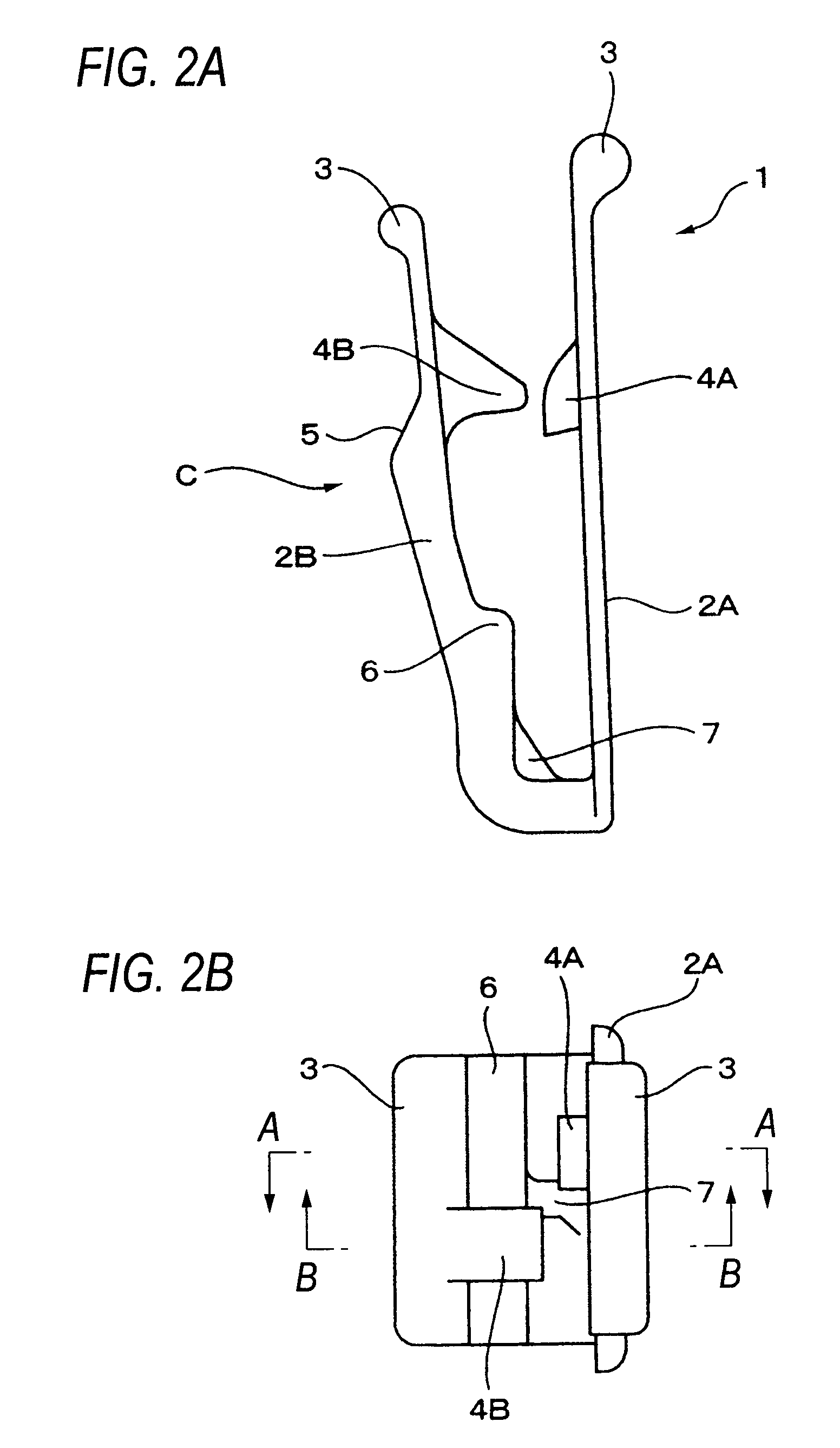

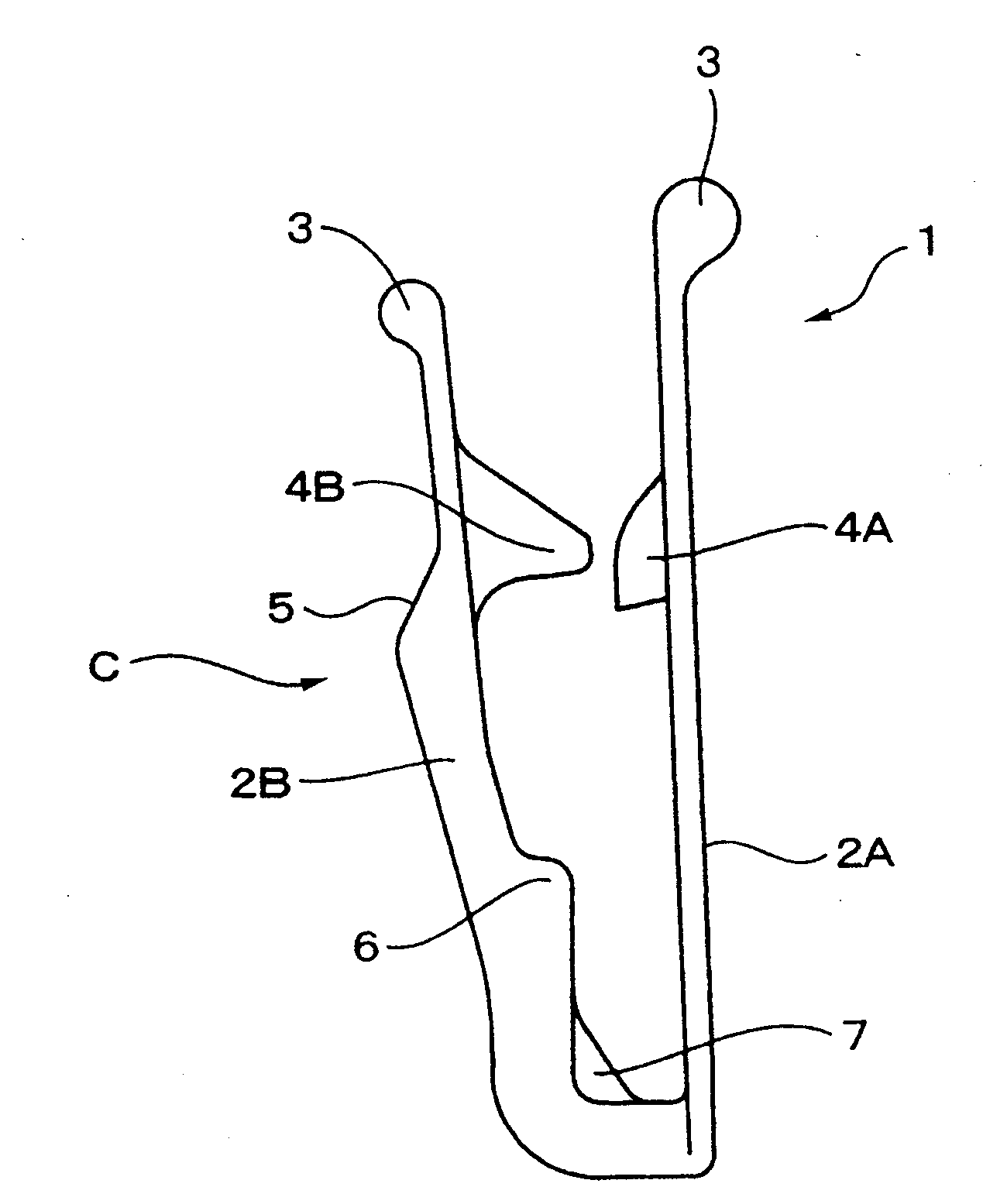

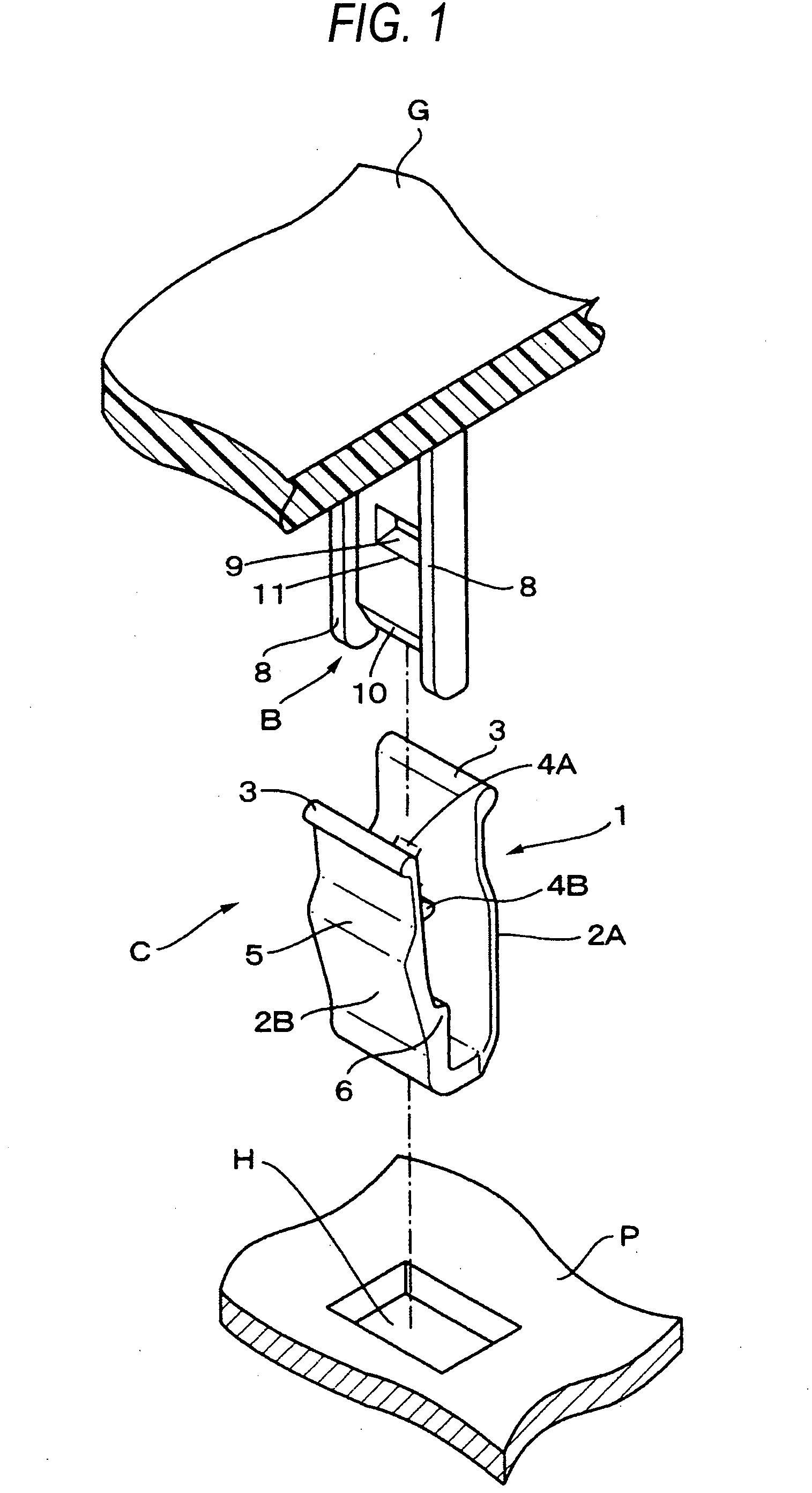

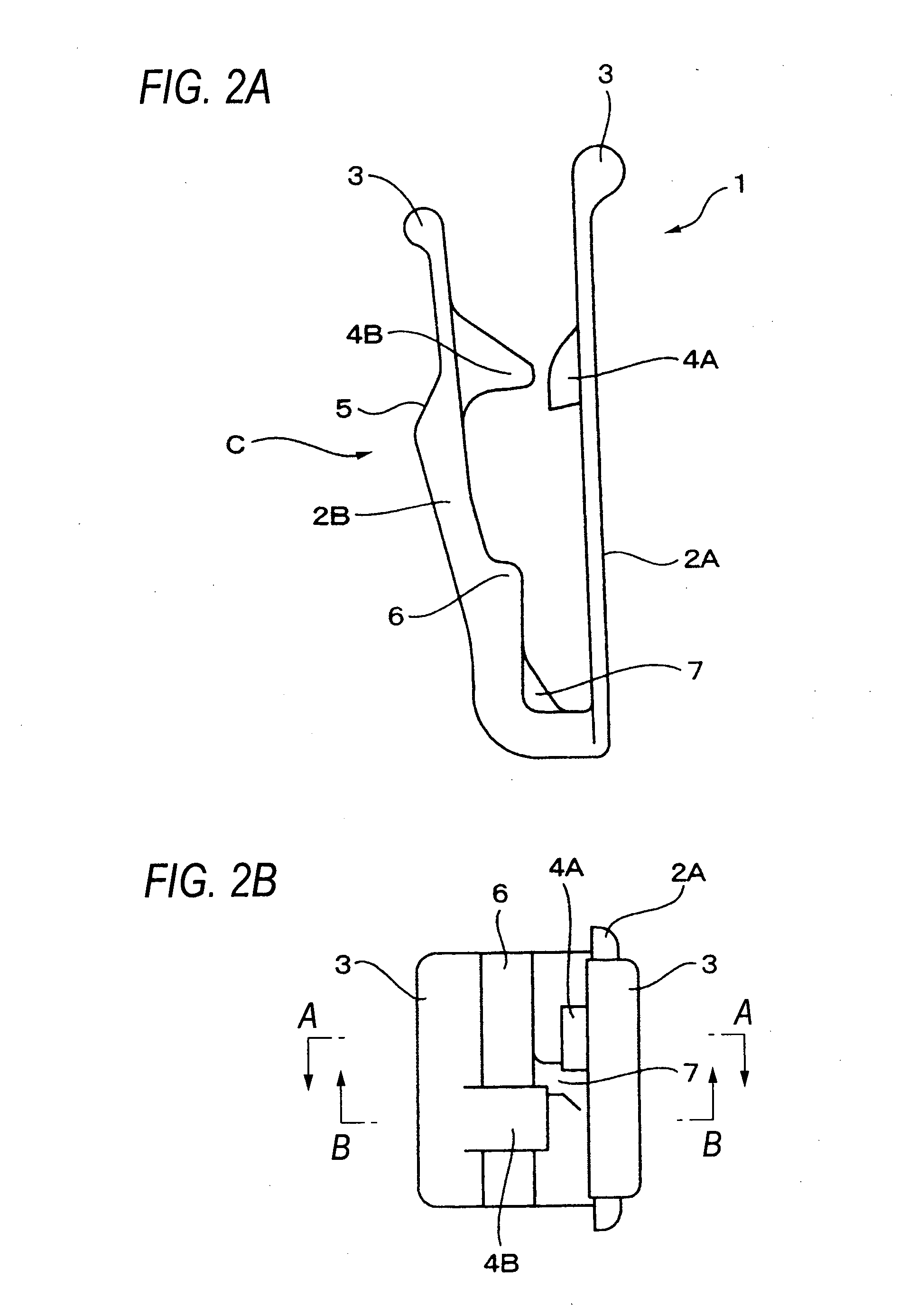

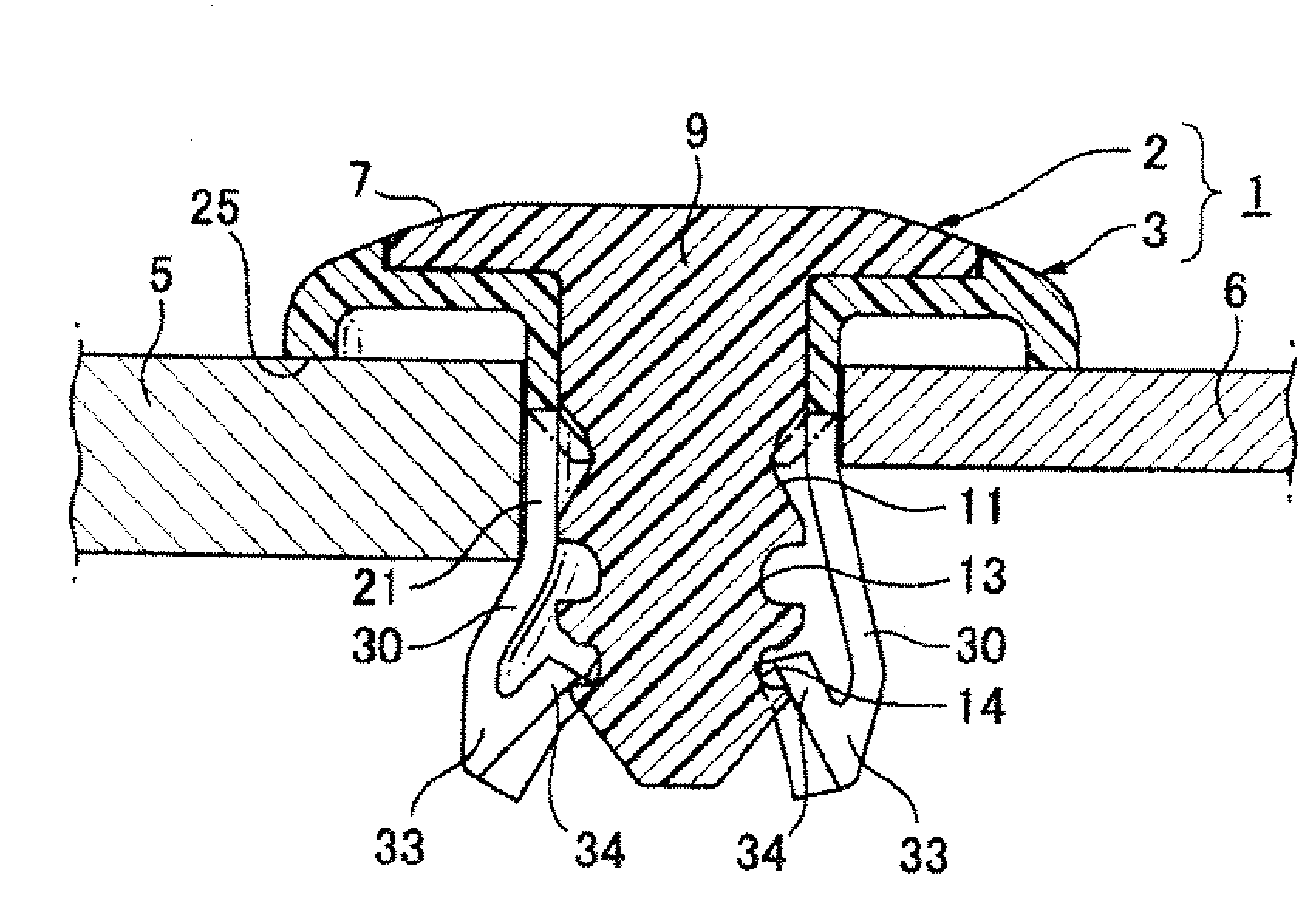

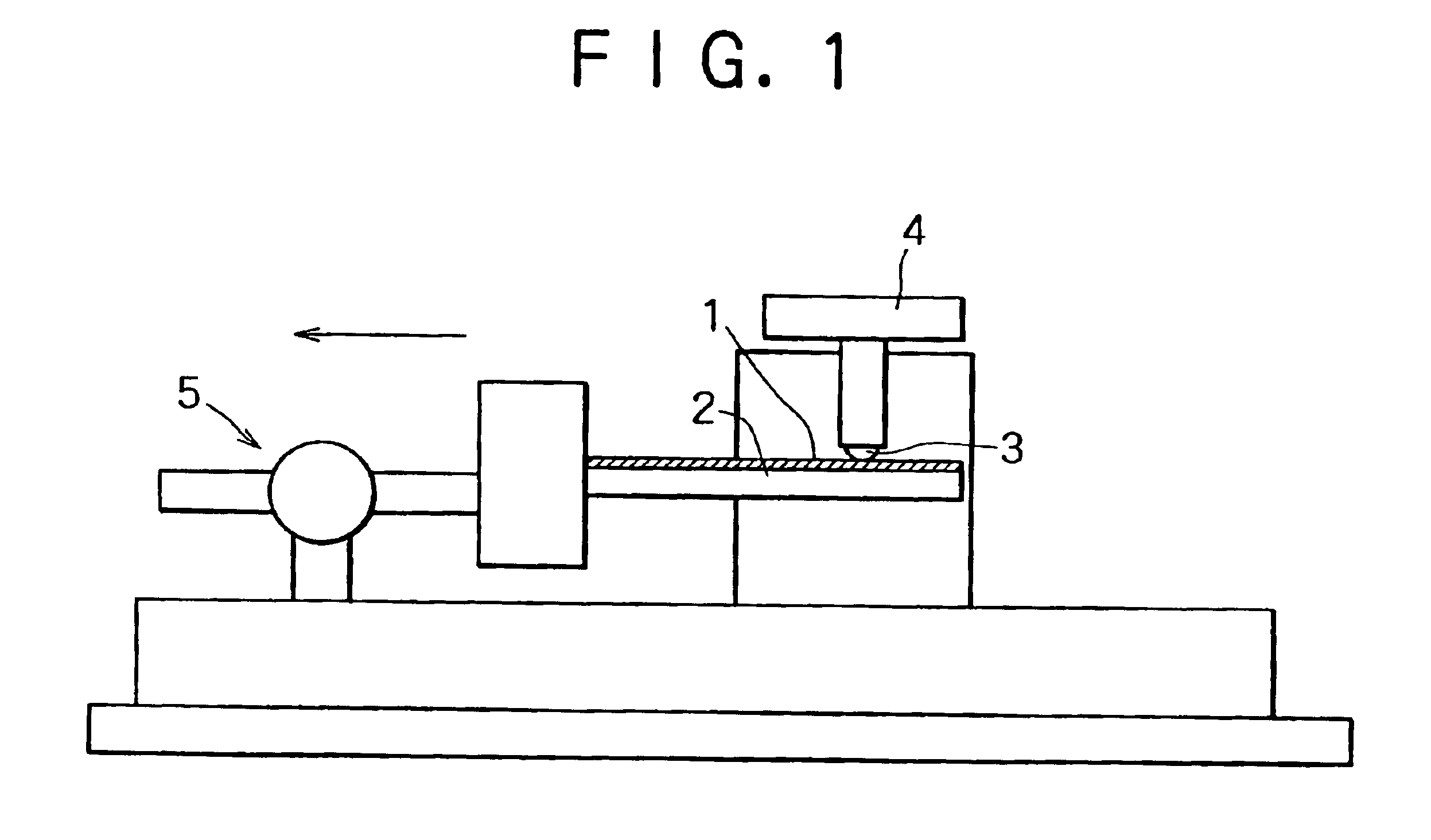

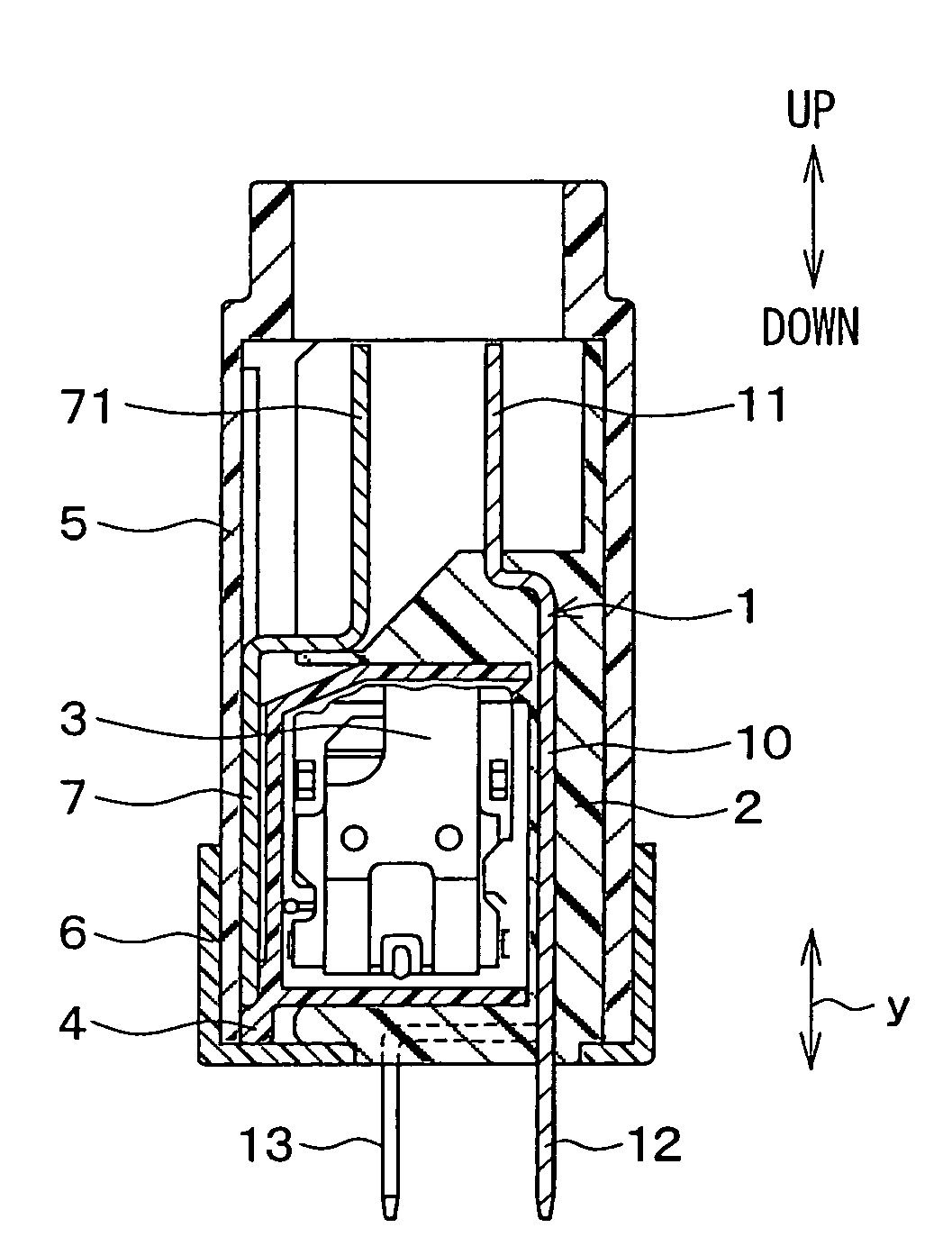

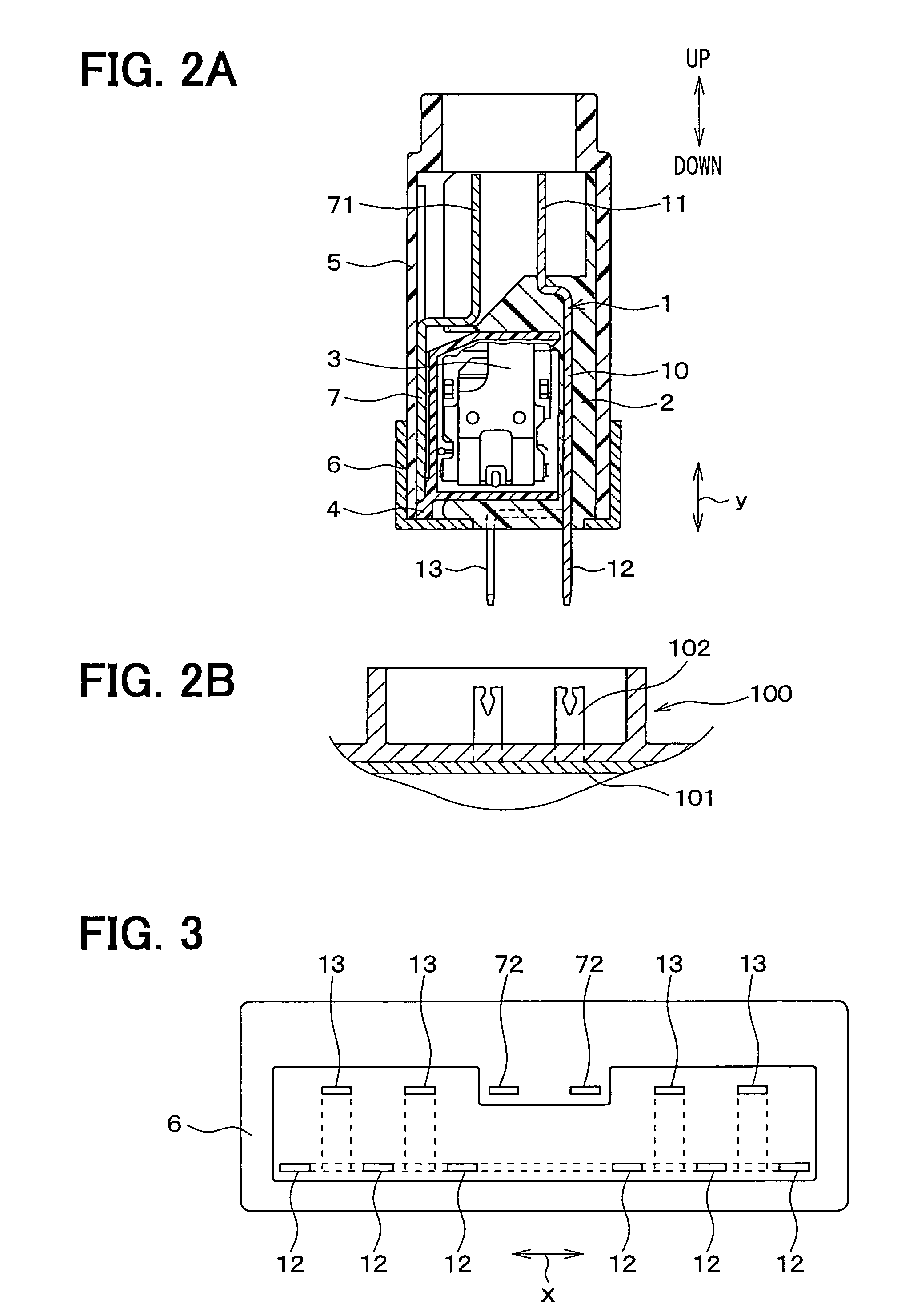

Female terminal fitting and connector provided therewith

InactiveUS7048582B2Increase the areaSufficient locking forceContact member manufacturingSecuring/insulating coupling contact membersEngineeringMechanical engineering

A female terminal fitting (20) has a main portion (21) that can be inserted into a cavity. An engaging portion (50) for engaging a lock (17) in the cavity is folded back from the front of the main portion (21). The fold (55) is rounded and contacts the lock (17) when the terminal fitting (20) is inserted into a cavity. Thus, resistance to insertion is low. The engaging portion (50) is distanced from an opposed surface (25) of the main portion (21) by an embossment (51). Thus, a large area of engagement with the lock (17) exists. A slanted surface (53) is formed at a corner of a locking surface (52) closer to the ceiling plate (25). Thus, the leading end of the lock (17) intrudes at the inner side of the slanted surface (53) to prevent the lock (17) from escaping.

