Lantern-shaped contact head

A technology of lantern flower and contact head, applied in the direction of contact parts, etc., can solve the problem of unreliable connection between socket and plug, and achieve the effect of light insertion and withdrawal force, stable contact and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The wire crimping device for conducting rods and cables of the present invention will be further described in detail with specific embodiments below in conjunction with specific drawings.

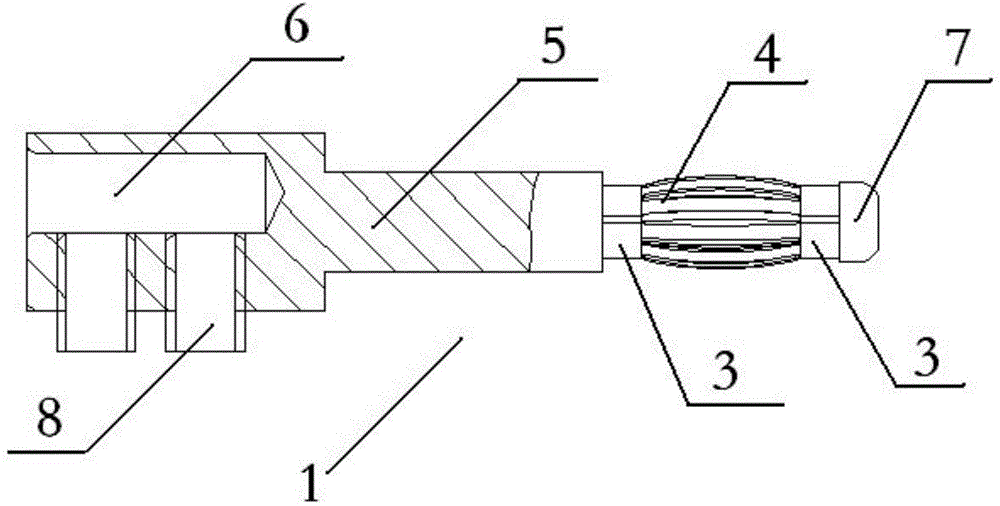

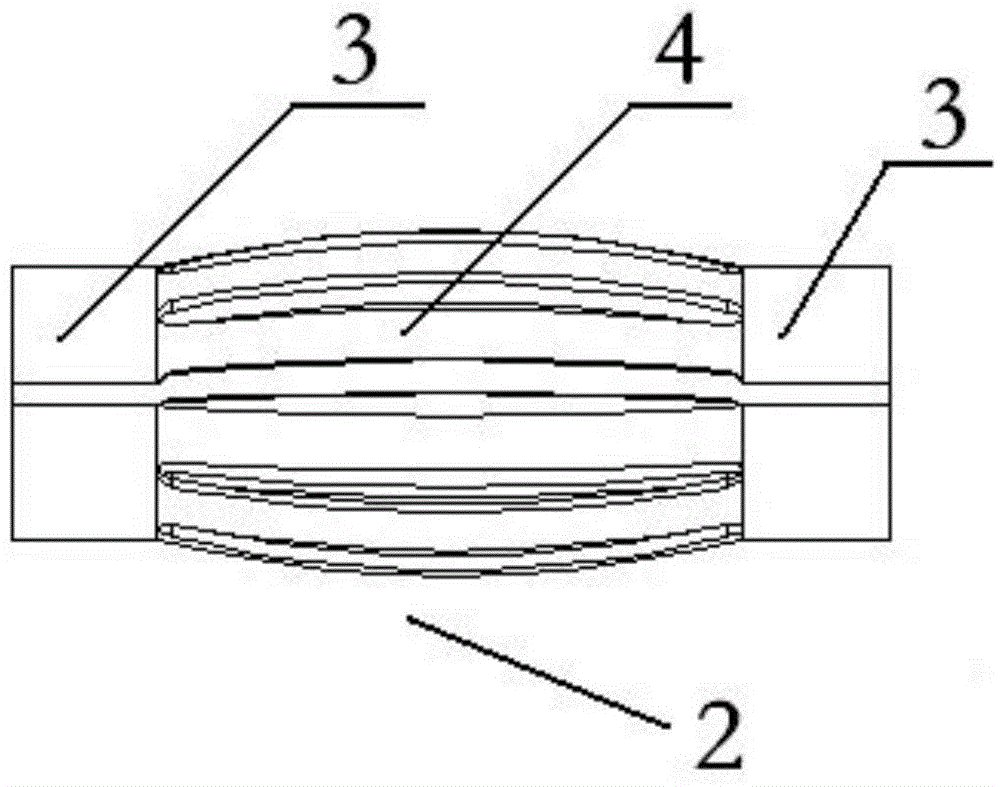

[0011] Such as figure 1 As shown, it is a lantern fancy contact head of the present invention, which is roughly in the shape of a "lantern", including a conductive rod 1 and a lantern fancy grid-type sleeve 2 therebetween (such as figure 2 shown), wherein, the lantern fancy grid-type sleeve 2 is formed by curling the upper and lower frame sides 3 and the grid-shaped elastic contact piece 4, and the conductive rod 1 is composed of a plug-in terminal 5 and a terminal 6, The lantern style grid-shaped sleeve 2 is sleeved on the contact head 7 of the plug-in terminal 5 , and one or more screw holes 8 are opened on the outer wall of the terminal 6 .

[0012] The grid-shaped elastic contact piece 4 is curved outward.

[0013] The upper and lower frame sides 3 are tightly sleeved on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com