Charging gun head and charging system

A charging system and power terminal technology, which is applied to circuits, electrical components, coupling devices, etc., can solve the problems of manual charging, such as high labor intensity, increased volume and cost, and difficult operation with both hands, and achieve simple structure, reduced labor intensity, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

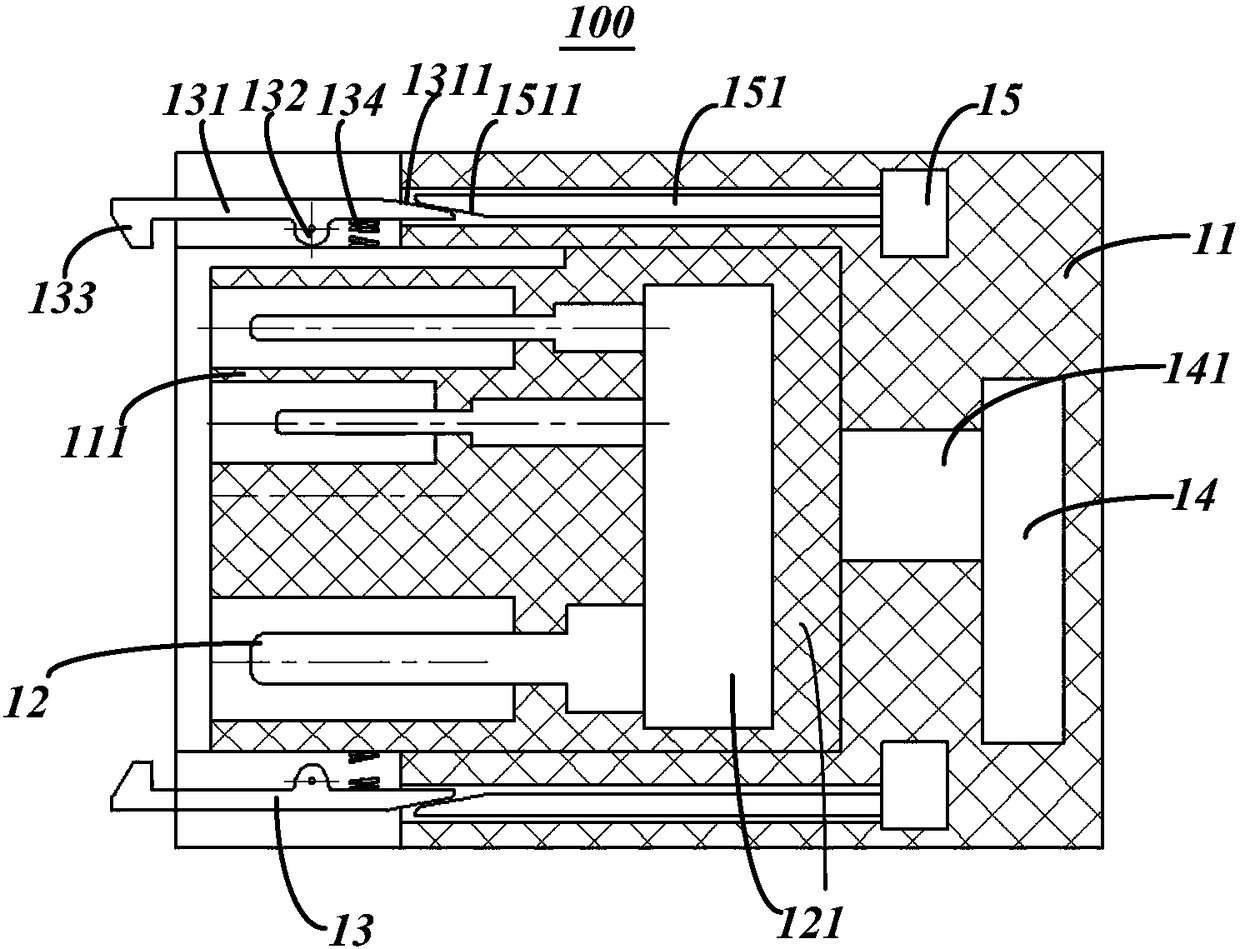

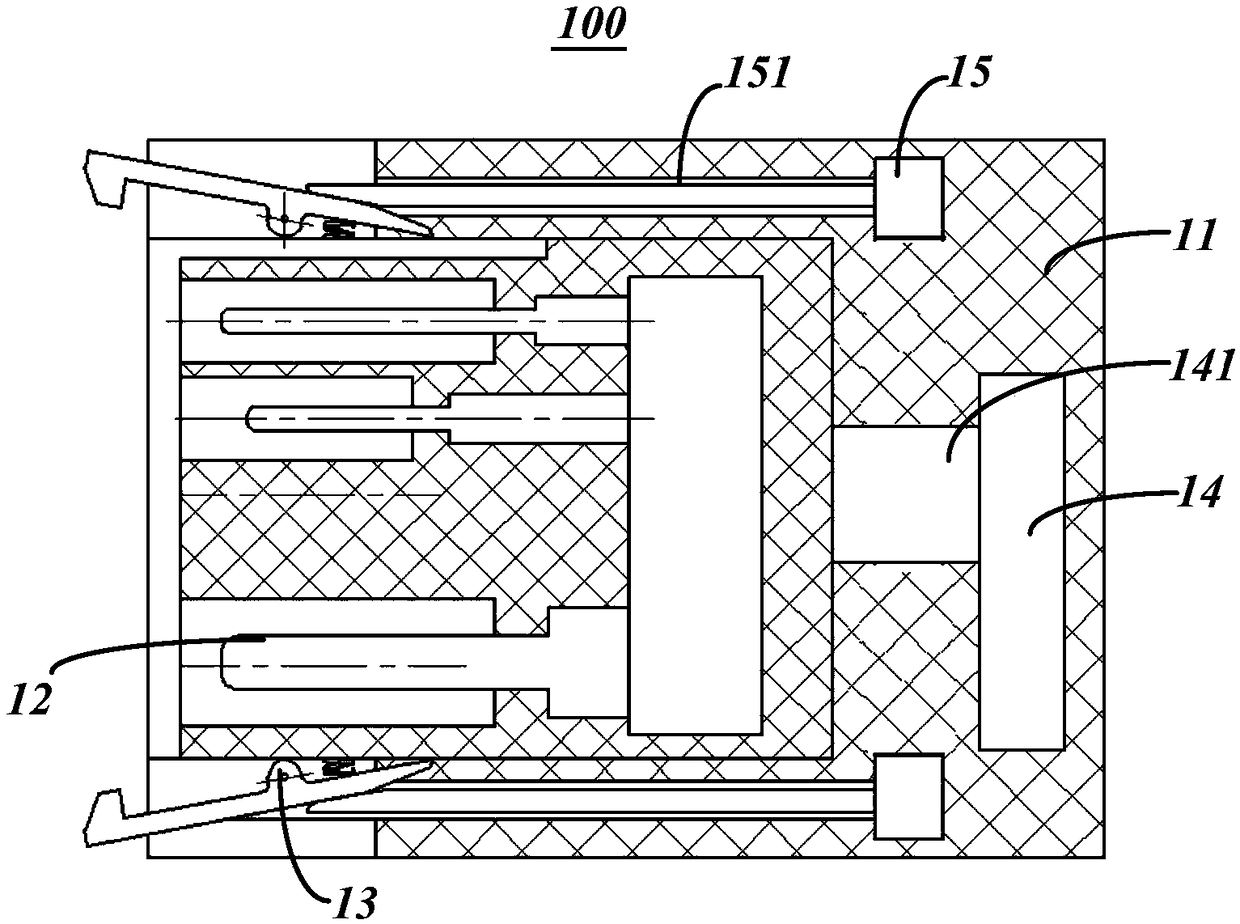

[0035] ginseng figure 1 As shown, the charging gun head 100 in this embodiment includes a gun head body 11 and a number of power terminals 12 located in the gun head body. Mechanism 13, the power terminal 12 is movable in the plug body 11 along the plugging direction, the rear end of the power terminal 12 is provided with a gun head drive module 14 for controlling the movement of the power terminal along the plugging direction, when the locking mechanism 13 is in the In the locked state, the gun head driving module 14 drives the power terminal 12 to move along the plugging and unplugging direction.