Owner:SUMITOMO WIRING SYST LTD

Female terminal fitting and connector provided therewith

InactiveUS20050227551A1Enhance locking forcePrevent from escapeContact member manufacturingSecuring/insulating coupling contact membersEngineeringMechanical engineering

A female terminal fitting (20) has a main portion (21) that can be inserted into a cavity. An engaging portion (50) for engaging a lock (17) in the cavity is folded back from the front of the main portion (21). The fold (55) is rounded and contacts the lock (17) when the terminal fitting (20) is inserted into a cavity. Thus, resistance to insertion is low. The engaging portion (50) is distanced from an opposed surface (25) of the main portion (21) by an embossment (51). Thus, a large area of engagement with the lock (17) exists. A slanted surface (53) is formed at a corner of a locking surface (52) closer to the ceiling plate (25). Thus, the leading end of the lock (17) intrudes at the inner side of the slanted surface (53) to prevent the lock (17) from escaping.

Owner:SUMITOMO WIRING SYST LTD

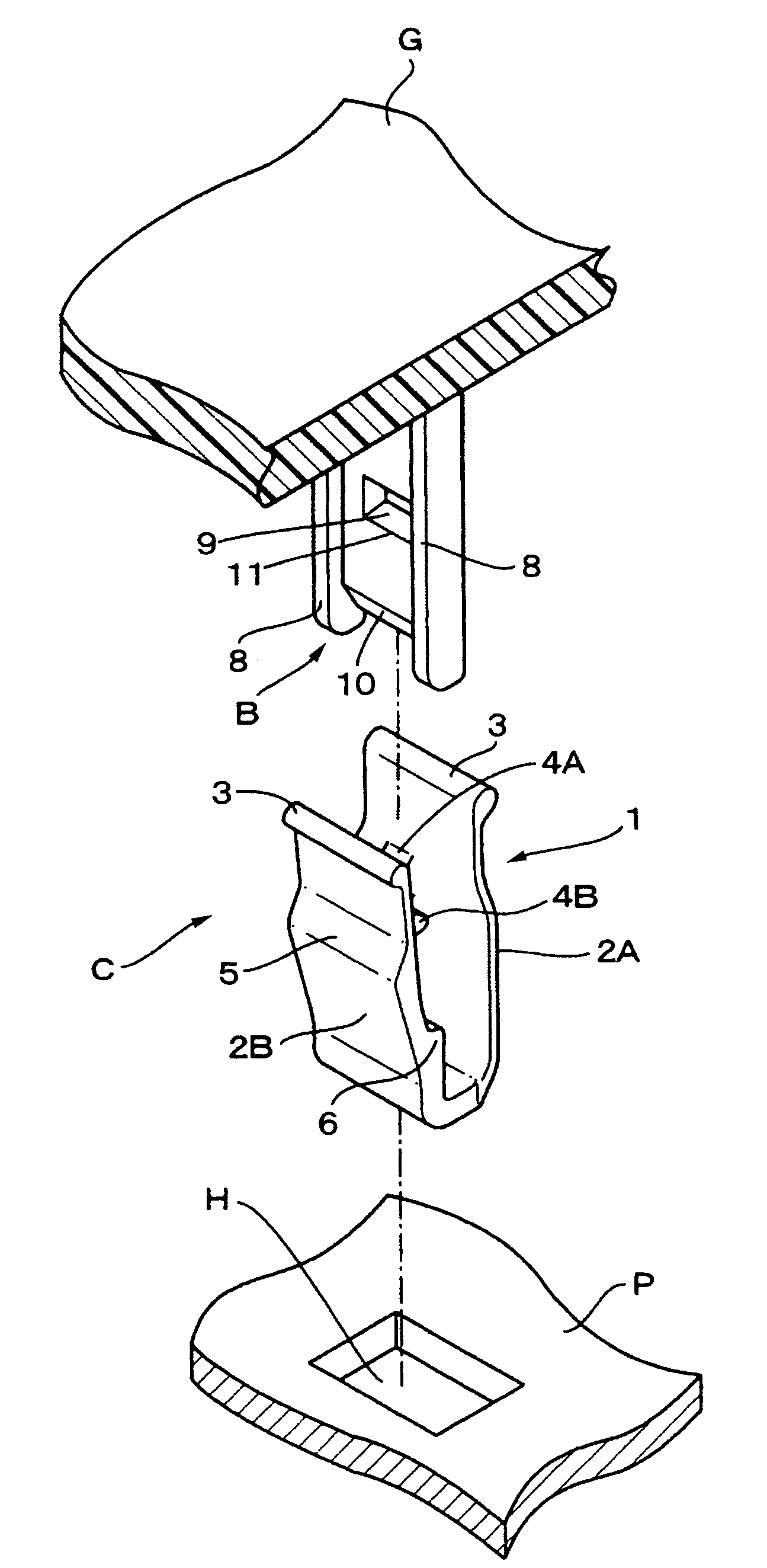

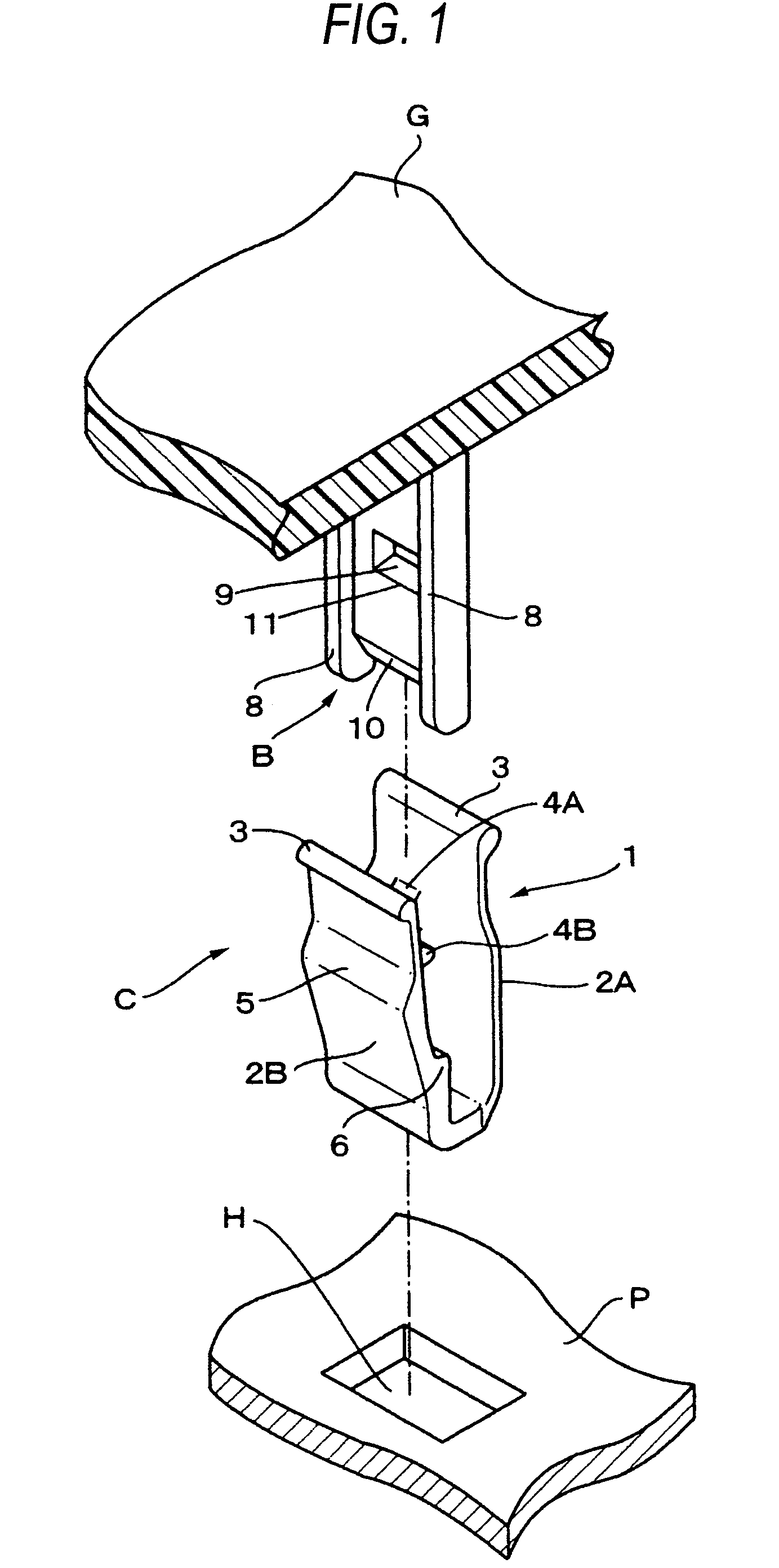

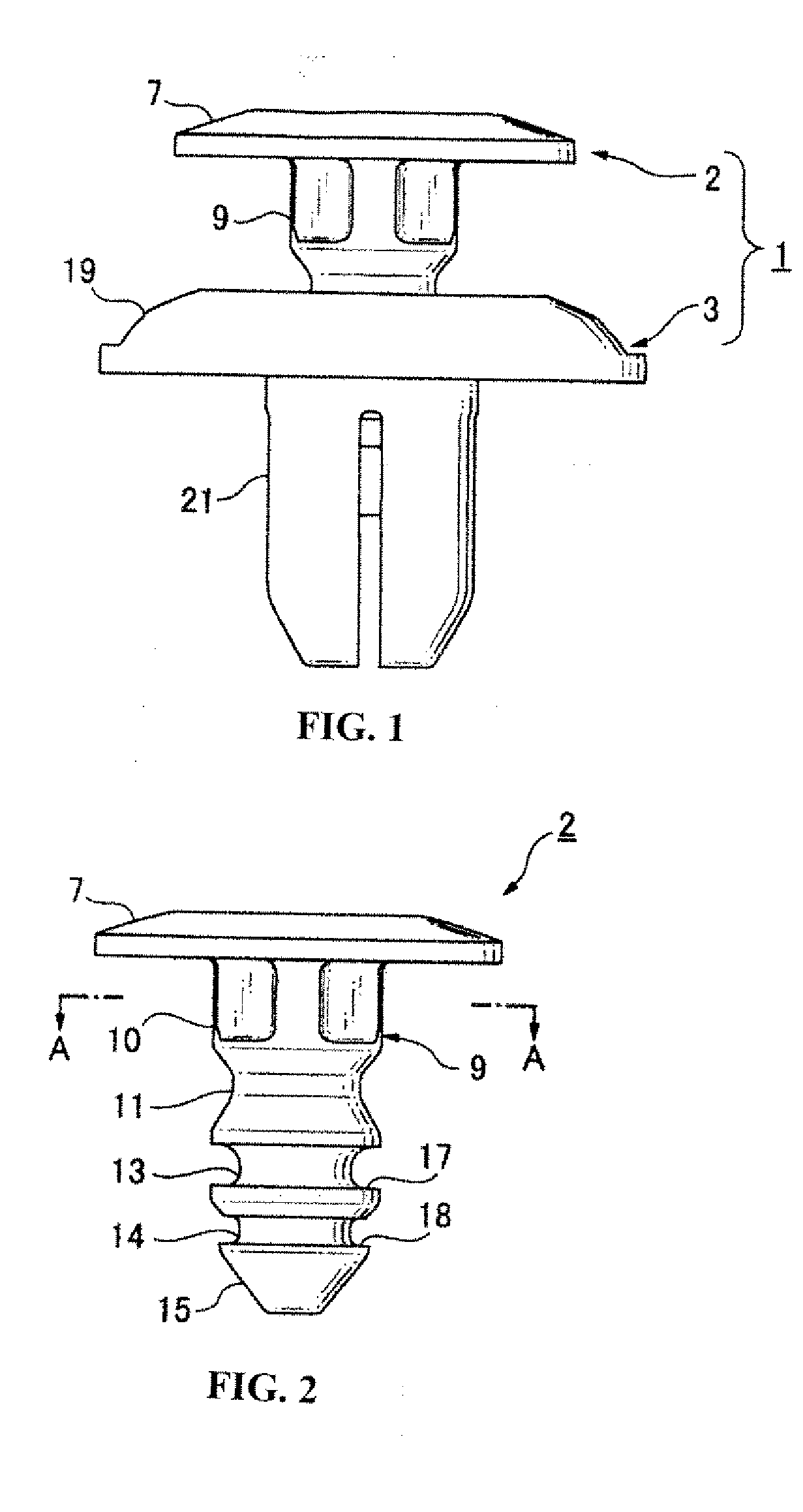

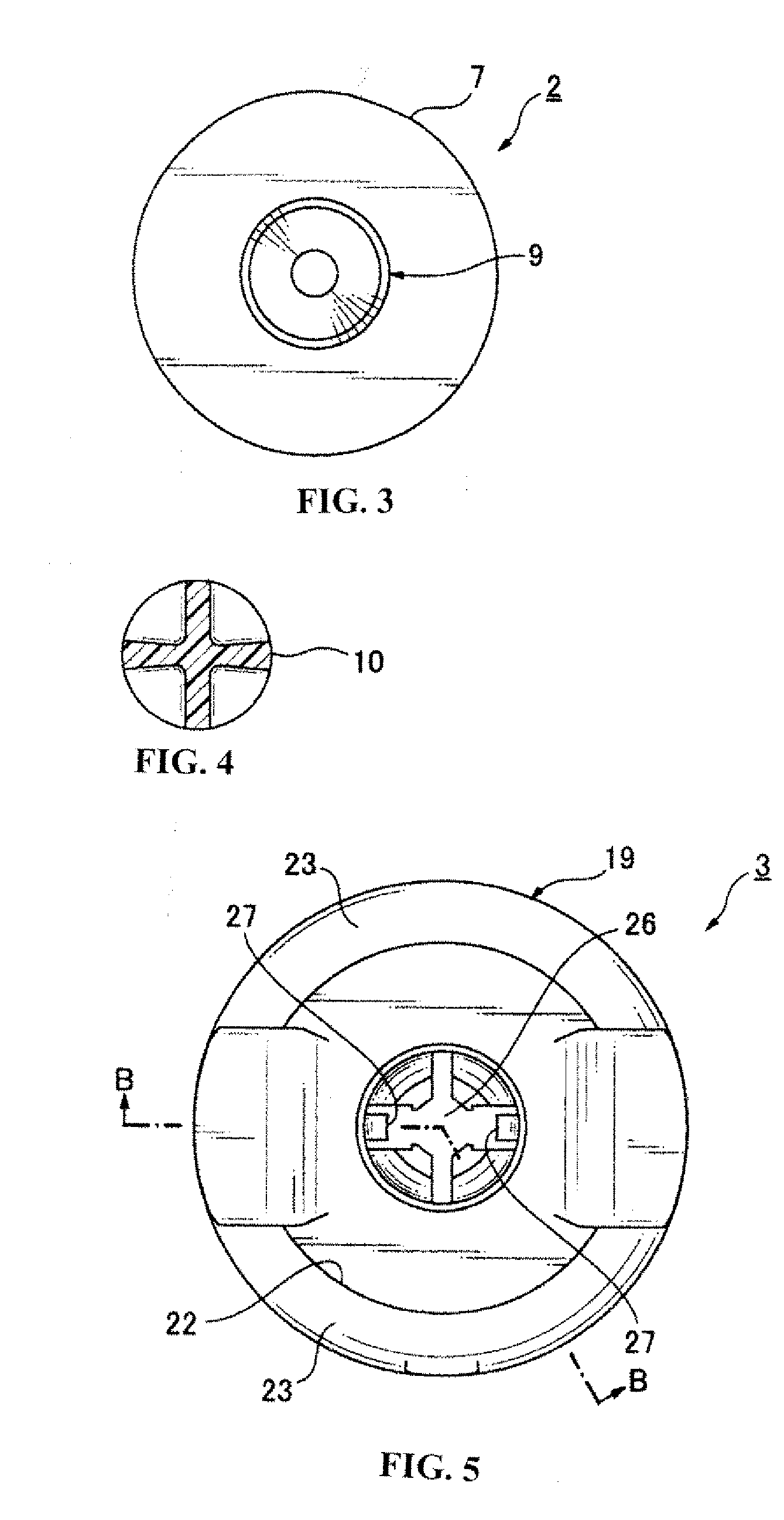

Mounting structure of vehicle interior material

InactiveUS7461436B2Reliably prevent the clip from being disengaged from the boss partImprove placement accuracySnap fastenersSheet joiningEngineeringMechanical engineering

Owner:PIOLAX CO LTD

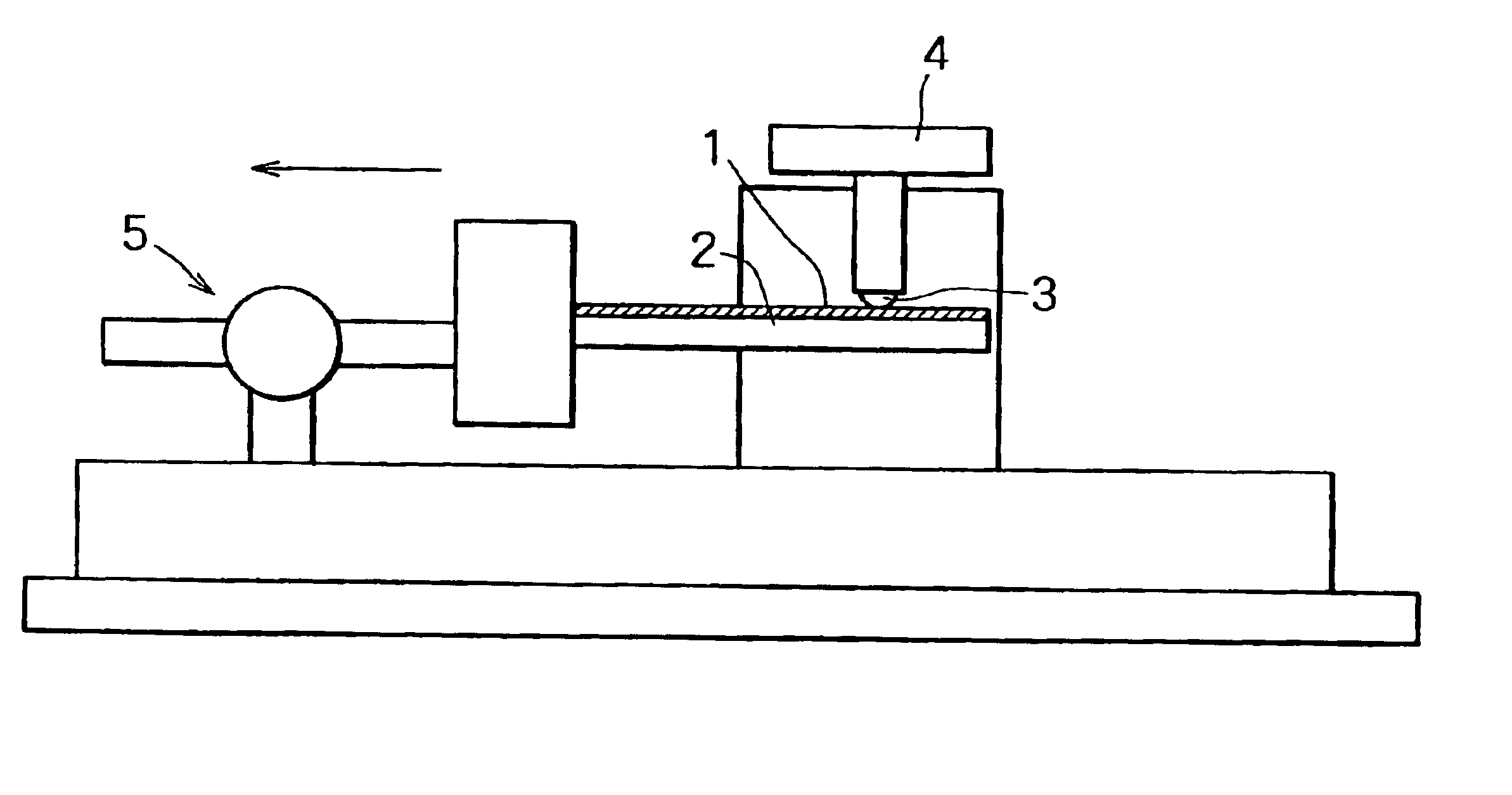

Plated copper alloy material and process for production thereof

InactiveUS20030129441A1Improve corrosion resistanceForce is smallDomestic articlesConductive pattern reinforcementCopper platingContact resistance

A plated copper alloy material for connecting terminals is provided which comprises a parent material of copper or copper alloy, a nickel layer and a copper-tin alloy layer. The nickel layer has a thickness of 0.1-1.0 .mu.m. The copper-tin alloy layer has a thickness of 0.1-1.0 .mu.m and contains 35-75 at % of copper. The material may additionally have a tin layer no thicker than 0.5 .mu.m for an engaging type terminal containing 0.001-0.1 mass % of carbon, or thicker than 0.5 .mu.m for a non-engaging type connector. The material meets requirements for capability of insertion with a small force, good electric reliability (due to low contact resistance) in a high-temperature atmosphere, workability for sharp bending without cracking, good solder wettability and good corrosion resistance to sulfur dioxide gas.

