Ferrule, fiber connector and manufacturing method of ferrule

An optical fiber connector and ferrule technology, which is applied in the field of optical communication and can solve the problems of fiber wear, low reliability of insertion and removal, and pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

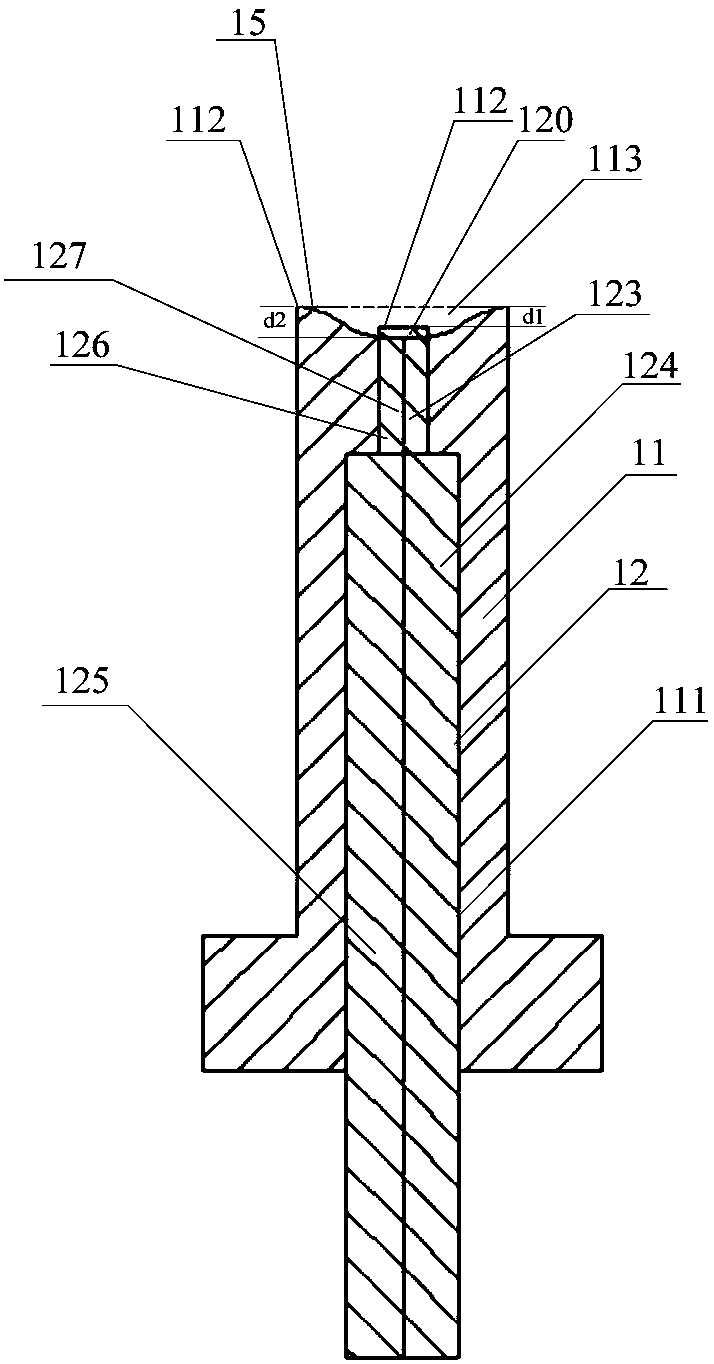

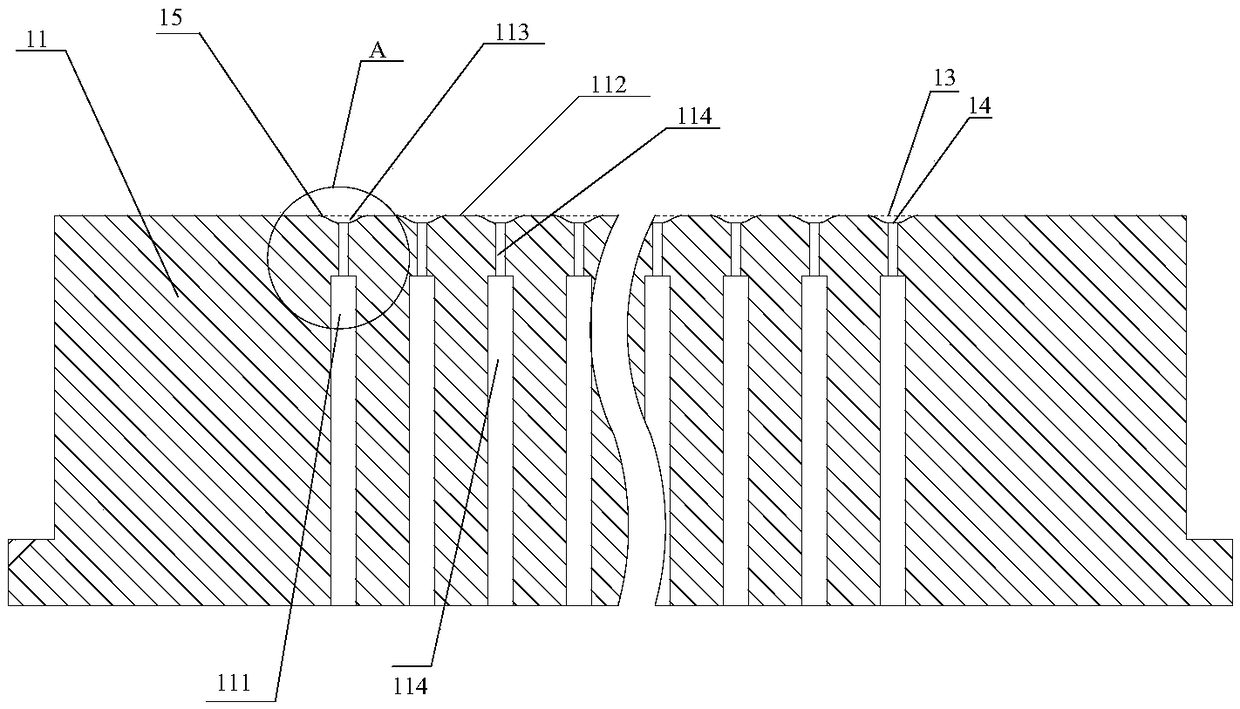

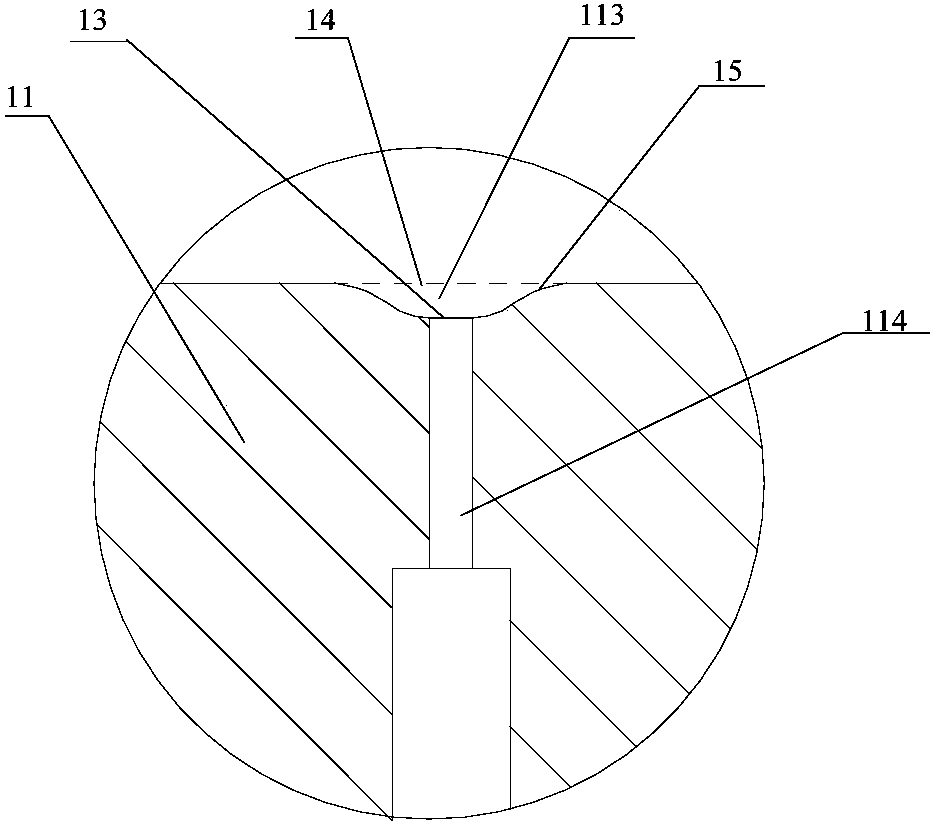

[0158] figure 1 Schematic partial cross-section of the ferrule provided for the embodiment of this application Figure 1 , figure 2 Schematic cross-section of the ferrule body provided for the embodiment of this application Figure 1 , image 3 for figure 2 Partial enlarged view of part A in, Figure 4 Schematic partial cross-section of the ferrule provided for the embodiment of this application Figure II , Figure 5 Schematic cross-section of the ferrule body provided for the embodiment of this application Figure II , Image 6 is a partial enlarged view of part B in Fig. 5.

[0159] see Figure 1 to Figure 6 , in the embodiment of the present application, at least one through hole 111 is arranged axially inside the ferrule body 11, for each optical fiber, the optical fiber 12 is passed through the corresponding through hole 111, and the first end 120 of the optical fiber 12 is located in the through hole 111. Inside the hole 111, the vertical distance between th...

Embodiment 2

[0178] Based on the previous embodiment, this embodiment introduces the setting of the first preset distance in the first embodiment in detail.

