Wrought copper alloy, copper alloy part, and process for producing wrought copper alloy

A manufacturing method and technology of copper alloys, applied in the field of metal parts, can solve problems such as easy fracture and use restrictions, and achieve the effects of excellent machinability, suppression of reduction in insertion and extraction force, and excellent strength and conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0057]

[0058] Nickel (Ni) and silicon (Si) in a preferred embodiment of the copper alloy wrought material of this embodiment are added for the purpose of controlling the content ratio of Ni and Si to form a metal base (base, base) Ni-Si precipitates (Ni 2 Si), thereby carrying out precipitation strengthening, so that the strength and electrical conductivity of the copper alloy stretched material are improved. The Ni-Si precipitates (Ni 2 Si: precipitates for precipitation strengthening) does not play a large role in the improvement of machinability.

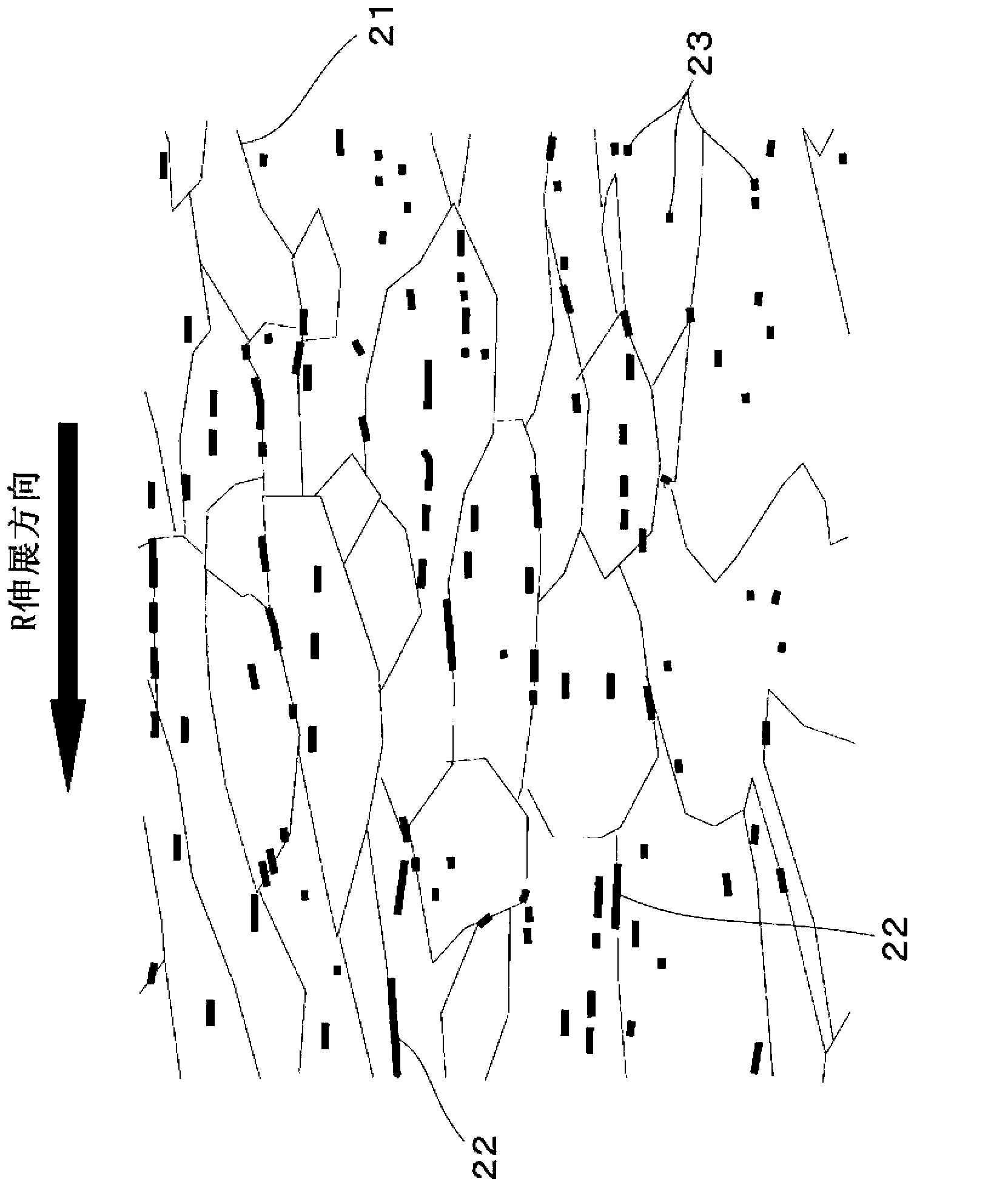

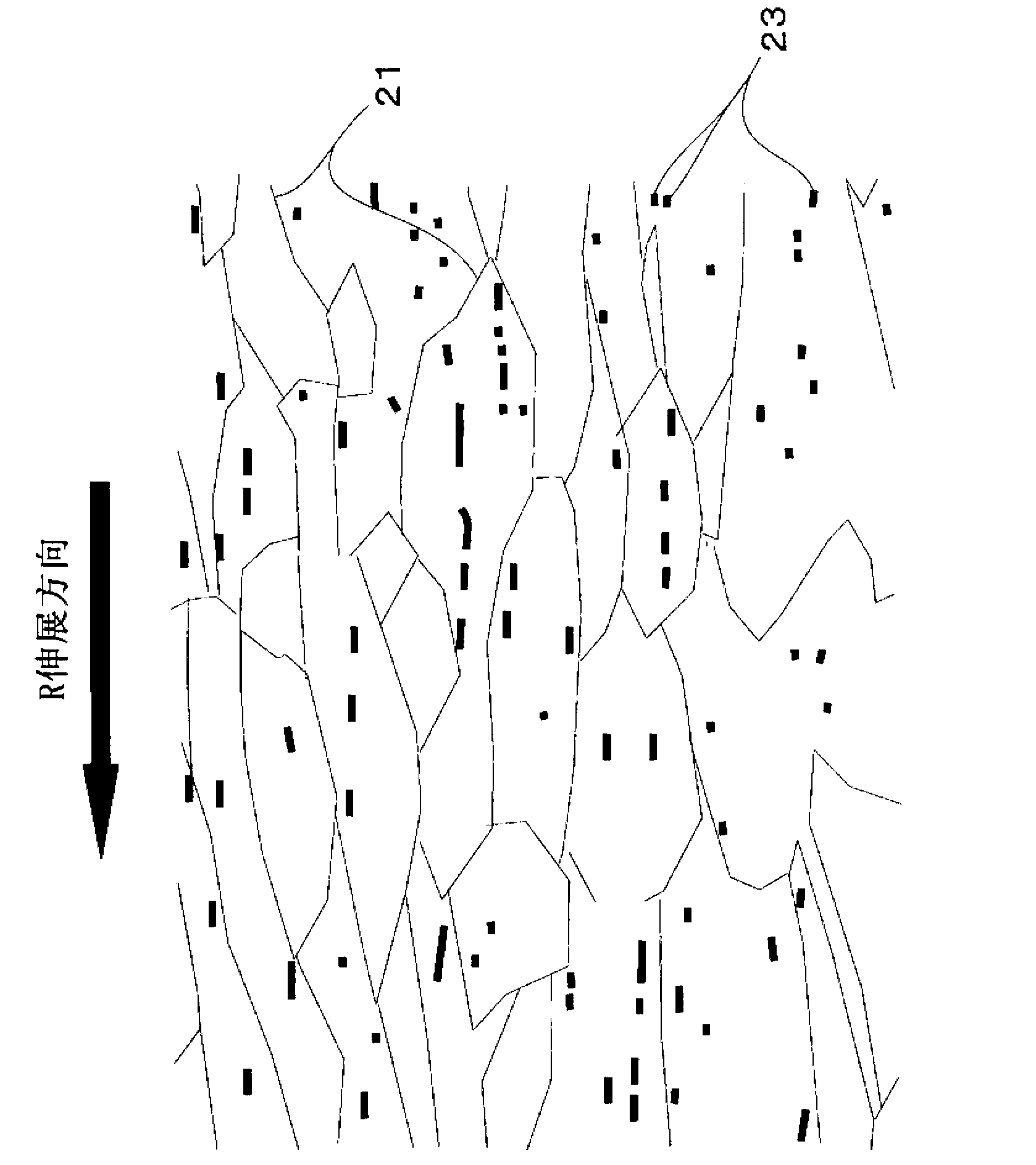

[0059] In a preferred embodiment of the copper alloy wrought material of this embodiment, the addition of sulfur (S) forms sulfides in the matrix that contribute to the improvement of machinability. This sulfide acts as a starting point for chip breakage during cutting, so that the chip chips are easily broken into fine pieces and the machinability is improved. In addition, by controlling the cooling rate during casting to...

no. 2 Embodiment approach

[0078]

[0079] In the copper alloy wrought material of the present embodiment, the content ratio of Ni and Si is also controlled. Its purpose is the same as that of the first embodiment.

[0080] In a preferred embodiment of the copper alloy wrought material of this embodiment, the addition of sulfur (S) forms sulfides in the matrix that contribute to the improvement of machinability. This sulfide acts as a starting point for chip breakage during cutting, so that chips are easily broken finely and machinability is improved; this is the same as the above-mentioned first embodiment. Sulfides are formed during casting, but most of them exist in grain boundaries when formed, and deteriorate hot workability and cold workability (that is, elongation). Therefore, for the sulfide formed in the ingot (cake billet or steel slab), by stretching and heat treatment, the sulfide with an area ratio of 40% or more in the cross section parallel to the stretching direction exists in t...