Owner:KOBE STEEL LTD

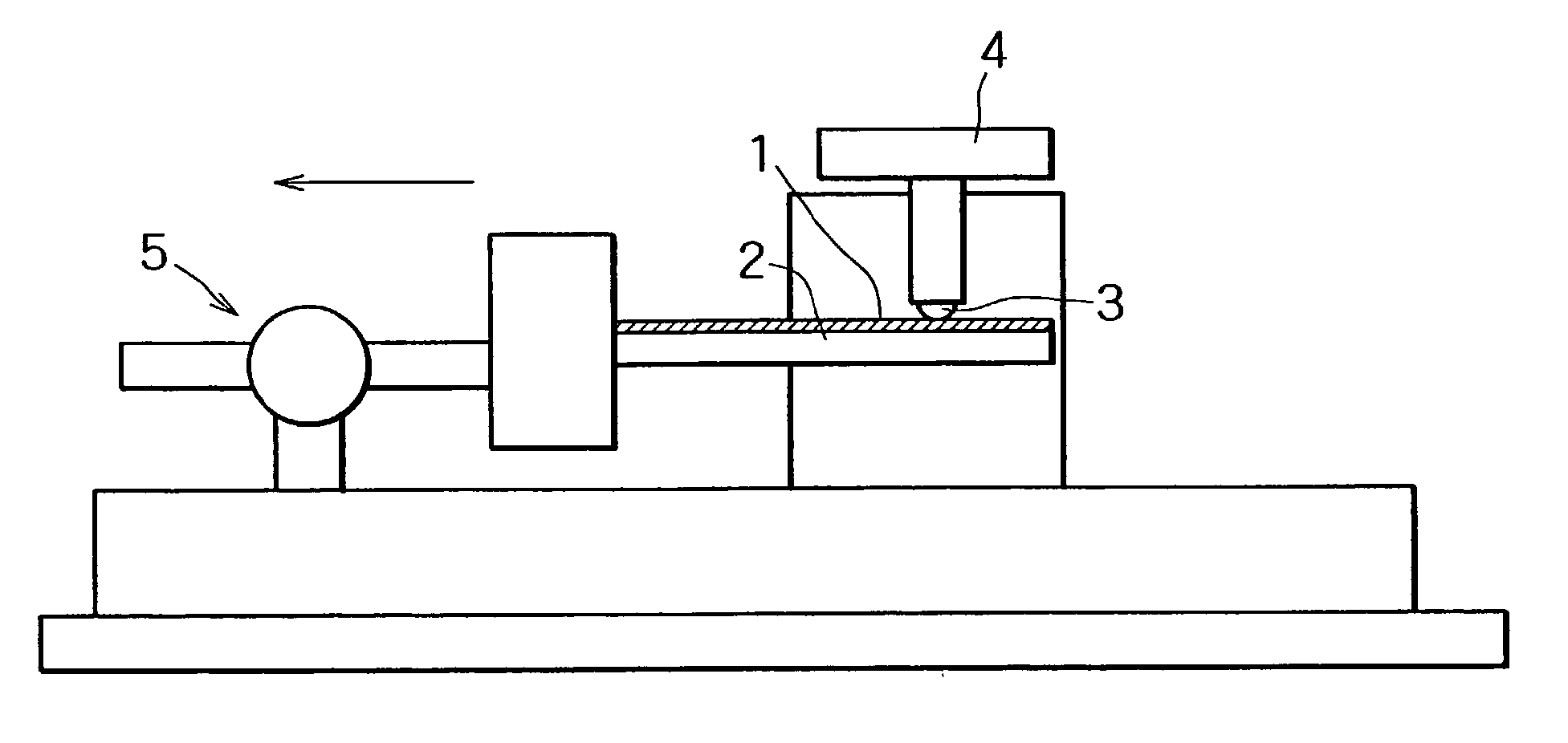

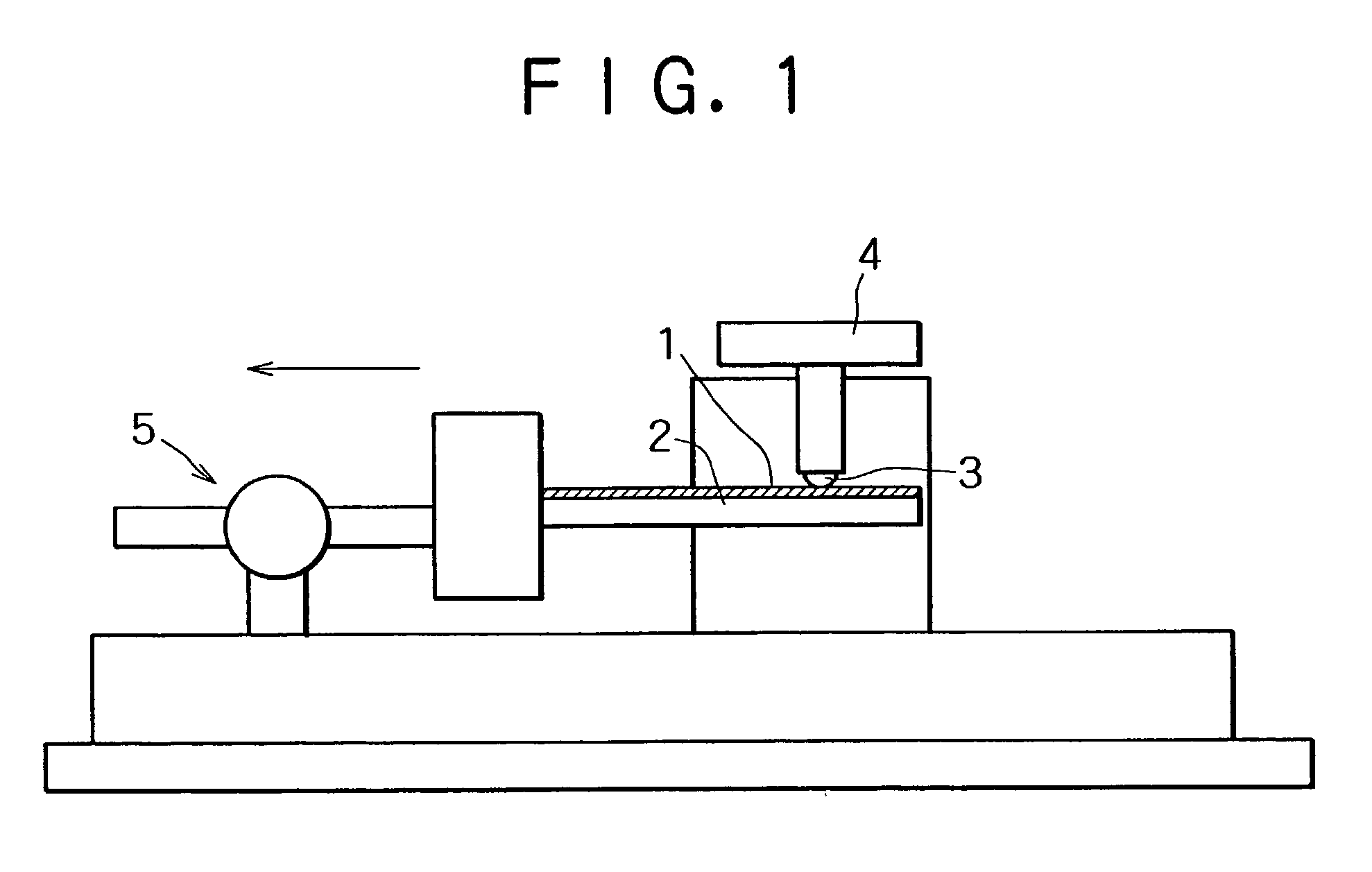

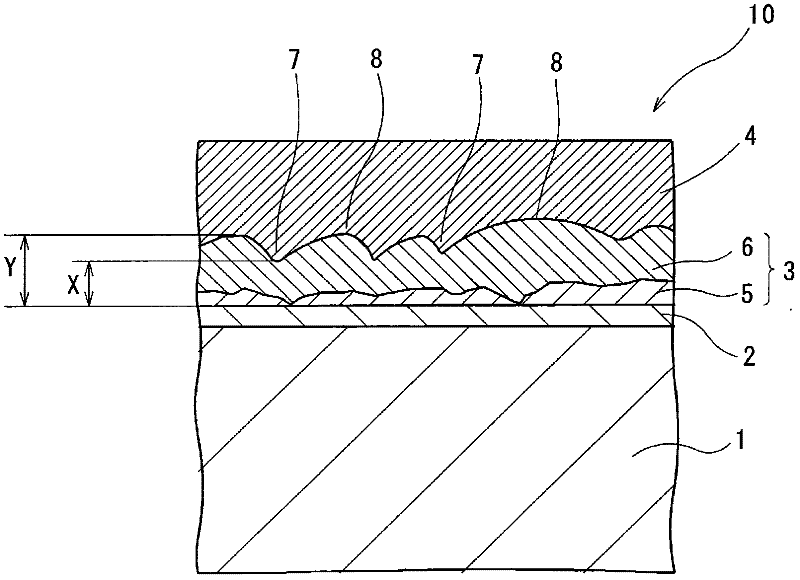

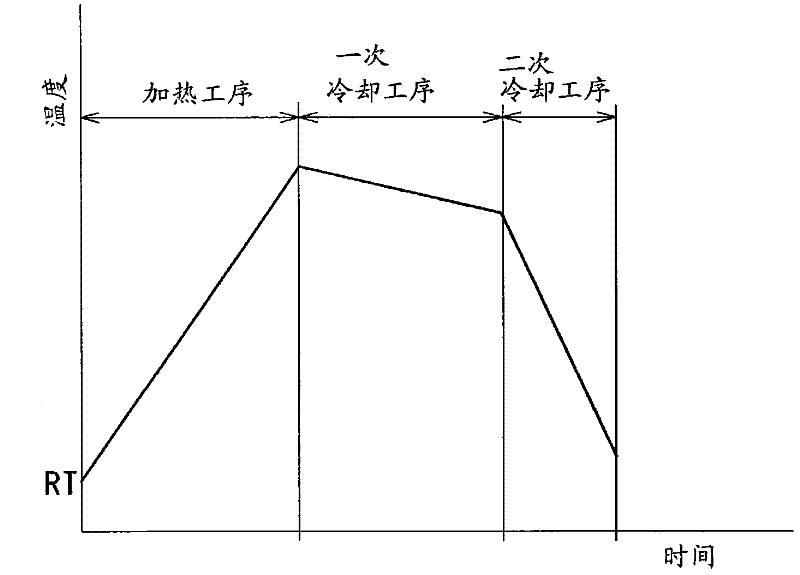

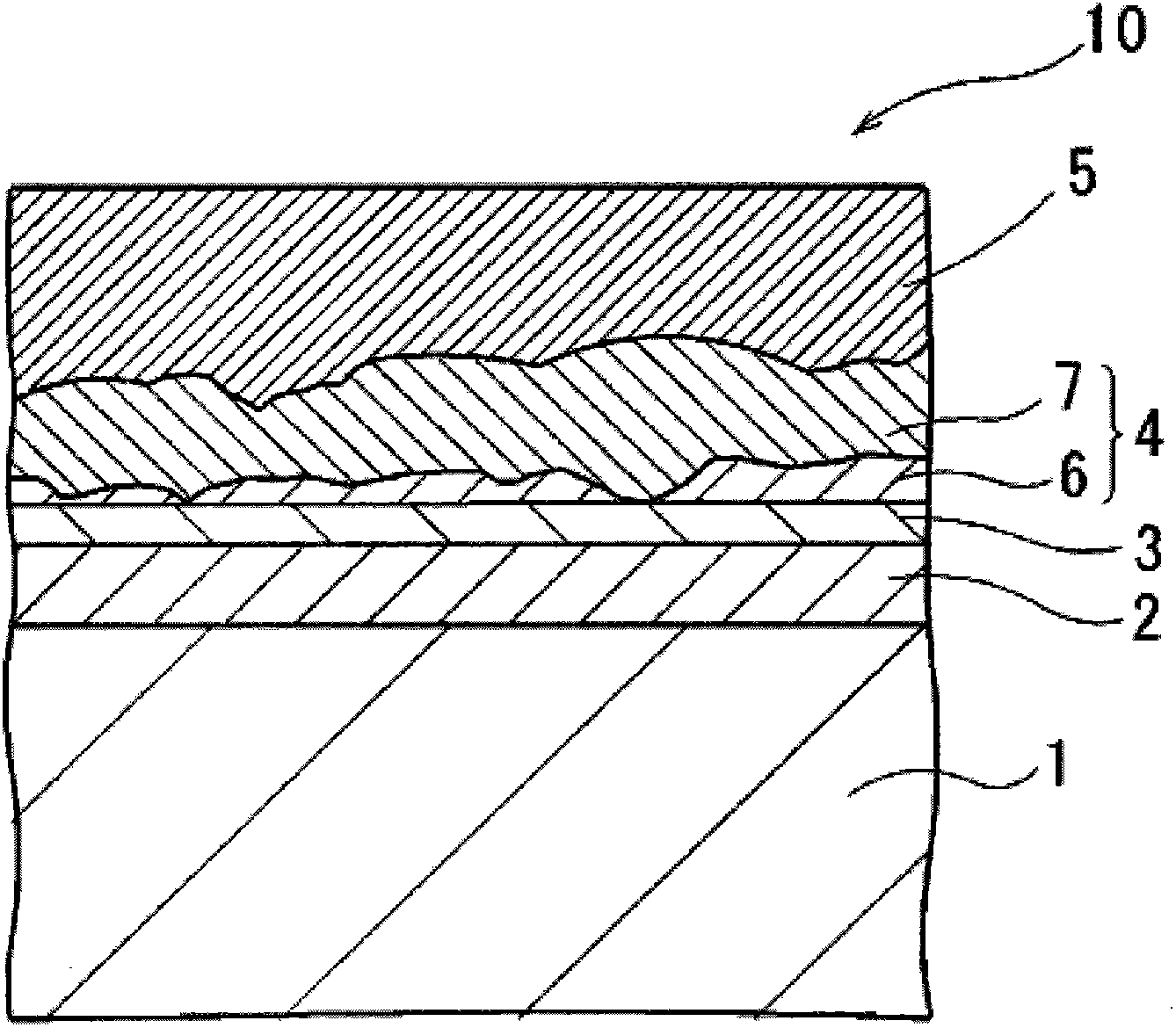

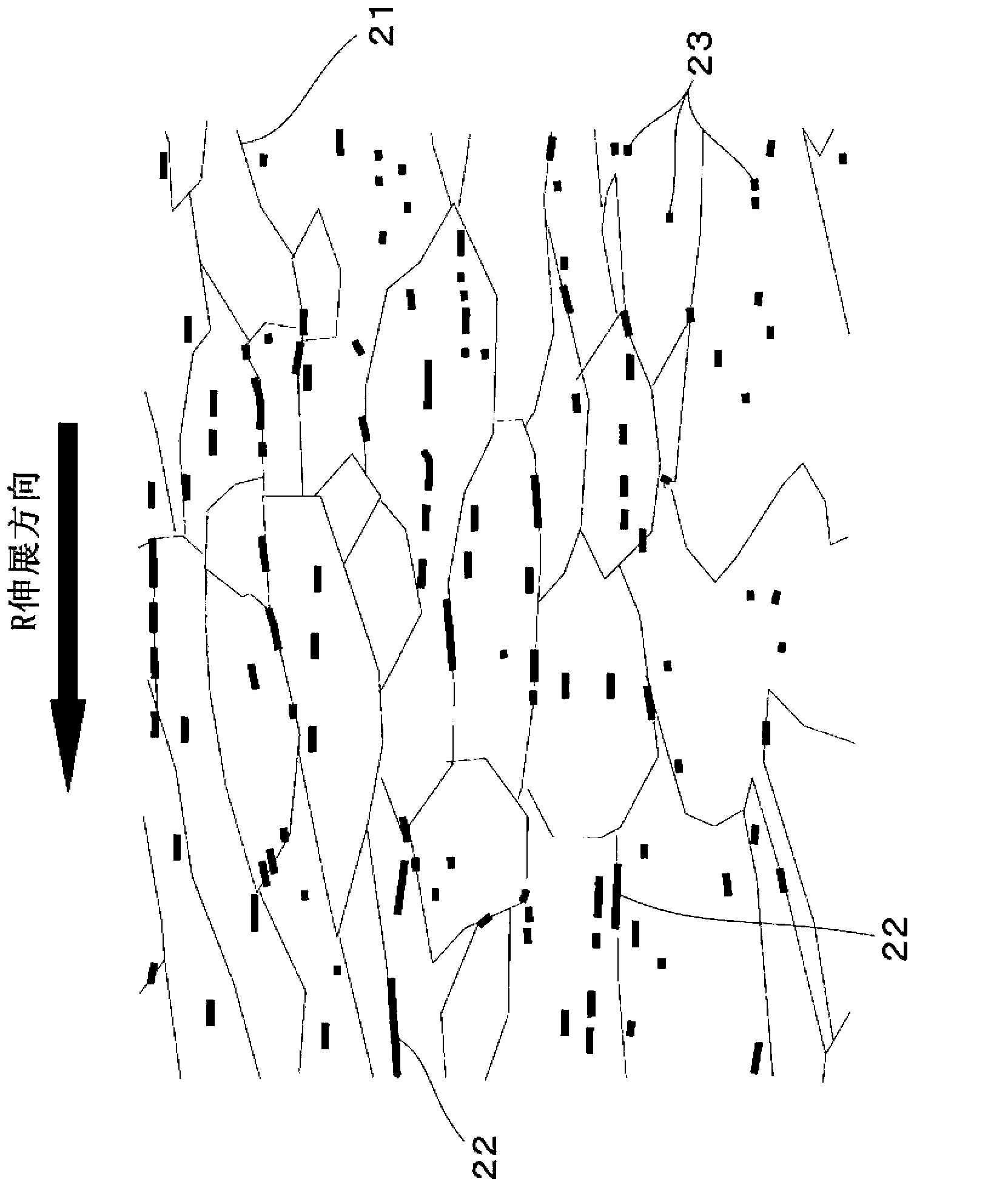

Conductive member and method for producing the same

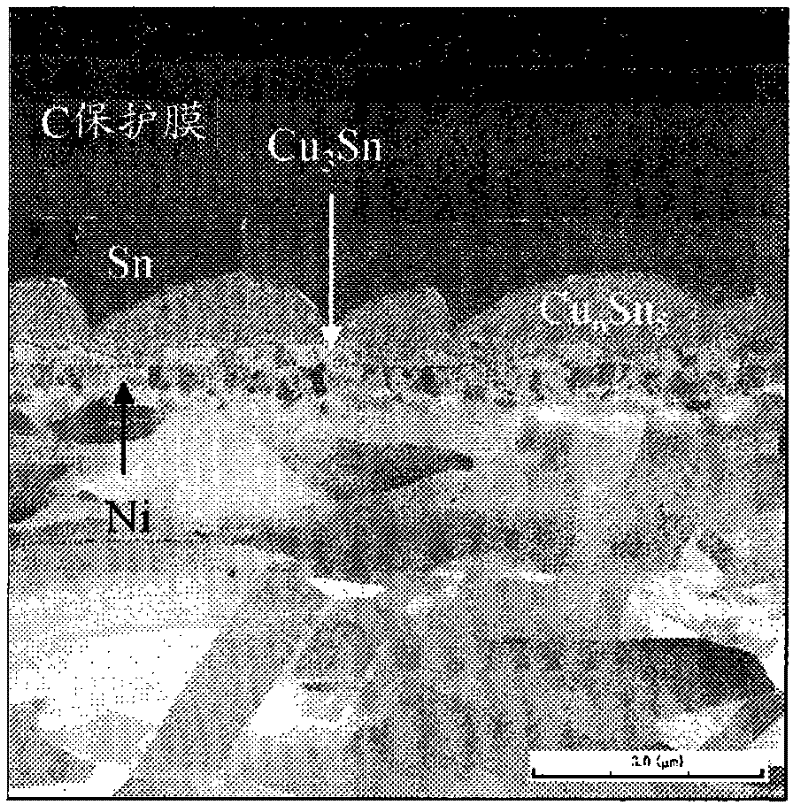

ActiveCN102239280APrevent proliferationPrevent peelingCoupling contact membersThin material handlingOptoelectronicsIntermetallic

Disclosed is a conductive member having a stable contact resistance, which is hardly separated and requires a small inserting / drawing force when used as a connector. The conductive member is characterized in that a Cu-Sn intermetallic compound layer (3) and an Sn surface layer (4) are formed in this order on the surface of a Cu substrate (1) through an Ni base layer (2); the Cu-Sn intermetallic compound layer (3) is composed of a Cu3Sn layer (5) arranged on the Ni base layer (2) and a Cu6Sn5 layer (6) arranged on the Cu3Sn layer (5); the Cu-Sn intermetallic compound layer (3) obtained by bonding the Cu3Sn layer (5) and the Cu6Sn5 layer (6) is provided with recesses and projections in the surface which is in contact with the Sn surface layer (4); thicknesses X at the recessed portions (7) are set to 0.05-1.5 [mu]m; the area coverage of the Cu3Sn layer (5) relative to the Ni base layer (2) is not less than 60%; the ratio of the thicknesses Y at the projected portions (8) to the thicknesses at the recessed portions (7) in the Cu-Sn intermetallic compound layer (3) is 1.2-5; and the average thickness of the Cu3Sn layer (5) is 0.01-0.5 [mu]m.

Owner:MITSUBISHI SHINDOH CO LTD

Mounting structure of vehicle interior material

InactiveUS20060085955A1Small insertion forceReliably prevent the clip from being disengaged from the boss partSnap fastenersSheet joiningEngineeringMechanical engineering