[0036] In this embodiment, the plugging direction is defined as the left-right direction, the insertion direction is along the extension direction of the terminal, and the extraction direction is the opposite direction of the insertion direction.

[0037] Preferably, a locking drive module 15 is provided at the rear end of the locking mechanism 13, the locking driving module 15 i...

Embodiment 2

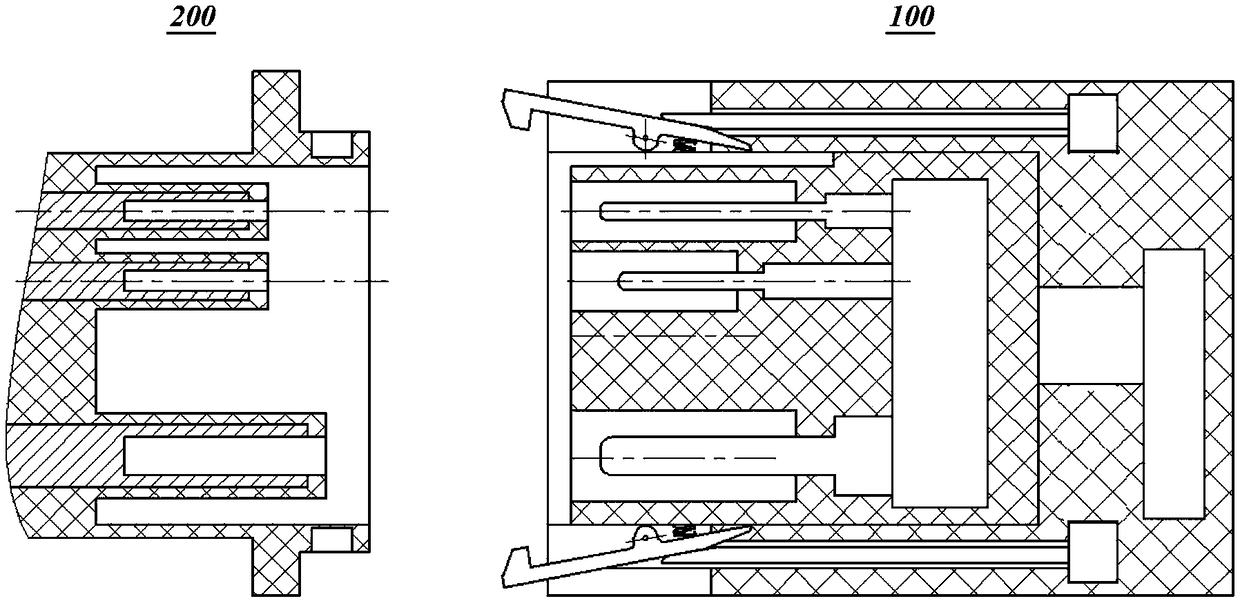

[0051] ginseng image 3 As shown, this embodiment discloses a charging system, including a charging gun head 100 and a charging socket 200 plugged into the charging gun head. The charging gun head 100 in this embodiment is completely the same as the charging gun head in Embodiment 1, and will not be repeated here.

[0052] combine Figure 4 As shown, the charging socket 200 in this embodiment includes a socket body 21 and a socket terminal 22 fixedly installed in the socket body 21 , and the socket terminal 22 is formed with a terminal receiving cavity 221 toward the direction of the charging gun head.

[0053] A locking slot 211 is provided at the end of the socket body 21 , and the buckle 133 on the locking mechanism 13 is fixed and locked in the locking slot 211 .

[0054] Preferably, a plurality of positioning accommodation cavities 212 are formed in the socket body 21 toward the direction of the charging gun head for accommodating the gun head positioning cavities 111 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com