[0179] The first preset distance in this embodiment is a distance that can have a gap between the optical fiber of the ferrule 100 and the optical fiber of the other ferrule after the ferrule 100 is docked with another ferrule, that is, includes the distance in this embodiment After the optical fiber connector of the ferrule 100 is connected to the optical fiber connector comprising another ferrule, there is an gap.

[0180] Wherein, the first preset distance can be based on the distance between the fiber protruding from the connecting end face of the ferrule body of the conventional MT ferrule type optical connector (it can also be said that the distance of the fiber protruding from the connecting end face of the ferrule body of the conventional MT ferrule, as follows This distance is called "conventional MT ferrule protrusion dist...

Embodiment 3

[0189] Based on the above-mentioned embodiments, this embodiment introduces in detail the arrangement of the first section of the through hole 113 of the ferrule 100 in the above-mentioned embodiments.

[0190] In this embodiment, the area of any cross section of the first through hole 113 in the axial direction perpendicular to the ferrule body is larger than the area of the end face 121 of the first end 120 of the optical fiber 12, and the optical fiber 12 is in the axial direction The projection of does not overlap with the projection of any cross section of the first section of the through hole 113 in the direction perpendicular to the axial direction of the ferrule body 11 .

[0191] Specifically, the shape of the first section of the through hole 113 can be regular or irregular, as long as the area of any cross section of the first section of the through hole 113 in the direction perpendicular to the axial direction of the ferrule body is greater than that of the op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com