Owner:PIOLAX CO LTD

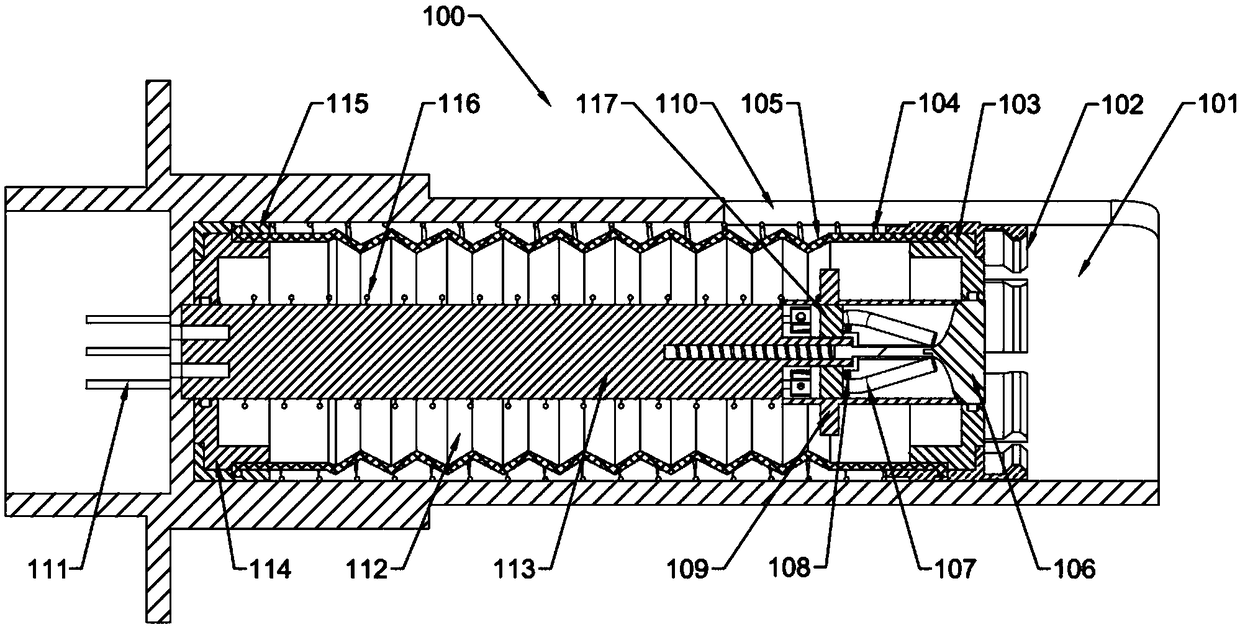

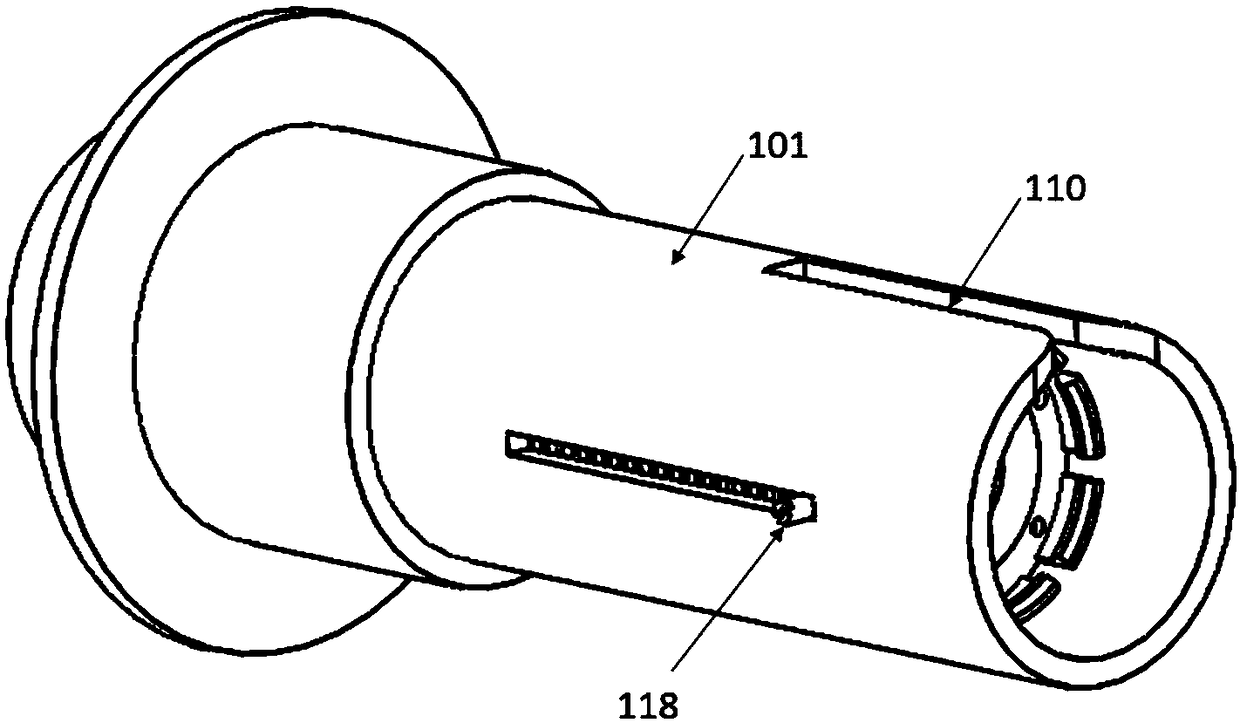

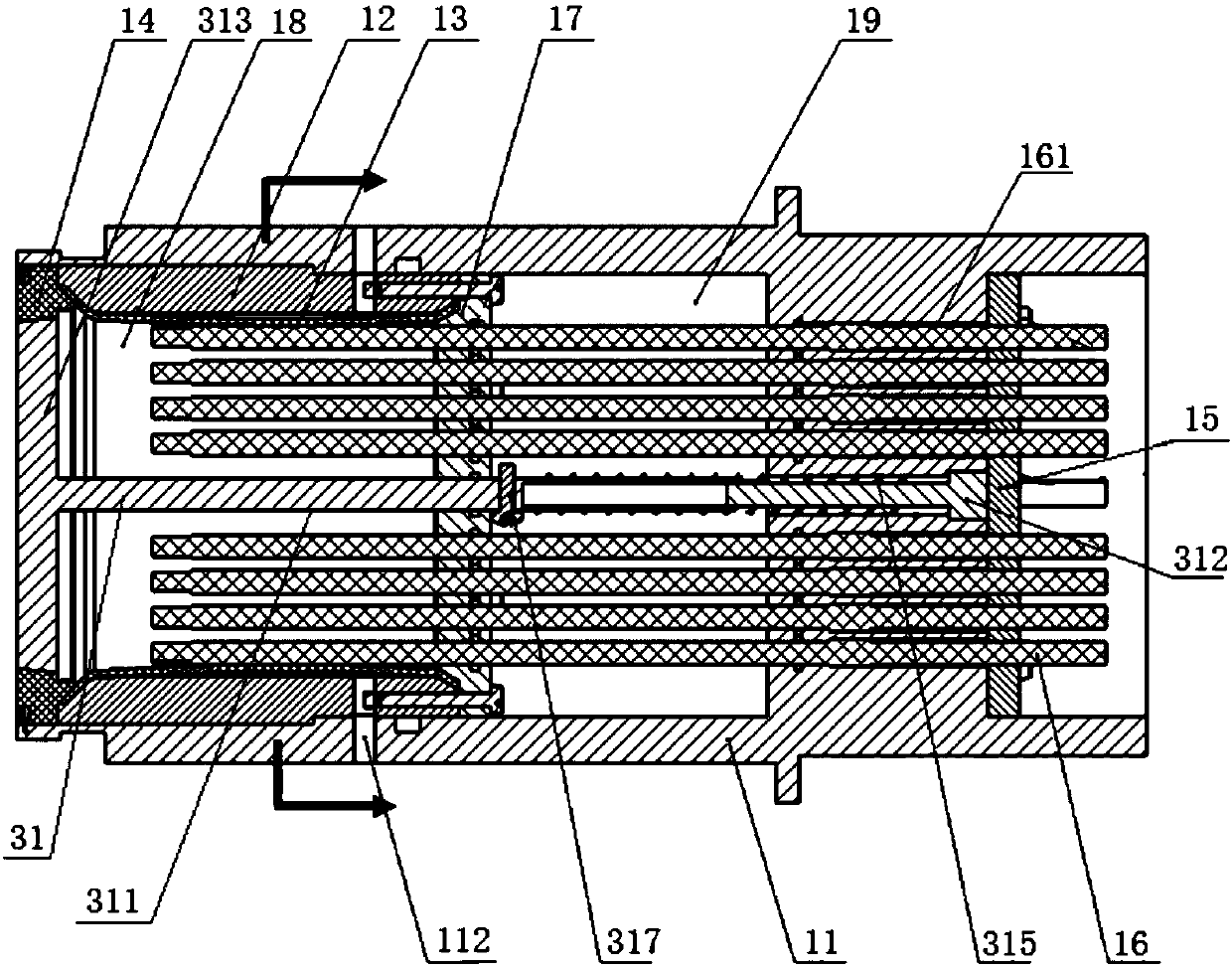

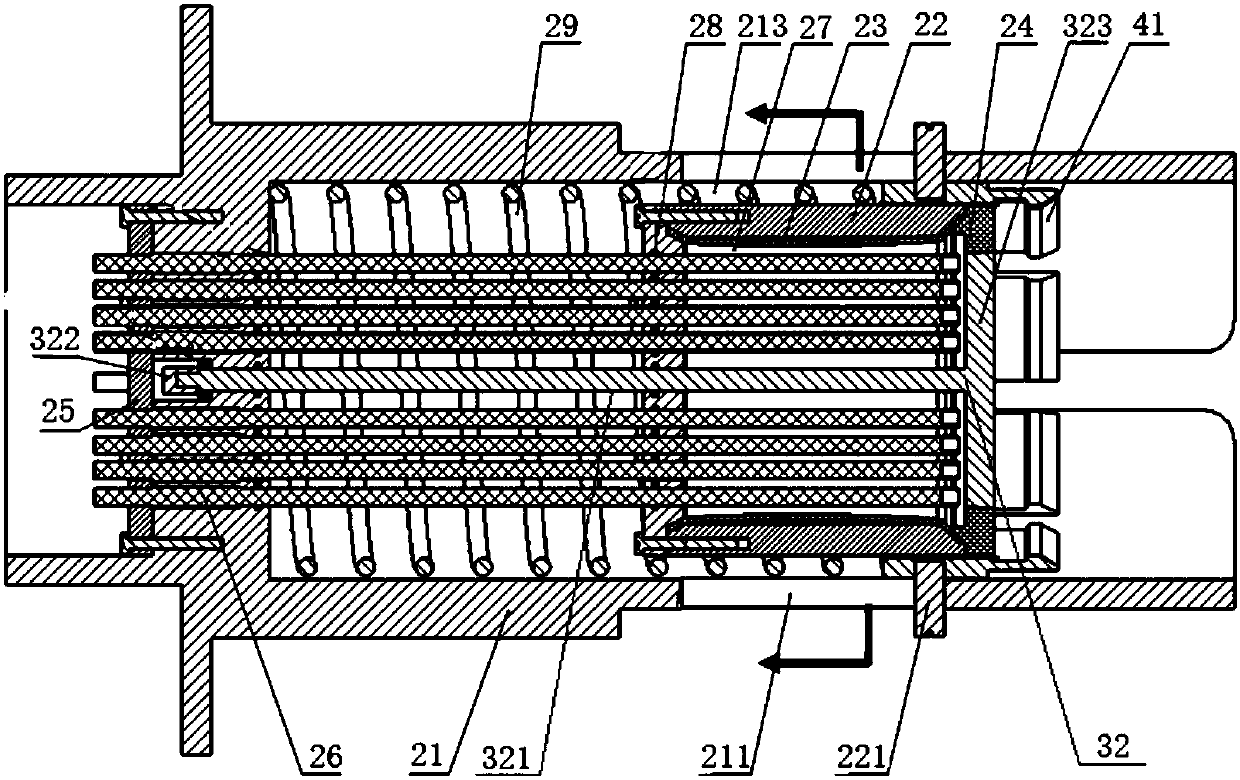

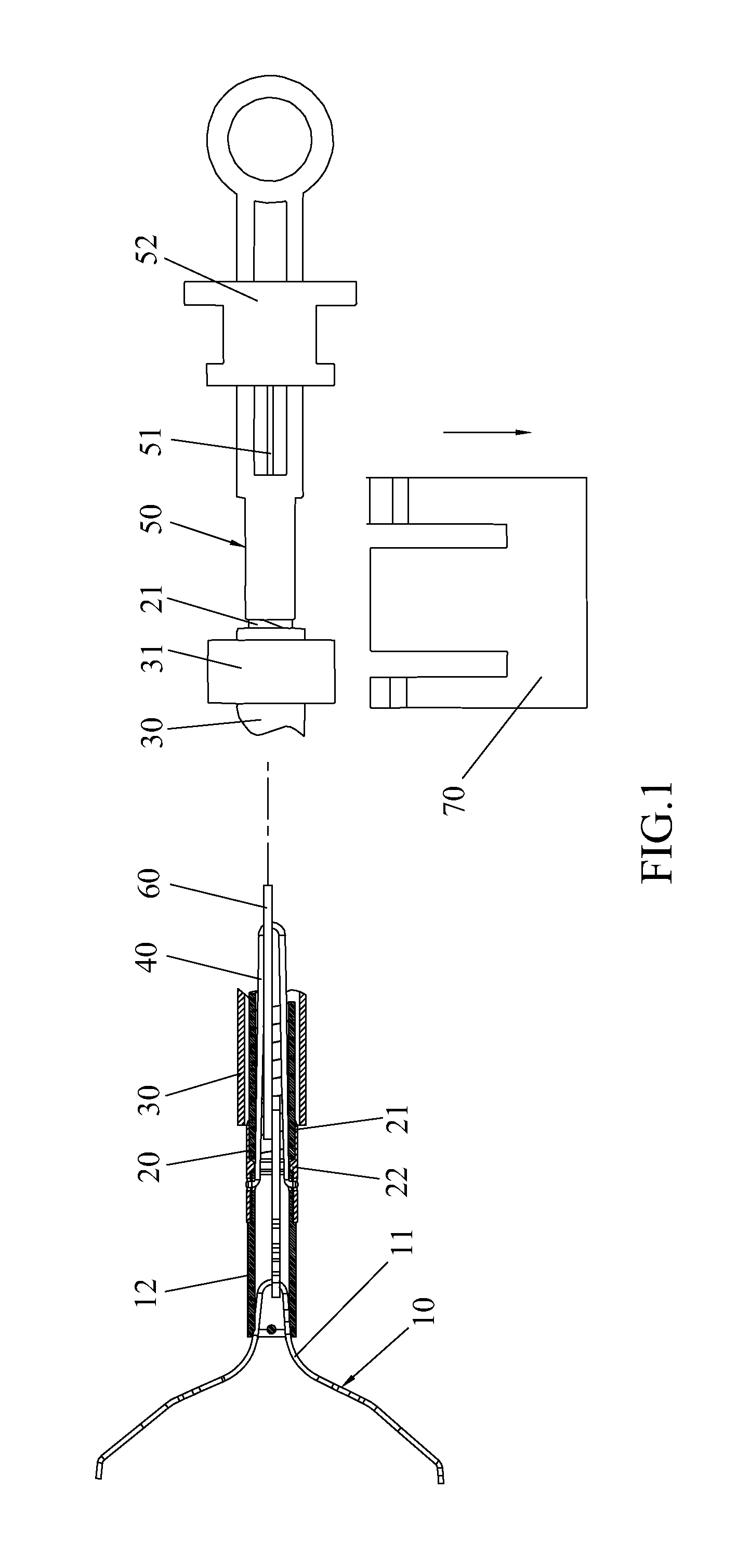

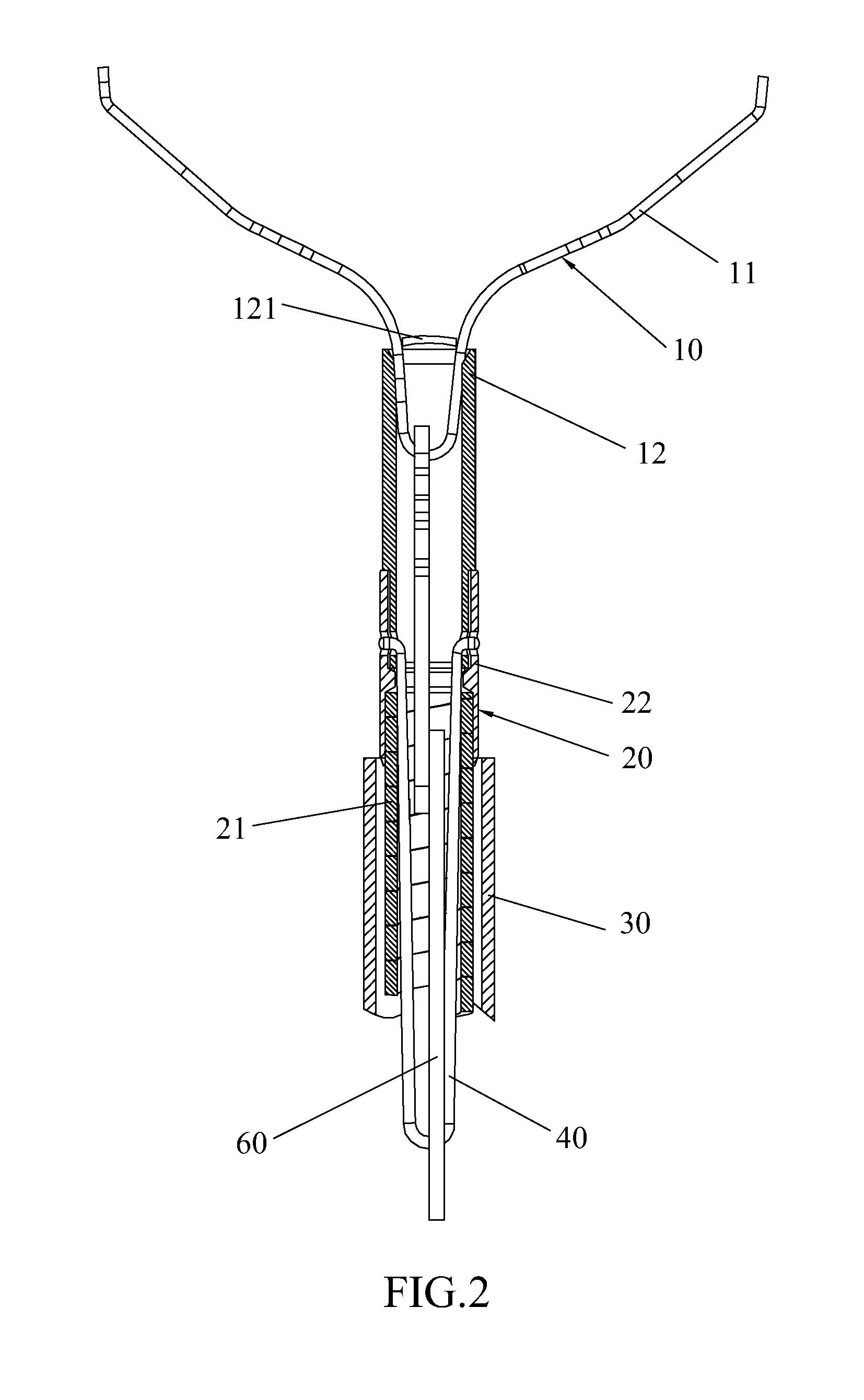

An open-close deep-sea plug-and-pull photoelectric composite connector

ActiveCN109244711AReduce internal and external pressure differenceSmall insertion forceCoupling contact membersCouplings bases/casesElectric power transmissionEngineering

The invention discloses an open-close deep-sea plug-and-pull photoelectric composite connector, which comprises a plug and a socket used for plug-and-match. The main body of the socket part is a socket opening and closing core, which is fixed on a rotating bracket through a hinge connection mode. When the plug and the socket are inserted, the socket opening and closing core can be opened under thepush of an umbrella-shaped curved surface of a plunger, the position of the largest opening angle is parallel to the central axis, and is connected with the photoelectric core inside the plug. The plug and the socket of the invention are respectively provided with a variable-volume bellows and a rubber bag as a pressure balancing device; The O-shaped sealing ring arranged in pairs is used for realizing the sealing in the inoperative state; The invention integrates optical signal and electric power transmission, fully considers internal and external pressure balance, has simple structure and simple insertion process, and can ensure reliable connection of deep water environment.

Owner:SOUTHEAST UNIV

Clip

A clip including a pin and a grommet, a leg is formed by a plurality of narrow leg pieces, the tip portions of the leg pieces have inside folded-back portions that are folded back from the tips toward the inside of the leg and extend toward a flange, a gap is formed between the inside folded-back portions and the outside portions of the tip portions of the leg pieces, and the leg pieces are formed in narrow flexible plate shapes which extend at constant thickness from the root portion adjacent the flange to intermediate positions in the tip portions.

Owner:NEWFREY

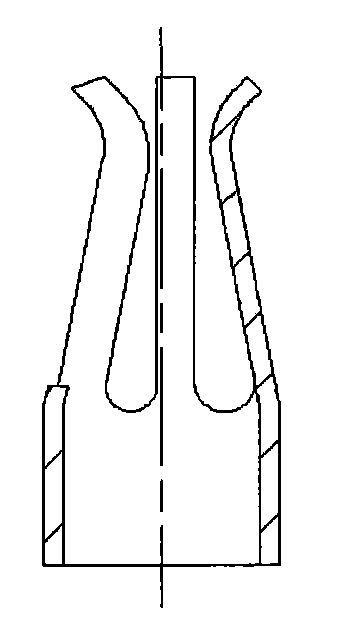

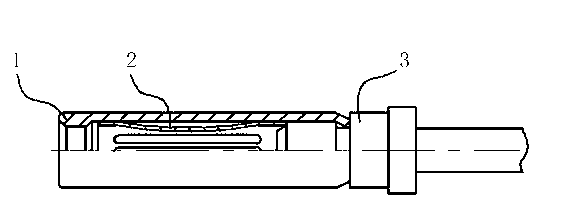

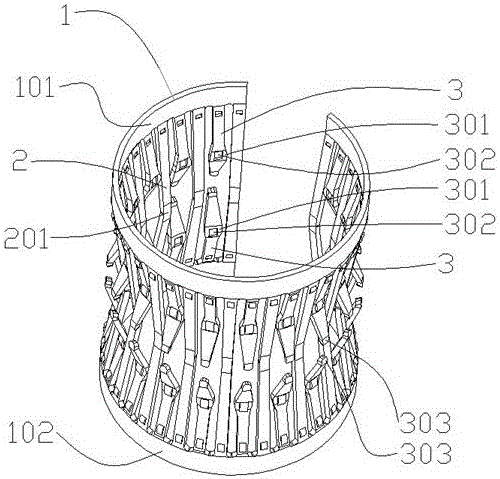

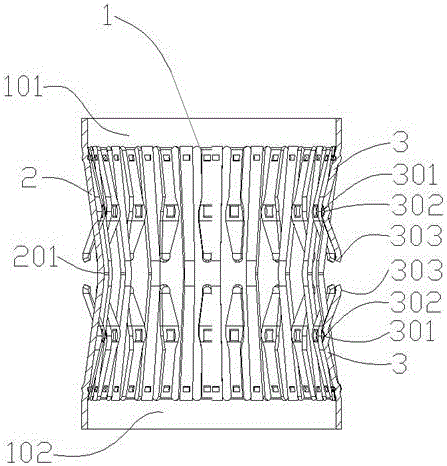

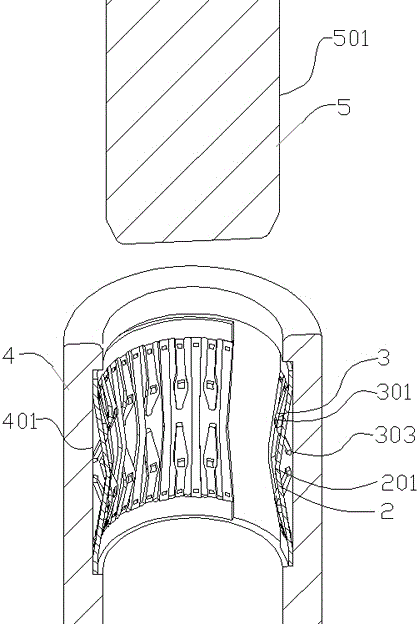

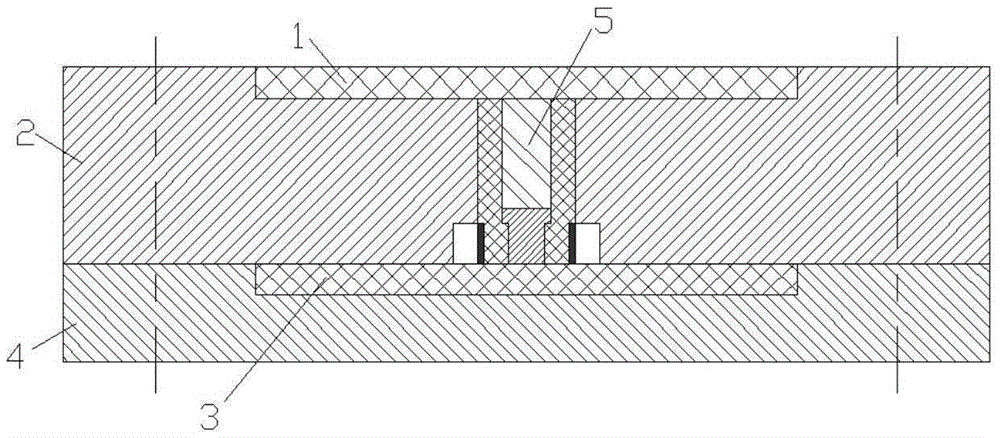

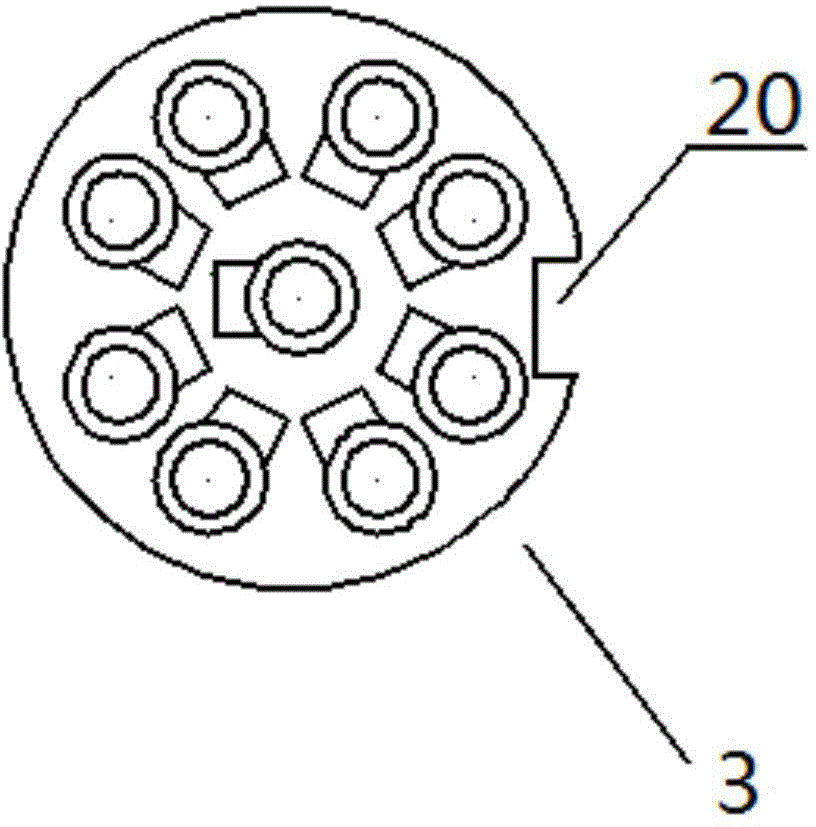

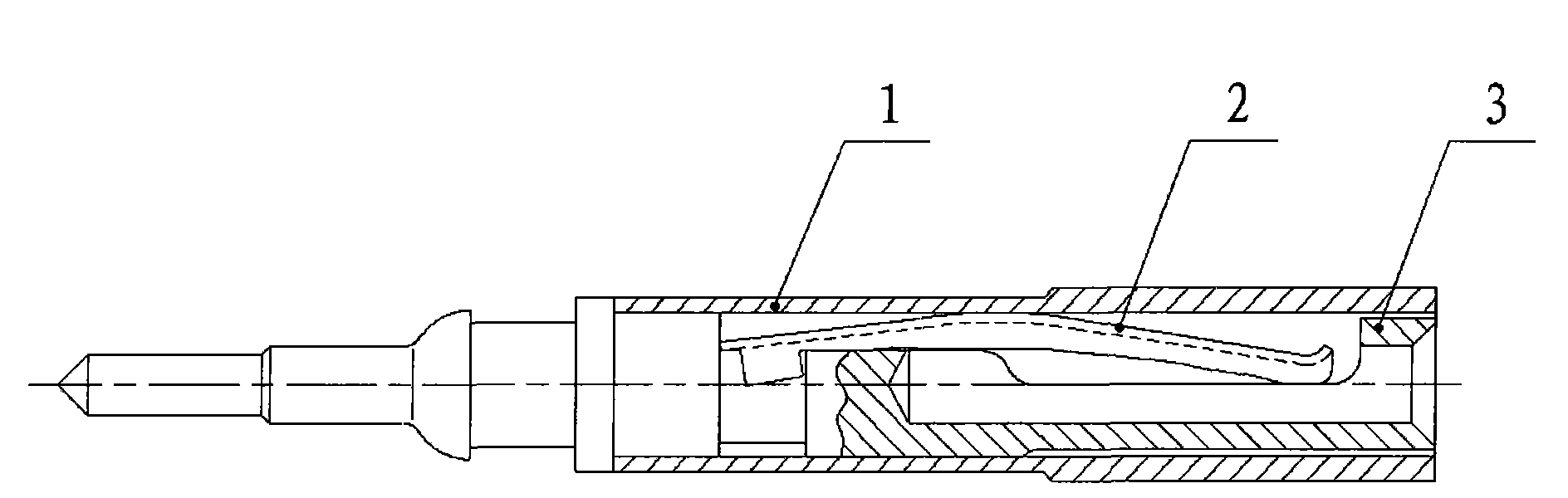

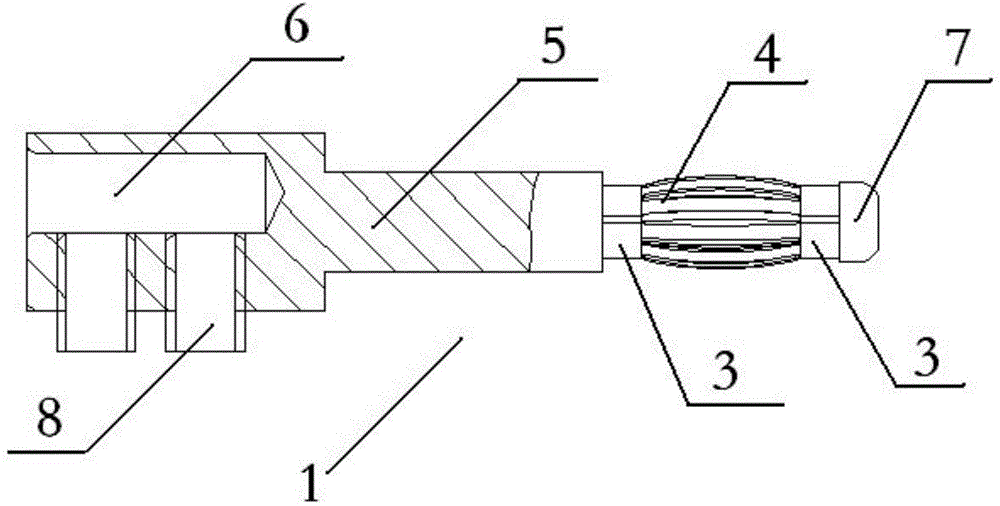

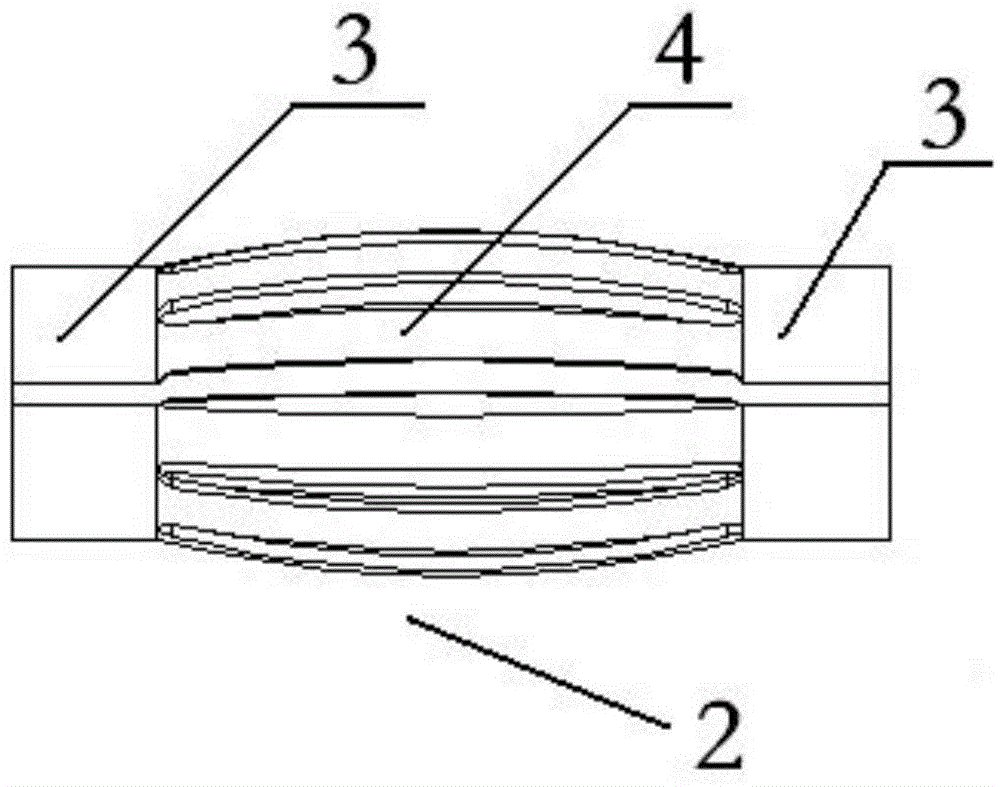

Jack of high-elasticity pawl spring type

InactiveCN102097696AEasy to fixReliable electrical connectionCoupling contact membersInterference fitEngineering

The invention discloses a jack of a high-elasticity pawl spring type, comprising a jacket (1), a pawl spring (2) and a jack. The pawl spring (2) is assembled and arranged on the excircle of the jack (3) which is provided with steps for realizing the axial limitation of the pawl spring (2), the pawl spring (2) is a rotary spare part provided with a plurality of elastic contact sheets, the end parts of the plurality of elastic contact sheets are folded into an incircle to form an elastic structure which can be strutted and have closing force, the jacket (1) is sleeved on the peripheries of the pawl spring (2) and the jack (3) so as to fix the pawl spring (2) in the jack (3), a guiding part in arc bending is arranged at the end part of each elastic contact sheet, and the jacket (1) and the jack (3) are in interference fit and compression joint to reliably fix the pawl spring (2) in the jack (3). The invention has a simple structure, high contact reliability, long contact length, small plugging force, overstress deformation resistance and favorable guidance.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Crown spring jack contacting piece

InactiveCN102801018ASimple structureReliable contactCoupling device detailsEngineeringMechanical engineering

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Connector

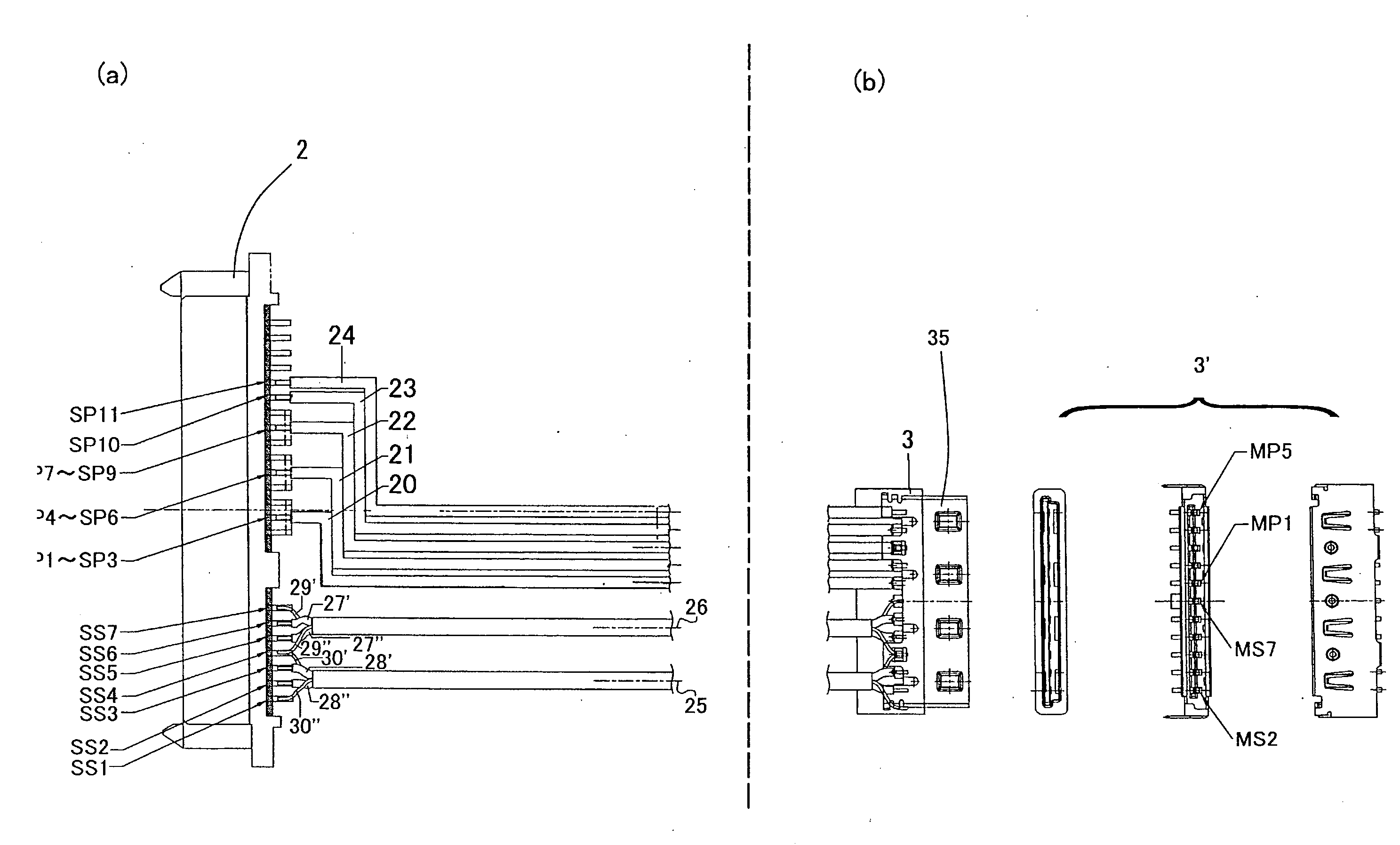

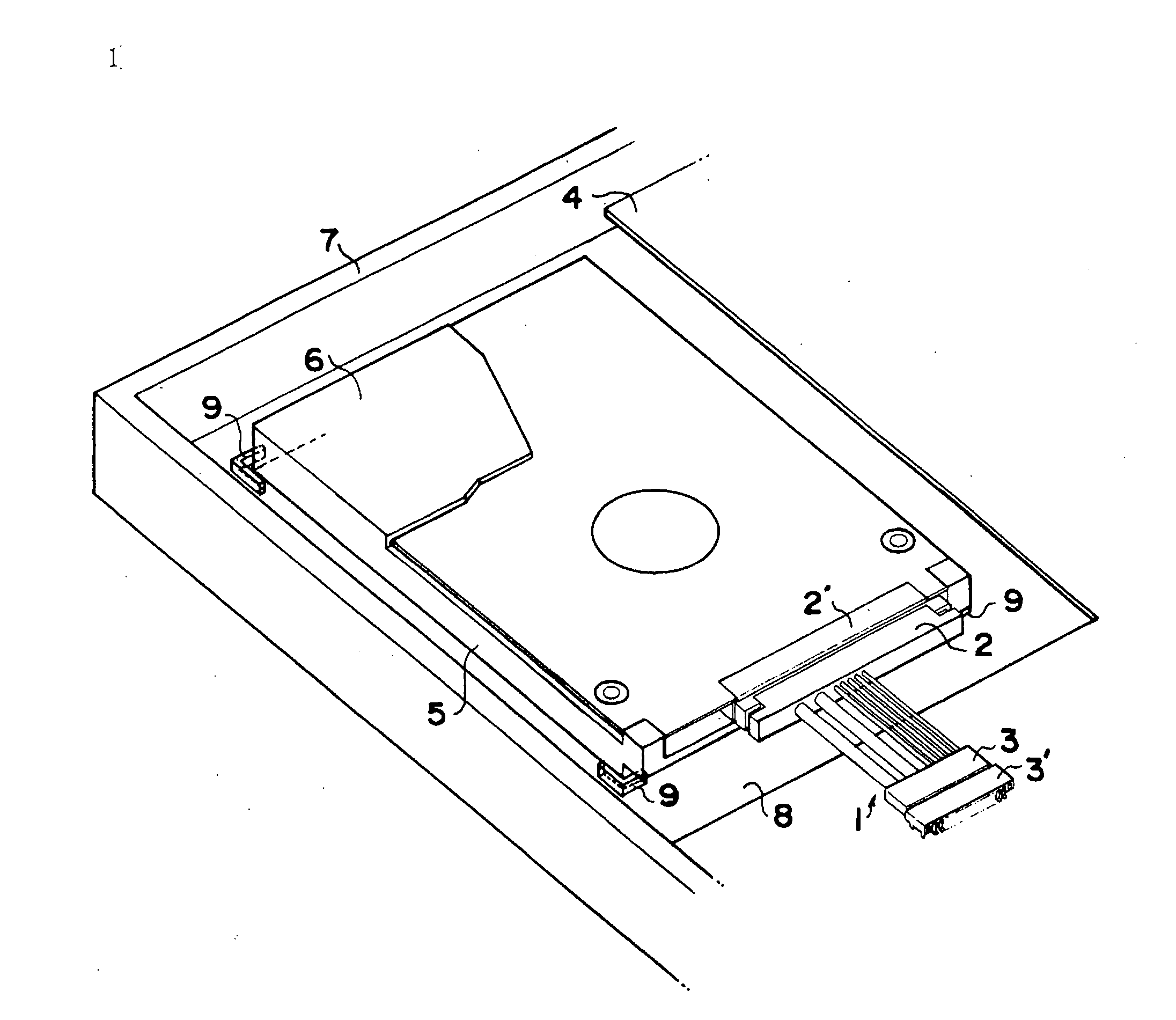

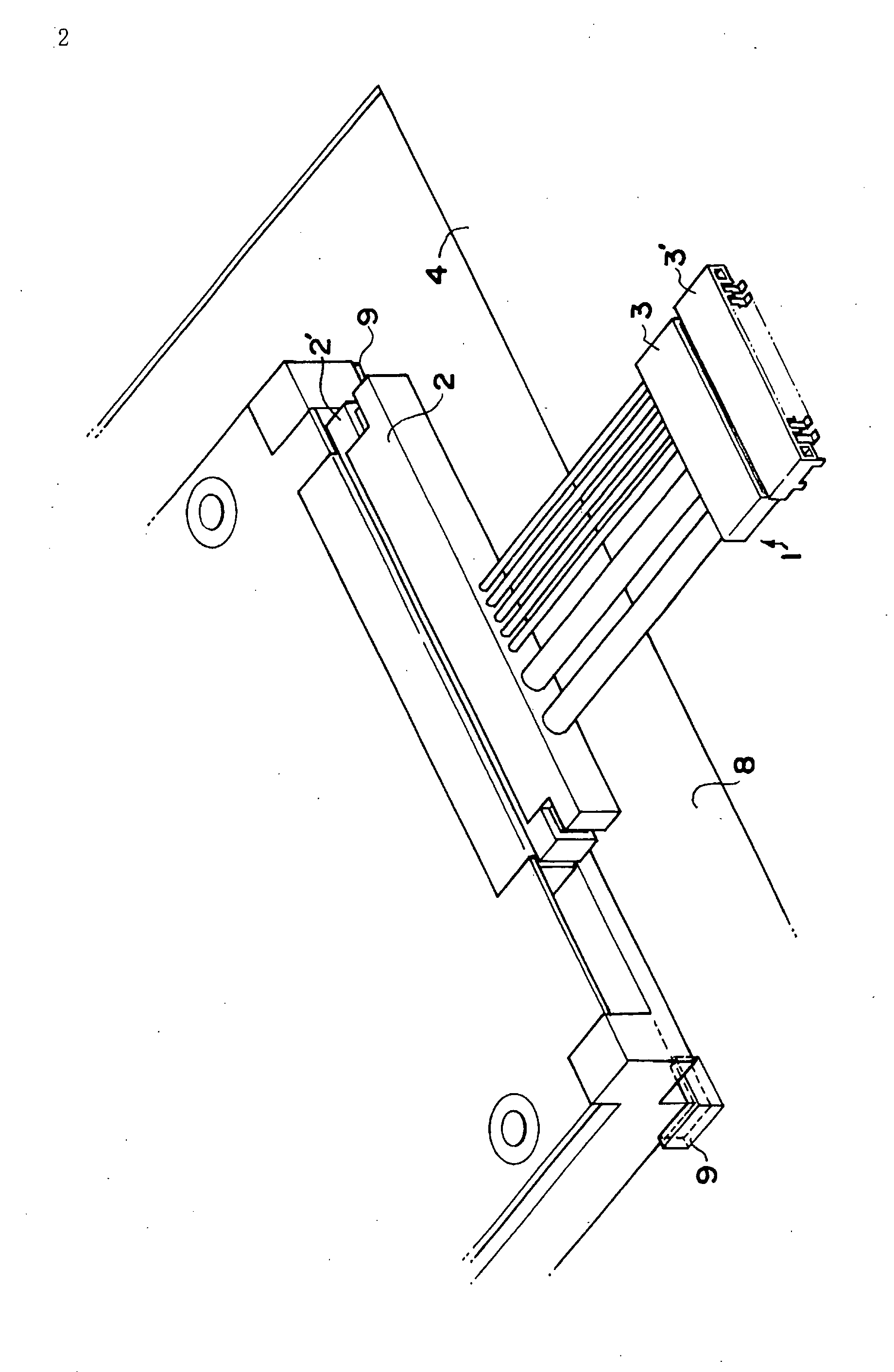

InactiveUS20080287005A1Increase freedomSmall insertion forceDigital data processing detailsCoupling device detailsMating connectionEngineering

A connector for electrically connecting a primary side mating connector having contacts and a secondary mating connector having contacts. The connector has parallelly arranged flexible cables and connectors provided at both ends of the cable and individually connected to the primary and secondary mating connectors. The number of the primary side contacts is less than the number of the secondary side contacts, and at least some of the secondary side contacts are connected to one cable that is shared by a set of contacts. The primary side mating connectors are fixed on a circuit board. The secondary mating connector is assembled in an information device that is movable on a mounting surface.

