Conductive member and manufacturing method thereof

A technology for conductive parts and manufacturing methods, which can be applied to contact parts, electrical components, circuits, etc., and can solve problems such as hindering plating and electroplating, poor appearance, and reduced current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

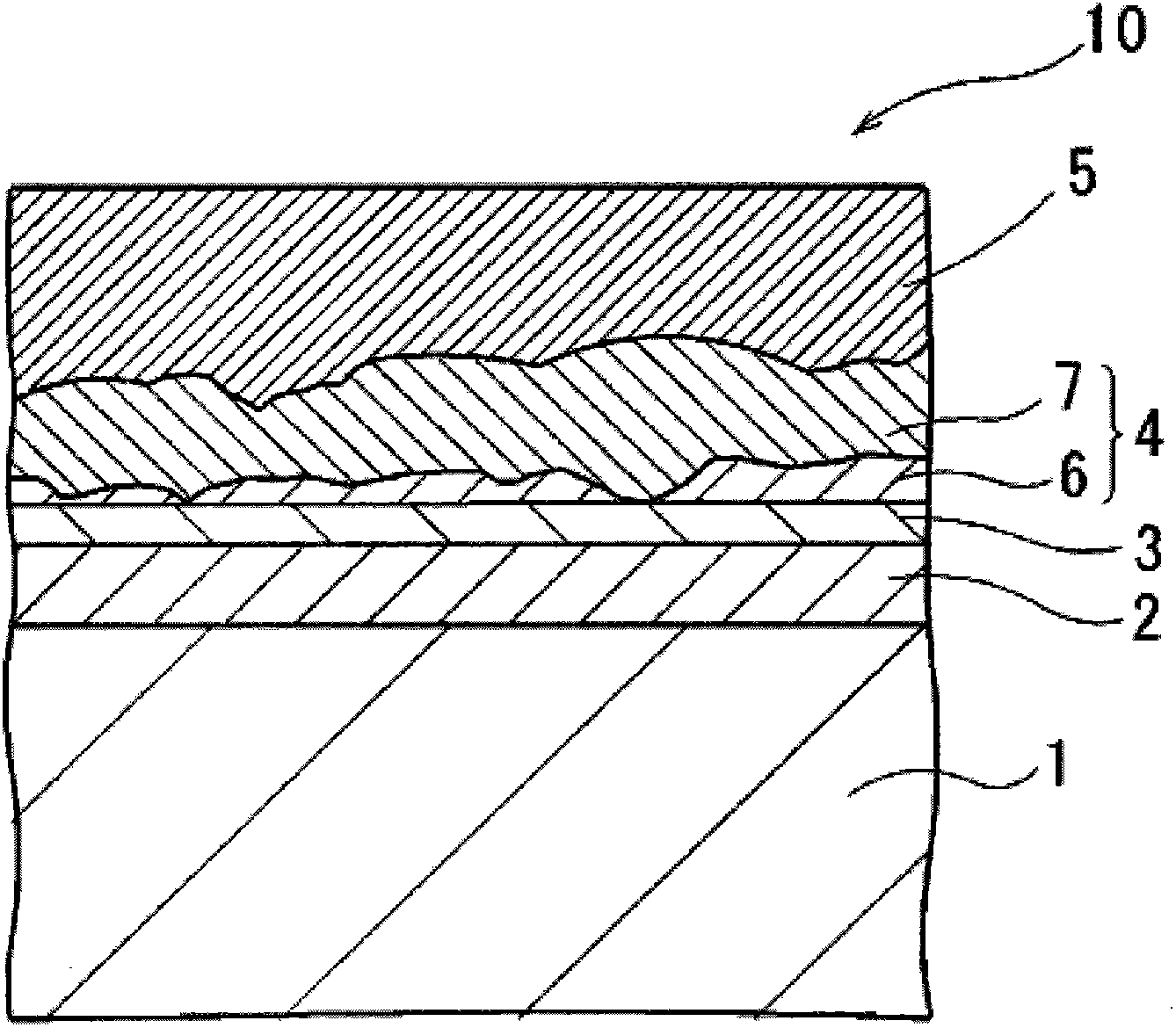

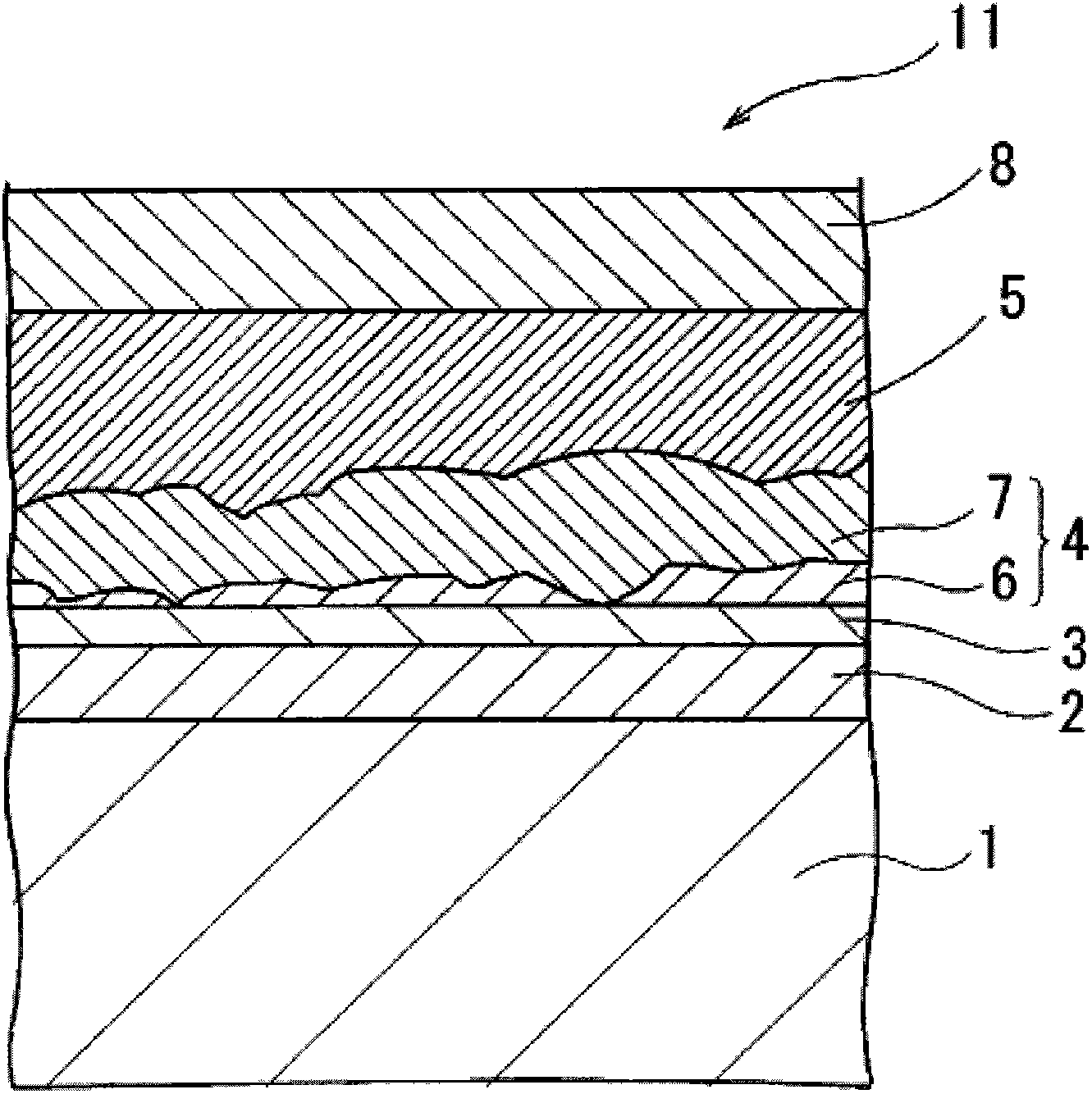

[0078] The conductive member 10 of the first embodiment is as figure 1 As shown, on the surface of the Cu-based substrate 1, a Ni-based underlayer 3, a Cu-Sn intermetallic compound layer 4, and a Sn-based surface layer 5 are sequentially formed through the Fe-based underlayer 2. At the same time, the Cu-Sn intermetallic compound layer 4 And then by Cu 3 Sn layer 6 with Cu 6 sn 5 layer 7.

[0079] The Cu-based substrate 1 is, for example, a plate-shaped substrate made of Cu or a Cu alloy. The material of the Cu alloy is not particularly limited, but Cu-Zn-based alloys, Cu-Ni-Si-based (Corson) alloys, Cu-Cr-Zr-based alloys, and Cu-Mg-P-based alloys are preferred. , Cu-Fe-P-based alloys, and Cu-Sn-P-based alloys, for example, MSP1, MZC1, MAX251C, MAX375, and MAX126 manufactured by Mitsubishi Shindoh Co., Ltd. can be preferably used.

[0080] The Fe-based underlayer 2 is formed by electroplating Fe or Fe alloy, and is formed on the surface of the Cu-based base material 1 wit...

no. 2 approach

[0125] Next, a second embodiment will be described.

[0126] Figure 4 An example of a manufacturing apparatus for carrying out the manufacturing method of the second embodiment is schematically shown. This conductive member manufacturing apparatus 31 is continuously provided with a degreasing and cleaning tank 32, a Ni plating tank 33, a Cu plating tank 34, a Sn plating tank 35, and cleaning tanks 36 to 38 arranged after the respective plating tanks 33 to 35, so that The copper strip 51 is plated while being continuously conveyed in the order of the degreasing cleaning tank 32 , the Ni plating tank 33 , the Cu plating tank 34 , and the Sn plating tank 35 . The degreasing and cleaning tank 32 is further composed of a degreasing tank 32a, a cleaning tank 32b, a pickling tank 32c, and a cleaning tank 32d.

[0127] Moreover, each plating tank 33-35 is as Figure 5 As shown, a pair of electrode plates 39 are disposed so as to face both sides of a continuously advancing copper s...

Embodiment

[0160] Next, examples of the present invention will be described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com