Envelope type wood pulp non-woven fabric and production process thereof

A production process and non-woven technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve the problems of short production rate of process flow, need for further improvement, easy pilling of non-woven fabrics, etc., and achieve good hand and drape feeling. , high elasticity, soft surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

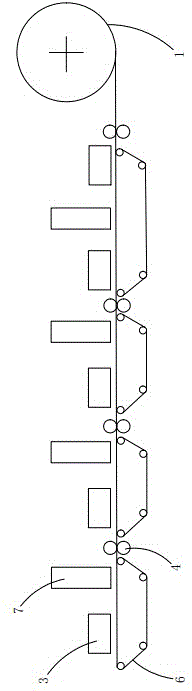

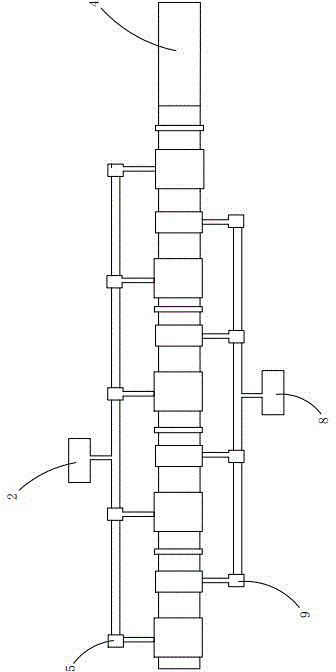

[0028] Figure 1 to Figure 3 Shown is the structural representation of the present invention.

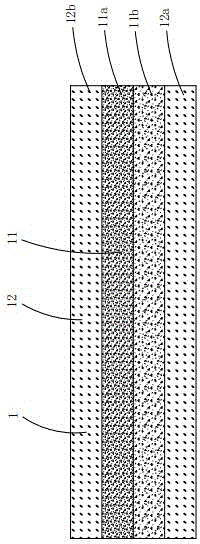

[0029] Wherein the reference numerals are: non-woven fabric 1, wood pulp fiber layer 11, first wood pulp fiber layer 11a, second wood pulp fiber layer 11b, filament fiber layer 12, lower filament fiber layer 12a, upper filament Fiber layer 12b, melt extruder 2, filament fiber web forming device 3, hot roll 4, melt metering distributor 5, net delivery curtain 6, wood pulp fiber web forming device 7, material mixing bin 8, material metering Dispenser9.

[0030] Such as Figure 1 to Figure 3 As shown, the present invention's

[0031] An enveloping wood pulp non-woven fabric comprises at least one wood pulp fiber layer 11, wherein each layer of wood pulp fiber layer 11 is laid between two layers of filament fiber layers 12, and the filament fiber lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com