Owner:FRAMATOME CONNECTORS INT SA

Ferrule, fiber connector and manufacturing method of ferrule

InactiveCN108490550AGood dust holding capacityReduce manufacturing costVacuum evaporation coatingPhotomechanical apparatusFiberEngineering

The invention provides a ferrule, a fiber connector and a manufacturing method of the ferrule. The ferrule comprises a ferrule body and at least one fiber; the fiber penetrates into a through whole arranged in axially in the ferrule body, the first end of the fiber is positioned in the through hole, and a vertical distance between the end surface of the first end of the fiber and a plane of a connection end surface of the ferrule core is a first preset distance, and a gap can be formed between the fiber of the ferrule and a fiber of a another fiber after butt joint of the ferrules via the first preset distance; the through hole comprises a first through hole segment, the plane where the top of the first through hole segment is positioned in the same with that where the connection end surface of the ferrule body is positioned, and an intersection of projection of the fiber in the axial direction and projection of a random cross section of the first through hole segment in the directionvertical to the axial direction equals projection of the fiber in the axial direction; and the outer wall of the fiber positioned in the first through hole segment is plated with an anti-reflection film. According to the ferrule, light transmission loss is low, and dust tolerance is high; and when the ferrule is plugged with the other ferrule, a plugging force is lower and the plugging reliabilityis higher.

Owner:HUAWEI TECH CO LTD

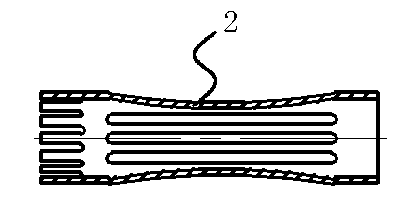

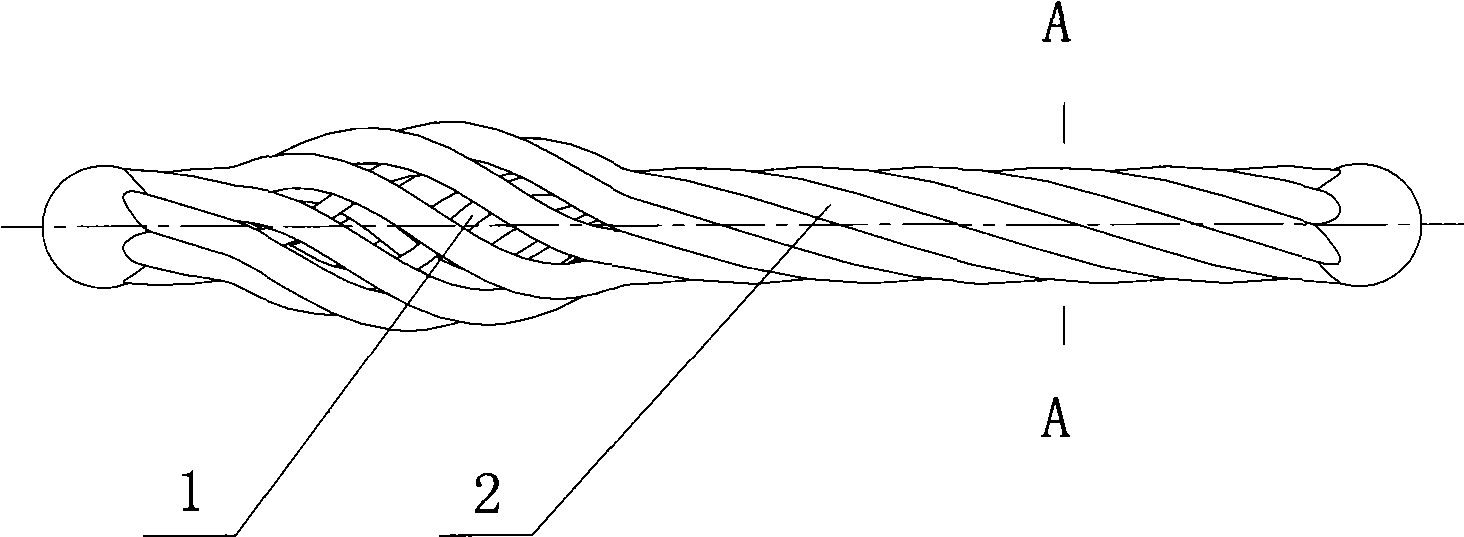

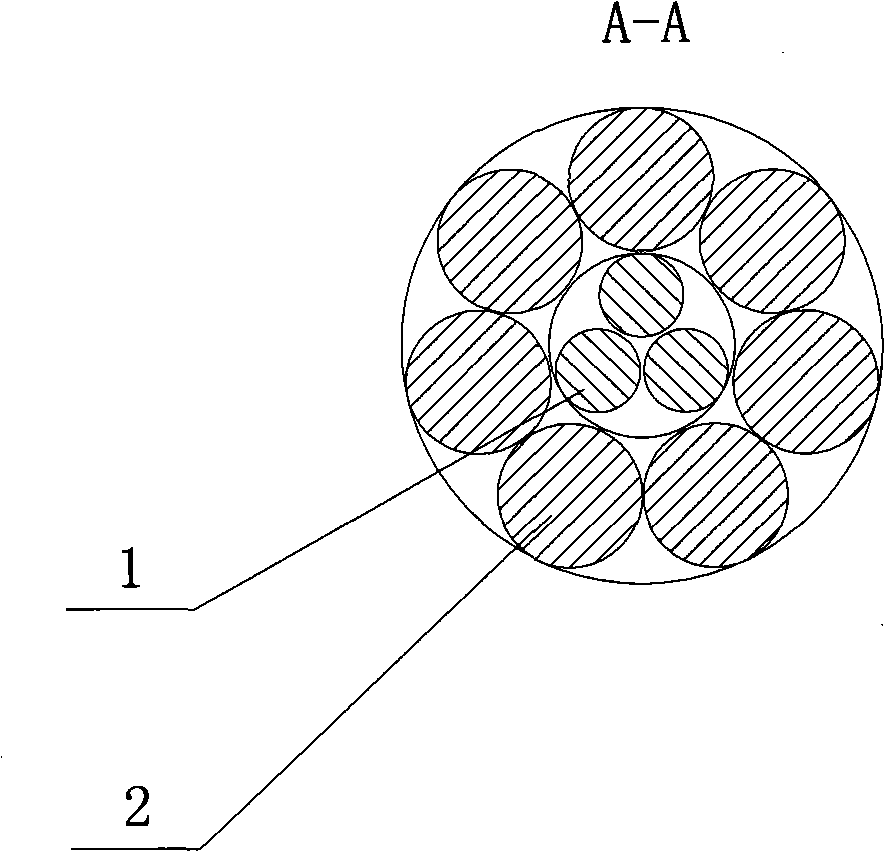

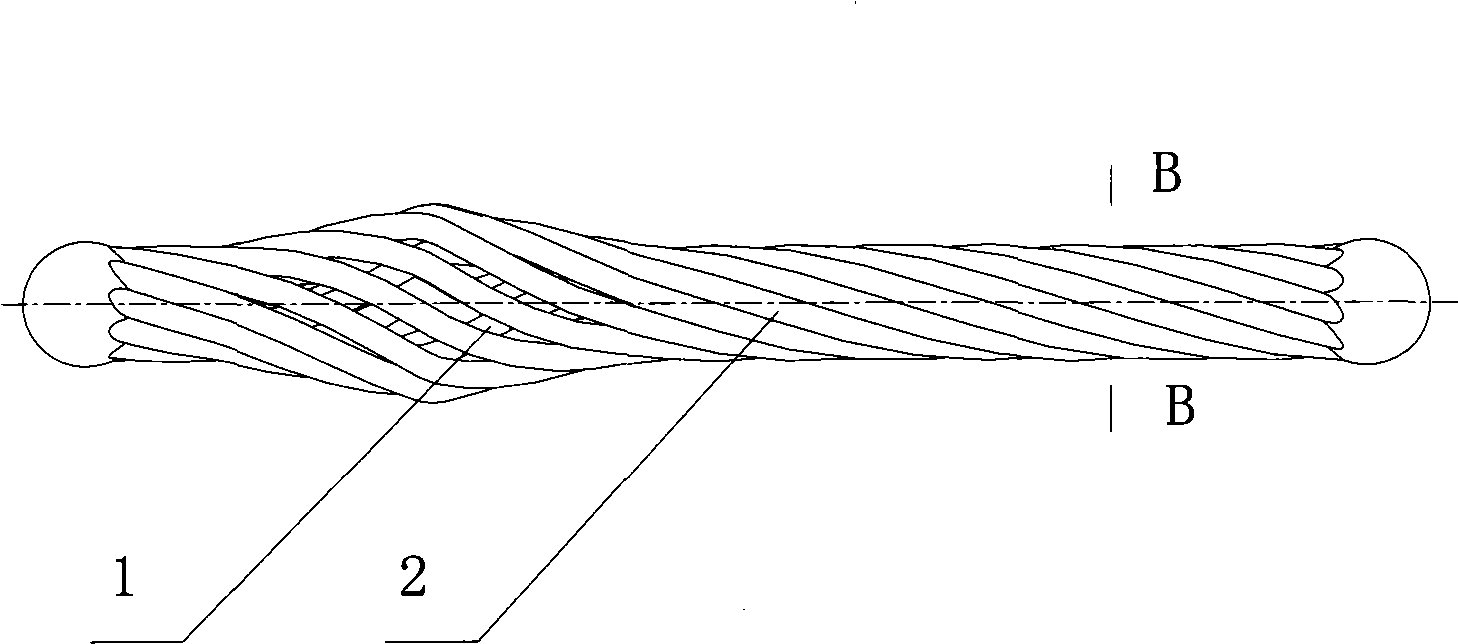

Twist needle light in inserting/pulling force

InactiveCN101546879ASmall insertion forceIncrease the effective contact areaCoupling contact membersPull forceMetal alloy

The invention provides a twist needle light in inserting / pulling force, which is twisted from two or more than two layers of metal alloy wires and is obtained by changing the number of the layers of the twist needle, the number of the lengths of the metal alloy wires in each layer and the diameter of the metal alloy wires in each layer. Compared with the prior thicker twist needle equivalent in outer diameter, the twist needle has the advantages of greatly reducing inserting / pulling force, having more contacts in butted connection with jack contact pieces, increasing the effective contact area of the electrical connection between contact pins and jacks, having better flexibility of contact-pin contact pieces and improving the reliability of the electrical connection between the contact pins and the jacks.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

Plated copper alloy material and process for production thereof

InactiveUS6939621B2Reduce contact resistanceImprove reliabilityElectrically conductive connectionsCoupling contact membersCopper platingTin

A plated copper alloy material for connecting terminals is provided which comprises a parent material of copper or copper alloy, a nickel layer and a copper-tin alloy layer. The nickel layer has a thickness of 0.1-1.0 μm. The copper-tin alloy layer has a thickness of 0.1-1.0 μm and contains 35-75 at % of copper. The material may additionally have a tin layer no thicker than 0.5 μm for an engaging type terminal containing 0.001-0.1 mass % of carbon, or thicker than 0.5 μm for a non-engaging type connector. The material meets requirements for capability of insertion with a small force, good electric reliability (due to low contact resistance) in a high-temperature atmosphere, workability for sharp bending without cracking, good solder wettability and good corrosion resistance to sulfur dioxide gas.

Owner:KOBE STEEL LTD

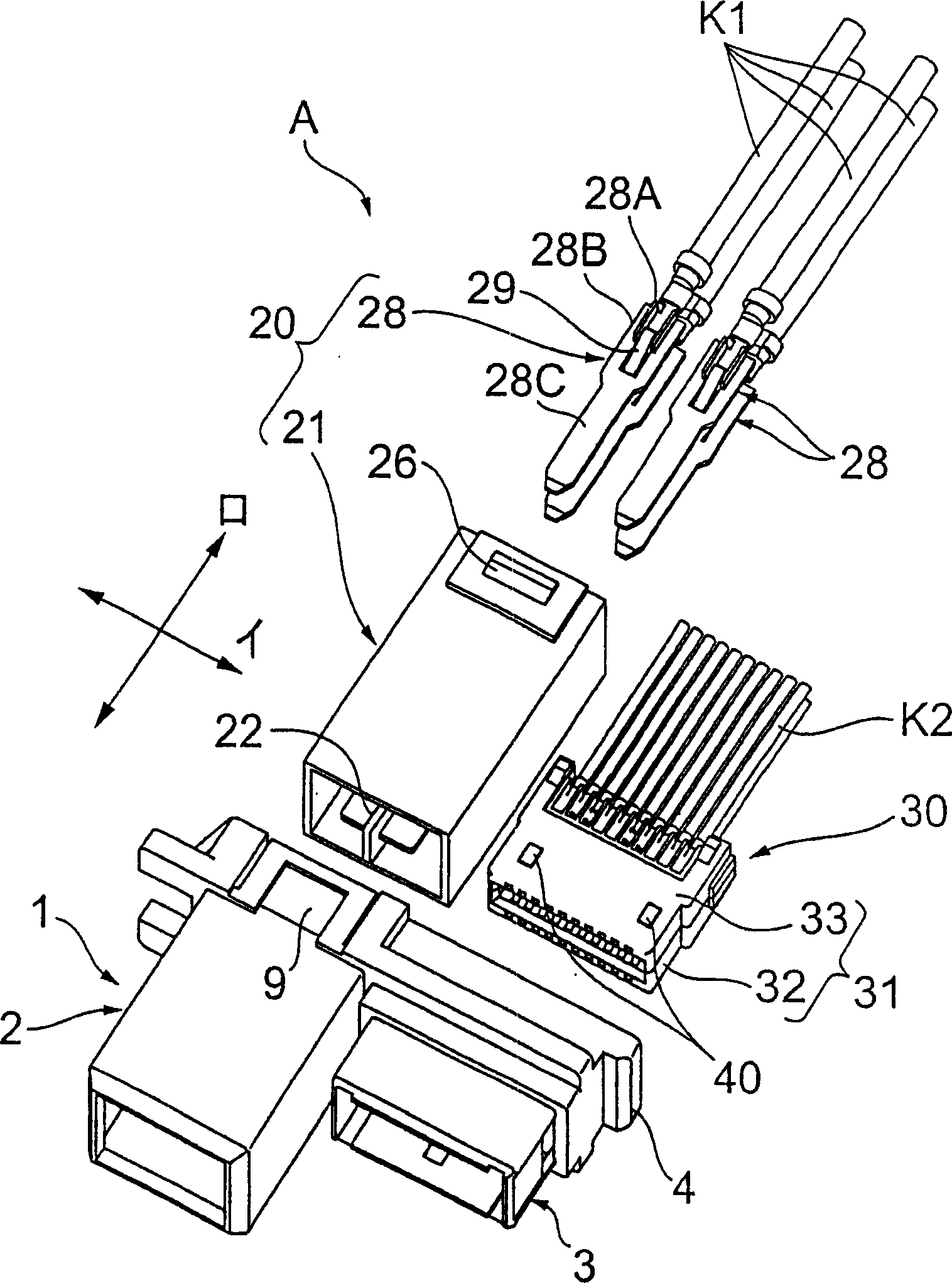

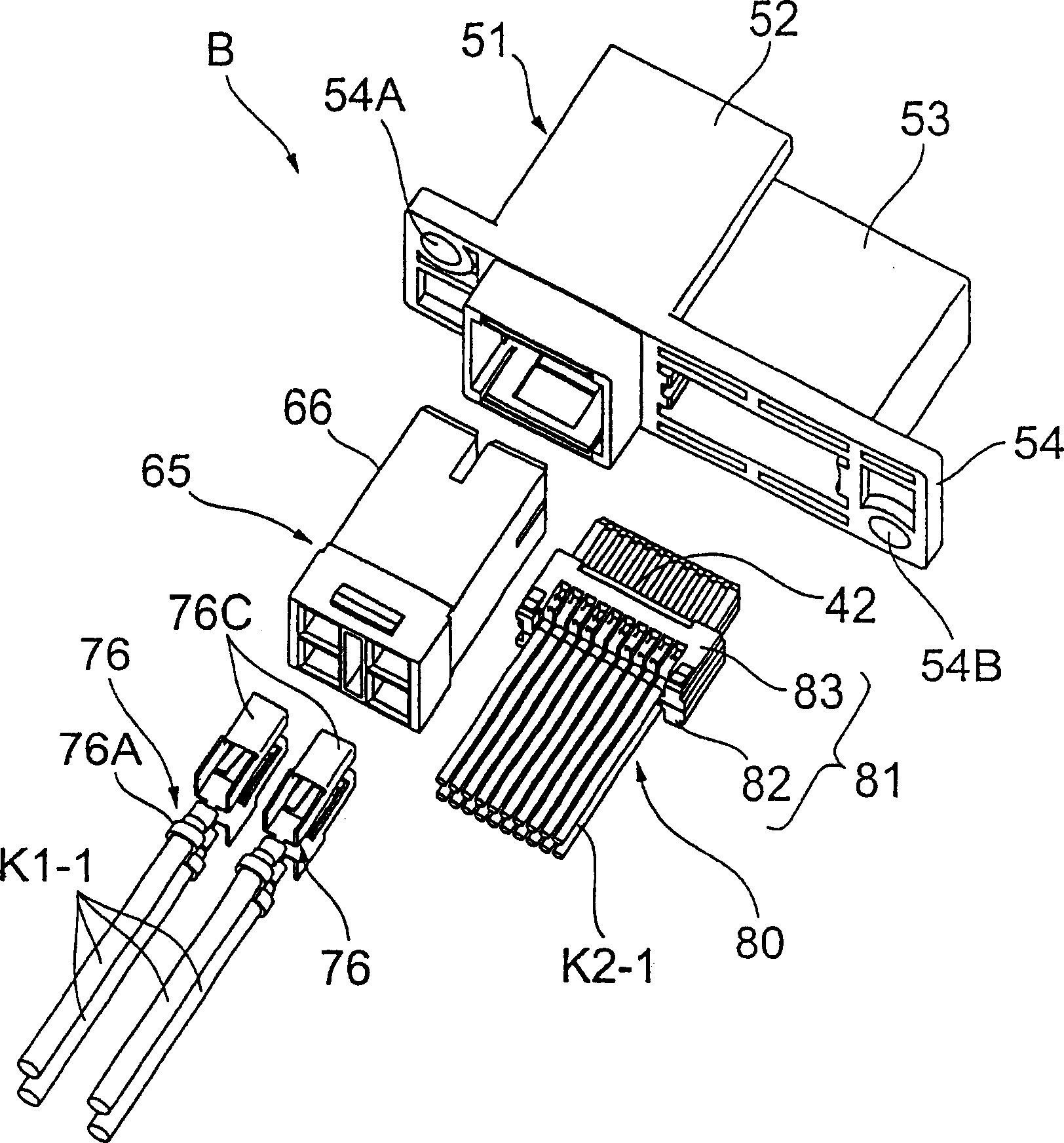

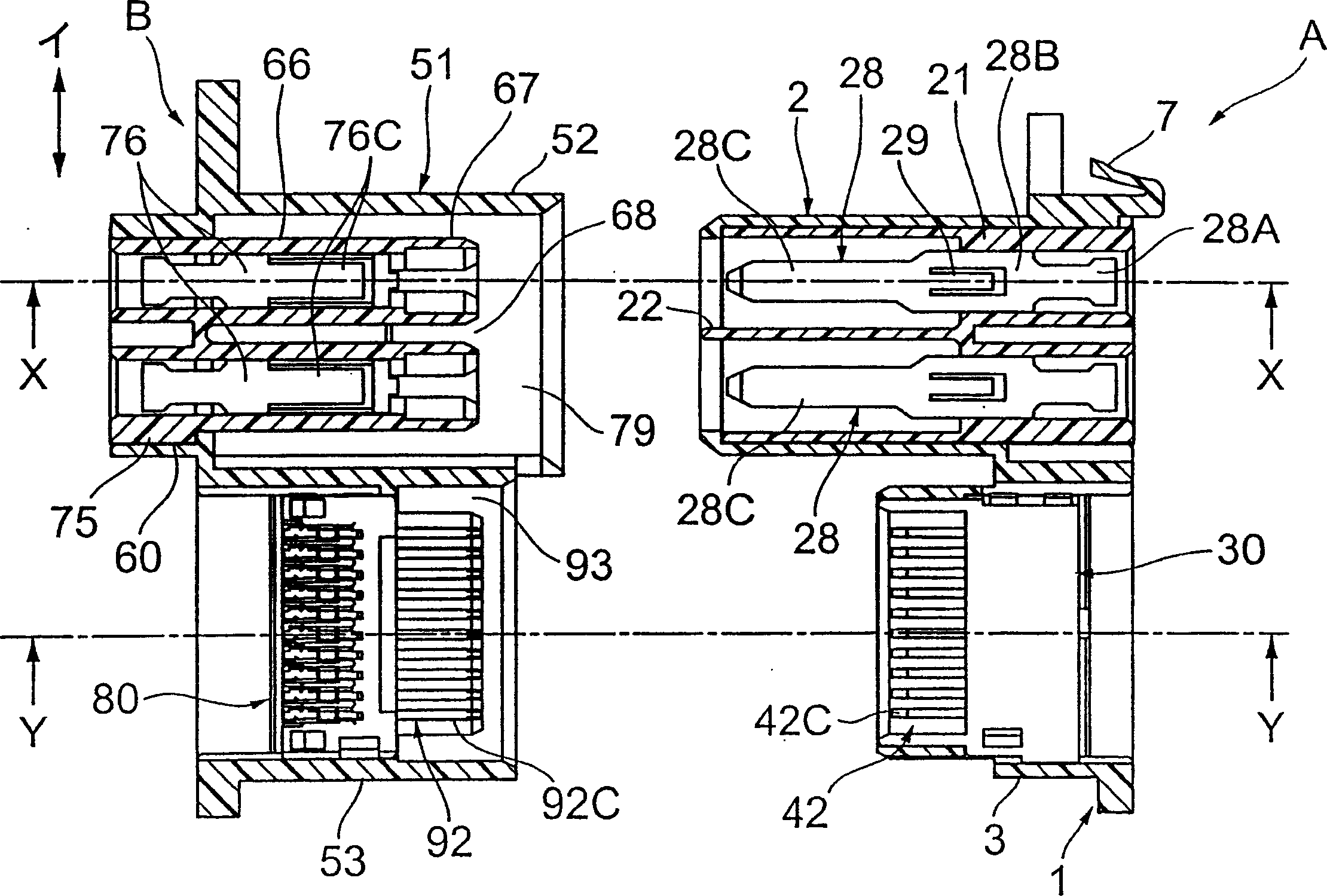

Multi-pole connector

InactiveCN1744387AAvoid breakingLongevityIncorrect coupling preventionSecuring/insulating coupling contact membersElectrical and Electronics engineeringBellows

To provide a multipolar connector allowing the number of conductors to be easily expanded and allowing its service life to be extended.Signal terminals 42 (mating signal terminals 92) are mounted to terminal mounting parts 45 (88) with one-side case part 32 (82) and the other-side case part 33 (83) expanded. Each signal terminal 42 is bent in a V-shaped form in profile; its bending point has a contact part 42C used as a contacting part 43; a bellows contact (that is, a contact made by bending a thin plate into a shape so as to obtain a uniform spring characteristic) is used for the signal terminal (female terminal) 42 as each mating signal terminal 92 has a flat linear mating contact part 92C; and the mating signal contact (male terminal) 92 uses the flat linear contact.