Embodiment 1-1

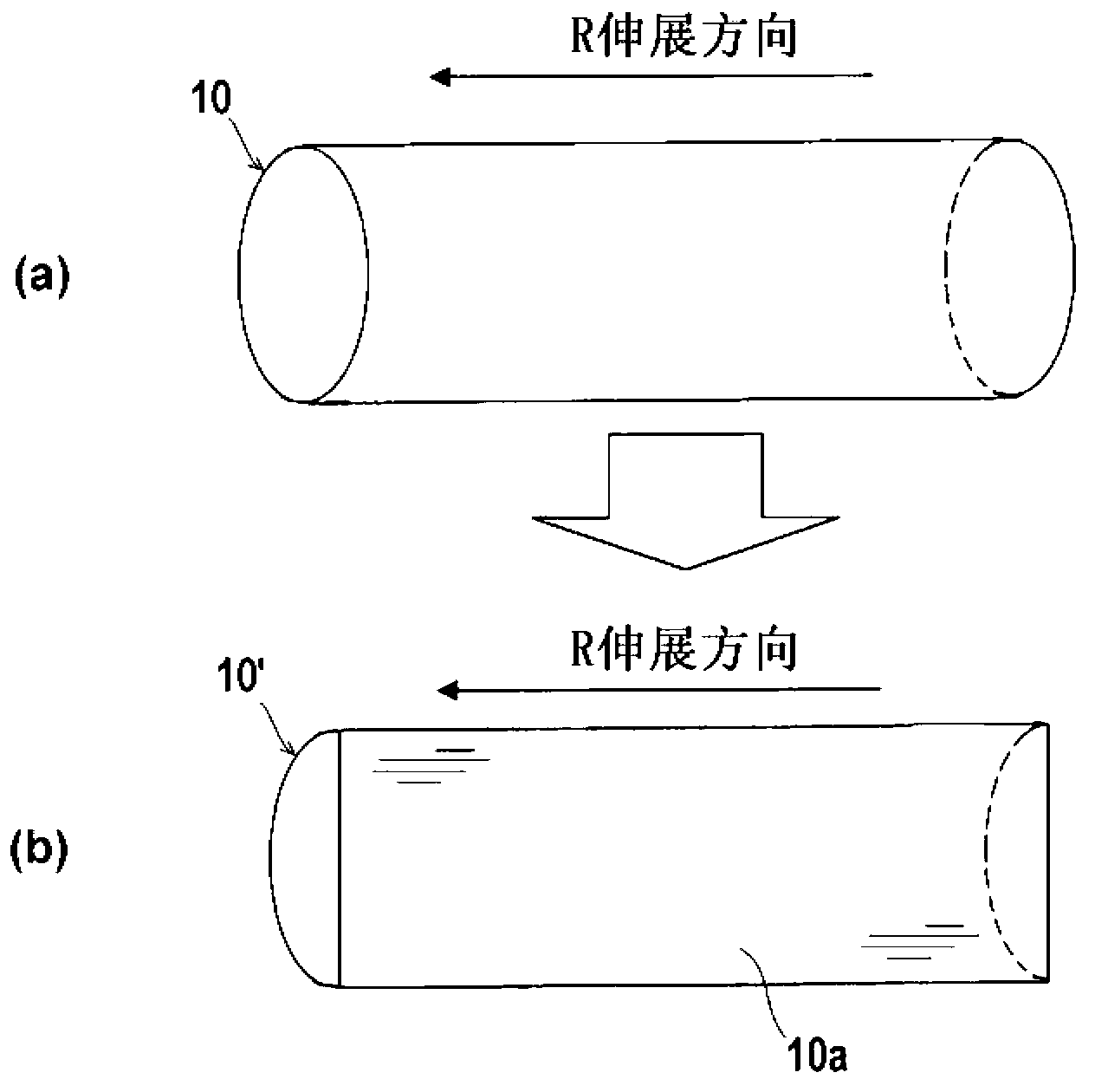

[0112] Copper alloys having the compositions shown in Table 1-1 were melted in a high-frequency melting furnace, and each slab was cast at a cooling rate of 0.5° C. / sec to 5° C. / sec. The diameter of the billet was set to 200 mm. The above billet was hot extruded at a temperature of 950° C., and immediately quenched in water to obtain a round bar with a diameter of 20 mm. Next, the above-mentioned round bar was cold drawn to produce a round bar with a diameter of 10 mm, and aging heat treatment was performed at a temperature of 450° C. for 2 hours.

[0113] For each copper alloy stretched material (round bar) sample thus obtained, [1] tensile strength, [2] electrical conductivity, and [3] machinability were investigated in the following manner. The measurement method of each evaluation item is as follows.

[0114] [1] Tensile strength

[0115] According to JIS Z 2241, three copper alloy stretched materials were measured, and the average value (MPa) was given.

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com