New type cylindrical crown spring

A technology of cylindrical and crown springs, which is applied in the field of electric vehicle electrical connector parts, can solve the problems of few reed contact points, large insertion and extraction force, and small insertion and extraction force, so as to reduce the insertion and extraction force and contact Resistive, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

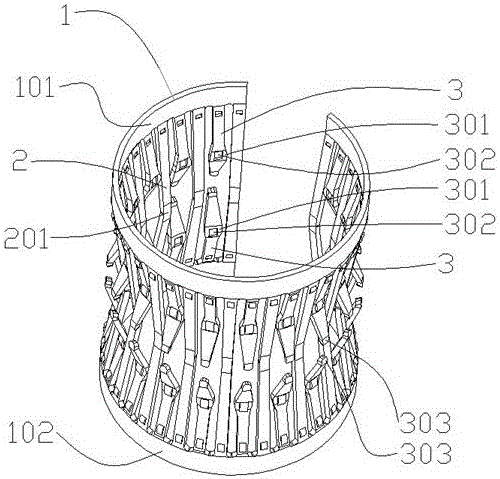

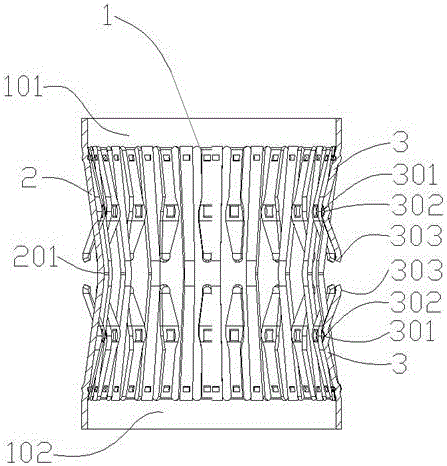

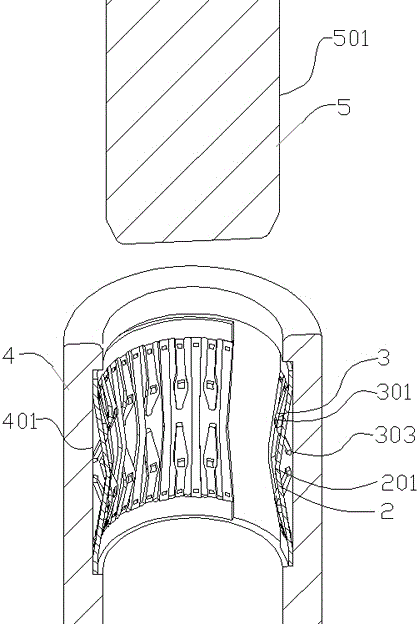

[0016] Such as Figure 1 to Figure 3 Shown, the present invention comprises the upper end band 101 that is arranged on cylindrical crown spring 1 two ends and the lower end band 102, and some reeds that are arranged between upper end band 101 and the lower end band 102, each reed has on the cylindrical crown spring 1 An axially extending contact portion. The upper end band 101 and the lower end band 102 are arranged axially along the cylindrical crown spring. The pin 5 is provided with a cylindrical contact surface 501 , and the socket 4 is provided with a concave crown spring installation groove 401 .

[0017] The reeds include reeds I2 and reeds II3, and the reeds I2 and reeds II3 are alternately distributed along the circumferential direction. This alternate distribution can be a single reed or a plurality of reeds; the contact portion It includes a reed I contact portion 201 arranged in the middle of the reed I2 and a reed II contact portion 301 arranged in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com