Owner:HIROSE ELECTRIC GROUP

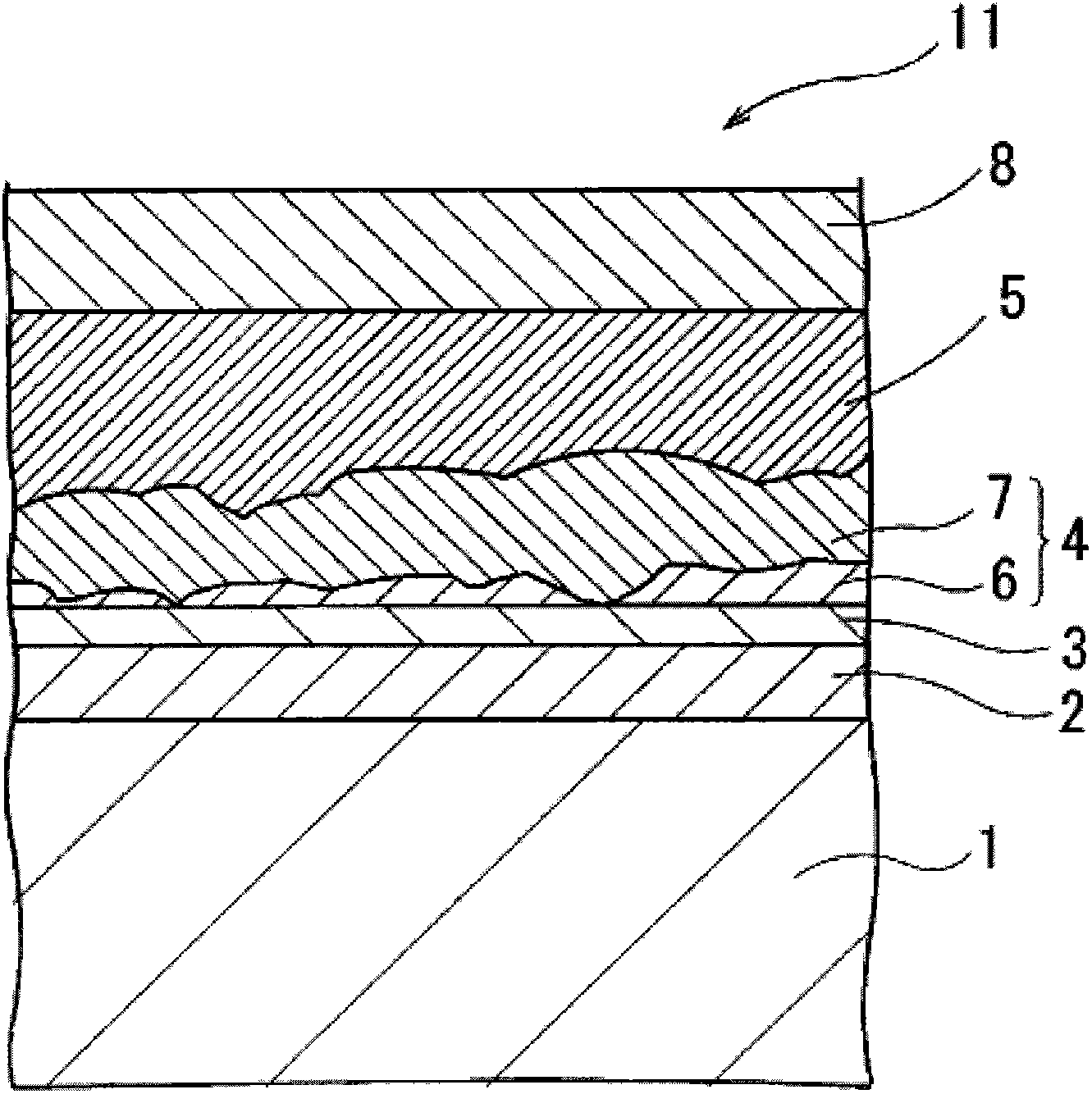

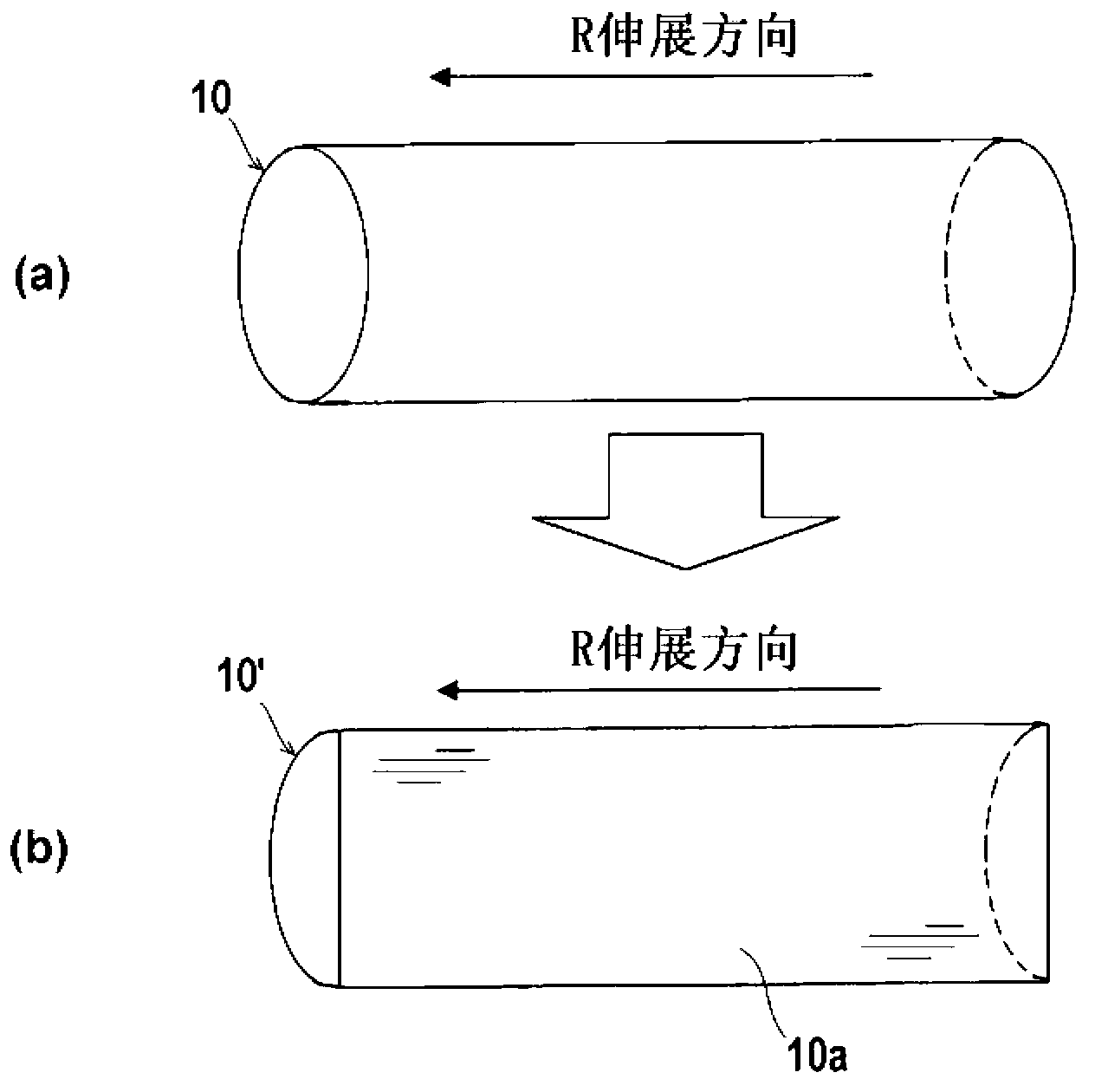

Conductive member and manufacturing method thereof

ActiveCN102395713AEfficient removalImprove plating efficiencyCoupling contact membersEmergency protective devicesOptoelectronicsIntermetallic

The conductive member has a stable contact resistance, resists peeling, displays a low insertion / removal force and is stable when used as a connector, and has an excellent fusing characteristic when used as a fuse. A Cu-Sn intermetallic compound layer (4) is formed between a Ni-based underlayer (3) formed on a Cu-based base material (1), and a Sn-based surface layer (5) that forms the surface. In addition, the Cu-Sn intermetallic compound layer (4) comprises a Cu3Sn layer (6) disposed on the Ni-based underlayer (3) and a Cu6Sn5 layer (7) that is disposed on the Cu3Sn layer (6). The surface roughness of the contact face between the Sn-based surface layer (5) and the Cu-Sn intermetallic compound layer (4) combining the Cu3Sn layer (6) and Cu6Sn5 layer (7) has an arithmetic mean roughness Ra of 0.05-0.25 [mu]m, and the maximum valley depth Rv of the roughness curve is 0.05-1.00 [mu]m. Furthermore, the Cu3Sn layer covers the Ni-based underlayer with a surface coverage of 60-100%.

Owner:MITSUBISHI SHINDOH CO LTD

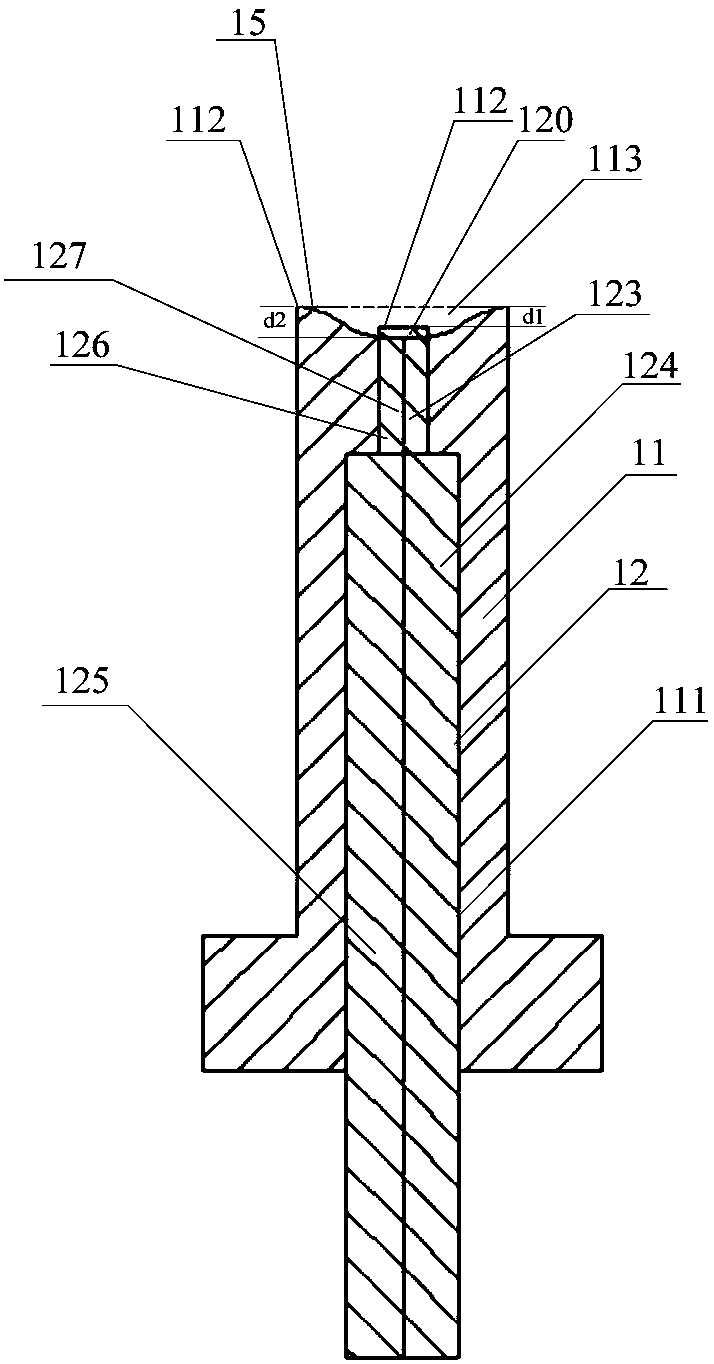

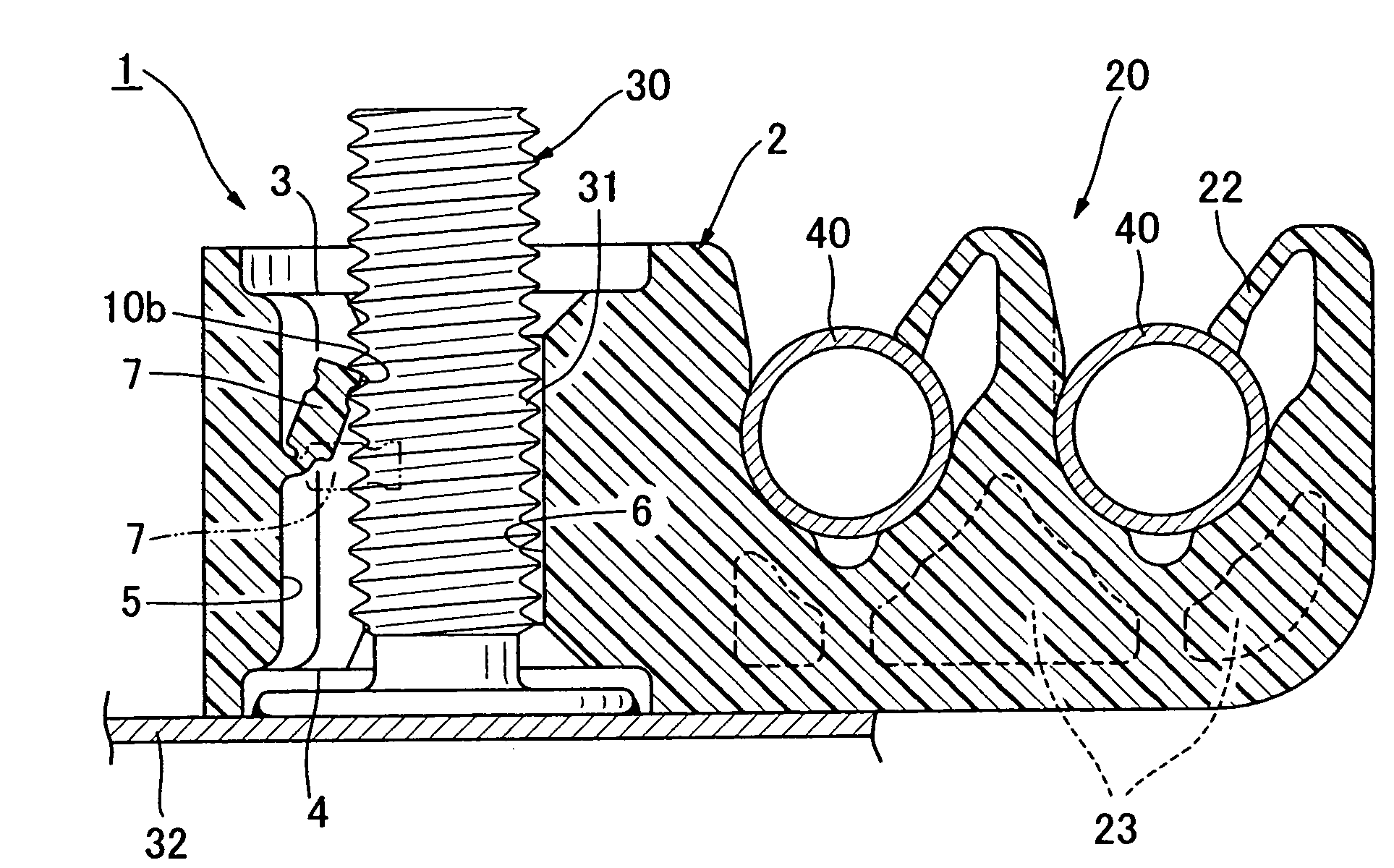

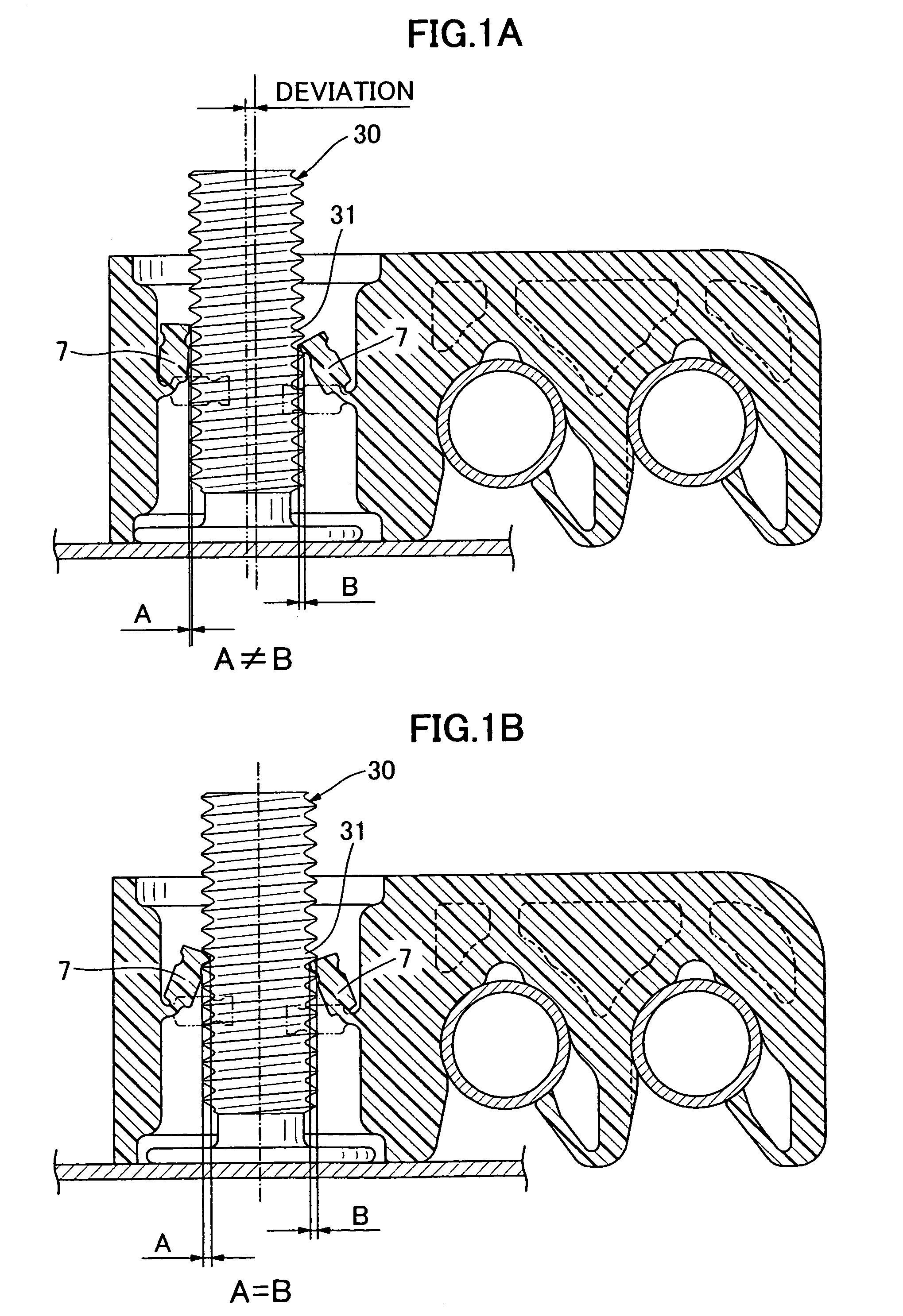

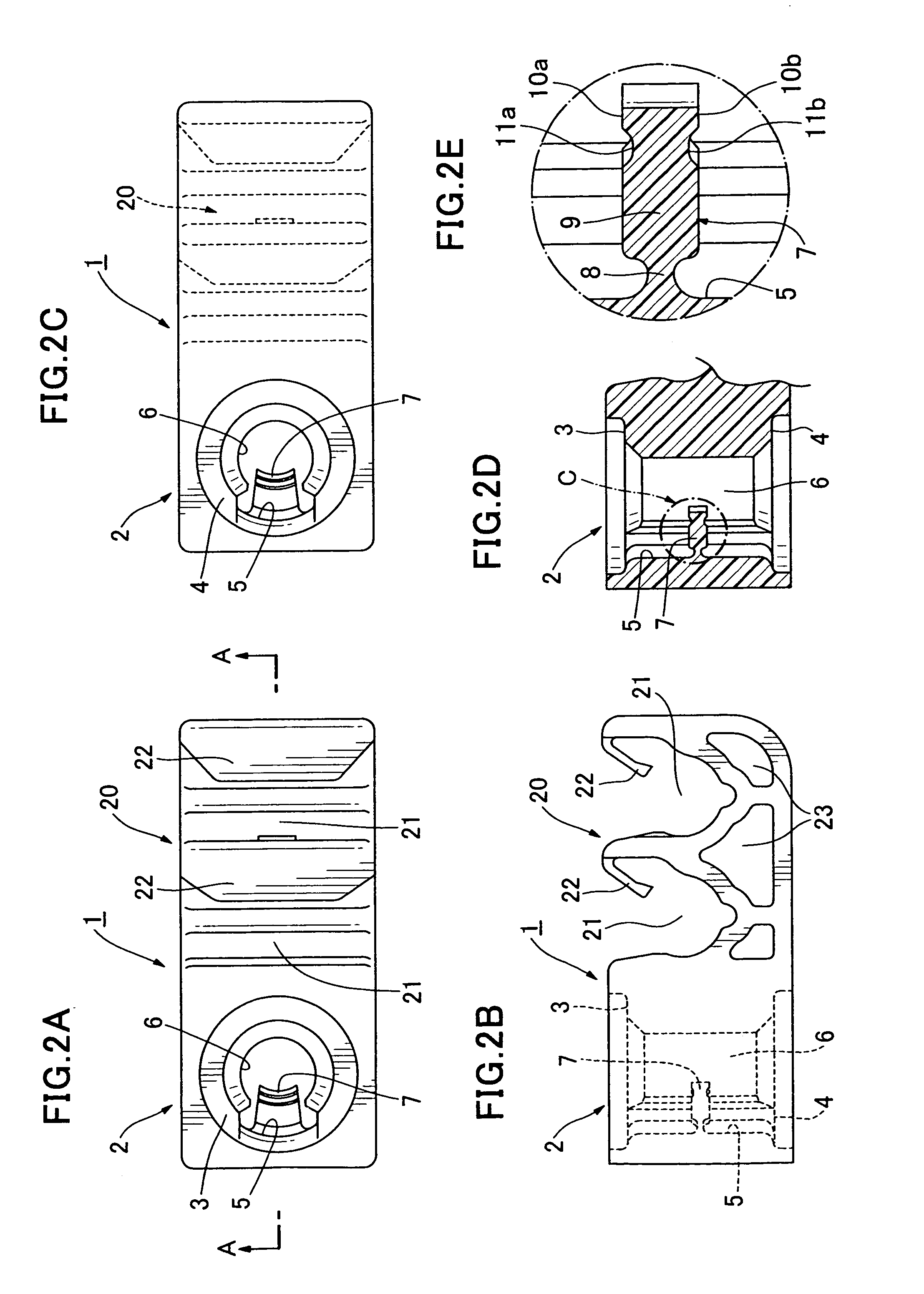

Device for mounting a component such as a pipe on a stud

InactiveUS7320571B2Minimize slippageSmall insertion forceSnap-action fastenersPipe supportsEngineeringScrew thread

A device for mounting a component, such as a pipe, on a threaded stud comprises a main body section with a bore for inserting a stud and a component mounting section. The device includes only a single pawl that extends from a first inner wall of the bore in a direction perpendicular to the axis of the bore. The pawl has a flexible thin section connected to the inner wall and a thick section extending from the thin section. The pawl can be bent in opposite directions at the thin section. A pair of thread engaging sections for engaging threads of the stud are formed at an end of the thick section. A pair of grooves for engaging threads are formed adjacent to respective engaging sections.

Owner:NEWFREY

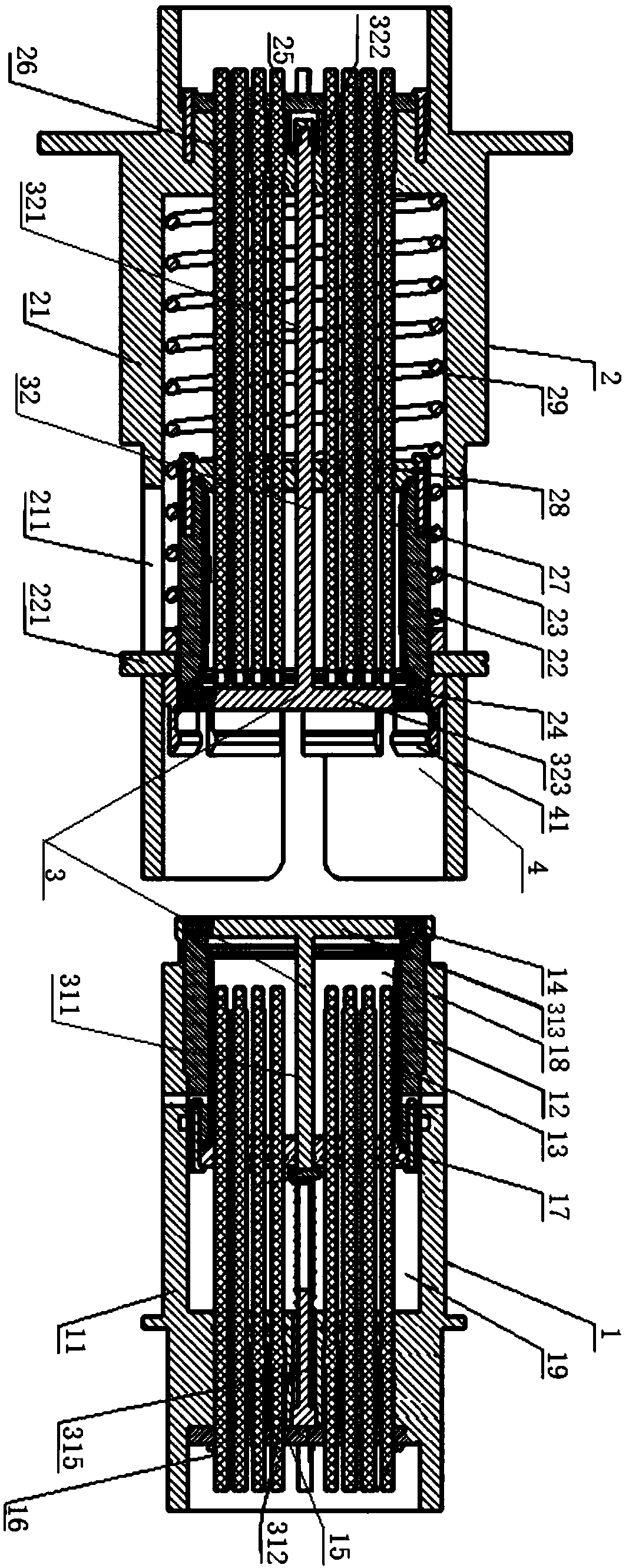

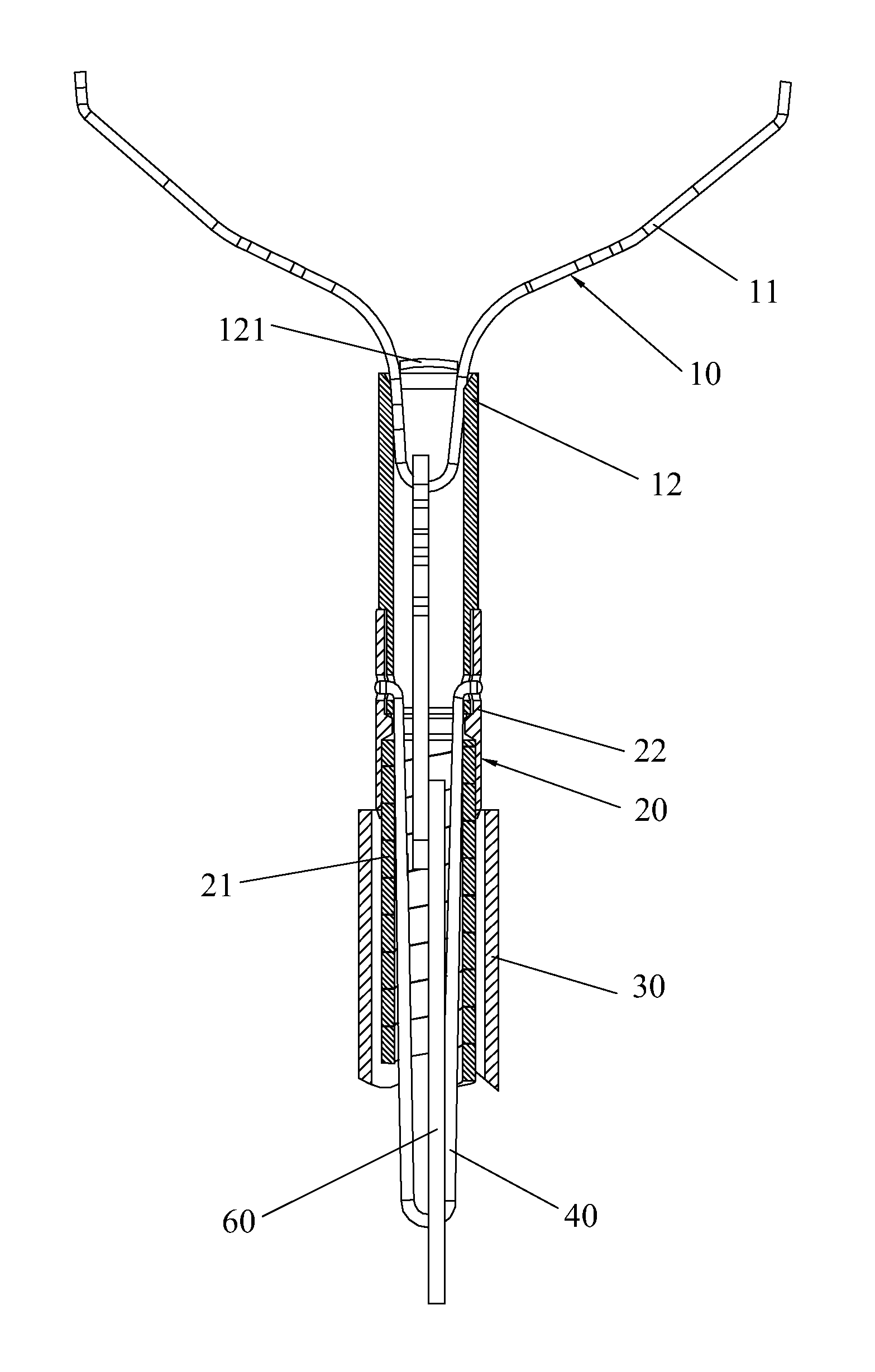

Rotary pluggable photoelectric combined connector used in deep sea

ActiveCN107728262AIncrease flexibilityStrong adaptability to working conditionsCoupling device detailsCoupling light guidesLocking mechanismWorking environment

The invention discloses a rotary pluggable photoelectric combined connector used in deep sea. The connector includes a plug and a socket which are matched with each other, and the plug includes a plugshell body, a plug elastic capsule body, a plug web, a plug tail plate and a plurality of plug photoelectric insertion cores; the socket comprises a socket shell body, a socket elastic capsule body,a socket web, a socket tail plate, a plurality of socket photoelectric insertion cores and a movable cavity; the connector is also provided with rotary mechanisms capable of covering / uncovering channels cooperating with the socket photoelectric insertion cores and the plug photoelectric insertion cores, and a locking mechanism is arranged between the front end of the plug and the front end of thesocket. The rotary pluggable photoelectric combined connector can adapt to working environments different in depth, and is reliable in sealing, simple to operate and small in required strength for plugging and pulling.

