Composite nano-fiber PM2.5 filtering material and preparation method thereof

A technology of composite nanofiber and filter material, which is applied in the field of composite nanofiber PM2.5 filter material and its preparation, can solve the problems of poor mechanical properties, hydrophilic air permeability, high airflow resistance, and low dust holding capacity, and achieve adhesion High precision, easy operation and uniform fiber distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Preparation of spinning solution

[0042] Weigh 10g of polyacrylonitrile (PAN) powder and dissolve it in 90g of N,N-dimethylformamide solution (DMF), stir at 80°C under a constant temperature magnetic stirrer for 4h until PAN is completely dissolved, and the prepared product has a mass percentage of 10 % PAN spinning solution; weigh 8g of gelatin particles and dissolve in 42g of acetic acid solution, stir at 60°C under a constant temperature heating magnetic stirrer for 2h until the gelatin particles are completely dissolved, and prepare a gelatin spinning solution with a mass percentage of 16%.

[0043] Step 2: Preparation of Composite Nanofibers

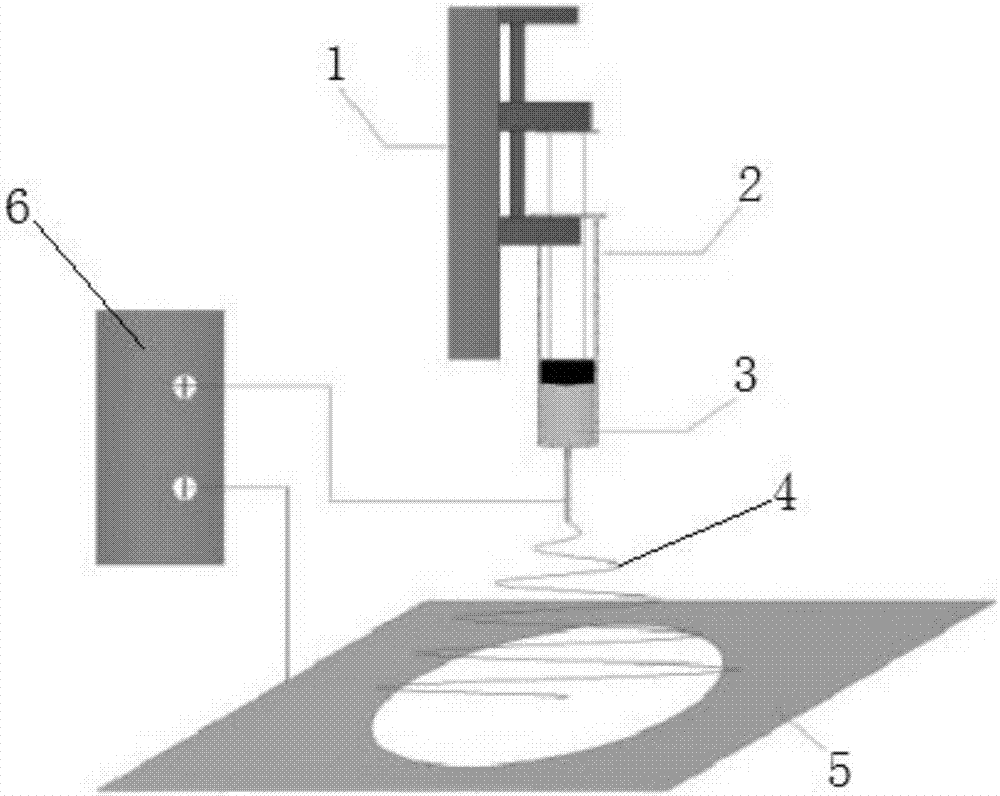

[0044] The above-mentioned PAN and gelatin spinning solution are mixed according to 1:1 and the spinning solution is injected into the liquid storage cylinder of the textile nozzle of the electrospinning machine (such as figure 1 shown), put the tinfoil paper on the receiving plate, turn on the PAN / gelatin mixed spi...

Embodiment 2

[0050] Step 1: Preparation of spinning solution

[0051] Weigh 12g of polyacrylonitrile (PAN) powder and dissolve it in 88g of N,N-dimethylformamide solution (DMF), stir at 80°C under a constant temperature magnetic stirrer for 4h until PAN is completely dissolved, and the prepared product has a mass percentage of 12 % PAN spinning solution; weigh 9g of gelatin particles and dissolve in 41g of acetic acid solution, stir at 60°C for 2h under a constant temperature heating magnetic stirrer until the gelatin particles are completely dissolved, and prepare a gelatin spinning solution with a mass percentage of 18%.

[0052] Step 2: Preparation of Composite Nanofibers

[0053] The above-mentioned PAN and gelatin spinning solution are mixed according to the volume ratio of 1:1 to prepare the spinning solution and inject it into the liquid storage cylinder of the textile nozzle of the electrospinning machine (such as figure 1 shown), place foil on the receiver plate. Turn on the PAN...

Embodiment 3

[0059] Step 1: Preparation of spinning solution

[0060] Weigh 16g of polyacrylonitrile (PAN) powder and dissolve it in 90g of N,N-dimethylformamide solution (DMF), stir at 80°C under a constant temperature magnetic stirrer for 4h until PAN is completely dissolved, and the prepared product has a mass percentage of 16 % PAN spinning solution; weigh 10 g of gelatin particles and dissolve in 40 g of acetic acid solution, stir at 60° C. under a constant temperature heating magnetic stirrer for 2 h until the gelatin particles are completely dissolved, and prepare a gelatin spinning solution with a mass percentage of 12%.

[0061] Step 2: Preparation of Composite Nanofibers

[0062] The above-mentioned PAN and gelatin spinning solution are mixed according to the volume ratio of 1:1 to prepare the spinning solution and inject it into the liquid storage cylinder of the textile nozzle of the electrospinning machine (such as figure 1 shown), place foil on the receiver plate. Turn on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com