Owner:SOUTHEAST UNIV

Power socket convenient to plug in and plug out for robot and plug-in and plug-out method of power socket

InactiveCN108199174AAvoid wear and tearAvoid deformationCoupling device engaging/disengagingCoupling contact membersMechanical engineeringRobot

The invention relates to the technical field of a robot, in particular to a power socket for a robot and a plug-in and plug-out method of the power socket. In the power socket, jacks are formed in oneside of a shell, a press plate is arranged in the shell, two arc conductive spring sheets are arranged in each jack, one end of each arc conductive spring sheet is fixedly connected with the jack, the other ends of the arc conductive spring sheets are fixedly connected with the press plate, sliding grooves are formed in an inner wall of the shell, sliding blocks are arranged at edges of the pressplate and match with the sliding grooves, handles on the press plate extend out of the shell, springs are connected with the inner wall of the shell and the press plate, a through hole is formed in aposition, corresponding to the jack, of the press plate, a top needle is arranged in a through hole, two racks are symmetrically arranged at a tail part of the top needle, the above rack is correspondingly engaged and connected with a first gear, the below rack is correspondingly engaged and connected with a second gear, and the first gear at the optimal edge and the second gear at the optimal edge are respectively engaged with racks arranged at side edges of the press plate. By the power socket, the service lifetime can be prolonged, the plug-in and plug-out force is reduced, and the power socket is favorable in contact.

Owner:佛山市南海惠家五金制品有限公司

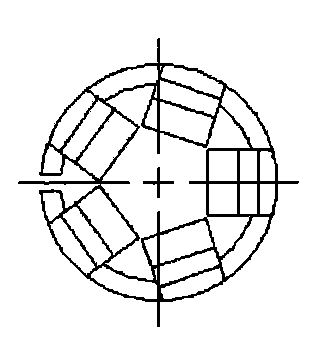

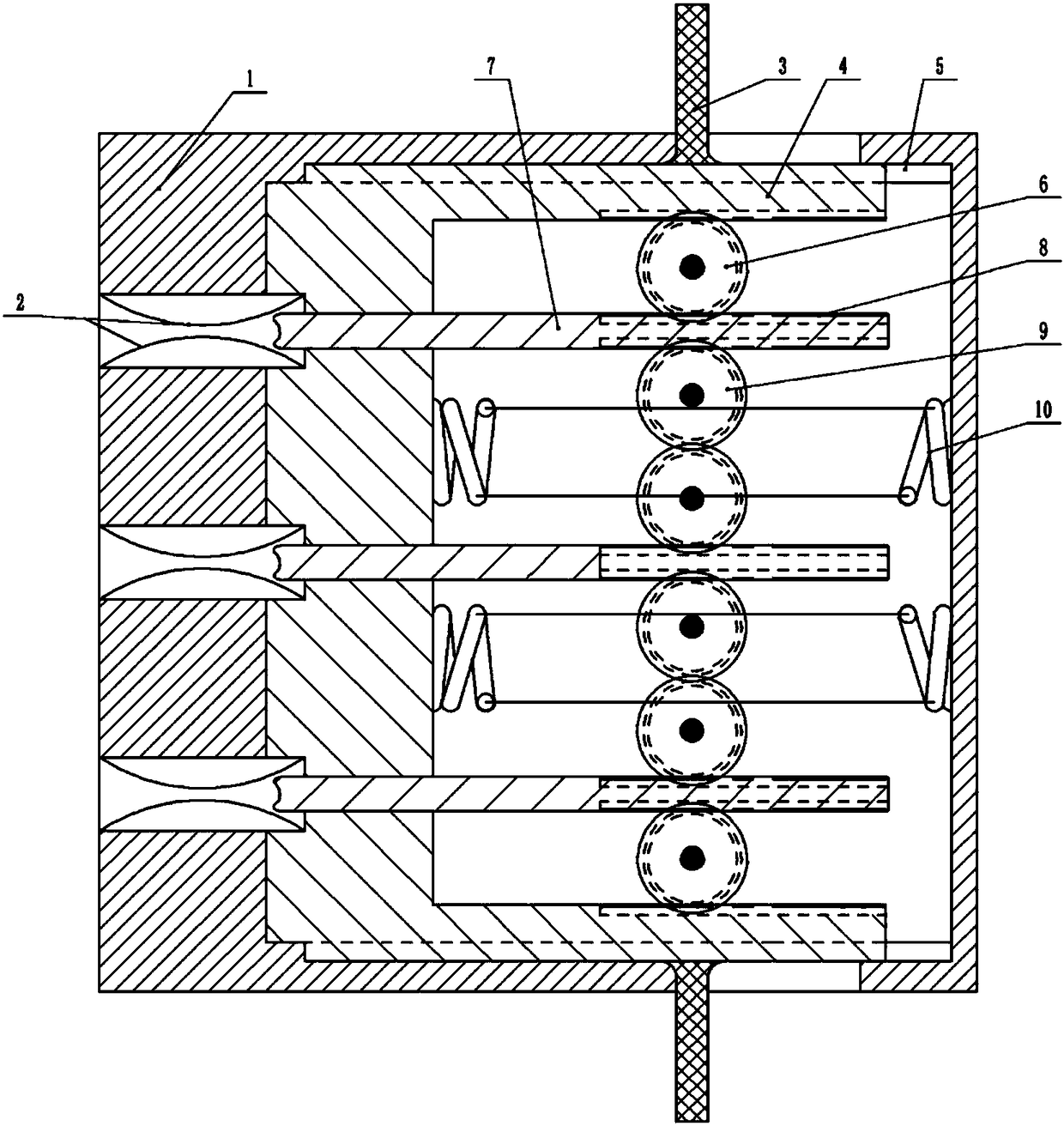

New type cylindrical crown spring

ActiveCN106340743ASatisfy the requirement of transmitting high currentIncreased durabilityCoupling contact membersClamped/spring connectionsEngineeringMechanical engineering

The invention provides a new type cylindrical crown spring. The invention is designed to mainly solve the problems in the prior art that a conventional spring is usually equipped with few contact points and requires large plugging force. According to the invention, a plurality of spring sheets are arranged at the upper end band and the lower end band of a crown spring's two ends as well as between the upper end band and the lower end band. Each spring sheet is provided with a contact part that can axially extend to the cylindrical crown spring. With the technical schemes of the invention, more contact points are available, which can effectively reduce the contact resistance. Further, as the inward protrusions of the spring sheets are divided into a plurality of layers, layers can be divided for the contact with the plugging needles in the process of plugging needle insertion, which effectively reduces the plugging force of insertion needles.

Owner:HENAN THB ELECTRIC

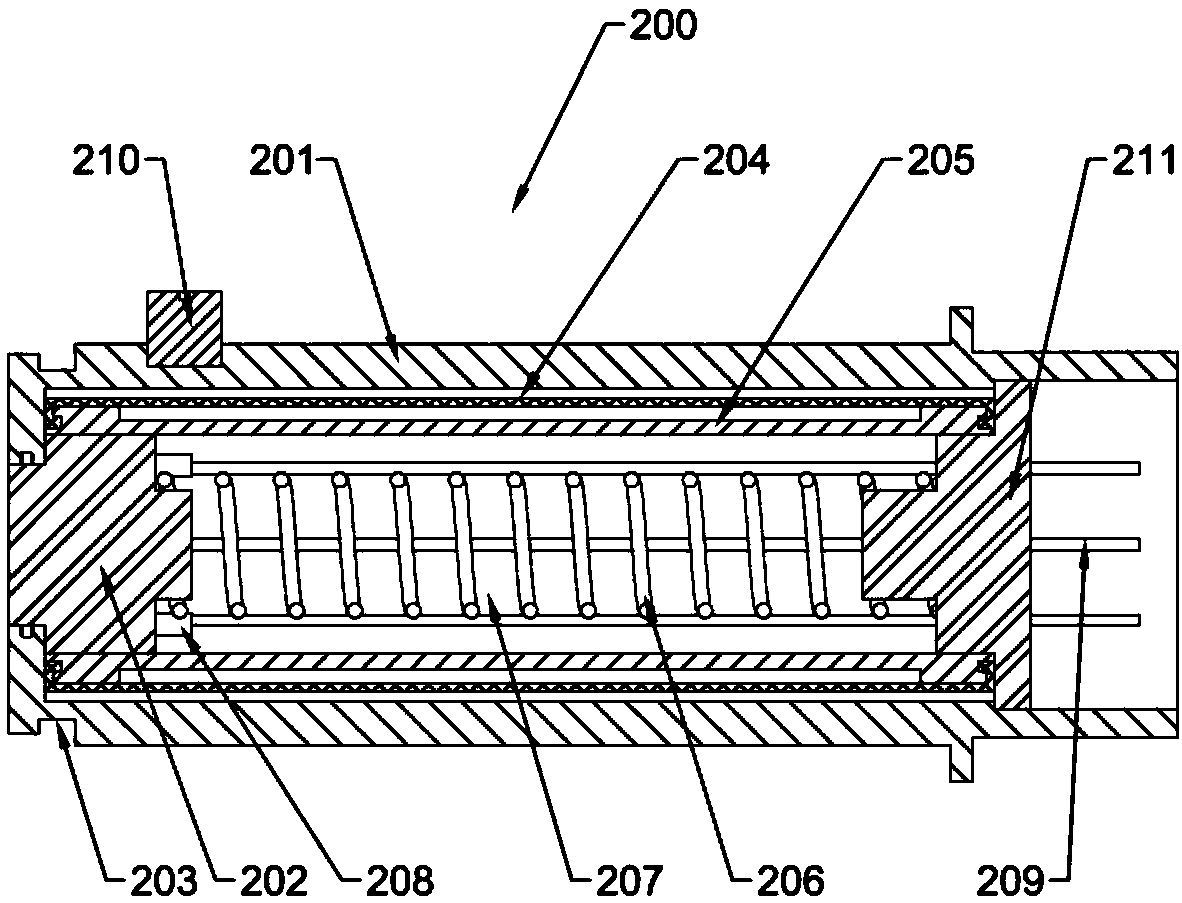

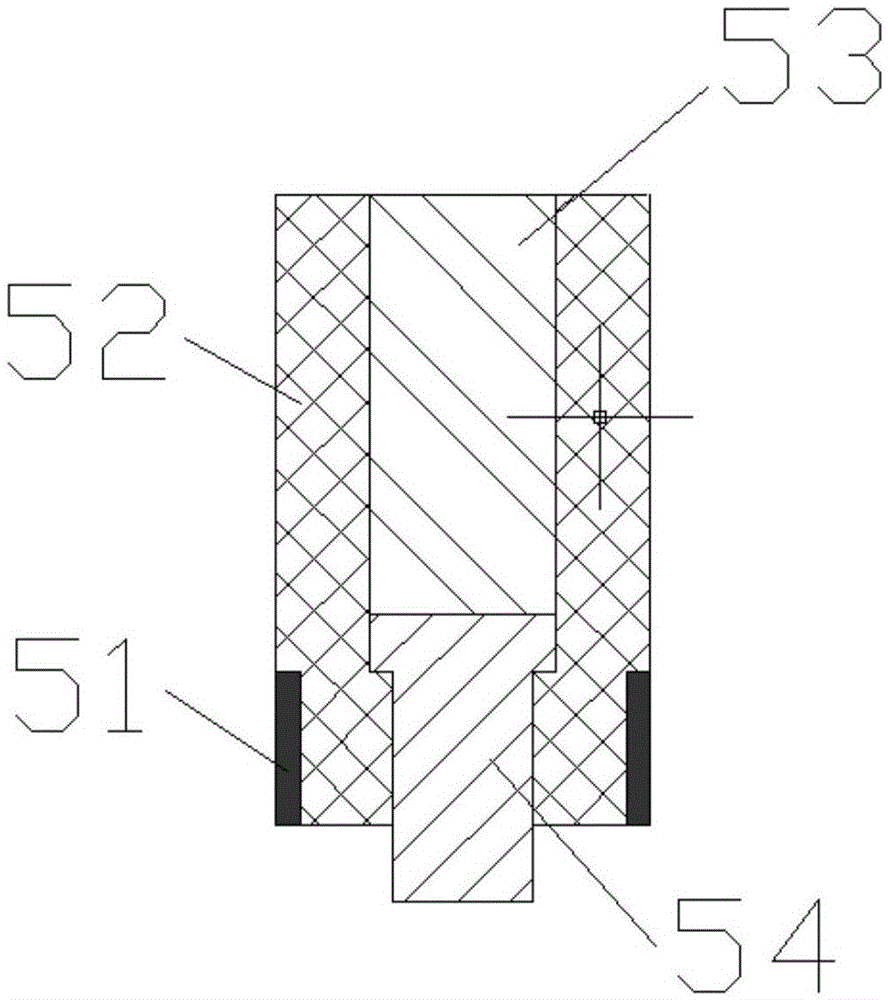

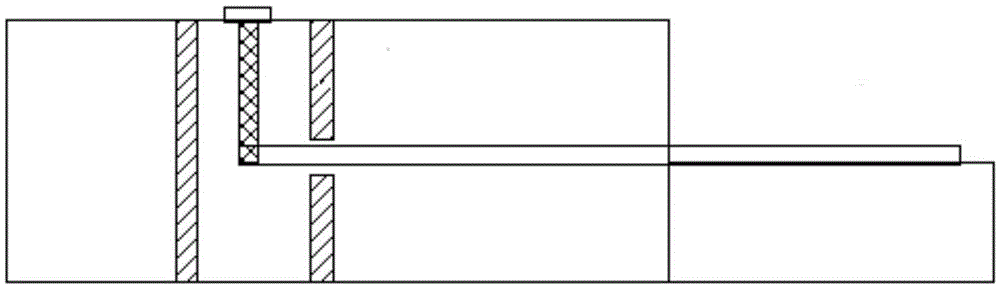

Radio-frequency vertical connection circuit between two-dimensional millimeter wave modules

The invention provides a radio-frequency vertical connection circuit between two-dimensional millimeter wave modules, aiming at the radio-frequency vertical connection circuit with higher reliability and more convenient assembly and disassembly. The radio-frequency vertical connection circuit is implemented through the following technical scheme: an upper module metal structural member (2) and a lower module metal structural member (4) are fixed through a screwed way or the other detachable way, and the lower end of the upper module metal structural member and the upper end of a lower module two-dimensional multi-chip circuit board component (3) are in pressure fit; a coaxial connector (5) is welded in the upper module metal structural member, so that a vertical circuit connection between an upper module two-dimensional multi-chip circuit board component (1) and the lower module two-dimensional multi-chip circuit board component is realized; and a fuzz button (53) is coaxially connected to a probe (54) of a step cylinder structure, and a small end of the probe (54) is higher than an outer circle insulating layer (52) to be in contact with the lower module two-dimensional multi-chip circuit board component. The radio-frequency vertical connection circuit has the advantages of simple structure, small insertion and extraction force and easiness in assembly and disassembly.

Owner:10TH RES INST OF CETC

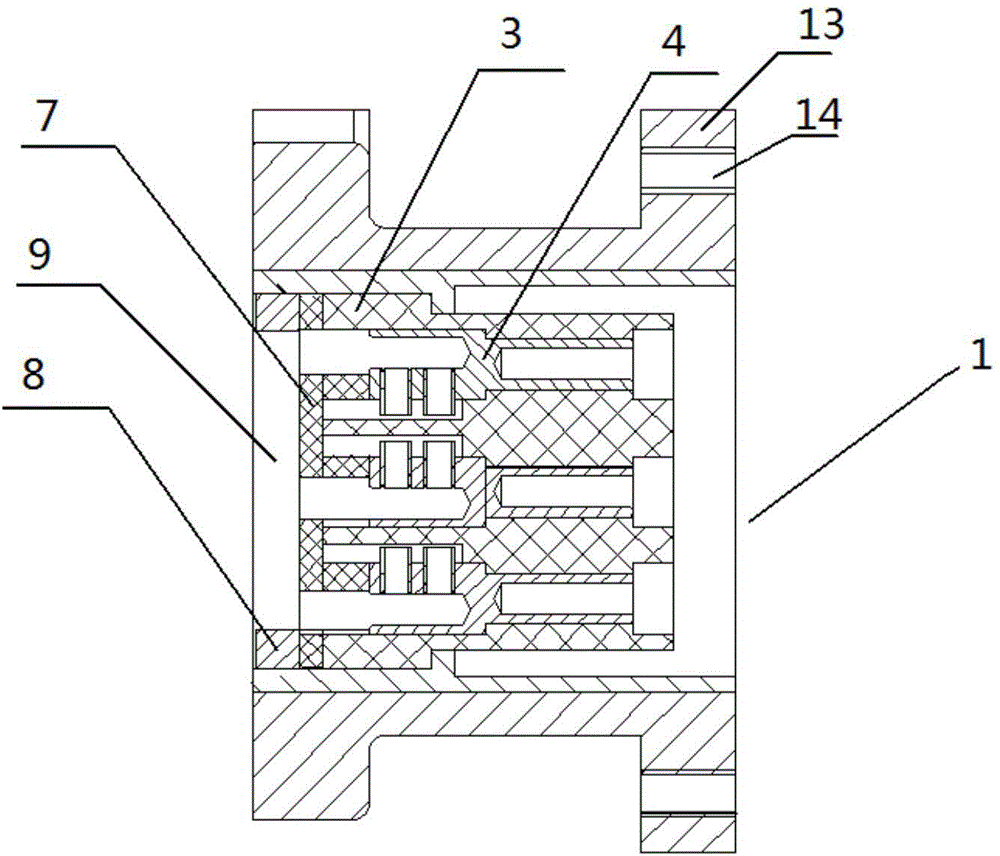

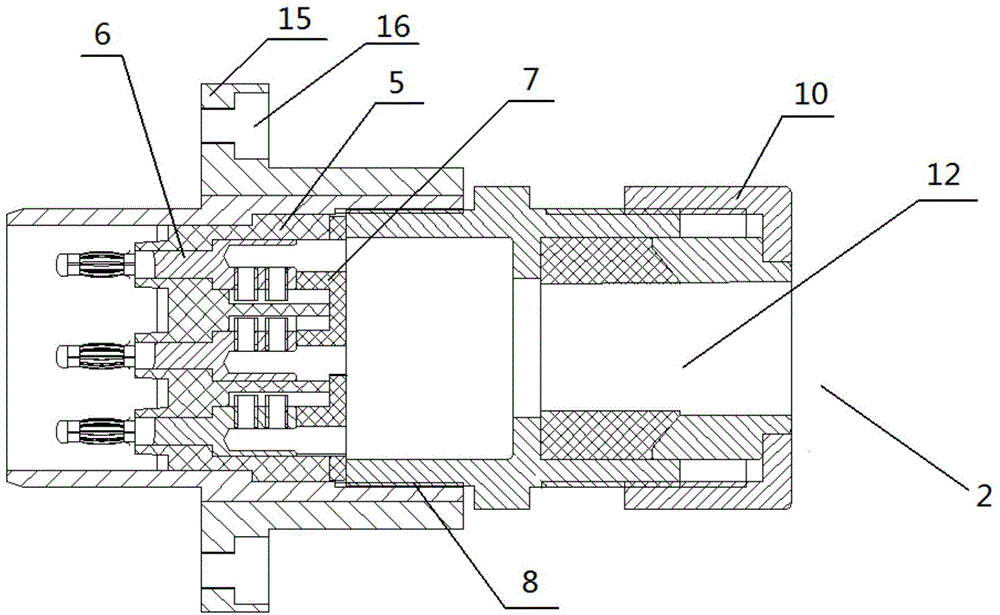

Multi-core mining explosive-proof cable connector

InactiveCN104466447AImprove contact reliabilitySmall insertion forceElectrically conductive connectionsCoupling device detailsEngineeringSwitchgear

The invention relates to a connecting device used for connecting a mining control cable and a piece of underground switchgear, and specifically relates to a multi-core mining explosive-proof cable connector. The multi-core mining explosive-proof cable connector comprises a plug component and a socket component. The socket component comprises an explosive-proof socket shell assembly, a multi-jack socket insulating member is arranged in the explosive-proof socket shell assembly, and an insertion bush assembly is arranged in each jack of the socket insulating member. The plug component comprises an explosive-proof plug shell assembly, a multi-jack plug insulating member is arranged in the explosive-proof plug shell assembly, an insertion rod assembly is arranged in each jack of the plug insulating member. The insertion rod assemblies are matched with the insertion bush assemblies, and the insertion rod assemblies can be exactly inserted into the insertion bush assemblies. When in use, the plug component equipped with a cable is inserted into the socket component, and when the plug component is fully in position, a hexagon bolt sequentially passes through a bolt hole of the plug component and a screw hole of the socket component to fasten and connect the plug component and the socket component together. The multi-core mining explosive-proof cable connector has the advantages of simple structure, convenient installation, and safe and reliable operation.

Owner:上海翔洲电气科技有限公司

Charging gun head and charging system

The invention discloses a charging gun head and a charging system. The charging gun head comprises a gun head body and a plurality of power supply terminals positioned inside the gun head body, wherein a plurality of locking mechanisms for being matched with external sockets are arranged at the end of the gun head body; the power supply terminals are arranged movably along the plugging direction inside the gun head body; a gun head drive module for controlling the power supply terminals to move along the plugging direction is arranged at the rear ends of the power supply terminals; and when the locking mechanism are in a locking state, the gun head drive module is used for driving the power supply terminals to move along the plugging direction. The charging gun head and the charging sockets are simple in structures, the plugging force can be reduced through the design of the charging gun head, the labor intensity is reduced, or the power of a charging mechanical arm is reduced greatly,and the cost of the charging system is reduced.

Owner:SHANGHAI ZHIDA TECHNOLOGY DEVELOPMENT CO LTD

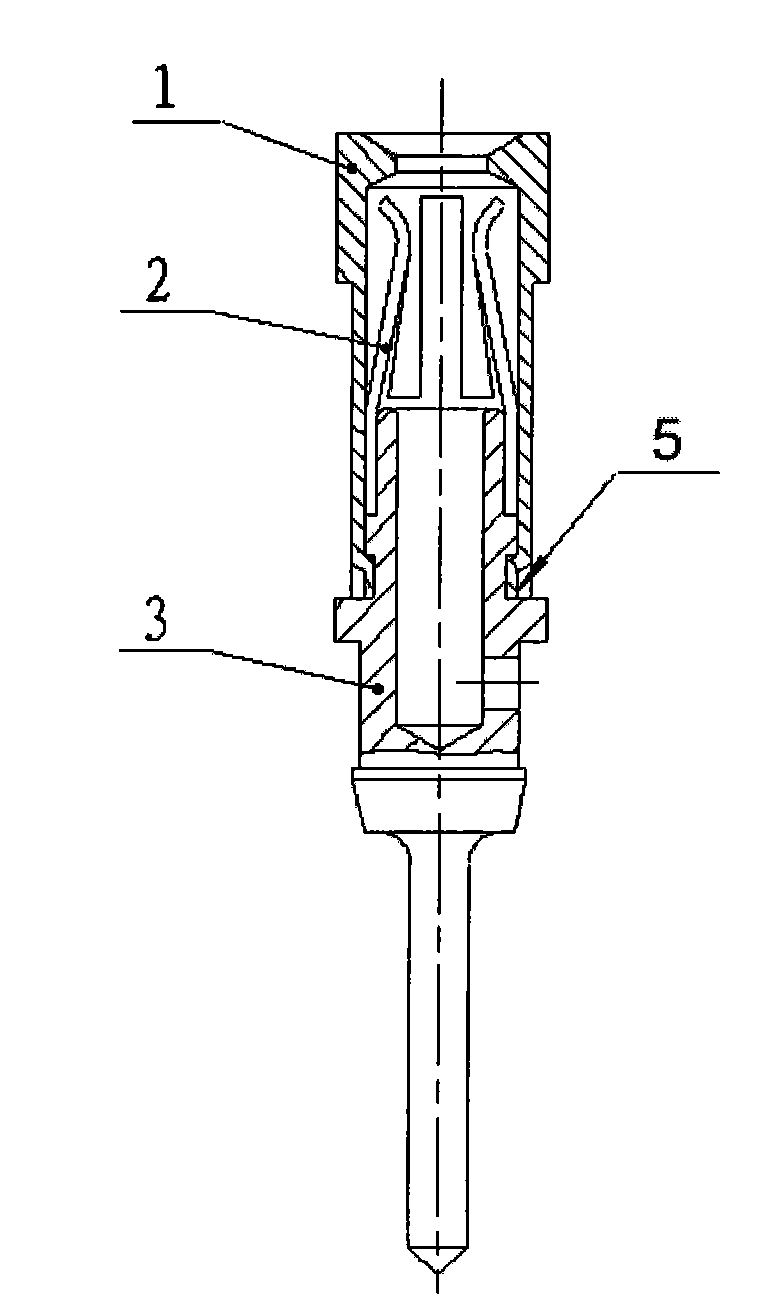

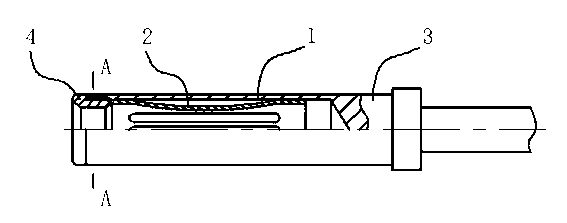

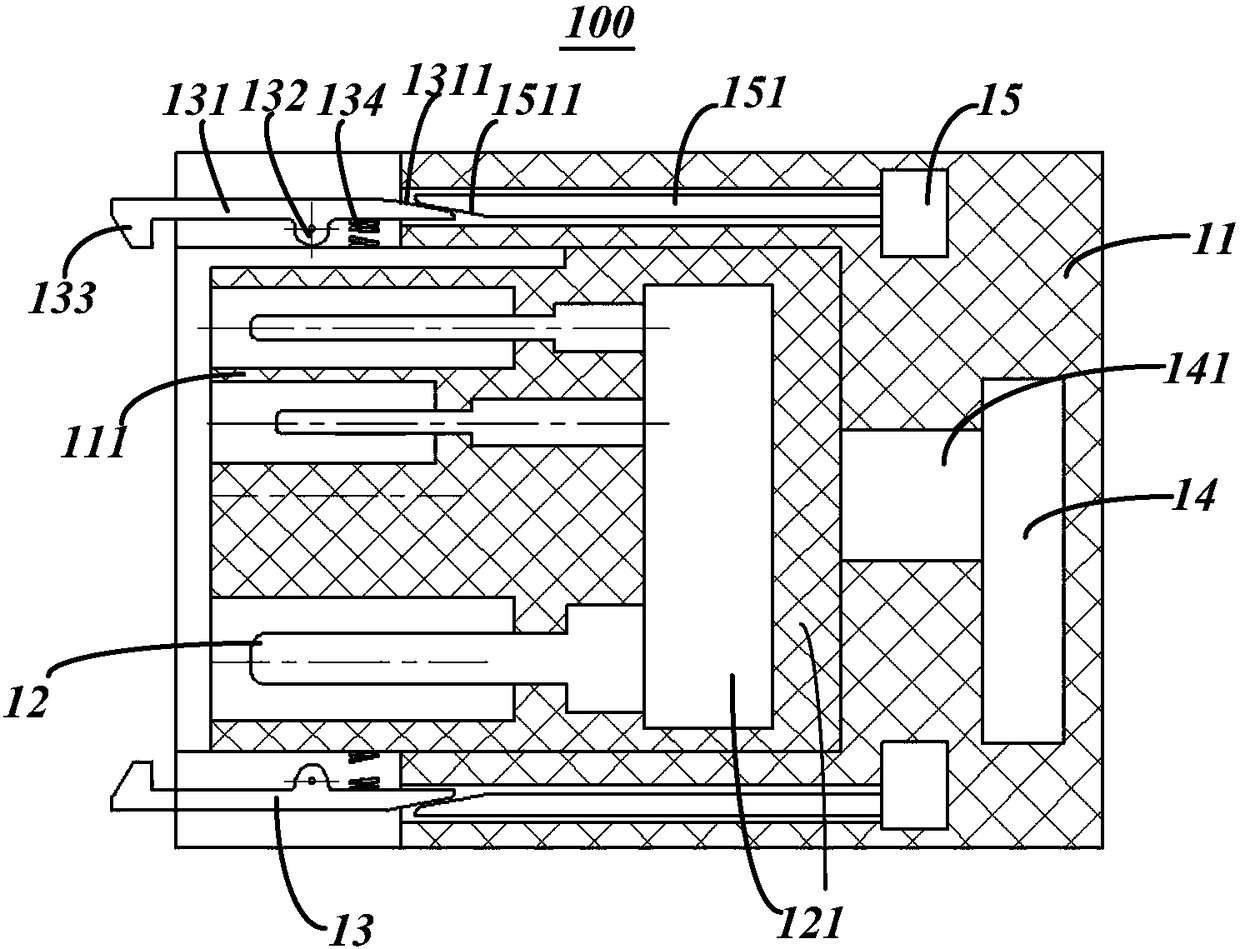

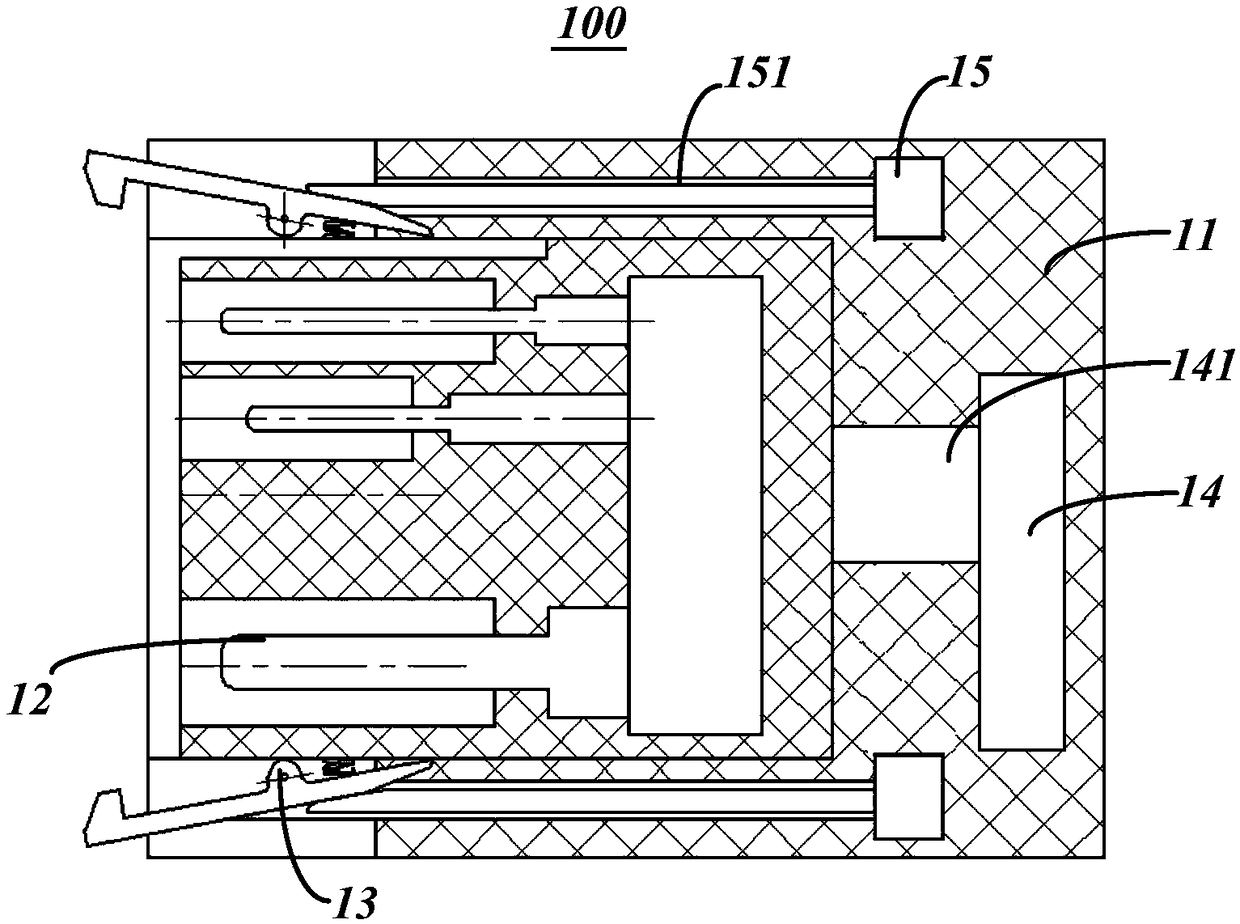

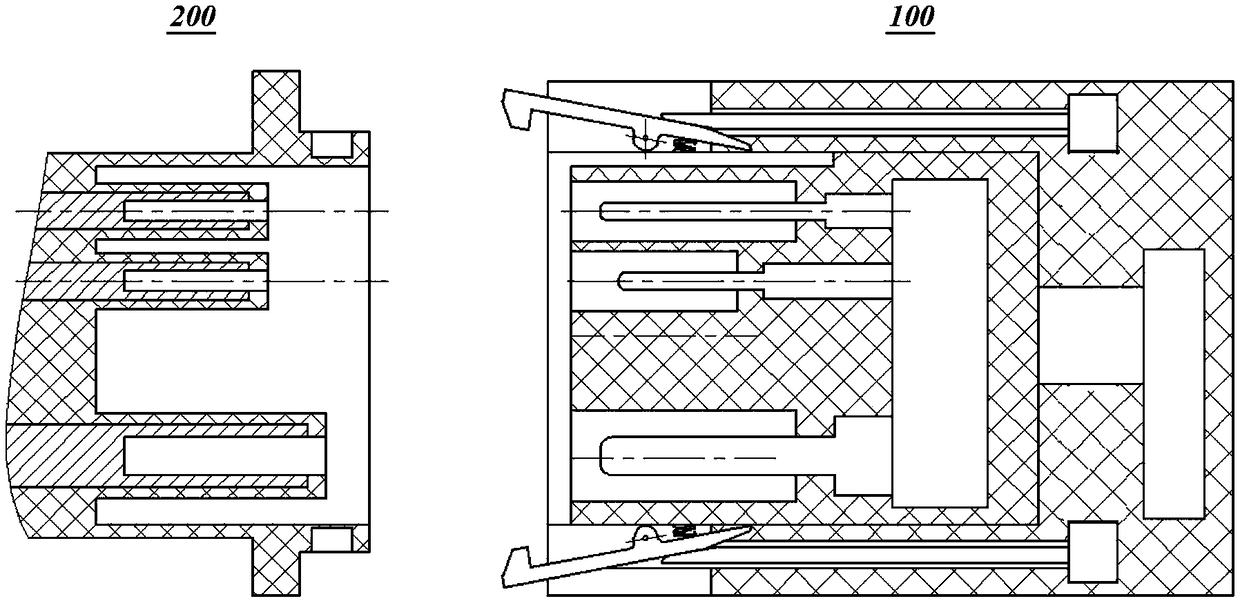

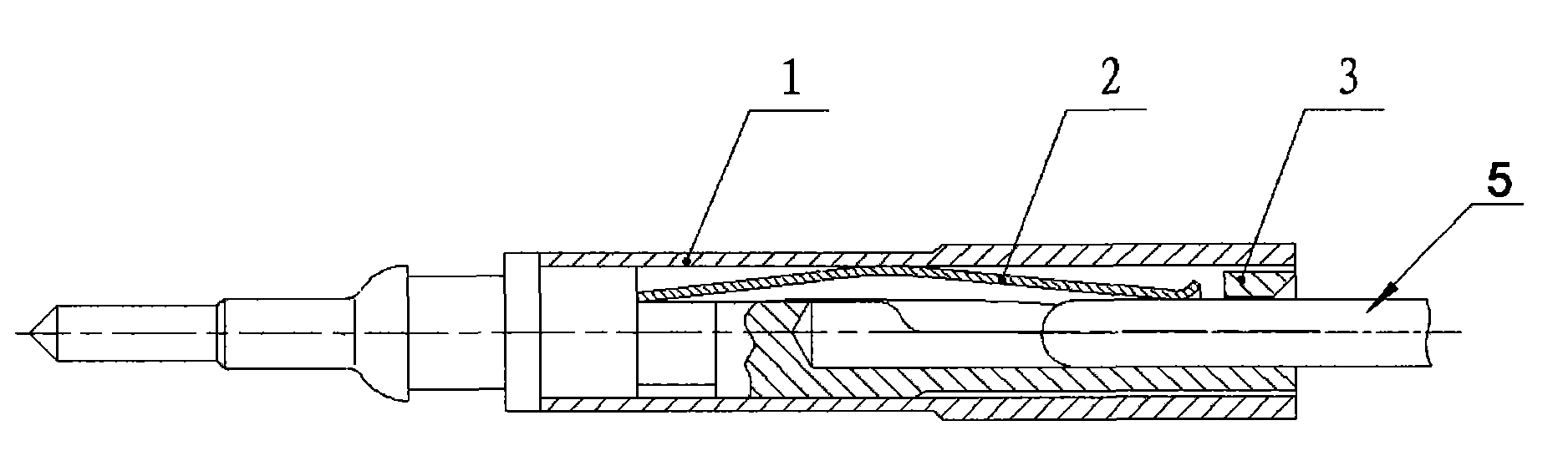

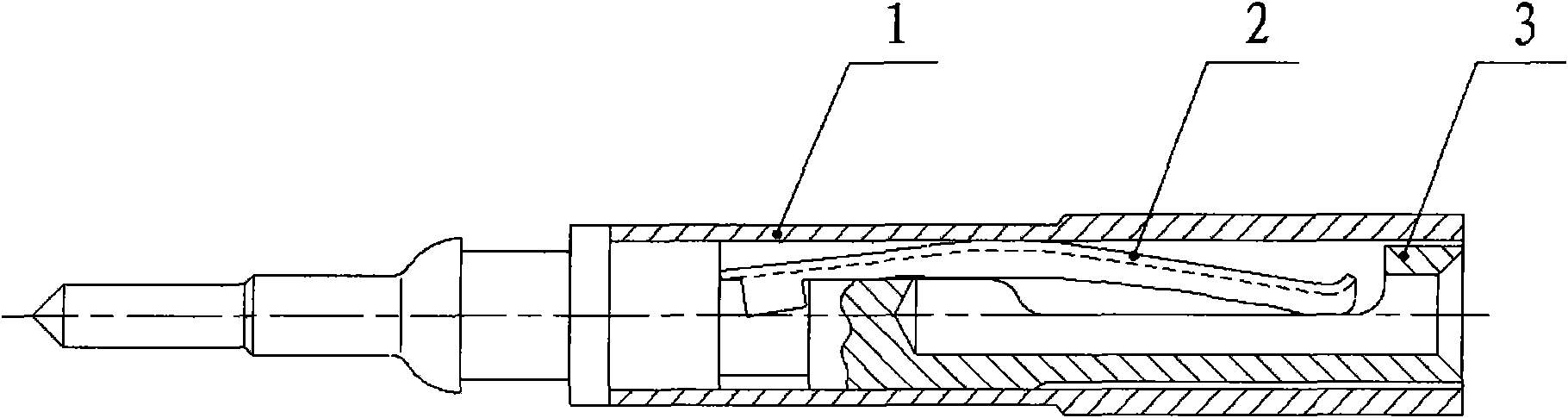

Connector jack with low insertion and extraction force

InactiveCN102097695ASimple structureSmall insertion forceCoupling contact membersEngineeringMechanical models

The invention discloses a connector jack with low insertion and extraction force, which comprises a jacket (1), a spring plate (2) and a jack (3), wherein the spring plate (2) is bent to be an arch; the highest point of the arch is contacted with the jacket (1) to form a sliding pivot; an end of the spring plate (2) is provided with a convex tooth; the inside of the jack (3) is provided with a convex tooth slot; the convex tooth is clamped in the convex tooth slot to fix the spring plate (2) axially, and a fixed pivot is formed; the other end of the spring plate (2) is a cantilever; the jack (3) is provided with a sectioning part; the other end of the spring plate (2) stretches into the jack (3) from the sectioning part. The sectioning part edge of the jack (3) provides a certain supporting surface for the spring plate (2). In the invention, a spring plate (2) of overhanging beam mechanical model is employed to form elastic connection with a contact pin, and the contact pin is pushed by the elastic force of the spring plate (2) to be attached to the inner wall of the jack (3), so that a direct electrical contact is formed between the contact pin and the jack (3). The invention is characterized by simple structure and low insertion and extraction force.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

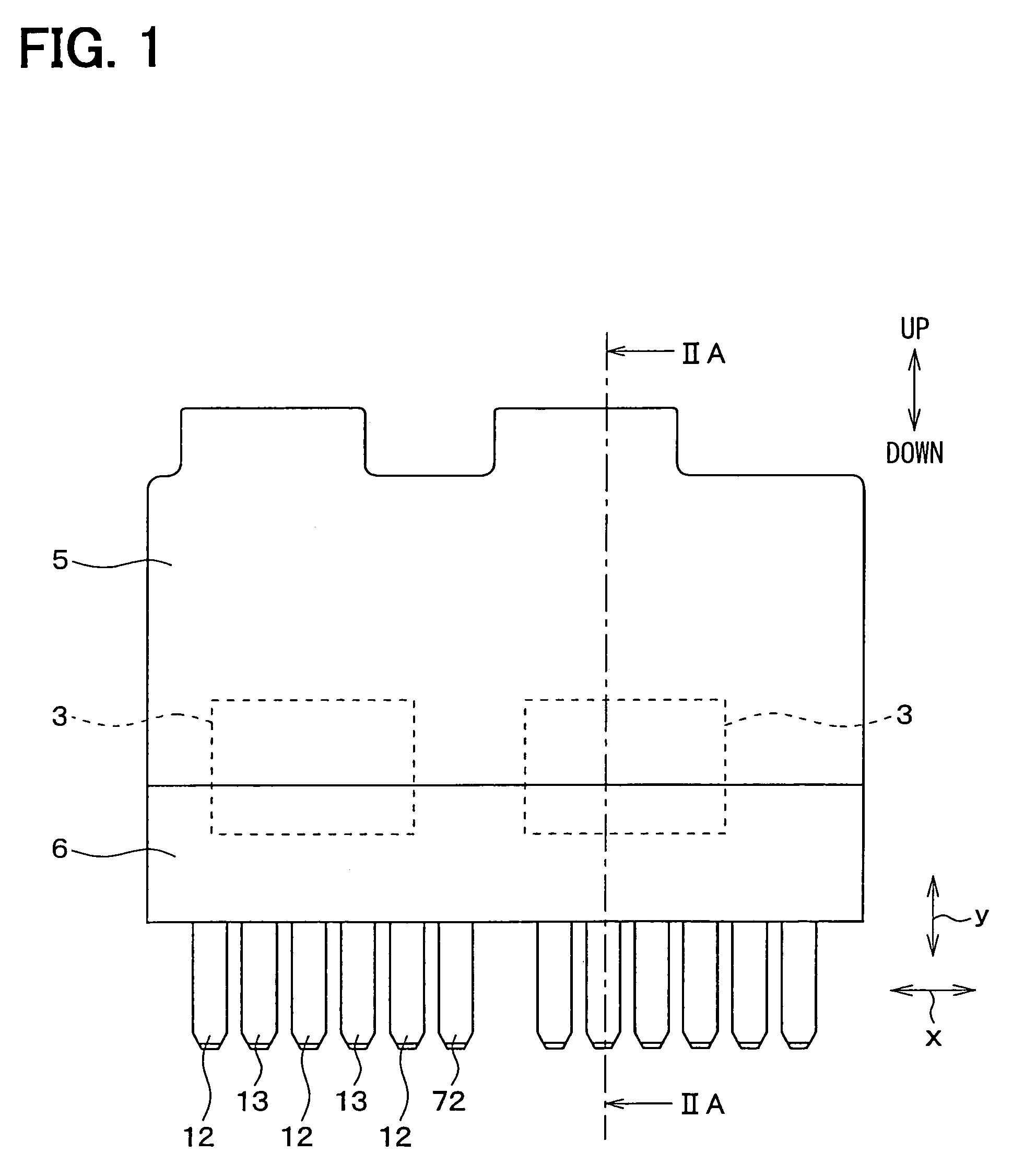

Electric apparatus having plural electric parts

InactiveUS7338296B2Improve stabilityHigh strengthElectric switchesElectromagnetic relay detailsElectrical devicesJunction box

In an electric apparatus having a bus bar, a plurality of electric parts and a number of terminals connected to external terminals are mounted on the bus bar. The terminals are arranged in two or more lines, plural terminals are arranged in each line. Therefore, a stability and strength in mounting the apparatus to a junction block is improved compared to an apparatus where the terminals are arranged in a single line. The electric apparatus according to the present invention can be mounted to a junction block by being supported with only the terminals of the apparatus.

Owner:ANDEN CORP

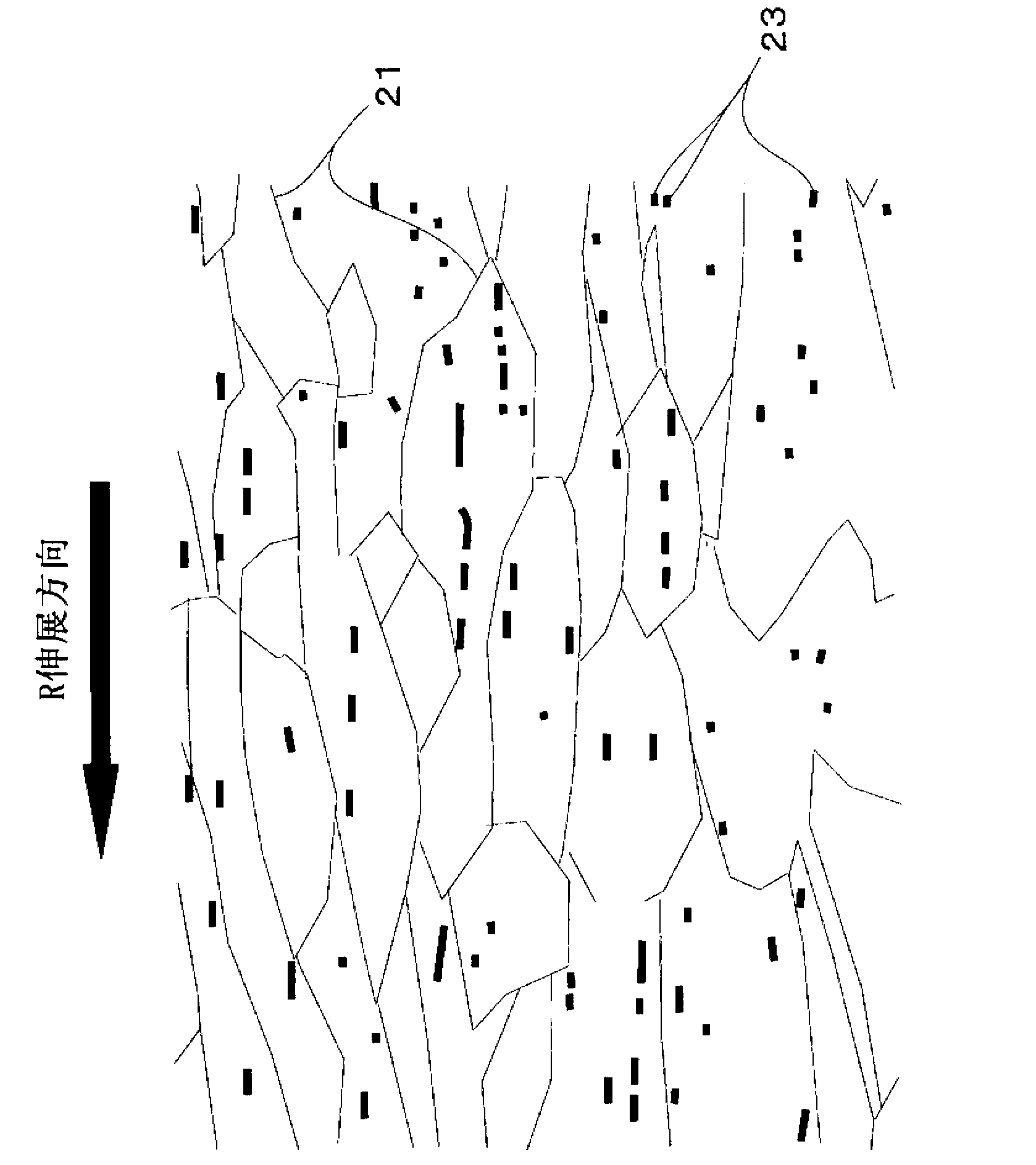

Wrought copper alloy, copper alloy part, and process for producing wrought copper alloy

Provided is a wrought copper alloy which has excellent cuttability and extensibility and is optimal for applications where high strength and / or high electrical conductivity is necessary while alleviating environmental burdens. The wrought copper alloy contains 1.5-7.0 mass% Ni, 0.3-2.3 mass% Si, and 0.02-1.0 mass% S and optionally further contains at least one element selected from a group consisting of Sn, Mn, Co, Zr, Ti, Fe, Cr, Al, P, and Zn in a total amount of 0.05-2.0 mass%, with the remainder comprising Cu and incidental impurities. The wrought copper alloy contains a sulfide dispersed therein which contributes to an improvement in cuttability, the sulfide having an average diameter of 0.1-10 [mu]m and an areal proportion of 0.1-10%. The wrought copper alloy has a tensile strength of 500 MPa or more and an electrical conductivity of 25% IACS or more.

Owner:FURUKAWA ELECTRIC CO LTD

Lantern-shaped contact head

InactiveCN104466482AContact stabilityImprove reliabilityCoupling contact membersElectrical connectionEngineering

The invention relates to the field of mining cable connectors, and particularly relates to a lantern-shaped contact head. The lantern-shaped contact head is roughly shaped as a 'lantern', and comprises a conductive rod and a lantern-shaped grid type pipe sleeve therein. The lantern-shaped grid type pipe sleeve is composed of an upper frame edge, a lower frame edge, and a plurality of grid type elastic contact sheets, which are curled. The conductive rod is composed of a plugging end and a wire connecting end. The lantern-shaped grid type pipe sleeve sleeves a contact head at the plugging end. The outer wall of the wire connecting end is provided with one or more screw holes. During use, the wire connecting end of the conductive rod is connected with a cable, the lantern-shaped contact head is inserted into an insert sleeve of a socket, and thus electrical connection between the plug and the socket is realized. By adoption of the structure, the lantern-shaped contact head has high contact reliability and long service life, and can be plugged and pulled with a small force.

Owner:上海翔洲电气科技有限公司

Clamping and ligation device

ActiveUS9492176B2Simple structureSmall insertion forceSurgical staplesSurgical forcepsPush and pullPenetration force

Owner:HANGZHOU AGS MEDTECH CO LTD

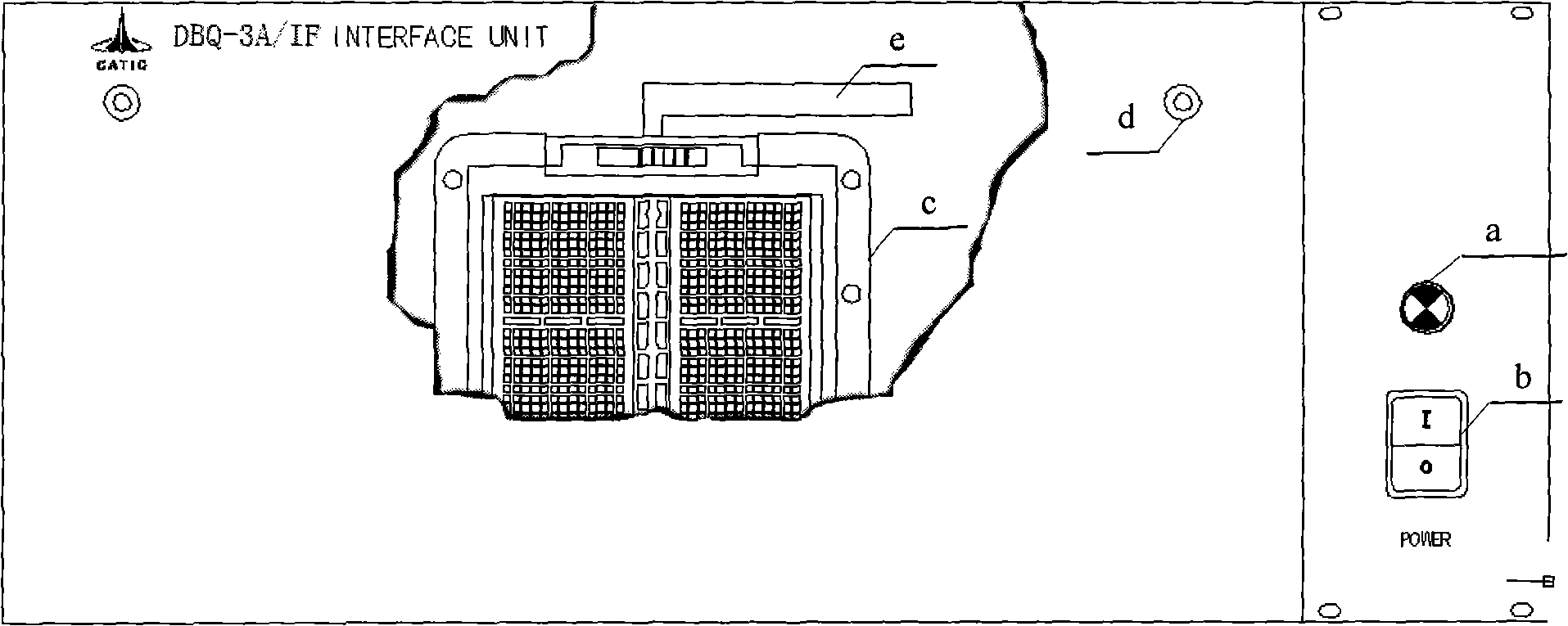

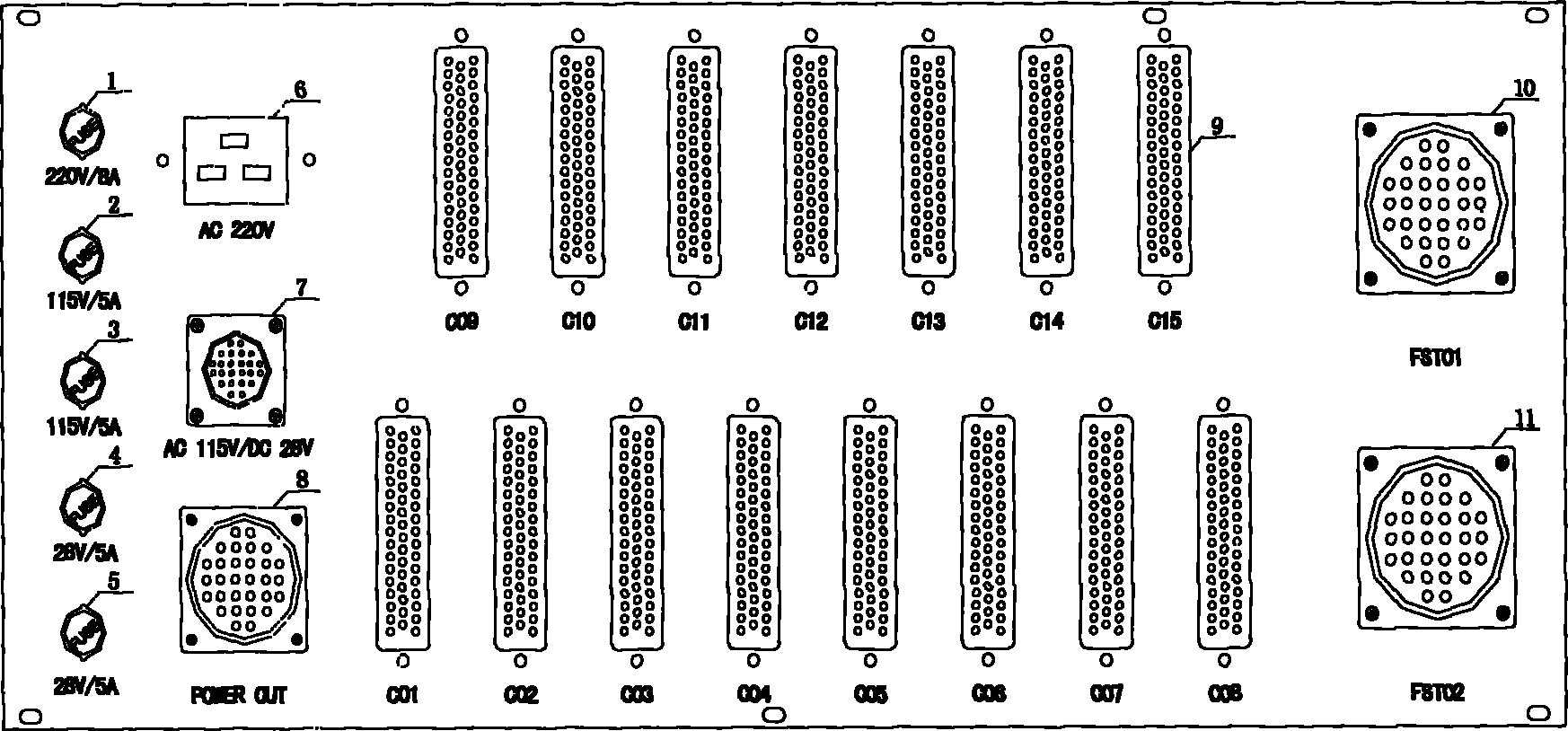

Low-frequency standard signal switching device

The invention relates to a low-frequency standard signal switching device. The device comprises a junction box, a zero insertion force (ZIF) socket, a first socket, a second socket and a fuse socket, wherein the ZIF socket is connected with an adaptor; the ZIF socket is provided with an indented handle; and the first socket, the second socket and the fuse socket are positioned on the back panel of the junction box. Compared with the prior art, the low-frequency standard signal switching device has the advantages of low insertion plug, safety, reliability and the like.

Owner:上海凯迪克航空工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com